Master Your Metal: The Ultimate Guide to Pneumatic Air Tools for Auto Body Work

Breathe New Life into Your Ride: Unleashing the Power of Pneumatic Tools for Auto Body Magic

Imagine this: your once-gleaming car sits dented and deflated, the victim of a fender bender or the ravages of time. Despair threatens to consume you, visions of exorbitant repair bills dancing in your head. But wait! Before resigning to a soulless rental car, hold on to a sliver of hope. Within your grasp lies a realm of transformative power, a treasure trove of potent tools fueled by the very breath of air itself: pneumatic air tools for auto bodywork. These are no mere wrenches and screwdrivers but instruments of resurrection, capable of whispering poetry onto crumpled sheet metal. With the controlled hiss of compressed air coursing through their veins, they become extensions of your will, shaping and molding metal as if it were clay.

Think of it as a symphony of air and steel, where the roar of an air compressor becomes the opening fanfare, the rhythmic hammering of a body dolly the driving beat, and the whisper of a spray gun the final, flourishing melody. Each tool, a virtuoso in its own right, awaits your touch to transform the mundane into the magnificent.

But fear not, maestro! This is not a conductor's baton reserved for the elite. This guide will be your Rosetta Stone, deciphering the language of pneumatic power and equipping you with the knowledge to confidently wield these tools. From the thunderous might of air hammers to the delicate caress of buffing pads, we'll delve into the world of bodywork essentials, helping you choose the perfect tools for your every need.

So, cast aside your despair and unleash the inner Michelangelo! Within these pages lies the power to breathe new life into your beloved car, to turn dents into dimples and scratches into stories. Are you ready to become a master of metal, an artist of the automotive canvas? Then let the symphony begin!

Key Takeaway

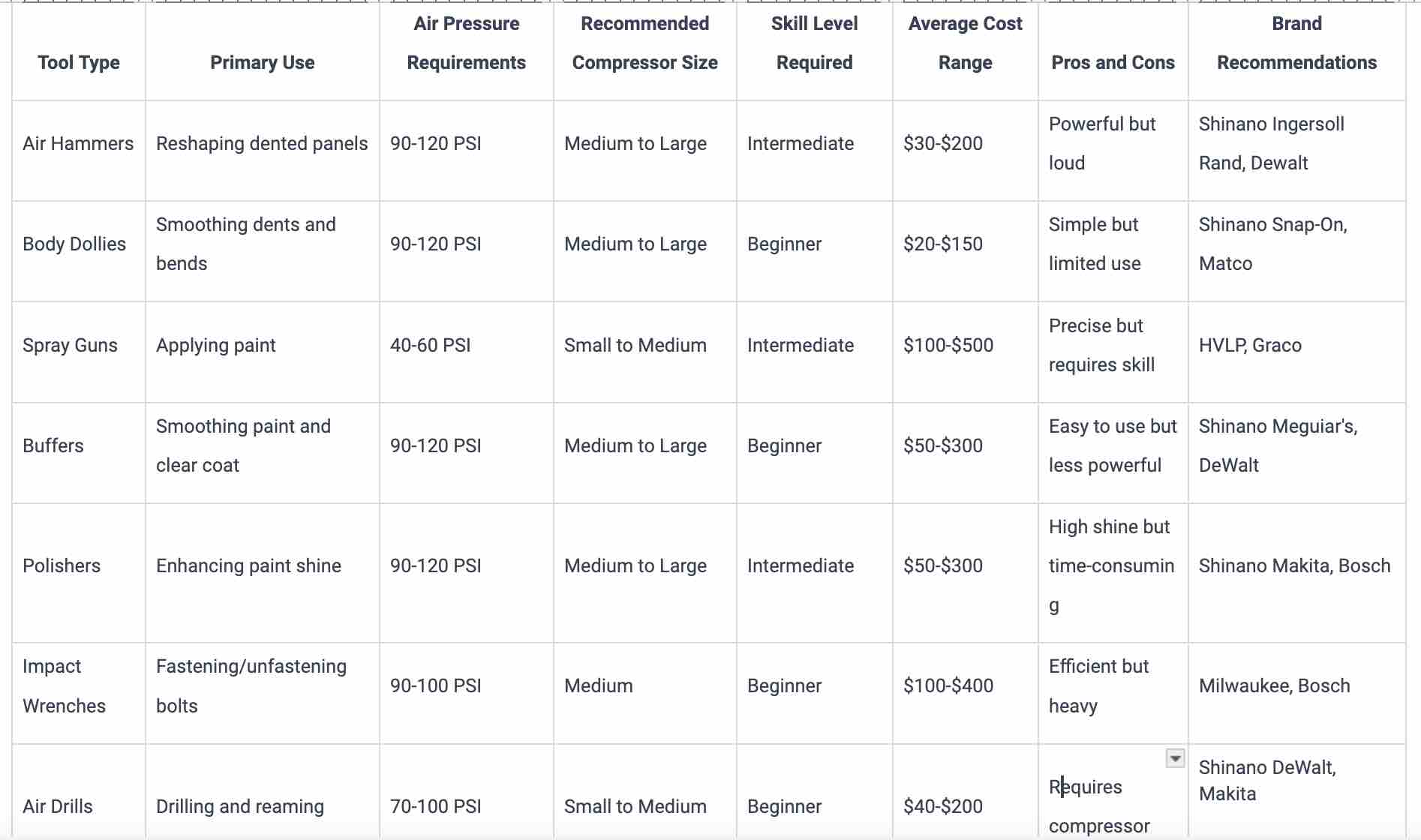

The key takeaway from this comprehensive guide is the transformative power of pneumatic tools in auto body work. These tools, ranging from air hammers and body dollies to spray guns and polishers, are essential for effectively tackling a variety of auto body tasks such as dent removal, panel repair, and achieving a flawless finish. The guide emphasizes the importance of selecting the right tool for each job, understanding the nuances of each tool’s operation, and appreciating the safety and efficiency benefits pneumatic tools offer over traditional hand tools.

Air tools provide unparalleled precision, power, and versatility, making them indispensable for both professionals and DIY enthusiasts in automotive bodywork. With proper usage, maintenance, and safety practices, these tools can significantly enhance the quality of auto body repairs and refinishing, turning a damaged vehicle into a work of art.

Essential Pneumatic Tools for Auto Body Work: Your Arsenal of Air-Powered Allies

Conquering the battlefield of auto body repair demands an arsenal of mighty tools. But unlike the cold steel of swords and axes, these weapons sing with the symphony of compressed air, each note a testament to their transformative power. Let's delve into the essential pneumatic tools that will equip you to confidently tackle any dent, rust patch, or paint imperfection.

A. Body Work & Panel Repair: Shaping the Sheet Metal Canvas

- The Air Compressor: Your Breath of Life: Just as any artist needs a steady flow of inspiration, your auto body projects rely on the unwavering power of an air compressor. Choosing the right one is like selecting the perfect brush – piston or rotary, CFM (cubic feet per minute) to match your tool demands, and tank size for extended sessions. Don't underestimate the importance of quality and proper maintenance, for a healthy compressor is the very heartbeat of your workshop.

- Air Hammers & Body Dollies: The Dance of Metal and Air: Imagine a skilled sculptor gently coaxing form from marble with precise hammer taps. Air hammers and body dollies become your sculpting tools, their rhythmic dance reshaping dented panels with controlled air bursts. From flat and spoon dollies for gentle coaxing to mushroom and shrinking dollies for targeted corrections, each tool plays a vital role in your metal-molding orchestra. Mastering the art of air pressure and hammer control will transform you from a novice tinkerer to a maestro of sheet metal manipulation.

- Stud Guns & Welders: Joining the Fragments of Form: Ripped fenders and cracked bumpers need more than just gentle nudges; they require the binding strength of welds and rivets. Pneumatic stud guns offer a swift and efficient way to secure new panels, their rapid-fire "pop pop" echoing like triumphant fanfare as they mend torn sheet metal. For more demanding repairs, a trusty MIG welder becomes your ally, its searing kiss fusing metal fragments into a unified whole. Safety is paramount – proper welding gear and ventilation are non-negotiables in this fiery art form.

- Sanders & Grinders: Smoothing the Rough Edges: Every masterpiece starts with a smooth canvas, and in the realm of auto bodywork, sanders and grinders are your sandpaper-wielding assistants. Orbital sanders waltz across surfaces, leaving behind a velvety smoothness ideal for final paint prep. The aggressive bite of angle grinders tackles tougher tasks like rust removal and weld grinding, their whirring blades sculpting away imperfections with resolute efficiency. Choosing the right grit for each task, be it feather-light finishing or aggressive metal sculpting, is key to achieving a flawless foundation for your paintwork.

- Cut-Off Tools & Nibblers: Precision Cuts with a Razor's Edge: Sometimes, sculpting requires more than finesse; it demands surgical precision. With their whisper-thin blades guided by steady hands, pneumatic cut-off tools perform intricate metal surgery, slicing through panels with laser-like focus. Nibblers, like miniature metal-munching beasts, nibble away at tight corners and curves, their meticulous bites leaving behind clean, defined edges. Remember, control and safety are paramount with these sharp-toothed tools – a steady hand and proper eye protection are your shields against accidental nicks and cuts.

- Impact Wrenches: Impact wrenches are crucial for fastening and unfastening nuts and bolts in auto body work. They can also be used for construction jobs, automotive repair, and other projects that require a wrench to produce high torque output.

- Air Drills: Air drills offer precision and efficiency, making them vital for drilling and reaming in auto body work.

- Air Staplers and Nailers: These tools are commonly used in automotive workshops for upholstery work and panel installation.

B. Painting & Finishing: The Grand Finale of Color and Shine

- Spray Guns: Weaving Threads of Color: The final act of auto-body transformation culminates in the artistry of paint. And your brush, in this case, is the mighty spray gun. Gravity-fed guns, like paint-filled chalices, offer simple control for beginners, while HVLP (high-volume, low-pressure) guns whisper atomized paint onto surfaces with remarkable efficiency. Mastering spray gun technique, from controlled trigger pulls to even overlaps, is an art in itself, transforming you from a paint-splattered novice to a color-wielding maestro.

- Clean Air, Happy Paint Jobs: Just as a sculptor wouldn't use a dusty chisel, a flawless paint job demands clean air. An air compressor paired with a moisture trap becomes your knight in shining armor, eliminating moisture and contaminants that can wreak havoc on your pristine finish. Consider upgrading to a refrigerated air dryer for maximum moisture control, ensuring your paint lays down like a smooth, shimmering dream.

- Buffers & Polishers: Bringing Out the Inner Glow: Once the paint dries, the magic truly begins. Buffers and polishers, armed with spinning pads and polishing compounds, become your alchemists of shine. Orbital buffers dance across the surface, erasing blemishes and buffing up the paint to a mirror-like gleam. With their more aggressive bite, Rotary polishers tackle deeper scratches and swirls, leaving behind a lustrous finish that seems to radiate light. Choosing the right pad and compound for your paint type

As you stand back and admire your transformed masterpiece, the metallic gleam reflecting the setting sun, a wave of pride washes over you. That crumpled, dented shell is no more; in its place stands a testament to your newfound skills, a symphony of air and metal woven into automotive art.

With each dent hammered smooth, each panel seamlessly welded, and each coat of paint gleaming under the polishing pad, you've discovered the transformative power of pneumatic tools. From the controlled dance of air hammers to the whisper of a spray gun, these tools become extensions of your will, empowering you to breathe new life into your beloved car.

Remember, the journey never ends with the final polish. Keep learning, exploring, and embracing the challenges with every dent and scratch. As your skills evolve, so too will your arsenal of tools. Invest in quality, prioritize safety, and, most importantly, always keep sight of the joy of creation. For in the realm of pneumatic art, the satisfaction of a job well done is more than just a shiny finish; it's a testament to your inner craftsman, forged in the fires of compressed air and the relentless pursuit of automotive perfection. So, keep exploring, keep creating, and remember, the only limit is your imagination. Your air compressor awaits, eager to join you on the next journey of metal-bending magic.

Bonus tip: For those itching to get started, remember to research local bodywork classes or online tutorials. Sharing your journey with fellow DIY enthusiasts and seasoned professionals can offer invaluable insights and accelerate your learning curve. So, grab your tools, crank up the compressor, and unleash your inner auto-body artist! The open road and the satisfaction of a self-repaired car await.

Advantages of using air tools over traditional hand tools in automotive bodywork

The advantages of using air tools over traditional hand tools in automotive bodywork are:

- Durability and Longevity: Air tools are designed to withstand higher levels of torque and pressure, making them less prone to wear and tear and enabling them to last longer than manual tools. This results in cost savings and reduced tool replacement frequency.

- Safety Benefits: Air tools are safer than traditional hand tools as they are powered by compressed air instead of electricity, reducing the risk of injuries. They are also designed to be lightweight, requiring less effort, which is ideal for automotive repairs, allowing technicians to work faster and more efficiently.

- Efficiency and Power: Air tools deliver consistent power, enabling faster and more efficient completion of tasks than hand tools, which rely on manual force and physical exertion. They offer precise and powerful performance, contributing to increased productivity and professional results.

- Reduced Fatigue: Air tools require less physical effort than hand tools, reducing operator fatigue and allowing technicians to work more extended periods without tiring out.

- Less Mess and Versatility: Air tools create less mess than hand tools, creating a cleaner work environment. They also offer capabilities electric tools cannot provide, such as filling tires, making them versatile for various automotive tasks.

- Cost-Effectiveness: Air tools are a cost-effective solution compared to hand tools, offering long-term value due to their durability, reduced maintenance costs, and efficient performance.

By considering these advantages, individuals and professionals can make informed decisions when selecting tools for automotive bodywork, ultimately enhancing the workshop's safety, efficiency, and productivity.

The Disadvantages of using air tools over traditional hand tools in automotive bodywork

The disadvantages of using air tools over traditional hand tools in automotive body work are:

- Dependency on Air Compressor: Air tools require an air compressor, which adds to the initial cost and may limit portability and flexibility in certain work environments.

- Potential Noise: Air tools can be noisy, especially if the air compressor is near the work area, which may require additional measures to reduce noise levels.

- Air Supply Dependencies: A clean and consistent air supply is essential for properly functioning air tools, which may pose challenges in some workshop settings.

- Initial Cost and Investment: The initial investment in an air compressor and air tools may be higher than that of traditional hand tools, which can be a consideration for some individuals or workshops.

- Limited Mobility: The dependency on an air hose and air compressor can limit the user's mobility when using air tools, especially in larger work areas or when working on vehicles in different locations.

By considering these disadvantages, individuals and professionals can make informed decisions when selecting tools for automotive body work, considering their work environment's specific requirements and constraints.

What is the brand recommendation for air tools for automotive bodywork?

Brand Recommendations: Regarding the most reputable global brands of pneumatic tools, Ingersol Rand, Shinano, Dewalt, and CP readily come to mind. Reputable brands like Ingersoll Rand, Snap-On, Matco, Shinano Pneumatic, Dynabrade and Chicago Pneumatic are highly regarded for quality pneumatic tools in automotive bodywork. By considering these reputable brands, individuals, and professionals can make informed decisions when selecting air tools for automotive body work, ensuring quality, durability, and performance.

Transform your auto body work with our ultimate guide to pneumatic air tools. Learn how to master tasks from dent removal to a perfect polish with expert tips and brand recommendations. Visit tendsupplies.com for top-quality tools and advice.