Rotary Screw vs. Piston Air Compressors: Choosing the Right Tool for the Job

Air compressors are crucial in powering various tools and equipment in industrial and commercial applications. When it comes to selecting the right air compressor for your needs, two of the most common types you'll encounter are rotary screw and piston compressors. Each has its advantages, limitations, and ideal use cases. This comprehensive guide will dive deep into the comparison between rotary screw and piston air compressors, helping you make an informed decision for your specific requirements.

Key Takeaway

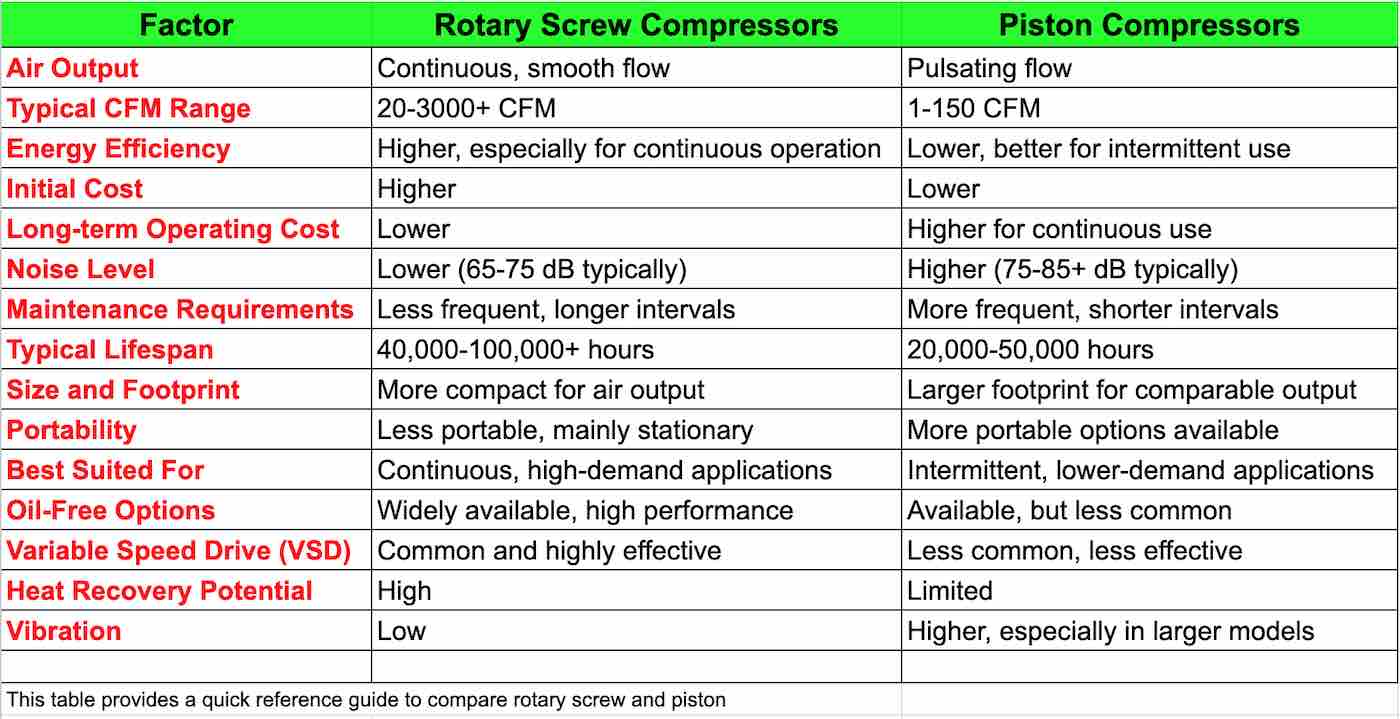

Choosing between a rotary screw and piston air compressor ultimately depends on your specific application, operating conditions, and long-term goals. Rotary screw compressors excel in high-demand, continuous operation scenarios and offer benefits in energy efficiency, noise reduction, and long-term cost savings. Piston compressors, on the other hand, provide advantages in terms of lower initial cost, portability, and suitability for intermittent-use applications.

By carefully evaluating your needs against the factors discussed in this guide, you can make an informed decision that will optimize your operations and provide the best value over time.

Understanding the Basics

Before we delve into the detailed comparison, let's start by understanding the fundamental working principles of both rotary screw and piston compressors.

Rotary Screw Compressors: The Heart of Continuous Air Flow

Rotary screw compressors operate on a principle of positive displacement using two interlocking helical screws, known as rotors. As these rotors turn, they draw in air and progressively reduce the volume of the air as it moves through the compression chamber. This process creates a continuous flow of compressed air.

Critical components of a rotary screw compressor include:

- Male and female rotors

- Intake valve

- Compression chamber

- Oil separation system

- Cooling system

- Discharge valve

Piston Compressors: The Powerhouse of Reciprocating Motion

Piston or reciprocating compressors use a crankshaft-driven piston that moves up and down within a cylinder. This reciprocating motion draws in air on the downstroke and compresses it on the upstroke, forcing the compressed air into a storage tank.

The main components of a piston compressor include:

- Piston and cylinder

- Crankshaft and connecting rod

- Valves (intake a

nd discharge)

nd discharge) - Compression chamber

- Air tank

- Cooling system

Comparative Analysis: Rotary Screw vs. Piston Compressors

Now that we understand how these compressors work, let's compare them across various crucial factors.

Air Output and Flow Characteristics

Rotary Screw Compressors:

- Provide a continuous, smooth flow of compressed air

- Ideal for applications requiring constant air supply

- Typically offer higher CFM (Cubic Feet per Minute) output

Piston Compressors:

- Deliver air in pulses, which may require additional equipment for smooth flow

- Better suited for intermittent use applications

- Generally have lower CFM output compared to rotary screw models of similar size

Real-world Example:

Consider a large-scale painting operation requiring 100 CFM of continuous airflow at 100 PSI. A rotary screw compressor rated at 125 CFM would be ideal, providing a steady air supply without the need for oversizing. In contrast, a piston compressor might need to be rated at 150 CFM or higher to account for its duty cycle and ensure consistent air delivery.

Energy Efficiency and Operating Costs

Rotary Screw Compressors:

- Generally more energy-efficient, especially in continuous operation

- Lower energy consumption per CFM of air produced

- Variable Speed Drive (VSD) options can further enhance efficiency

Piston Compressors:

- Less energy-efficient in continuous operation

- More suitable for intermittent use where energy efficiency is less critical

- Simpler design often results in lower initial energy costs for small-scale applications

Cost Analysis:

Let's consider a scenario where a manufacturing plant requires 500 CFM of air at 100 PSI for 10 hours a day, six days a week.

Rotary Screw Option:

- 75 HP compressor with VSD

- Energy consumption: Approximately 55 kW/hour

- Annual energy cost (at $0.10/kWh): $17,160

Piston Compressor Option:

- 100 HP compressor (oversized to account for duty cycle)

- Energy consumption: Approximately 75 kW/hour

- Annual energy cost (at $0.10/kWh): $23,400

In this case, the rotary screw compressor could save about $6,240 per year in energy costs.

Maintenance Requirements and Longevity

Rotary Screw Compressors:

- Fewer moving parts, resulting in less wear and tear

- Longer service intervals

- Higher upfront cost but potentially lower long-term maintenance expenses

- Typical lifespan: 40,000 to 100,000+ operating hours

Piston Compressors:

- More moving parts requiring more frequent maintenance

- Lower initial cost but potentially higher long-term maintenance expenses

- Shorter service intervals

- Typical lifespan: 20,000 to 50,000 operating hours

Maintenance Comparison:

For a 50 HP compressor operating 2,000 hours per year:

Rotary Screw:

- Annual maintenance cost: Approximately $1,500

- Major overhaul every 5-7 years: $5,000 - $7,000

Piston:

- Annual maintenance cost: Approximately $2,500

- Major overhaul every 2-3 years: $3,000 - $5,000

- Noise Levels and Environmental Considerations

Rotary Screw Compressors:

- Generally quieter operation (typically 65-75 dB)

- Better suited for noise-sensitive environments

- Often come with built-in soundproofing enclosures

Piston Compressors:

- Tend to be louder (typically 75-85 dB or higher)

- May require additional soundproofing measures

- Vibration can be a concern, especially in larger models

Environmental Impact:

Lower noise levels of rotary screw compressors can be crucial in urban or mixed-use areas. For example, a construction company working in a residential area might choose a rotary screw compressor to minimize noise complaints and comply with local regulations.

Size and Portability

Rotary Screw Compressors:

- Generally more compact for their air output

- Better suited for permanent installations

- Portable options are available but less common

Piston Compressors:

- More portable options available, especially in smaller sizes

- It is ideal for mobile applications or job sites without permanent air systems

- Larger models can be bulky and less space-efficient

Application Example:

A mobile tire service company might opt for a trailer-mounted piston compressor for its portability and ability to handle intermittent, high-pressure demands. Conversely, a large manufacturing facility would likely benefit from a stationary rotary screw system for its continuous operation and space efficiency.

Initial Investment and Long-term Value

Rotary Screw Compressors:

- Higher upfront cost

- Lower operating costs over time

- Better value for high-use, continuous operation scenarios

Piston Compressors:

- Lower initial investment

- Higher operating costs in the long run for continuous use

- Better value for low-use, intermittent operation scenarios

Investment Analysis:

Consider a small manufacturing company needing 30 CFM of air at 100 PSI for 8 hours a day, 5 days a week.

Rotary Screw Option:

- Initial cost: $15,000

- Annual energy cost: $2,500

- Annual maintenance cost: $800

- 10-year total cost of ownership: $47,000

Piston Compressor Option:

- Initial cost: $5,000

- Annual energy cost: $3,500

- Annual maintenance cost: $1,200

- 10-year total cost of ownership: $52,000

In this scenario, despite the higher upfront cost, the rotary screw compressor proves more economical over 10 years.

Advanced Considerations

Variable Speed Drive (VSD) Technology

Rotary screw compressors often offer VSD options, which adjust the motor speed based on air demand. This can lead to significant energy savings, especially in applications with fluctuating air needs. While some modern piston compressors also offer VSD, it's more commonly found and more effective in rotary screw models.

Oil-Free Options

Both rotary screw and piston compressors are available in oil-free variants. These are crucial for applications where air purity is paramount, such as food processing, pharmaceuticals, or electronics manufacturing. Oil-free rotary screw compressors typically offer higher air quality and lower maintenance compared to oil-free piston models.

Heat Recovery Systems

Large rotary screw compressors can be equipped with heat recovery systems that capture and repurpose the heat generated during compression. This can be used for space heating or preheating water, further improving overall energy efficiency.

Duty Cycle

Duty cycle refers to the percentage of time a compressor can run without overheating and needing to cycle off for cool down. It's a crucial factor to consider when choosing between rotary screw and piston compressors.

- Rotary Screw Compressors: Typically boast a 100% duty cycle, meaning they can run continuously without overheating. This makes them ideal for applications with constant air demand, such as large manufacturing facilities or paint shops.

- Piston Compressors: Generally have a lower duty cycle (often around 50-75%). They're better suited for intermittent use applications where the compressor isn't constantly running, such as powering nail guns or inflating tires. Exceeding the recommended duty cycle for a piston compressor can lead to overheating and premature wear.

Understanding your application's air demand and duty cycle requirements is essential for selecting the right compressor type. If you need continuous airflow, a rotary screw compressor is the way to go. If your air use is occasional or in bursts, a piston compressor might be sufficient.

Air Treatment Needs

Compressed air often contains moisture and contaminants like dust particles or oil (depending on the compressor type). The level of air purity required by your application will determine the need for additional air treatment equipment like dryers and filters.

- Rotary Screw Compressors: Generally produce drier air due to their lower operating temperatures. This reduces the need for additional air drying in some applications. However, depending on the specific requirements, additional filtration might still be necessary.

- Piston Compressors: Since they operate at higher temperatures, the compressed air from piston compressors typically contains more moisture. In most cases, additional air dryers will be necessary to achieve the desired level of air purity. Additionally, filtration is crucial to remove contaminants like oil carryover, which can damage sensitive equipment.

Decision-Making Guide

To help you choose between a rotary screw and piston compressor, consider the following factors:

- Air Demand:

- High, continuous demand: Rotary Screw

- Low, intermittent demand: Piston

- Budget:

- Higher upfront investment possible: Consider Rotary Screw

- Limited initial budget: A Piston may be more suitable

- Energy Efficiency Priority:

- High priority: Rotary Screw

- Lower priority: Piston can suffice

- Noise Constraints:

- Noise-sensitive environment: Rotary Screw

- Noise not a significant concern: Either option

- Space Limitations:

- Limited space: Rotary Screw

- Space is not an issue: Either option

- Portability Needs:

- High portability required: Piston

- Stationary installation: Either option, leaning towards Rotary Screw

- Maintenance Capacity:

- Limited maintenance resources: Rotary Screw

- Capable of frequent maintenance: Either option

- Air Quality Requirements:

- Ultra-high air purity needed: Oil-free Rotary Screw

- Standard air quality acceptable: Either option

Ready to find the perfect air compressor for your needs? Tend Industrial Supplies offers a wide range of both rotary screw and piston compressors to suit any application. Our team of experts can help you analyze your requirements and recommend the ideal solution.

Visit tendsupplies.com to explore our comprehensive selection of air compressors and related equipment. For personalized assistance and expert advice, contact our sales team at sales@tendsupplies.com. Today, let us help you power your operations with the correct air compression technology!