Top 10 Must-Have Pneumatic Tools for Every Workshop in 2025

In the ever-evolving world of workshop technology, pneumatic tools continue to stand out for their power, efficiency, and reliability. As we approach 2025, these air-powered marvels are becoming increasingly essential for both professional mechanics and DIY enthusiasts. Whether you're setting up a new workshop or upgrading your existing toolkit, here's our comprehensive guide to the top 10 must-have pneumatic tools that will revolutionize your work in 2025.

1. Air Compressor: The Heart of Your Pneumatic System

No pneumatic tool setup is complete without a high-quality air compressor. In 2025, we're seeing more efficient and quieter models that cater to various workshop sizes and needs.

Key Features to Look for:

- Capacity: 20-30 gallon tank for most workshop applications

- Output: 4-5 CFM at 90 PSI for versatility

- Noise Level: Look for models with noise reduction technology

- Portability: Consider wheeled options for easy movement

Top Pick: The Tend Industrial Supplies Ultra-Quiet 30-Gallon Compressor offers an ideal balance of power and noise reduction, perfect for residential workshops.

Key Features:

- Adequate CFM output for your tools (typically 4-30 CFM)

- Appropriate tank size (10-80 gallons)

- Oil-lubricated or oil-free design

Applications:

- Powering all pneumatic tools

- Inflating tires

- Cleaning with compressed air

Safety Tip: Regularly drain the tank to prevent moisture buildup.

Noise Level: Varies widely, from 60 dB (quiet models) to 90+ dB (larger units)

2. Air Impact Wrench: Power Meets Precision

Impact wrenches remain a staple in automotive work and heavy-duty applications. The 2025 models offer improved torque control and ergonomic designs.

Key Benefits:

- High torque output for stubborn bolts and nuts

- Faster than manual wrenches

- Reduces user fatigue

Recommended Model: Shinano 3/8 Square Drive Pneumatic Air Impact Wrench from Tend Industrial Supplies, known for its durability and precision.

Key Features:

- High torque output (typically 500-1200 ft-lbs)

- Variable speed control

- Compact design for tight spaces

Applications:

- Changing tires and removing lug nuts

- Working on suspension systems

- Loosening seized bolts in automotive repair

Safety Tip: Always use impact-rated sockets to prevent shattering.

Noise Level: Approximately 90-100 dB

3. Air Drill: Versatility in Boring

Air drills continue to outperform their electric counterparts in terms of power-to-weight ratio and durability.

Advantages:

- Cooler operation for extended use

- More compact design for tight spaces

- Consistent power output

Featured Product: 1/2 Shinano Reversible Pneumatic Drill 800 RPM SI-5305-8A, ideal for steel drilling and automotive work.

Key Features:

- High RPM (usually 1800-2600 RPM)

- Reversible direction

- Chuck sizes from 3/8" to 1/2"

Applications:

- Drilling holes in metal, wood, or plastic

- Reaming existing holes

- Light grinding with appropriate attachments

Safety Tip: Use clamps to secure workpieces and wear eye protection.

Noise Level: Approximately 90-100 dB

4. Air Sander: Smooth Operator

For achieving flawless finishes in woodworking and auto body repair, an air sander is indispensable.

Types to Consider:

- Orbital sanders for general smoothing

- Belt sanders for large surface areas

- Detail sanders for intricate work

Top Choice: Shinano Mini Dual Action Sander SI-2107A, offering precision and efficiency in a compact design.

Key Features:

- Orbital or linear sanding motion

- Variable speed control

- Dust collection system

Applications:

- Smoothing wood surfaces before finishing

- Prepping metal for paint application

- Removing rust or old paint

Safety Tip: Always use in well-ventilated areas and wear a dust mask.

Noise Level: Around 80-90 dB

5. Air Nailer/Stapler: Fastening Made Easy

In 2025, air nailers and staplers are more versatile than ever, accommodating a wide range of fasteners for various applications.

Applications:

- Woodworking and carpentry

- Upholstery

- Roofing and siding installation

Recommended: Universal Tool Pneumatic Nailer, compatible with multiple nail sizes for diverse projects.

Key Features:

- Sequential and bump firing modes

- Depth adjustment

- Easy-to-load magazine

Applications:

- Framing and construction work

- Installing trim and molding

- Upholstery and woodworking projects

Safety Tip: Never point the tool at yourself or others, even when not in use.

Noise Level: Approximately 70-80 dB

6. Air Spray Gun: Perfect Finish Every Time

For painting and coating applications, nothing beats the consistency and coverage of an air spray gun.

Key Features:

- Adjustable spray patterns

- Easy-clean nozzles

- Compatibility with various paint viscosities

Best Pick: FPX Air Tools HVLP Gravity Feed Spray Gun Kit FPX-535K for professional-grade finishes.

Key Features:

- Adjustable spray patterns

- Precise fluid control

- Easy-to-clean design

Applications:

- Painting vehicles or furniture

- Applying stains or varnishes

- Spraying texture on walls or ceilings

Safety Tip: Always use in a well-ventilated area and wear appropriate respiratory protection.

Noise Level: Around 70-80 dB

7. Air Ratchet: Tight Spaces, No Problem

When working in confined spaces, an air ratchet is your best friend, offering power and maneuverability.

Benefits:

- Faster than manual ratchets

- Reduces hand fatigue

- Ideal for automotive and machinery maintenance

Top Model: 3/8 Flex-Head Air Ratchet Aircat 811, known for its flexibility and precision.

Key Features:

- Compact head for tight spaces

- Typically 30-60 ft-lbs of torque

- Lightweight design for extended use

Applications:

- Removing and installing engine components

- Working in confined spaces under vehicles

- Quick assembly of furniture or equipment

Safety Tip: Keep your fingers clear of moving parts and use appropriate PPE.

Noise Level: Around 85-95 dB

8. Air Hammer: Break It Down

For demolition work, chiseling, and heavy-duty material removal, an air hammer is essential.

Applications:

- Automotive body work

- Construction and renovation

- Sculptural work

Recommended: Pistol Air Hammer Universal Tool UT8645-1, offering robust performance for various tasks.

9. Air Grinder: Precision Grinding and Cutting

Versatile and powerful, air grinders are crucial for metalworking, welding prep, and surface finishing.

Types:

- Die grinders for precision work

- Angle grinders for larger surfaces

- Cut-off tools for metal cutting

Featured Product: SP-180 Heavy Duty Pneumatic 7-inch Air Angle Grinder, suitable for welding, woodworking, and automotive detailing.

Key Features:

- High RPM (typically 10,000-25,000 RPM)

- Various wheel sizes available (usually 2"-7")

- Safety guard and ergonomic grip

Applications:

- Cutting metal pipes or rods

- Smoothing welds

- Sharpening tools

Safety Tip: Always use the appropriate wheel for the material and task.

Noise Level: Around 90-100 dB

10. Air Blow Gun: Clean and Clear

Often overlooked but incredibly useful, an air blow gun is perfect for cleaning workspaces and machinery.

Uses:

- Removing debris from hard-to-reach areas

- Drying surfaces quickly

- Clearing dust from sensitive equipment

Top Choice: FPX Air Blow Gun with adjustable nozzle for versatile cleaning applications.

Key Features:

- Adjustable air flow

- Lightweight design

- OSHA-compliant nozzle

Applications:

- Cleaning dust and debris from workspaces

- Drying parts after washing

- Clearing blockages in machinery

Safety Tip: Never use compressed air to clean clothing or skin.

Noise Level: Approximately 80-90 dB

Others

Air Chisel

Key Features:

- Variable speed control

- Quick-change chisel retention

- Vibration-reducing design

Applications:

- Cutting sheet metal

- Removing stuck bolts or rivets

- Breaking up concrete or tile

Safety Tip: Use a tool rest to minimize hand fatigue and improve accuracy.

Noise Level: Approximately 100-110 dB

Comparison of Top 10 Pneumatic Tools

| Tool Type | Power Output | Noise Level | Versatility | Maintenance Needs |

| Air Compressor | High | Medium-High | High | Medium |

| Impact Wrench | Very High | High | Medium | Low |

| Air Drill | High | Medium | High | Low |

| Air Sander | Medium | Medium | High | Medium |

| Nailer/Stapler | Medium | Low | High | Low |

| Spray Gun | Low | Low | Medium | High |

| Air Ratchet | Medium | Low | Medium | Low |

| Air Hammer | Very High | Very High | Medium | Medium |

| Air Grinder | High | High | High | Medium |

| Air Blow Gun | Low | Medium | High | Very Low |

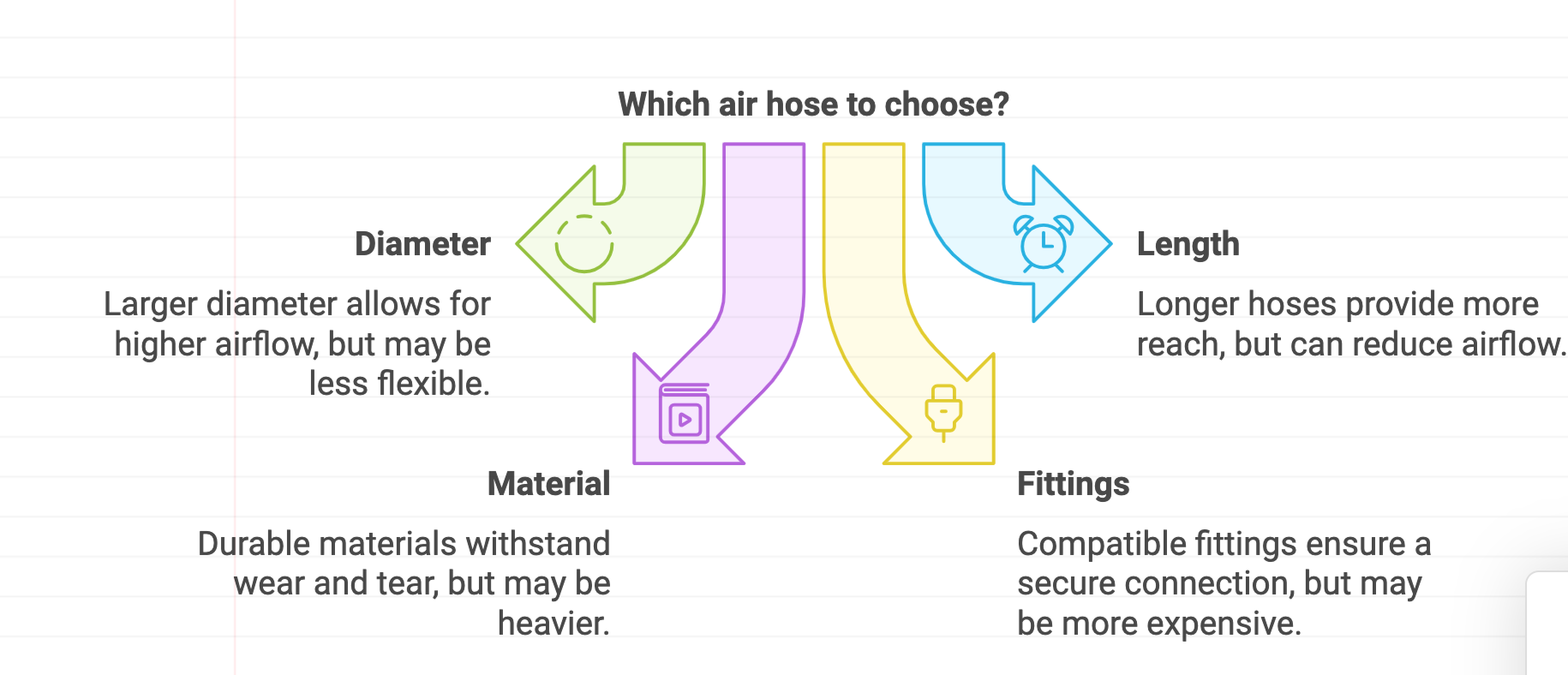

Air Hose Selection

Choosing the right air hose is crucial for the efficient operation of your pneumatic tools:

- Diameter: Most tools require a 1/4" or 3/8" inner diameter hose.

- Length: Keep hoses as short as practical to minimize pressure loss.

- Material: Options include rubber (durable, flexible), PVC (lightweight, less flexible), and hybrid (balances durability and weight).

Safety Tip: Regularly inspect hoses for cracks or damage, and ensure proper connection to prevent accidental detachment.

General Safety Considerations

- Proper Ventilation: Ensure good airflow, especially when using tools that generate dust or fumes.

- Personal Protective Equipment (PPE): Always wear safety glasses, hearing protection, and other PPE as required for each tool.

- Tool Maintenance: Regularly clean and lubricate tools according to manufacturer instructions.

- Pressure Regulation: Use the correct air pressure for each tool to ensure safe operation and optimal performance.

- Training: Familiarize yourself with each tool's operation and safety features before use.

Safety and Maintenance Tips:

- Always wear appropriate PPE, including safety glasses, hearing protection, and gloves.

- Regularly inspect air hoses and fittings for wear and damage.

- Lubricate tools according to manufacturer instructions, typically before each use.

- Drain moisture from the air compressor tank daily to prevent rust and contamination.

- Store tools in a clean, dry place to prevent corrosion and damage.

Choosing the Right Pneumatic Tools:

When selecting pneumatic tools for your 2025 workshop, consider the following factors:

- Assess Your Needs: Identify the tasks you perform most frequently.

- Evaluate Your Air Compressor: Ensure it can handle the CFM requirements of your tools.

- Quality and Durability: Invest in reputable brands known for reliability.

- Ergonomics: Choose tools that are comfortable for extended use.

- Versatility: Look for tools that can perform multiple functions.

- Budget: Balance cost with expected usage and longevity.

- Noise Levels: Consider quieter models for residential workshops.

- Future Expansion: Choose tools that can adapt to increasing demands.

FAQs: Pneumatic Tools for Workshops in 2025

Q: Are pneumatic tools more powerful than their electric counterparts?

A: Generally, yes. Pneumatic tools often deliver more power and torque for their size compared to electric tools, making them particularly effective for heavy-duty tasks.

Q: How do I maintain my pneumatic tools to ensure longevity?

A: Regular maintenance is key. Lubricate tools with air tool oil before each use, clean them after use, store in a dry place, drain moisture from the air compressor tank regularly, and replace worn parts promptly.

Q: Can I use the same air hose for all my pneumatic tools?

A: While many tools use standard fittings, it's important to check the air flow requirements (CFM) and pressure (PSI) for each tool. Some high-demand tools may require larger diameter hoses for optimal performance.

Q: Are pneumatic tools safe to use in wet conditions?

A: Pneumatic tools are generally safer than electric tools in damp environments as there's no risk of electric shock. However, always follow safety guidelines and avoid submerging tools in water.

Q: How do I choose the right size air compressor for my workshop?

A: Consider the CFM (Cubic Feet per Minute) requirements of your most demanding tools. For most workshop applications, a compressor with 20-30 gallon tank capacity and 4-5 CFM at 90 PSI is sufficient.

Q: What are the advantages of pneumatic tools over cordless tools?

A: Pneumatic tools often offer higher power-to-weight ratios, consistent performance without battery drain, and lower tool costs. However, they require an air compressor and are less portable than cordless options.

Q: How do I troubleshoot common problems with pneumatic tools?

A: For low power, check air pressure and hose connections. For air leaks, inspect O-rings and fittings. If problems persist, consult the tool's manual or a professional.

Q: Where can I find repair services for my pneumatic tools?

A: Many hardware stores offer repair services. Additionally, manufacturer-authorized service centers can provide specialized repairs and maintenance.

Q: How often should I service my pneumatic tools?

A: For heavy use, service tools every 3-6 months. For occasional use, annual servicing is usually sufficient. Always follow manufacturer recommendations.

Q: Can I use the same air compressor for all my pneumatic tools?

A: While many tools can share a compressor, ensure it provides sufficient CFM (Cubic Feet per Minute) for your most demanding tool. Some specialized tools may require a larger or more powerful compressor.

By incorporating these must-have pneumatic tools and following proper safety protocols, you'll be well-equipped to tackle a wide range of projects in your 2025 workshop. Remember to always prioritize safety and proper tool maintenance for the best results and longevity of your equipment.