Workshop Organization: Practical Tips and Creative Ideas for Maximizing Space and Accessibility

An organized workshop is the linchpin of productivity and safety for any mechanic or hobbyist. How your workspace is set up can significantly impact your workflow, efficiency, and the quality of your work. However, organizing a workshop comes with challenges, from dealing with limited space to finding a home for every tool. In this guide, we'll explore practical tips and innovative strategies to transform your workshop into a model of efficiency and safety.

Understanding Your Space

It is essential to assess your workshop Layout to start organizing your workshop. Start by taking a good look at your current workshop layout. Note the positioning of large equipment, workbenches, and storage areas. Is there a logical flow to your workspace? Can you move quickly from one task to another? Understanding the strengths and limitations of your existing setup is the first step to making effective changes.

Identifying Underutilized Areas (Maximizing Workshop Space)

Often, workshops have underutilized areas that can be transformed into valuable storage or workspaces. Look for unused corners, high walls, or under-workbench spaces. You can uncover hidden opportunities to expand your workshop’s functionality by identifying these areas.

Tips for Creating a Flexible Workspace

A flexible workspace adapts to different projects and needs. Consider modular furniture and movable storage solutions that can be reconfigured as needed. Utilize fold-down workbenches or rolling tool carts that can be tucked away when not in use to maximize your space.

Essential Workshop Tools

Essential workshop tools will depend on the type of workshop you have and the kind of projects you typically undertake. However, there's a general collection of basic hand tools that form the foundation of most workshops, regardless of their focus. Here's a list of essential workshop tools to get you started.

Overview of Must-Have Workshop and Mechanic Tools

Every workshop should be equipped with a core set of tools. These fundamental items, from wrenches and screwdrivers to pliers and hammers, are indispensable for many tasks. Review a comprehensive list of essential workshop and mechanic tools to ensure your collection is complete.

We might get a commission if you buy products from links here at no cost to you

Socket wrench set (including both standard and metric sizes): This versatile tool allows you to tighten and loosen nuts and bolts of various shapes and sizes. It typically includes a ratchet handle, sockets, and extensions.

Buy from Amazon Socket wrench set

Wrenches: There are different types of wrenches, each with its own purpose. Adjustable wrenches can be used on nuts and bolts of various sizes, while combination wrenches have two heads, one on each end, with different sizes.

Buy Combination wrench from Amazon

Pliers: Pliers are used for gripping, twisting, and cutting. There are different types of pliers, such as slip-joint pliers, locking pliers, and needle-nose pliers.

Buy Needlenose pliers in Amazon

Screwdrivers: Screwdrivers are used for turning screws. There are different types of screwdrivers, such as flat-head screwdrivers and Phillips screwdrivers.

Buy Flathead screwdriver From Amazon

Hammer: A hammer is used for driving nails, breaking objects, and applying force. There are different types of hammers, such as claw hammers and rubber mallets.

Buy Rubber mallet from Amazon

Tape measure: A tape measure is used for measuring distances.

In addition to these essential hand tools, consider including some of these following tools in your essential workshop toolkit:

Level: Levels are used to check if a surface is horizontal or vertical. There are different levels, such as torpedo and bubble levels.

Torpedo level

Utility knife: A utility knife is a versatile cutting tool that can be used for a variety of purposes, such as cutting cardboard, rope, or carpet.

Safety glasses: Safety glasses are essential for protecting your eyes from debris when working with tools.

With this essential toolkit, you'll be equipped to tackle a wide range of basic workshop projects! Remember, you can always expand your collection of tools as your projects become more complex and require specialized equipment.

Organizing Tools by Frequency of Use

Organize your tools based on how frequently you use them. Keep commonly used Workshop tools within easy reach, while less frequently used items can be stored away. This approach minimizes time spent searching for tools and keeps your workspace clutter-free.

Highlighting the Benefits of Quality Tools for Efficiency

Different workshops can cater to various purposes, such as woodworking, metalworking, mechanics, or even DIY repairs. A single study comparing tools across these diverse disciplines wouldn't be very practical. However, there are numerous tool brands, each with strengths and target audience. A study might compare specific features within a brand or compare similar tools from different brands for a particular task. However, finding a broad comparison encompassing all functionalities and brands would be difficult. New tools and features are constantly emerging, making maintaining a long-term, relevant study challenging.

Investing in high-quality tools can significantly impact your work's efficiency and outcome. Quality tools are generally more durable, precise, and comfortable, contributing to better results and fewer replacements. For example, we did an article on the best brands of hand tools in 2024

Storage Solutions for Workshops

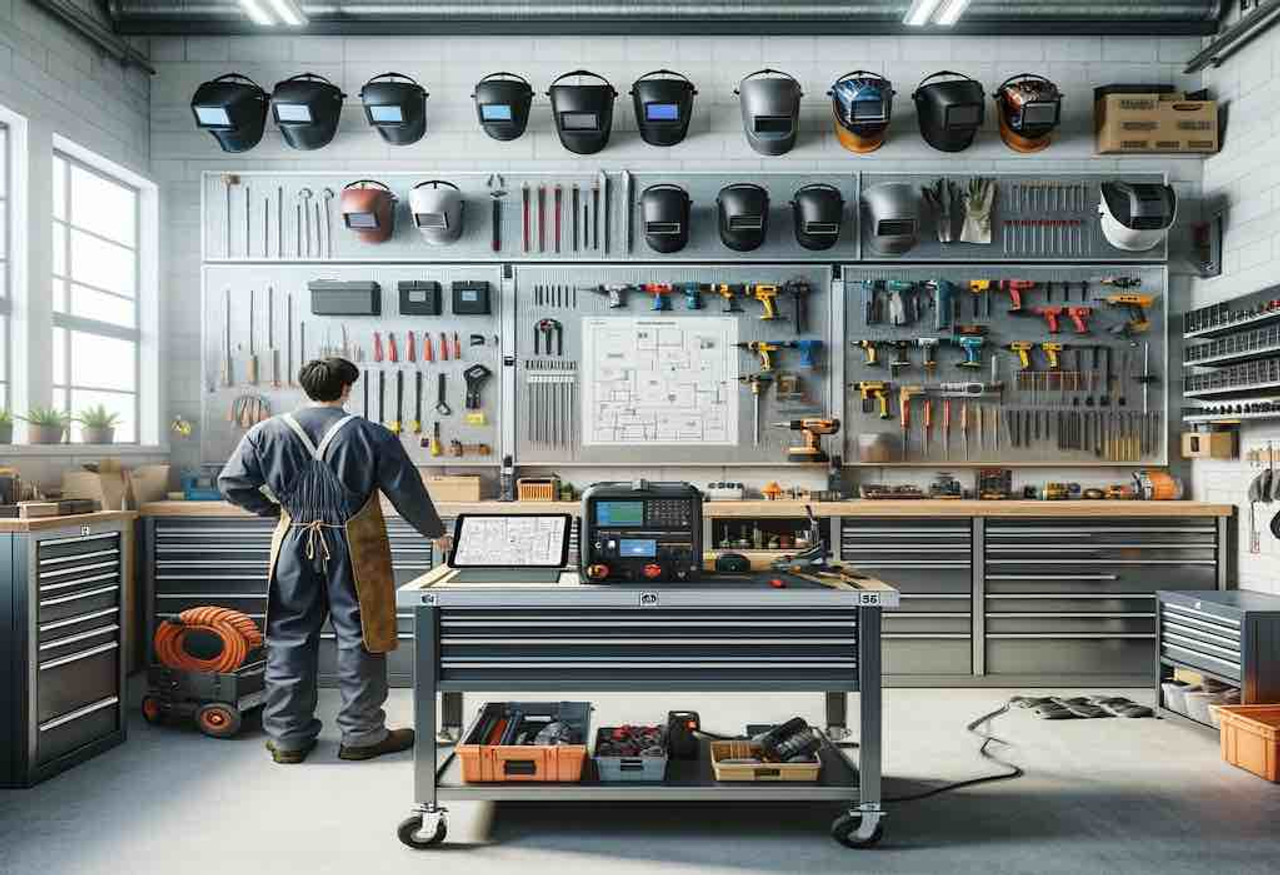

Types of Storage Systems: Cabinets, Shelving, and Pegboards

Choosing the proper storage solutions is crucial for maintaining an organized workshop. Cabinets can secure valuable or delicate tools, shelving units are ideal for organizing larger items, and pegboards provide accessible storage for frequently used tools.

Creative DIY Storage Solutions

Not all storage solutions need to come from the store. Many practical storage ideas can be implemented with creativity and DIY spirit. From repurposed containers to custom-built racks, explore how you can create your storage solutions tailored to your specific needs.

Comparing Commercial vs. Homemade Storage Options

While DIY storage solutions can be cost-effective and customized, commercial options offer convenience and durability. Weigh the pros and cons of each to decide what’s best for your workshop, considering costs, time investment, and specific storage needs.

By implementing these practical organization tips and creative ideas, you can transform your workshop into a streamlined, efficient space that supports your projects and enhances your productivity.

Tool Organization Techniques

Effective tool organization transcends mere arrangement – it embodies the principles of efficiency and precision:

- Categorizing and Labeling Tools for Easy Access: Organize your tools into categories based on their type and function. Then, label each section clearly. This method speeds up the retrieval process but also aids in returning tools to their proper place.

- Best Practices for Tool Maintenance and Storage: Regular cleaning, proper lubrication, and immediate repairs extend your tools' lifespan and maintain functionality. For a detailed guide, refer to Maintaining Your Workshop Tools.

- Innovative Tool Organization Products: The market has products that keep your tools organized and protected. Explore the options available here, from magnetic tool holders to modular storage systems.

Safety and Accessibility

An organized workshop is a safer workshop:

- Importance of Keeping Tools Accessible but Secure: Tools should be accessible when needed and securely stored away to prevent accidents. This balance is crucial for maintaining a safe working environment.

- Safety Considerations in Tool Placement and Storage: Properly storing sharp, heavy, or hazardous tools can significantly reduce the risk of workplace injuries. For comprehensive safety tips, seeWorkshop Safety Tips.

- Accessibility Tips for Different Abilities: An inclusive workshop considers various abilities, ensuring everyone can work effectively and safely. This ergonomic study reveals ergonomic solutions and adaptations.

Maximizing Workspace Efficiency

An efficient layout streamlines projects from start to finish:

- Layout Strategies for Optimizing Workflow: Arrange your workspace to minimize unnecessary movement. Tools and materials should be within reach, and frequently used equipment should be the most accessible.

- Implementing Lean Principles in Workshop Organization: Lean principles such as 'Sort', 'Set in order', 'Shine', 'Standardize', and 'Sustain' can vastly improve efficiency. Apply these principles to keep your workshop organized and reduce waste.

- Case Studies of Efficient Workshop Layouts: Learn from the best. Review case studies of successful workshop layouts to inspire and guide your organizational strategy.

Overcoming Common Organization Challenges

Every workshop faces unique challenges, but solutions are available:

- Solutions for Small or Cluttered Workshops: Utilize vertical space, invest in multi-functional furniture, and declutter regularly to make the most out of a small workshop.

- Dealing with Seasonal Tool Storage: Rotate tools based on seasonal needs, storing off-season items securely and making room for those in current use.

- Addressing Common Organization Pitfalls: Avoid potential disorganization by regularly reviewing and adjusting your storage strategies. For more solutions, visit Solving Workshop Organization Challenges.

By applying these techniques and strategies, your workshop can become a model of organization, safety, and efficiency, regardless of your challenges.

Advanced Workshop Organization Ideas

Elevate your workshop organization with the latest technological advancements and forward-thinking strategies:

- Technological Tools for Inventory and Organization: Integrate smart inventory systems or digital tool trackers to maintain an accurate and efficient organizational system. Explore our detailed guide here for a deep dive into the latest tech tools revolutionizing workshop organization.

- Future Trends in Workshop Organization: Stay ahead of the curve by understanding the evolving landscape of workshop management. Access the latest industry trends report to discover emerging trends, such as modular storage solutions and AI-driven organization systems.

Conclusion

As we wrap up, remember that the foundation of a productive workshop lies in its organization. By recapping the key points for effective workshop organization, you can create a space that not only boosts efficiency but also enhances safety and job satisfaction. We Encourage you to Start Small and Improve Gradually—organizational excellence isn't achieved overnight but through consistent effort and iterative improvements.

Call to Action

We're eager to hear from you! Invite Readers to Share Their Organization Tips by emailing us at sales@tendsupplies.com. Your insights could inspire others to enhance their workshop setups. Additionally, we offer a comprehensive Downloadable Checklist for Workshop Organization. This resource is designed to help you track your progress and ensure every detail is noticed.

FAQs

How do I keep my workshop organized with limited space?

- Start by utilizing vertical storage solutions and keep only the most essential tools within arm's reach. For more strategies,

What's the best way to categorize tools?

- Group them by function or frequency of use, and consider color-coding or labeling for easier identification.

How often should I reevaluate my workshop organization?

- We recommend reviewing your setup quarterly or whenever your workflow changes significantly.

Can technology make a difference in tool organization?

- Absolutely! Technology can streamline and enhance your organizational system from inventory apps to tool tracking devices.

What should I do with rarely used tools?

- Store them in clearly labeled, out-of-the-way areas to keep your workspace clutter-free, but ensure they're still accessible when needed.

How can I involve my team in maintaining an organized workshop?

- Create clear guidelines, delegate responsibilities, and encourage regular feedback sessions to involve everyone in maintaining the workshop's organization.

For additional information and guidance or to explore a wide range of organization solutions, visit Tend Industrial Supplies at tendsupplies.com. Let's create the optimal workshop environment together!

Organizing Your Workspace for Efficiency