A Beginner's Guide to Hydraulic Torque Wrenches: Understanding Types, Features, and Applications

Hydraulic torque wrenches are sophisticated tools critical for achieving precise bolt tightening and loosening in various industrial settings. They are indispensable in manufacturing, construction, and automotive repair, where they ensure the structural integrity and operational efficiency of machinery and structures. This guide introduces the basics of hydraulic torque wrenches and highlights their importance in different industries.

Understanding Hydraulic Torque Wrenches

Hydraulic torque wrenches are devices that apply a predetermined, controlled amount of torque to a fastener, typically nuts or bolts. They operate based on hydraulic mechanisms that convert fluid pressure into torque output, allowing for accurate and efficient application of force. Unlike manual torque wrenches, which rely on the user's strength and judgment, or pneumatic and electric wrenches, which use air or electricity, hydraulic torque wrenches offer superior precision and consistency. They are especially advantageous for their high torque output, adaptability in tight spaces, and minimal operator strain, making them ideal for heavy-duty applications.

The Science Behind the Torque: How Hydraulic Wrenches Convert Pressure to Power

At the heart of every hydraulic torque wrench lies a sophisticated hydraulic system. This system converts the pressure exerted by hydraulic fluid into the mechanical force required to tighten or loosen fasteners. Here's a simplified look at the process:

- Hydraulic Pump: An external hydraulic pump (electric or air-powered, sometimes manual) generates high-pressure hydraulic fluid, typically oil.

- Fluid Transfer: This pressurized fluid travels through high-pressure hoses to the wrench's internal cylinder.

- Piston Movement: Inside the wrench, the fluid acts on a piston, forcing it to move.

- Leverage and Gearing: The linear motion of the piston is then converted into rotary motion via a pawl mechanism and a reaction arm. This system amplifies the force, allowing the wrench to produce immense torque.

- Reaction Arm: Crucially, the reaction arm is a separate component that braces against an adjacent surface (like another bolt head or part of the structure) to counteract the rotational force, ensuring that the applied torque is directed solely to the fastener. Without a proper reaction point, the wrench would simply spin without tightening the bolt.

- Controlled Release: After the desired torque is achieved, the pressure is released, and the piston retracts, allowing the wrench to reset for the next cycle.

This precise control over fluid pressure directly translates to accurate torque output, making hydraulic wrenches indispensable for applications demanding exact fastener tension.

How Hydraulic Torque Wrench WOrks

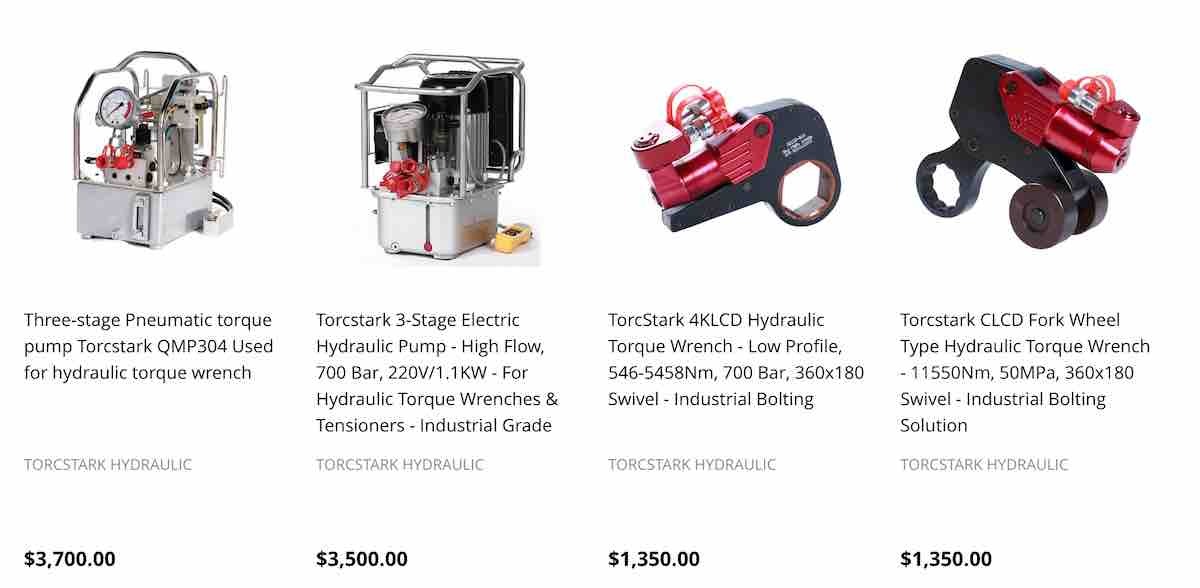

Types of Hydraulic Torque Wrenches

Hydraulic torque wrenches come primarily in three types: low-profile, square and thin-series hydraulic torque drive.

-

Low-profile Torque Wrenches:

- These compact and versatile wrenches are designed for tight spaces where traditional wrenches can't fit. They are typically used in applications with limited overhead clearance or side-to-side space, such as flange work in pipelines or machinery repair. The low-profile design does not compromise on power, making it an ideal solution for challenging environments.

-

Square Drive Torque Wrenches:

- These are more traditional in design, resembling a ratchet wrench powered by hydraulic fluid. They have a square drive that can fit various sockets, making them suitable for multiple applications. They are instrumental when bolt sizes vary or a single tool is needed for various fastening tasks.

-

Super Thin Series Hydraulic Torque Wrench:

- This type is ideal for small bolts, such as Blow Out Preventor Bolts (BOP), commonly used in oil refineries. The Super Thin link provides accurate and powerful torque in tight applications, using a concentric strap for strength and accuracy.

Beyond the Basics: Specialized Hydraulic Torque Wrench Designs

While low-profile, square drive, and super thin series wrenches cover most applications, the world of industrial bolting is vast. Other specialized hydraulic torque wrench designs cater to unique requirements:

- Geared Hydraulic Torque Wrenches: These tools integrate internal gearing systems to provide even higher torque output from a more compact footprint, often used for extremely large or stubborn fasteners.

- Custom-Engineered Solutions: For highly specialized industrial machinery or unique structural designs, some manufacturers offer custom-engineered hydraulic torque wrenches designed to fit exceptionally confined spaces or achieve specific bolting patterns that off-the-shelf tools cannot.

Understanding these variations ensures that you can identify the most effective tool, even for the most challenging bolting scenarios.

Key Features of Hydraulic Torque Wrenches

Hydraulic torque wrenches are known for several key features that make them indispensable tools in industrial applications:

- Accuracy and Precision: They provide precise torque control, ensuring that bolts are tightened or loosened to the exact specifications required, reducing the risk of over- or under-tightening.

- Power and Performance: Hydraulic torque wrenches deliver high torque output with minimal operator effort, making them suitable for heavy-duty tasks that would be challenging or impossible with manual wrenches.

- Durability and Reliability: Built to withstand harsh industrial environments, these wrenches are robust and reliable, ensuring long service life even under challenging conditions.

- Safety Features: With safety a paramount concern in industrial settings, hydraulic torque wrenches are designed with features such as low noise levels and minimal vibration, reducing the risk of operator fatigue or injury.

By understanding hydraulic torque wrenches' types, features, and applications, beginners can make informed decisions when selecting and using these tools in their respective fields. These wrenches enhance the efficiency and safety of industrial operations and ensure the longevity and reliability of their machinery and structures.

Enhanced Safety: Protecting Operators and Assets

Beyond minimizing noise and vibration, modern hydraulic torque wrenches incorporate advanced safety features to protect both the operator and the integrity of the bolted joint:

- Hands-Free Operation Accessories: Many systems allow for remote operation or incorporate accessories that keep the operator's hands clear of pinch points and potential hazards during tightening or loosening.

- Anti-Lock Mechanisms: These features prevent the wrench from binding on the fastener, ensuring smooth operation and preventing accidental jamming or tool damage.

- Pressure Relief Valves: Integrated into the hydraulic pump or wrench itself, these valves prevent over-pressurization of the system, protecting the equipment from damage and reducing the risk of hose bursts.

- Swivel Hoses and Couplers: Designed to articulate and rotate, these components prevent hose kinking and tangling, reducing trip hazards and ensuring consistent fluid flow.

- Ergonomic Design: Many wrenches are designed with balanced weight distribution and comfortable grips to reduce operator fatigue and the risk of musculoskeletal injuries during prolonged use.

Investing in tools with robust safety features is not just about compliance; it's about safeguarding your most valuable assets – your workforce and your equipment.

Selecting the Right Hydraulic Torque Wrench

When venturing into hydraulic torque wrenches, selecting the right tool is paramount for both efficiency and safety. The primary factors to consider include torque requirements, which hinge on the specific needs of the task at hand; space constraints, as some environments may necessitate a compact tool; and the material of the components being worked on, which can dictate the wrench's necessary power and durability. Tips for choosing the right model encompass understanding your project's specific needs, consulting with industry experts, and considering future applications to ensure a versatile investment.

Applications of Hydraulic Torque Wrenches

Hydraulic torque wrenches find their place in a myriad of settings. Industrial applications like manufacturing, mining, and construction provide the necessary strength and precision for heavy-duty bolting. For maintenance purposes, they are indispensable in the automotive, aerospace, and marine industries, where they ensure machinery operates smoothly and safely. Moreover, specialized sectors such as wind energy and power plants rely on these tools for critical bolting tasks that demand exactness and reliability.

Real-World Scenarios: Where Precision Bolting Makes a Difference

To truly appreciate the versatility of hydraulic torque wrenches, consider these specific industry applications:

- Wind Energy: Critical for assembling and maintaining wind turbines, where massive bolts secure tower sections, blades, and gearbox components. The precise torque prevents loosening due to vibration and ensures structural integrity against high winds.

- Oil & Gas Refineries and Pipelines: Essential for leak-free flange connections in high-pressure environments. The super thin series wrenches are particularly valuable for tightening Blowout Preventor (BOP) bolts in confined spaces.

- Heavy Equipment Manufacturing: Used in the assembly of large construction vehicles, mining equipment, and agricultural machinery, where high torque is needed for durable chassis and component connections.

- Bridge and Infrastructure Construction: Facilitating the secure fastening of structural steel beams and columns, ensuring the long-term stability and safety of vital infrastructure.

- Power Plants (Nuclear, Thermal, Hydroelectric): Crucial for maintaining turbines, generators, and piping systems, where accurate torque prevents costly downtime and ensures operational safety.

In each of these demanding environments, the combination of power, precision, and safety offered by hydraulic torque wrenches makes them indispensable.

Operating Hydraulic Torque Wrenches

Operating a hydraulic torque wrench requires a solid understanding of the tool's basic setup and operation. This begins with assembling the wrench correctly and setting the desired torque value based on the task's specifications. Safety precautions must be addressed; always wear protective gear, ensure the workspace is secure, and be mindful of the tool's operation. Regular maintenance and care are also crucial for the longevity of the wrench, involving routine checks and cleanings post-usage to keep the tool in optimal condition.

The Importance of Calibration: Ensuring Accuracy and Compliance

The ability of a hydraulic torque wrench to deliver accurate torque is its primary advantage. However, this accuracy must be maintained and verified through regular calibration.

- Why Calibrate? Over time and with repeated use, the internal components of a torque wrench can wear, and the hydraulic system can lose its precise linearity. Calibration ensures that the torque output displayed by the wrench (and delivered by the pump) truly matches the actual torque being applied to the fastener.

- Compliance and Standards: Many industries have strict regulatory requirements for bolting integrity. Adhering to standards like ISO 17025 for calibration laboratories demonstrates commitment to quality and safety. Regular, certified calibration provides documented proof of accuracy, which is vital for audits and liability.

- Frequency of Calibration: While manufacturer guidelines vary, a general recommendation is to calibrate hydraulic torque wrenches at least once a year, or more frequently if used in high-stress applications, harsh environments, or if signs of inaccurate performance are observed.

- Choosing a Calibration Service: Always opt for an accredited calibration laboratory that provides traceable calibration certificates. This ensures the process meets recognized industry standards.

A well-calibrated hydraulic torque wrench is a reliable one, minimizing the risk of under- or over-tightening, which can lead to catastrophic joint failure or component damage.

Troubleshooting Common Issues

Even with meticulous care, users may encounter issues with their hydraulic torque wrenches. The manufacturer's troubleshooting guides often help identify and resolve typical problems, such as inaccurate torque delivery, hydraulic system leaks, or hose connector problems. Knowing when to seek professional help is crucial; if the problem persists or is beyond your technical know-how, consulting with an expert or returning the tool to the manufacturer for service is advisable.

Conclusion

The importance and versatility of hydraulic torque wrenches in today’s industrial and maintenance applications cannot be overstated. They bring unparalleled accuracy, power, and reliability, addressing various industries' broad spectrum of bolting needs. This guide has walked you through the essential knowledge, from understanding how these tools work to selecting the right one for your specific requirements. Remember, using the appropriate wrench enhances efficiency and safety and ensures the longevity and reliability of the tool and the projects it undertakes.

Additional Resources

Resources are available for those looking to expand their understanding and expertise. Delve further into hydraulic torque wrenches by exploring additional reading materials, educational guides, and videos. Joining professional associations or participating in training opportunities can provide deeper insights, practical skills, and networking prospects. These resources can be invaluable in keeping abreast of the latest trends, technologies, and best practices in the field.

Frequently Asked Questions (FAQs) About Hydraulic Torque Wrenches

Navigating the world of industrial bolting can lead to many questions. Here are some of the most common inquiries about hydraulic torque wrenches:

Q: How do hydraulic torque wrenches compare to pneumatic or electric torque wrenches? A: Hydraulic torque wrenches generally offer superior precision and higher torque output compared to pneumatic or electric alternatives, especially for heavy-duty applications. They are also quieter and produce less vibration. Pneumatic and electric wrenches might be lighter and more portable for certain lower-torque tasks.

Q: Can I use any hydraulic pump with my hydraulic torque wrench? A: It is highly recommended to use a hydraulic pump specifically designed and matched for your torque wrench. Mismatched pumps can lead to inaccurate torque, inefficient operation, and potential damage to the wrench or pump due to incompatible pressure ratings or flow rates.

Q: What is the lifespan of a hydraulic torque wrench? A: With proper operation, regular maintenance, and timely calibration, a high-quality hydraulic torque wrench can last for many years, even decades. Durability is a key feature of these tools, designed for demanding industrial environments.

Q: What are the main causes of inaccurate torque delivery? A: Common causes include an uncalibrated wrench or pump, incorrect pressure settings, worn internal components, using the wrong reaction arm setup, or improper bolt preparation (e.g., lack of lubrication on threads).

Q: Do I need to lubricate the bolts before using a hydraulic torque wrench? A: Yes, lubrication is almost always recommended unless specified otherwise. Lubricating bolt threads and the nut's bearing surface reduces friction, ensuring that a larger percentage of the applied torque contributes to bolt tension, leading to more accurate and consistent tightening.

By integrating these blocks, you'll significantly enhance the article's depth, address more user queries, provide more context, and naturally include more keywords, all of which contribute to stronger SEO performance. Remember to update your internal linking strategy to connect new sections to relevant product pages where applicable.

Call to Action

Are you ready to enhance your operations with the proper hydraulic torque wrench? Tend Industrial Supplies is here to assist with all your needs. Our range of high-quality, reliable hydraulic torque wrenches is designed to meet the diverse requirements of various industries. Whether you are new to the field or looking to upgrade your equipment, our expert team can guide you to the perfect solution tailored to your specific applications. Don’t hesitate to reach out for advice, further information, or to make a purchase. Contact us today at sales@tendsupplies.com or visit our website at tendsupplies.com. Invest in the right tool, and ensure your projects are built on a precision, safety, and efficiency foundation with Tend Industrial Supplies.