2025 Workshop Space Design: Real Layout Examples for Efficiency & Safety

Imagine this: You’re mid-way through a precision glue-up. The clock is ticking, the adhesive is setting, and you reach for your bar clamps, only to remember they’re buried behind the table saw. The path is blocked by extension cords, scrap wood, and tool carts. By the time you return, the glue has set, the part is ruined, and productivity has taken a hit.

Scenes like this aren’t just inefficient, they’re unsafe. Poor layouts increase trip hazards, slow down workflow, and lead to preventable injuries. In 2025, as tools become heavier, smarter, and more compact, the old “put it wherever there’s room” approach simply can’t keep up.

This article delivers the definitive 2025 Workshop Space Design standards, complete with real layout examples, safety improvements, and workflow-boosting strategies used in top automotive, woodworking, and fabrication shops worldwide.

Key Takeaways:

1. Mobility Is the 2025 Standard

Mobile bases, rolling storage, and modular “Triad Carts” now outperform fixed benches in small and mid-sized shops.

2. Adopt a 360-Degree Workflow

Centering table saws or automotive lifts dramatically reduces wasted movement and eliminates blind corners.

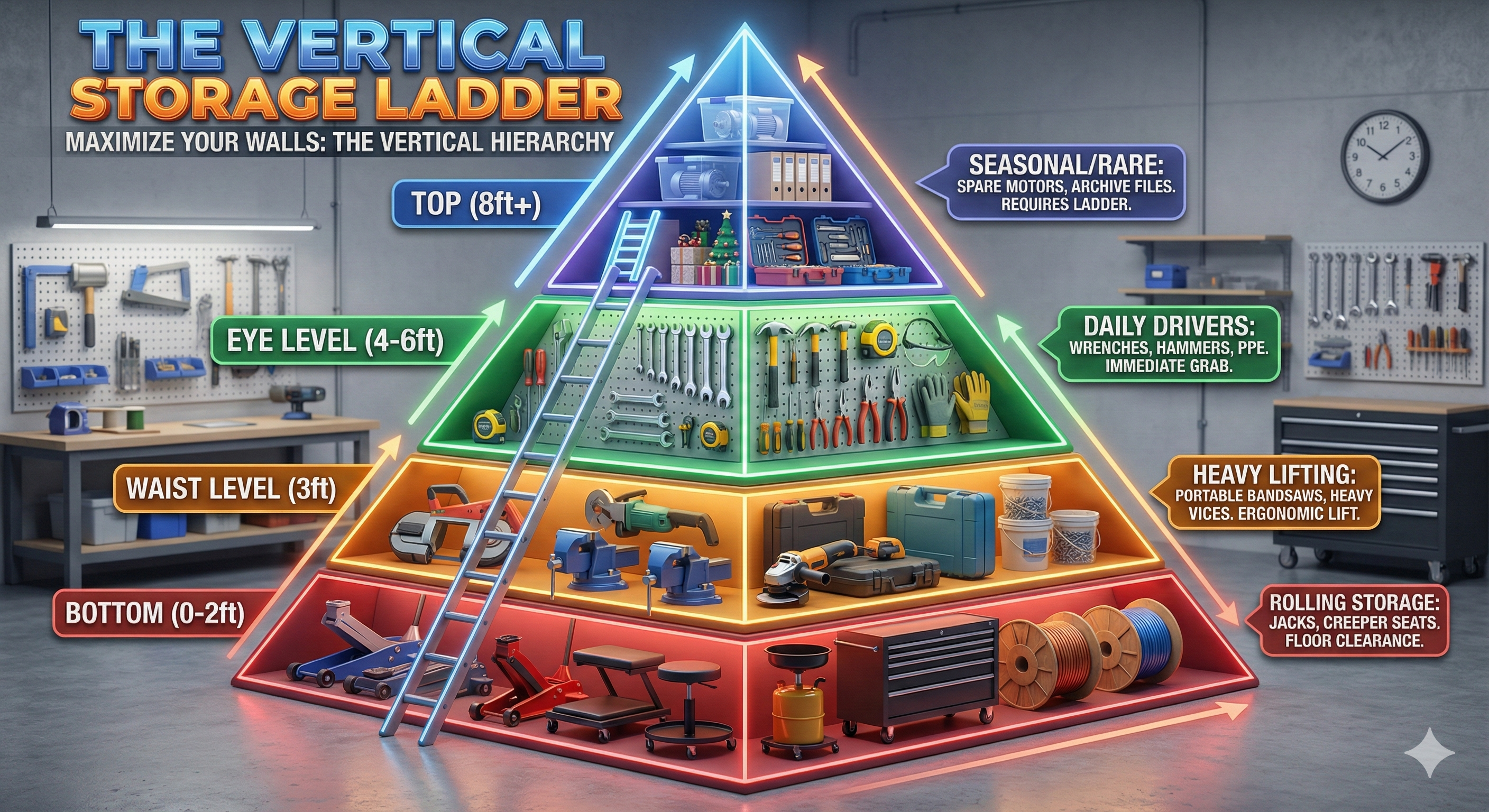

3. Vertical Storage Beats Floor Space

French cleat systems and “Vertical Hierarchy Walls” free floor space and reduce tool-finding time by up to 30%.

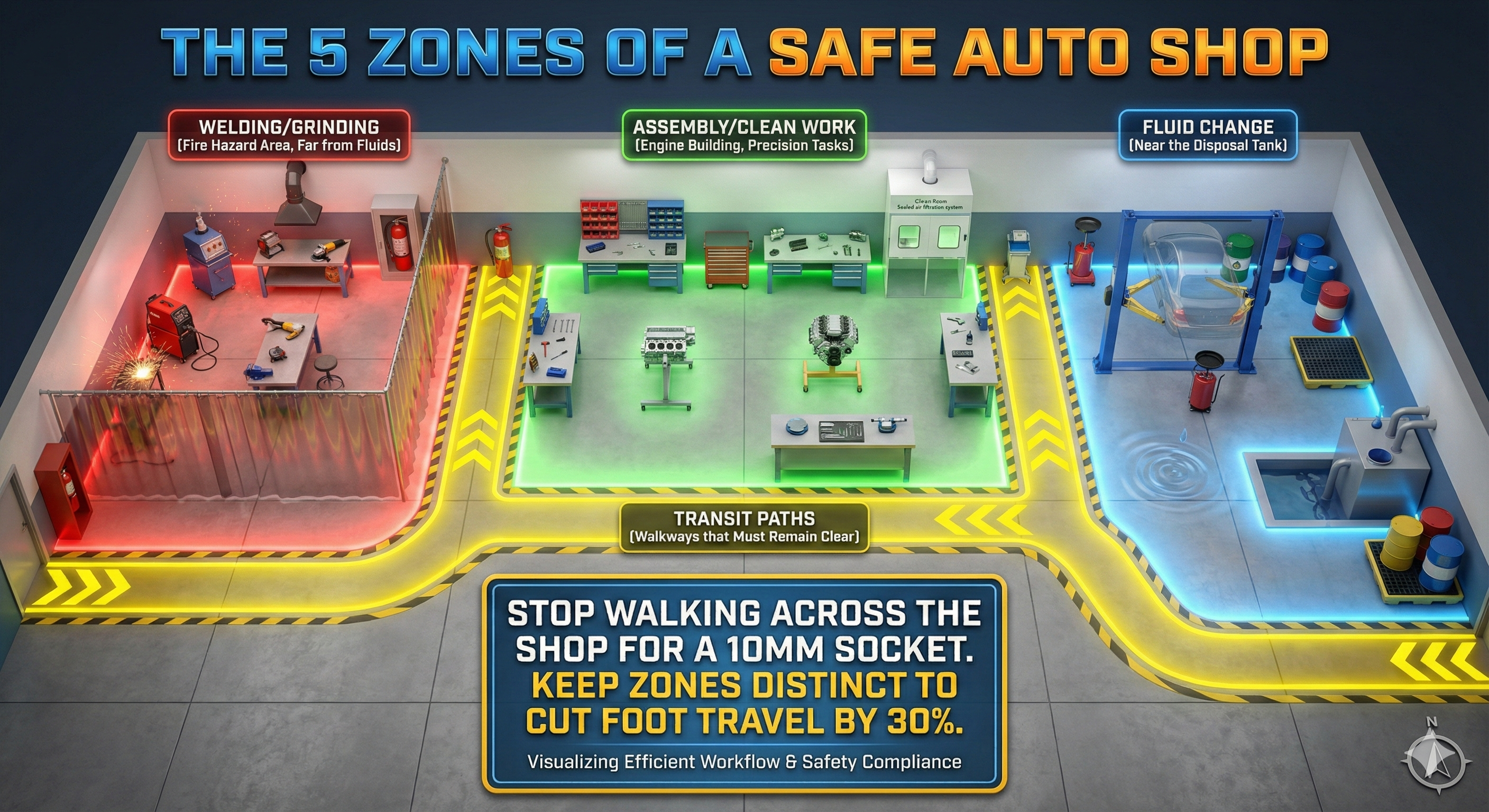

4. Safety Requires “Zone Defense”

Separate hot work, clean assembly, and dust-producing tools using strategic zoning and fire-resistant barriers.

5. Utility Infrastructure Determines Real Efficiency

Voltage stabilizers, ventilation paths, and secure storage now form part of the core workshop design, not extras.

H2: The Lean Automotive Layout (2025 Standard for Mechanics)

Best for: tire bays, auto repair, diagnostics, quick-lube shops.

1. Center-Stage Lift (360° Workflow Zone)

Place lifts centrally with 4 ft clearance on all sides.

Add overhead retractable air/power reels to eliminate floor cables (key for OSHA/ISO compliance).

2. The “Mobile Triad Cart” System

-

Diagnostic Cart – laptops, scanners, OBD modules

-

Fluid Cart – funnels, pans, absorbents

-

Heavy/Impact Cart – socket sets, impacts, torque tools

This cuts walking distance by 30–45%.

Pro Tip:

In humid regions, house the air compressor in a ventilated closet with an automatic moisture drain to prevent rust.

H2: The Modular Woodworking Studio (Garage & Small Commercial)

Best for: Cabinet makers, furniture designers, and joinery.

Woodworking requires distinct "Dusty" and "Clean" stages. The 2025 trend is Mobile Bases on everything.

1. The "Island" Table Saw

Place your table saw in the center of the room, but pair it with a multi-function outfeed table.

- The Design: The outfeed table should be the same height as your table saw and double as an assembly bench.

- Storage: The space under the outfeed table is prime real estate for wood scraps or portable thickness planers.

2. The French Cleat Wall System

Stop using static shelving. Cover your primary wall with French Cleats.

- Why it works: You can rearrange tool holders instantly. If you change your workflow from "sanding" to "finishing," you can physically move the relevant tools to your immediate reach.

Global Standard: This is the #1 recommended storage solution by lean manufacturing experts worldwide for keeping "frequency of use" tools accessible.

H2: The "Hot Work" Fabrication Layout (Welding & Metal)

Best for: Welders, metal fabricators, and heavy equipment repair.

Safety is the layout driver here. You must manage heat, fumes, and UV light.

1. The Airflow Tunnel

Position your primary welding table near the large bay door or install a dedicated fume extraction arm.

- The Flow: Fresh air should enter behind the welder and pull fumes away from their face toward the exhaust.

- Flash Protection: Use heavy-duty welding curtains on tracks (not fixed frames) so you can open the space up for large projects like gates or trailers.

2. Fire-Safe Corner

Grinders throw sparks up to 20 feet. Design a "Grinding Booth" lined with sheet metal or fire-resistant drywall, situated opposite from your flammable storage (gasoline, paints).

H2: Global Design, Local Reality: Adapting for Your Location

GEO-Optimized Advice for Industrial Hubs (e.g., Lagos, Port Harcourt, Texas, Dubai)

While the layouts above are global standards, your local environment dictates the "hidden" infrastructure.

- Power Stability: In regions with fluctuating power grids, your 2025 layout must include space for a Voltage Stabilizer or UPS for sensitive CNC machines and diagnostic tools. Don't hide this; make it accessible for monitoring.

- Heat & Ventilation: In tropical or desert climates, passive ventilation isn't enough. Plan your layout so that large machinery does not block cross-ventilation from windows or bay doors.

- Security: For high-theft urban areas, design a "Secure Cage", a lockable steel mesh section within the shop for high-value impact tools and scanners, rather than leaving them on open benches overnight.

Frequently Asked Questions (FAQs)

1. What is the most efficient layout for a small workshop?

Answer: For shops under 1,000 sq. ft., the "Mobile Island" layout is the 2025 standard.

- The Concept: Instead of lining all equipment against the walls, place your primary workstation (like a table saw or lift) in the center of the room.

- The Benefit: This creates a 360-degree workflow, allowing you to handle long materials or move around a vehicle without hitting obstructions.

- Key Requirement: All peripheral storage must be mobile (on wheels) to clear floor space instantly when project sizes change.

2. How much clearance do I need around a car lift?

Answer: You need a minimum of 4 feet (1.2 meters) of clearance on all sides of the vehicle.

- Why: This allows a tool cart to roll completely around the car without obstruction.

- Safety Factor: It ensures mechanics have an escape path in emergencies and prevents "door dings" against walls or workbenches.

- Pro Tip: Pair this clearance with overhead retractable reels for air and power to keep the floor clear of trip hazards (a common OSHA violation).

3. What is a French Cleat wall system?

Answer: A French Cleat is a wall storage method using 45-degree angled strips of wood/metal that allow you to hang and move tool holders instantly without screws.

- Best For: Woodworking and fabrication shops where workflows change frequently.

- Efficiency: It adheres to "Lean" manufacturing principles by keeping the tools you use most often at eye level, while allowing you to rearrange the wall in seconds without tools.

4. How should I ventilate a welding workshop?

Answer: Use the "Airflow Tunnel" method.

- Setup: Position the welding table near a large bay door or exhaust fan.

- Direction: Ensure fresh air enters from behind the welder and pulls fumes away from their face toward the exhaust.

- Equipment: In 2025 designs, mobile fume extraction arms are preferred over fixed hoods because they can be positioned directly at the source of the arc, protecting the welder's lungs more effectively.

5. What are the "Triad Carts" in automotive shop design?

Answer: The "Triad Cart" system replaces the single massive toolbox with three specialized, mobile units:

- Diagnostic Cart: Holds laptops and scanners (kept clean).

- Fluid Cart: Holds oils, funnels, and pans (kept near disposal tanks).

- Impact Cart: Holds heavy wrenches and sockets.

- The Goal: This separates sensitive electronics from grease and reduces the time mechanics spend walking back and forth to a main toolbox.

6. How do I prevent fire hazards in a small fabrication shop?

Answer: Implement a "Zone Defense" layout.

- Separation: Distinctly separate your "Hot Work" zone (welding, grinding) from your "Flammable Storage" zone (paints, gas).

- Barriers: Use movable fire-resistant welding curtains rather than permanent walls.

- Placement: Locate the grinding station in a corner lined with sheet metal or fire-resistant drywall, strictly opposite from any combustible materials to contain spark throw.

7. Do I need a voltage stabilizer for my workshop?

Answer: Yes, specifically if you use modern diagnostic tools or CNC machinery.

- The Risk: In many industrial hubs, grid fluctuations can fry the sensitive motherboards in 2025-era equipment.

- The Design Fix: Don't just plug these into the wall. Design your electrical layout with a dedicated space for a Voltage Stabilizer or UPS (Uninterruptible Power Supply) to condition the power before it reaches your expensive assets.

Related Articles:

1. The Ultimate Guide to Garage Workshop Layouts: Maximizing Space and Efficiency

2. Essential Storage Solutions for Every Workshop: A Complete Guide

3. The 5S System for Workshop Excellence: Organize, Improve Safety, and Boost Efficiency

4. The Ultimate Guide to Storing and Organizing Workshop Hardware

5. How to Organize Your Mechanic Tool Kit

Conclusion

Ultimately, a well-designed workshop is more than just a building; it is a precision instrument that dictates your speed, safety, and profitability. By shifting away from static, cluttered benches and embracing modular tool storage solutions, you do more than just tidy up, you actively maximize garage workspace efficiency and eliminate the "wasted motion" that kills productivity.

Whether you are focused on automotive shop workflow optimization in a commercial bay or setting up a dedicated fabrication zone, the rules for 2025 are clear: if it doesn't add value, get it off the floor. Implementing these small workshop layout ideas, from mobile triangulation to vertical zoning ensures your space meets industrial safety compliance while remaining flexible enough to adapt to new machinery.

Don't let a poor layout steal your time. Invest in flexible workshop infrastructure, put your workflow on wheels, and build a space that works as hard as you do.

Designing a safe, efficient workspace requires more than just good ideas, it requires the right infrastructure. Whether you are setting up a new automotive bay or upgrading a fabrication floor, TendSupplies.com offers expert procurement advice to ensure you get the best ROI on your equipment.

Shop Modular Storage & Workshop Tools Today. Questions about specific dimensions? Email us at sales@tendsupplies.com