Breathe Easy: Maintenance Best Practices for Pneumatic Tools

Your pneumatic tools are indispensable allies in the workshop, offering unmatched power and precision through the simple force of compressed air. Yet, to maintain their efficiency and prolong their lifespan, a rigorous maintenance routine is essential. This guide is designed to elevate you from a tool user to a maintenance expert, ensuring your pneumatic tools operate flawlessly for years to come.

Key Takeaway

Effective maintenance of pneumatic tools involves more than occasional check-ups. It requires a consistent routine that includes daily inspections, proper lubrication, moisture management, and the timely replacement of worn parts. Embracing advanced maintenance techniques and using comprehensive resources like those provided by Tend Industrial Supplies will elevate your tool care regimen, enhance tool performance, and extend their operational life significantly.

Unveiling the Enemies Within Common Pneumatic Tool Woes

Understanding what typically goes wrong with pneumatic tools can significantly aid in preventing these issues. Here are some of the most common problems:

Moisture Buildup: In the arch-nemesis of pneumatic tools, moisture can infiltrate air compressors and tools, leading to rust and corrosion, which degrade tool components and impair performance. This moisture generally enters through the air intake or condenses within the air lines or the tool itself.

Lack of Lubrication: Pneumatic tools require consistent lubrication to minimize internal friction; neglecting this can cause the moving parts to wear out prematurely. This wear reduces the tool's lifespan, diminishes its efficiency, and can lead to mechanical failures.

Clogged Filters and Air Lines: Just as a respiratory system functions best with clear airways, pneumatic tools rely on clean, unobstructed paths for airflow. Clogged filters and air lines restrict this flow, reducing output and potentially causing long-term damage to the tool’s internal mechanics.

Improper Storage: Exposure to extreme temperatures, dust, or corrosive environments can accelerate the deterioration of pneumatic tools. Proper storage conditions are, therefore, crucial to maintaining the tool's integrity and functionality.

Conquering the Gremlins: A Guide to Pneumatic Tool Maintenance

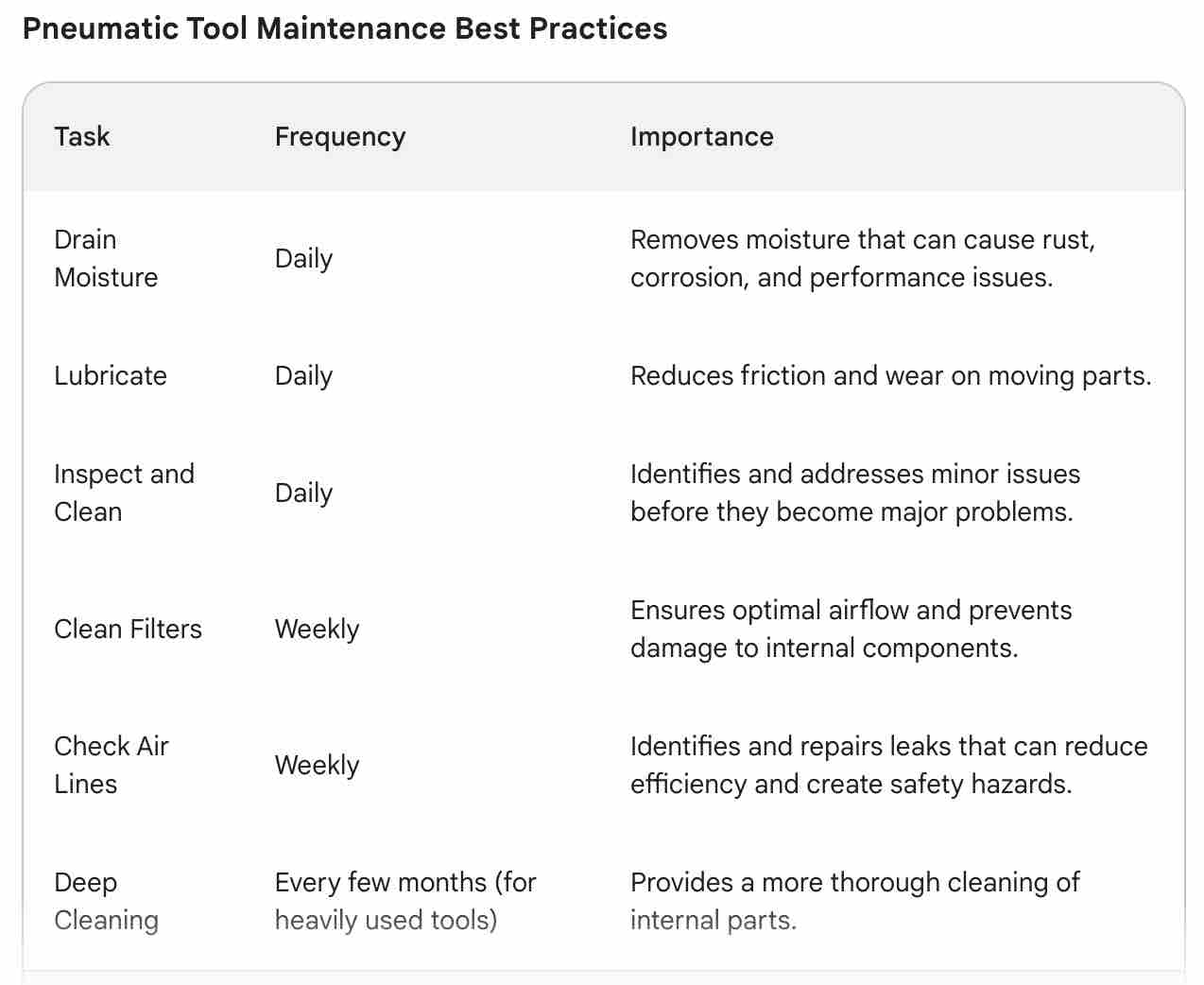

With the common issues outlined, let’s explore the maintenance protocols that can keep these problems at bay:

Daily Rituals:

- Drain Moisture: Start daily by draining any accumulated moisture from the air compressor's tanks. Moisture release valves are typically included, especially critical after high-usage periods.

- Lubricate: Add a few drops of high-quality pneumatic tool oil into the air inlet before use. This simple step is pivotal in reducing internal friction and wear.

- Inspect and Clean: Perform a quick visual inspection for any signs of wear or damage and clean the tool’s exterior to remove any dirt or debris that might compromise its function.

Weekly Maintenance:

- Clean Filters: Ensure that air filters are free from debris that could impede airflow. Depending on the manufacturer's guidance, clean or replace the filters regularly to maintain optimal air quality.

- Check Air Lines: Examine hoses and connections for any signs of wear, leaks, or damage. Promptly replace any compromised parts to avoid efficiency losses or potential safety hazards.

Periodic Deep Cleaning:

- For heavily used tools, a thorough cleaning every few months is advisable. This might include disassembling specific components to clean internal parts not typically accessible from the outside..

Beyond the Basics: Unlocking Advanced Maintenance Techniques

For enthusiasts and professionals alike who take pride in their tool performance, delving into advanced maintenance techniques can provide even greater returns on the functionality and longevity of pneumatic tools.

Invest in a Maintenance Kit:

Many tool manufacturers offer specialized maintenance kits designed specifically for their products. These kits typically include the correct grade of lubricants, replacement filters, seal kits, and sometimes tools designed to reach delicate areas without causing damage. Investing in these kits ensures that you have exactly what you need to keep your tools in top condition.

Store Wisely:

Proper storage of pneumatic tools can significantly extend their service life. Store tools in a clean, dry environment that protects them from the elements and extremes of temperature. If possible, keep them in a case or a covered area to avoid dust buildup, which can migrate into the tool and cause abrasion or clogging internal components.

Read the Manual:

While often overlooked, the owner's manual is a crucial resource. It contains specific maintenance schedules, troubleshooting tips, and safety information tailored to your model. Adhering to these guidelines can prevent costly mistakes and avoid unnecessary wear on your tools.

Use of Air Dryers:

Installing an air dryer in your pneumatic system can be a game-changer, especially in humid climates. Air dryers remove moisture from the compressed air, preventing water from entering your tools and causing internal corrosion or freezing in cold environments.

Regular Replacement of Wearable Parts:

Components such as O-rings, gaskets, and seals are prone to wear over time and can often be the culprit behind declining tool performance. Regular checks and timely replacement of these components can prevent gradual decline and sudden failures.

Integrating Expert Advice

Consult the Experts:

Utilizing the expertise available at Tend Industrial Supplies can drastically simplify maintaining your pneumatic tools. Whether it’s choosing the right maintenance kit, understanding your tools' specific needs, or troubleshooting unexpected issues, the professionals at Tend Industrial Supplies can provide invaluable guidance.

Professional Training:

Consider participating in workshops or training sessions on pneumatic tool maintenance. These can provide hands-on experience and deeper insights into the intricacies of pneumatic tool care, often covering topics not fully detailed in the user manuals.

Let's now prepare to conclude our guide by summarizing the essential points, offering a final takeaway, and guiding you toward making the best maintenance decisions for your pneumatic tools with the support of Tend Industrial Supplies. We'll also address some frequently asked questions that can clarify any remaining uncertainties.

Maximizing Efficiency and Longevity

Adhering to the maintenance best practices outlined in this guide transforms your approach from reactive to proactive care for your pneumatic tools. Regular maintenance ensures that your tools perform at their peak and prevents premature wear and costly breakdowns that can derail your projects. Remember, the longevity of your tools is directly influenced by the care they receive.

Additional Tips:

- Invest in a maintenance kit designed for your specific tools.

- Store tools in a clean, dry place with moderate temperature.

- Read the tool's manual for specific maintenance instructions.

- Consider using an air dryer to remove moisture from compressed air.

- Regularly replace wearable parts like O-rings, gaskets, and seals.

- Consult with the experts at Tend Industrial Supplies for guidance and support.

Call to Action

Ready to take your pneumatic tool maintenance to the next level? Visit Tend Industrial Supplies to explore our wide range of maintenance kits, state-of-the-art air dryers, and professional-grade pneumatic tools. Our expert team is ready to assist you with personalized recommendations and practical solutions tailored to your needs. Take your time with a breakdown to think about maintenance. Start today to ensure your tools are always in top condition!

FAQs

- How often should I lubricate my pneumatic tools?

- Lubricate your tools daily if they are used regularly. A few drops of pneumatic tool oil in the air inlet should suffice for a day’s use.

- What is the best way to store pneumatic tools?

- Store pneumatic tools in a clean, dry environment. If possible, use airtight bags or containers with desiccants to avoid moisture buildup which can lead to rust and corrosion.

- Can I use any type of oil for my pneumatic tools?

- It’s essential to use oil designed explicitly for pneumatic tools as it is formulated to vaporize in the air stream and coat internal components effectively. Using the wrong type of oil can cause deposits that hinder performance.

- What signs do my air tool’s filters need cleaning or replacing?

- Reduced performance, sporadic tool operation, or excessive moisture in exhaust air are common indicators that filters might be clogged and need attention.

- Why is it important to have a moisture drain routine?

- Draining accumulated moisture from air compressors prevents water from entering your tools. This can cause internal damage and affect the operation, especially in tools sensitive to water, like grinders and sanders.

With the proper care and the support of Tend Industrial Supplies, your pneumatic tools can continue to perform at their best, project after project. Make maintenance a priority and witness your tool investments' prolonged efficiency and durability.