Exploring the functions and applications of hydraulic power packs

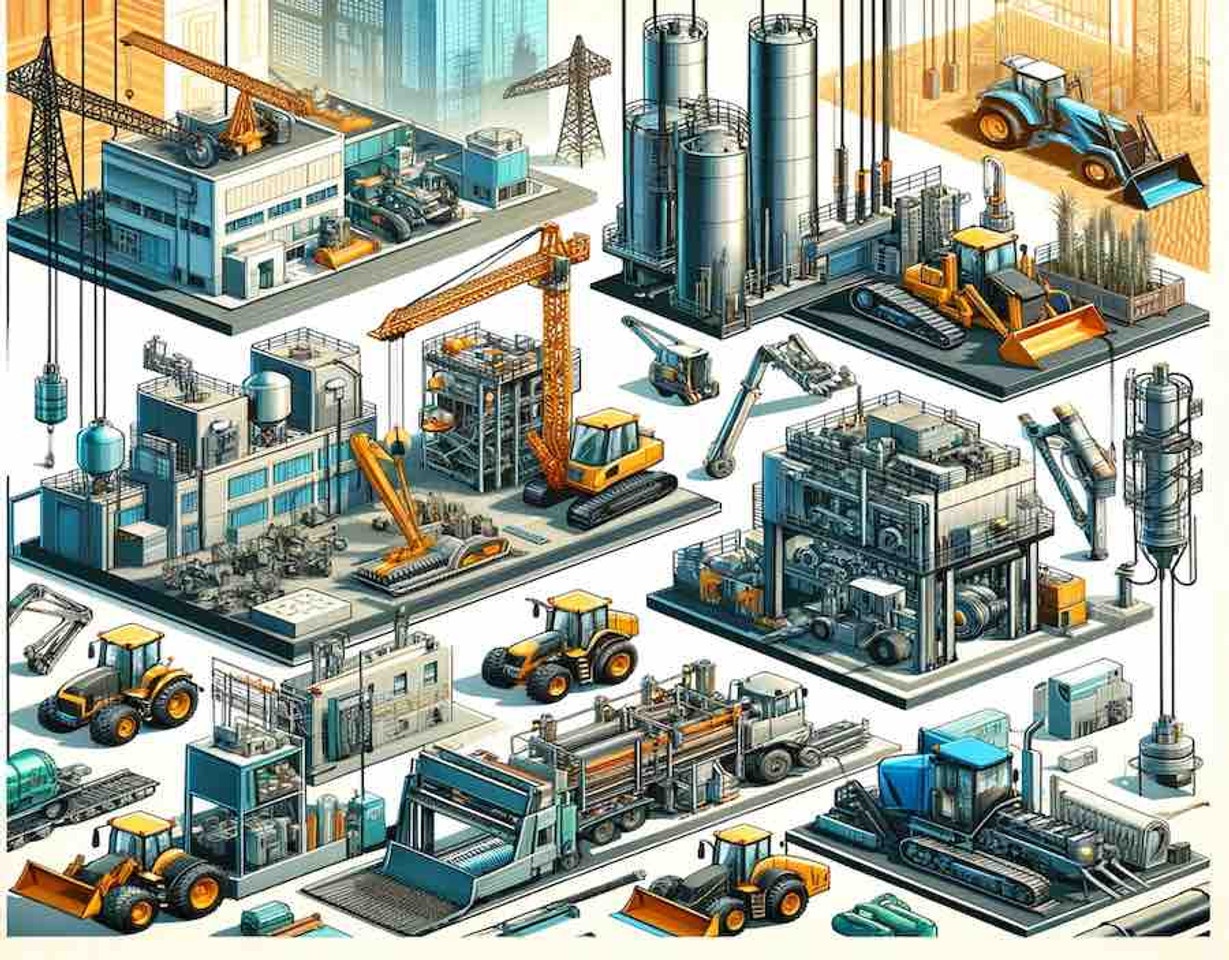

Ever wondered what makes heavy machinery move with precision and power, tackling tasks that seem larger than life? Enter hydraulic power packs - the unsung heroes behind the seamless operations of various industries. Picture this: a hydraulic power pack is like the beating heart of the machinery world, pumping life into massive equipment with finesse and force. You might not see them front and center, but their impact is undeniable. In the article we will delve deep into the intricate world of hydraulic power packs - demystifying their functions, unveiling their diverse applications across different sectors, and offering insights into their crucial role in powering everything from construction equipment to manufacturing processes. Whether you’re a seasoned engineer or simply curious about the inner workings of these powerhouses, this read promises to enlighten and engage. So, buckle up as we embark on a journey to explore the magic behind hydraulic power packs, uncovering the secrets to their efficient operation, maintenance tips, and even custom build options. Stay tuned for a no-nonsense breakdown of this fascinating technology that keeps the wheels of industries turning smoothly. Get ready to witness the power of hydraulics in action like never before!

Key Takeaways:

- Purpose and Importance: Hydraulic power packs are vital for driving hydraulic machinery in various industries, acting like the heart of these systems by supplying pressurized hydraulic fluid for energy transmission.

- Versatility and Applications: They are used in numerous sectors including construction, automotive, agriculture, and manufacturing, showcasing their adaptability and essential role in facilitating heavy-load operations and precision in tasks.

- Operational Mechanics: The article explains the working of hydraulic power packs, which use pressurized fluid based on Pascal's law, detailing components like hydraulic fluid, pumps, motors, control valves, and how these elements interconnect for efficient operation.

- Maintenance and Customization: It underscores the importance of regular maintenance for optimal performance and safety, and discusses custom build options to cater to specific industrial requirements, highlighting their customizable nature.

- Educational Value: Provides a comprehensive overview suitable for both seasoned engineers and novices, enhancing understanding of hydraulic systems and their critical functions in various applications.

Introduction to Hydraulic Power Packs

Hydraulic power packs play a crucial role in various industries, providing a reliable source of power to drive hydraulic machinery and systems. These compact and self-contained units are designed to generate tremendous amounts of power, making them an essential component in many hydraulic machines.

One of the main functions of a hydraulic power pack is to supply pressurized hydraulic fluid, which enables the transmission of energy from the power pack to the hydraulic system. This hydraulic fluid allows for precise control and movement of heavy loads, making it a vital component in industries such as construction, automotive, agriculture, fishing, and more.

Hydraulic power packs offer versatility and adaptability, meeting the demands of different applications. From the simplest form to the most complex setups, hydraulic power packs have the capability to deliver the high level of power required to perform various tasks efficiently.

With their integrated power supply, hydraulic power packs provide direct access to a pressurized fluid, allowing for quick and controlled operation. This makes them invaluable for tasks that require a consistently high power output, such as lifting heavy loads or operating heavy machinery.

In the following sections, we will delve deeper into how hydraulic power packs work, explore their functions and construction, discuss maintenance tips, and even explore custom build options to cater to specific requirements. So, let's dive in and explore the fascinating world of hydraulic power packs.

What is a hydraulic power pack?

A hydraulic power pack, also known as a hydraulic power unit, is an essential component of many hydraulic systems. It is a self-contained unit that combines multiple hydraulic components, such as a hydraulic reservoir, pump, motor, regulators, and pressure supply and relief lines, into a single integrated power supply. "A hydraulic power pack serves as the heart of any hydraulic system, providing the necessary power and control for heavy-load operations."

The main function of a hydraulic power pack is to provide the required hydraulic power to operate various hydraulic machinery. It achieves this by utilizing the principles of Pascal's law, which states that a change in pressure at any point in an enclosed fluid is transmitted equally to all points in the fluid.

In simpler terms, a hydraulic power pack uses pressurized fluid to generate tremendous amounts of power, allowing it to perform heavy-duty tasks in different industries. From construction sites to car mechanic workshops, hydraulic power packs are a vital component that enables the smooth operation of hydraulic systems.

Key Components of a Hydraulic Power Pack:

- Hydraulic Reservoir: It stores the hydraulic fluid needed for the system's operation.

- Hydraulic Pump: It pressurizes the fluid and creates flow within the system.

- Hydraulic Motor: It converts the hydraulic energy from the fluid into mechanical energy to perform work.

- Regulators: They control the flow and pressure of the hydraulic fluid based on the specific requirements of the system.

- Pressure Supply and Relief Lines: These lines distribute the pressurized fluid to the desired endpoints and provide a way for excess pressure to be released.

A hydraulic power pack is a versatile and flexible solution that can be customized to meet the demands of different applications. Its self-contained design and integrated power supply make it an efficient and reliable choice for powering hydraulic machinery.

How does a hydraulic power pack work?

A hydraulic power pack is a self-contained unit that generates and delivers hydraulic power for various applications. It consists of several components working together to perform specific functions, ensuring efficient operation in different industries.

1. Hydraulic Fluid

Hydraulic power packs rely on hydraulic fluid to transmit and distribute power. This fluid is typically an incompressible liquid, such as oil, that can handle high pressure and temperature changes without losing its properties. It serves as an energy carrier and provides lubrication to the moving parts of the system.

2. Hydraulic Pump

The hydraulic pump, driven by an electric motor or an internal combustion engine, creates flow and pressurizes the hydraulic fluid. It draws fluid from the reservoir and delivers it to the system at a specific pressure level required for the application.

3. Control Valves and Regulators

Control valves and regulators regulate the flow and pressure of the hydraulic fluid. They direct the fluid to different components and control the speed and force of hydraulic actuators. By adjusting these valves and regulators, operators can precisely control the movement or force exerted by the hydraulic system.

4. Hydraulic Motors

Hydraulic motors convert the hydraulic energy from the pressurized fluid into mechanical energy. They drive various types of machinery, such as pumps, fans, and conveyor belts, depending on the specific application. These motors generate rotational motion, allowing for the desired mechanical output.

5. Return Lines

After the hydraulic fluid has performed its function, it returns to the reservoir through return lines. These lines complete the hydraulic circuit and ensure a continuous flow of fluid within the system.

6. Filters and Coolers

To maintain the efficiency and longevity of the hydraulic power pack, filters and coolers are installed. Filters remove contaminants and particles from the hydraulic fluid, preventing damage to the components. Coolers help dissipate heat generated during operation, ensuring optimal performance and preventing overheating.

Understanding how a hydraulic power pack works is essential for operators and maintenance personnel. It enables them to identify and troubleshoot potential issues, ensuring the smooth functioning and longevity of the hydraulic system.

Remember, regular maintenance checks and adhering to manufacturer guidelines are crucial for optimal performance and safety.

Applications of hydraulic power packs

Hydraulic power packs serve a crucial role in numerous industries, offering a reliable and efficient power source for various applications. Let's explore the diverse functions and uses of hydraulic power packs in different sectors:

1. Construction: Hydraulic power packs are extensively utilized in construction equipment, such as cranes, bulldozers, and hydraulic lifts. They provide the necessary power to operate heavy machinery, ensuring smooth movement and precise control.

2. Automotive: Within the automotive industry, hydraulic power packs are employed in vehicle brake systems, power steering, and suspension systems. They assist in applying the required force for effective braking and maneuvering.

3. Agriculture: Hydraulic power packs are vital for agricultural machinery, including tractors, harvesters, and irrigation systems. They enable efficient operation of hydraulic cylinders, facilitating tasks like lifting and moving heavy loads.

4. Fishing: In the fishing industry, hydraulic power packs are utilized in equipment like fishing net winches and lobster pot haulers. They offer the necessary power for lifting heavy fishing gear, enhancing productivity and reducing manual labor.

5. Manufacturing: Hydraulic power packs find extensive use in manufacturing processes, such as pressing, cutting, and molding. They provide the required force for operating hydraulic presses, shearing machines, and injection molding equipment.

6. Material Handling: Within warehouses and distribution centers, hydraulic power packs are crucial for equipment like forklifts, stackers, and conveyor systems. They enable safe and efficient movement of goods, optimizing logistics operations.

7. Mining: Hydraulic power packs play a significant role in the mining industry, powering equipment like rock drills, excavators, and conveyor belts. They provide reliable force and control, ensuring smooth operations in challenging underground environments.

By fulfilling these functions, hydraulic power packs contribute to improved productivity, enhanced safety, and efficient operations in diverse industries. Regular maintenance and adherence to industry standards are essential for maximizing their performance and longevity.

Construction of hydraulic power packs

Hydraulic power packs are self-contained units that play a vital role in various industries. Understanding their construction and components is essential to comprehend their functionality and utility. Here, we explore the basic construction of hydraulic power packs:

1. Hydraulic reservoir:

The hydraulic reservoir serves as a storage tank for hydraulic fluid. It provides a ready supply of fluid to meet the system's requirements. The size and design of the reservoir may vary based on the specific application.

2. Pump:

A hydraulic pump is a critical component of a power pack that generates the required fluid flow. It converts mechanical energy into hydraulic energy, creating the necessary pressure to operate the system.

3. Motor:

The hydraulic motor receives pressurized fluid from the pump and converts it into mechanical rotational energy. It drives the operation of different hydraulic machinery, depending on the specific requirements.

4. Regulators:

Regulators are responsible for controlling the fluid flow and pressure within the power pack. They ensure the system operates at optimal levels while accommodating fluctuations in demand.

5. Pressure supply & relief lines:

These lines connect the various components within the hydraulic power pack, ensuring the proper distribution of fluid, pressure regulation, and relieving excess pressure when necessary.

The construction of hydraulic power packs may vary in design and complexity, depending on the specific industry and application. Understanding these components is crucial for maintenance and troubleshooting purposes. Remember, regular maintenance checks and adherence to the manufacturer's guidelines are essential for preserving the functionality and longevity of hydraulic power packs.

Ready to elevate your operational efficiency with top-notch supplies? Don't wait any longer! Visit tendsupplies.com to explore our comprehensive range of products tailored to meet your every need. Whether you're looking for the latest in industry innovations or essential everyday supplies, we've got you covered. For personalized service and expert advice, reach out to our dedicated team at sales@tendsupplies.com. We're here to assist you in finding the perfect solutions to keep your operations running smoothly and efficiently. Act now and transform your business with Tend Supplies – your partner in success!

Related article