Hand Tool Maintenance: Tips for Longevity and Performance

Hand Tool Maintenance

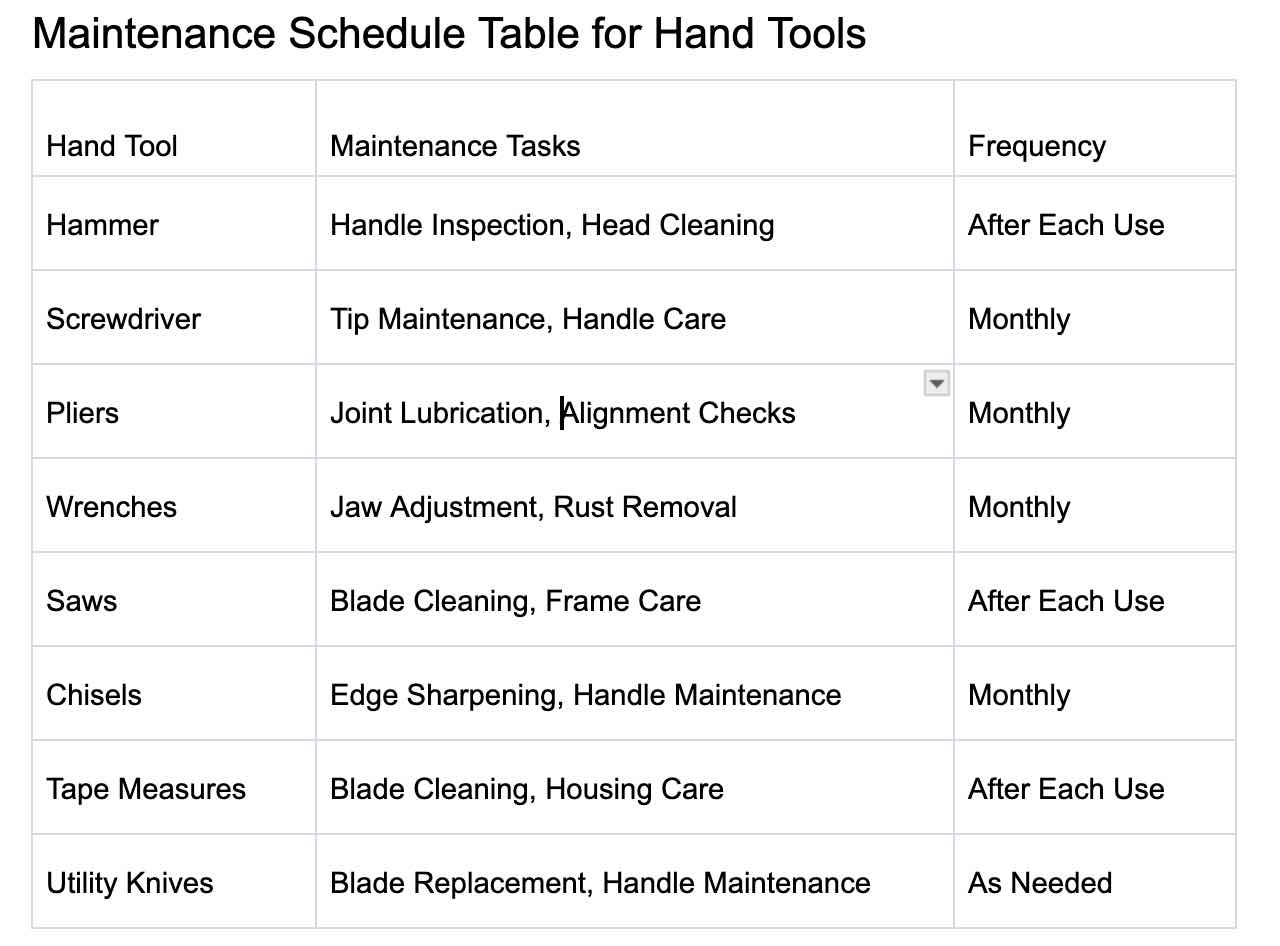

Discover the importance of hand tool maintenance for longevity and performance. This guide covers essential maintenance tips for standard tools, storage solutions, and a detailed schedule. Ensure your tools last longer with Tend Industrial Supplies.

Introduction

A. Importance of Regular Hand Tool MaintenanceMaintaining your hand tools is not just about keeping them looking new; it's about ensuring they function at their best. Regular maintenance can significantly extend the life of your tools, ensuring they remain reliable and safe to use.

B. Impact on Tool Longevity and PerformanceWell-maintained tools not only last longer but also perform more efficiently. Whether you're a professional craftsman or a DIY enthusiast, the performance of your tools can significantly impact the outcome of your projects.

C. Scope of the ArticleIn this article, we'll delve into the basics of hand tool maintenance, offering tips and insights to ensure your tools remain in top condition. Explore our collection at Tend Industrial Supplies for a comprehensive range of hand tools and maintenance products.

The Basics of Hand Tool Maintenance

A. Regular Inspection. Before diving into the cleaning and lubrication processes, it's crucial to understand the importance of regular inspections.

- Checking for Wear and Tear

- Look for signs of wear, such as dull blades or worn-out grips. Tools that are worn out may not only be inefficient but can also be hazardous.

- For a guide on identifying wear and tear on specific tools.

- Identifying Damages and Defects

- Check for cracks, chips, or any other damages. Damaged tools can be dangerous and may cause accidents.

- If you need clarification on the condition of a tool, our experts at Tend Industrial Supplies can offer advice on whether it's time for a replacement.

B. Proper CleaningDirt, grease, and rust can significantly impact a tool's performance. Regular cleaning ensures your tools function efficiently and safely.

- Removing Dirt and Rust

- Use a wire brush or sandpaper to remove rust and dirt from metal parts.

- For more detailed instructions on rust removal, visit our Rust Removal Guide.

- Appropriate Cleaning Materials and Methods

- Use mild soap and water for general cleaning. Ensure tools are thoroughly dried to prevent rusting.

- For tools with wooden handles, avoid soaking them in water. Instead, wipe them down with a damp cloth.

- Explore our range of cleaning products specifically designed for hand tools.

C. Lubrication and Protection Lubrication reduces friction in moving parts, while protection prevents tools from corroding.

- Benefits of Lubricating Moving Parts

- Lubrication ensures smooth operation and reduces wear on moving parts.

- Regularly lubricate tools like pliers, wrenches, and shears for optimal performance. Check out some selection of lubricants for hand tools.

- Protecting Tools from Corrosion

- Store tools dryly and use protective sprays or oils to prevent rust.

- For protective products, such as corrosion-inhibiting chemicals, visit GZ online shop to understand how it works.

Specific Maintenance Tips for Common Hand Tools

A. HammersHammers are among the most commonly used hand tools. Proper maintenance ensures they deliver the right force and precision.

- Handle Inspection and Replacement

- Regularly inspect the handle for cracks or splinters. A damaged handle can break during use, leading to accidents.

- Consider replacing the handle or investing in a new hammer if it shows signs of wear.

- Head Cleaning and Rust Prevention

- Clean the head after each use to remove dirt and debris.

- Store in a dry place and occasionally apply a light coat of oil to prevent rust.

B. ScrewdriversPrecision is critical when it comes to screwdrivers. Proper maintenance ensures accurate and efficient use.

- Tip Maintenance and Sharpening

- Ensure the tip is not worn out or damaged. A worn-out tip can strip screws.

- For flat-head screwdrivers, you can sharpen the tip using a fine file.

- Handle Care

- Wipe the handle clean after use.

- Avoid using a screwdriver with a damaged handle as it can lead to slippage.

C. PliersPliers are versatile tools that require regular maintenance for smooth operation.

- Joint Lubrication

- Apply a drop of lubricant to the joint to ensure smooth movement.

- Wipe away any excess lubricant to prevent dirt accumulation.

- Alignment Checks

- Ensure the jaws align correctly. Misaligned jaws can damage materials or result in imprecise work.

D. WrenchesWrenches are essential for tightening and loosening nuts and bolts.

- Jaw Adjustment and Tightening

- Ensure the adjustable jaw moves smoothly.

- Tighten any loose components to ensure proper grip.

- Rust Removal

- Store wrenches in a dry place.

- Use a wire brush to remove any rust. For stubborn rust, consider using a rust remover.

E. SawsA sharp saw ensures clean cuts and efficient work.

- Blade Cleaning and Sharpening

- Clean the blade after each use.

- Sharpen the blade regularly to ensure clean cuts.

- Frame and Handle Care

- Ensure the frame is free from damage or bends.

- Clean the handle and check for any cracks or splinters.

F. ChiselsChisels require a sharp edge for precise work.

- Edge Sharpening and Honing

- Regularly sharpen the edge using a sharpening stone.

- Honing the edge ensures it remains sharp and delivers clean cuts.

- Handle Maintenance

- Check the handle for damage or wear.

- Replace damaged handles to ensure safe use.

G. Tape MeasuresAccuracy is crucial when measuring. Proper maintenance ensures your tape measure remains accurate.

- Blade Cleaning and Lubrication

- Wipe the blade clean after use.

- Apply a light lubricant to ensure smooth retraction.

- Housing Care

- Ensure the housing is free from damage.

- Store in a dry place to prevent rust or damage to the blade.

H. Utility KnivesA sharp blade ensures efficient cutting.

- Blade Replacement

- Replace dull or damaged blades.

- Always retract the blade after use to prevent accidents.

- Handle and Locking Mechanism Maintenance

- Ensure the locking mechanism works correctly.

- Clean the handle and check for any damage.

Proper maintenance of your hand tools not only ensures longevity but also guarantees safety and efficiency. For a comprehensive range of hand tools and maintenance products,Tend Industrial Supplies has got you covered. For expert advice and recommendations, reach out to us at sales@tendsupplies.com.

Storage Solutions for Hand Tools

A. Importance of Proper StorageProper storage of hand tools is crucial for their longevity and performance. Storing tools dry, organized prevents them from rusting, getting damaged, or becoming a safety hazard. Moreover, an organized storage system ensures that you can easily locate and access your tools when needed, saving time and effort.

B. Options for Tool StorageDifferent tools require different storage solutions. Here are some popular options:

-

Toolboxes and Chests

- These are classic storage solutions that come in various sizes and configurations. They offer compartments and drawers to organize tools efficiently.

- They are portable, making them ideal for those who need to carry their tools to different locations.

- Check out our range of durable toolboxes and chests for all your storage needs.

-

Pegboards and Racks

- Pegboards are wall-mounted boards with holes that can hold hooks or pegs. They are perfect for hanging tools and keeping them visible and accessible.

- Racks are similar to pegboards but are often used for specific tools like wrenches or screwdrivers.

-

Soft Storage Bags

- These are fabric bags with pockets and compartments designed for tools. They are lightweight and portable.

- They are ideal for carrying specific tools for a particular job.

- Browse our selection of soft storage bags for flexible storage solutions.

Conclusion

Hand tools are integral to various tasks, from simple home repairs to intricate craftsmanship. Proper maintenance and storage of these tools are paramount to ensure their longevity, safety, and optimal performance. By implementing the tips and practices outlined in this article, you can enhance the life of your tools and ensure they serve you well for years to come.

Call to Action

Your hand tools are an investment; like any investment, they require care and attention. Regular maintenance not only prolongs the life of your tools but also ensures safety and efficiency in your tasks. Tend Industrial Supplies is your go-to destination for a comprehensive range of maintenance products, tool storage solutions, and expert advice. Don't compromise on the health of your tools. Contact us at sales@tendsupplies.com and give your tools the care they deserve.