How to Choose the Right Torque Wrench for Your Needs

Tightening lug nuts on a wheel or assembling delicate engine components, applying the correct torque is crucial to ensure safety, performance, and longevity. That's where the torque wrench comes in. This essential tool allows you to apply a specific amount of rotational force to a fastener, preventing over-tightening or under-tightening, which can lead to damage or failure. This guide, brought to you by Tend Industrial Supplies, will walk you through the intricacies of choosing the correct torque wrench for your needs, empowering you to make informed decisions and achieve professional-grade results.

Key Takeaway:

Selecting the right torque wrench is essential for any mechanic or DIY enthusiast who works with fasteners. Understanding the different types, drive sizes, torque ranges, and features will help you choose a tool that meets your specific needs and ensures accurate and safe tightening.

Types of Torque Wrenches:

- Beam Type: The simplest and most affordable type. A pointer indicates the torque value on a graduated scale as you tighten the fastener. Requires careful observation and can be less accurate than other types.

- Click Type: The most common type. Produces an audible "click" when the desired torque is reached. Offers good accuracy and ease of use.

- Digital: Provides the highest accuracy and often includes advanced features like digital readouts, angle measurement, and data logging. More expensive than other types.

Drive Size:

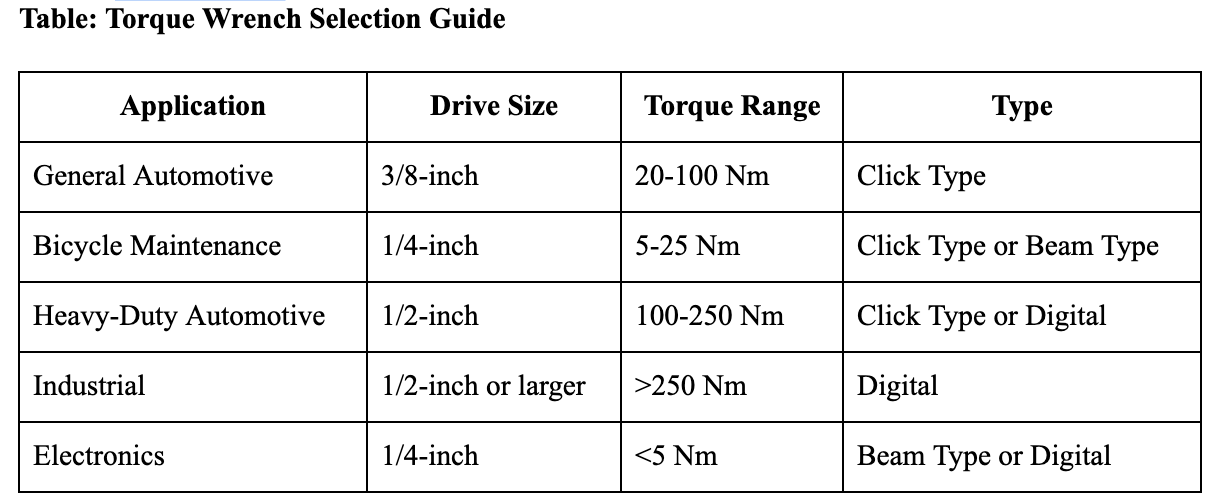

The drive size refers to the square opening on the torque wrench that accepts sockets. Common drive sizes include:

- 1/4-inch drive: Suitable for smaller fasteners and lower torque ranges, often used for electronics, bicycles, and small engines.

- 3/8-inch drive: The most versatile size, suitable for a wide range of automotive and general-purpose applications.

- 1/2-inch drive: Used for larger fasteners and higher torque applications, common in heavy-duty automotive and industrial settings.

Torque Range:

Torque wrenches are designed to operate within a specific torque range. Choose a wrench with a range that covers the torque values you'll be working with.

- Low Range: Typically 5-25 Nm (Newton meters) or 4-18 ft-lb (foot-pounds). Used for delicate fasteners and smaller components.

- Mid-Range: Commonly 20-100 Nm or 15-75 ft-lb. Suitable for most automotive and general-purpose applications.

- High Range: Typically 100-250 Nm or 75-185 ft-lb and above. Used for larger fasteners and heavy-duty applications.

Features:

- Accuracy: Look for a torque wrench with an accuracy of +/- 4% or better.

- Calibration: Choose a wrench that can be easily calibrated or comes with a calibration certificate.

- Ratcheting Mechanism: Allows for quick and efficient tightening.

- Ergonomics: Consider features like comfortable grips and easy-to-read scales.

- Additional Features: Some wrenches offer features like angle measurement, peak hold, and preset torque values.

Application:

Consider the specific applications you'll be using the torque wrench for:

- Automotive: For general automotive work, a 3/8-inch drive click-type torque wrench with a mid-range torque range is a good choice.

- Bicycle: A 1/4-inch drive torque wrench with a low torque range is suitable for bicycle maintenance.

- Industrial: Heavy-duty industrial applications may require a 1/2-inch drive torque wrench with a high torque range.

List: Common Applications for Torque Wrenches

- Tightening lug nuts on wheels

- Assembling engine components (cylinder heads, connecting rods)

- Installing suspension components

- Working on bicycles and motorcycles

- Assembling furniture and equipment

Ensure precision and safety in your mechanical work with a high-quality torque wrench from Tend Industrial Supplies! Browse our selection of torque wrenches at tendsupplies.com. Our team of experts can help you choose the perfect tool for your needs. Contact us at sales@tendsupplies.com for personalized recommendations and expert advice.

Frequently Asked Questions (FAQs)

Q1: What is the difference between a click-type and a beam-type torque wrench?

A1: A click-type torque wrench produces an audible click when the desired torque is reached, while a beam-type torque wrench uses a pointer on a graduated scale to indicate the torque value. Click-type wrenches are generally more accurate and easier to use.

Q2: How do I know what torque value to use for a specific fastener?

A2: The torque value for a specific fastener is usually specified in the vehicle's service manual or on the component itself. You can also find torque specifications online or in repair manuals.

Q3: How often should I calibrate my torque wrench?

A3: It's recommended to calibrate your torque wrench at least once a year or after any significant impact or drop. You can send it to a calibration service or, for some models, calibrate it yourself using a specialized tester.

Q4: Can I use a torque wrench to loosen fasteners?

A4: Using a torque wrench to loosen fasteners is generally not recommended, as this can affect its calibration. Use a regular wrench or breaker bar to loosen fasteners before tightening the torque wrench to the correct specification.

Q5: What is the importance of using a torque wrench?

A5: Using a torque wrench ensures that fasteners are tightened to the correct specification, preventing over-tightening, which can damage components, or under-tightening, which can lead to loosening and potential failure.

Related Content:

- The 7 Top Brands of Mechanic Tool Kits

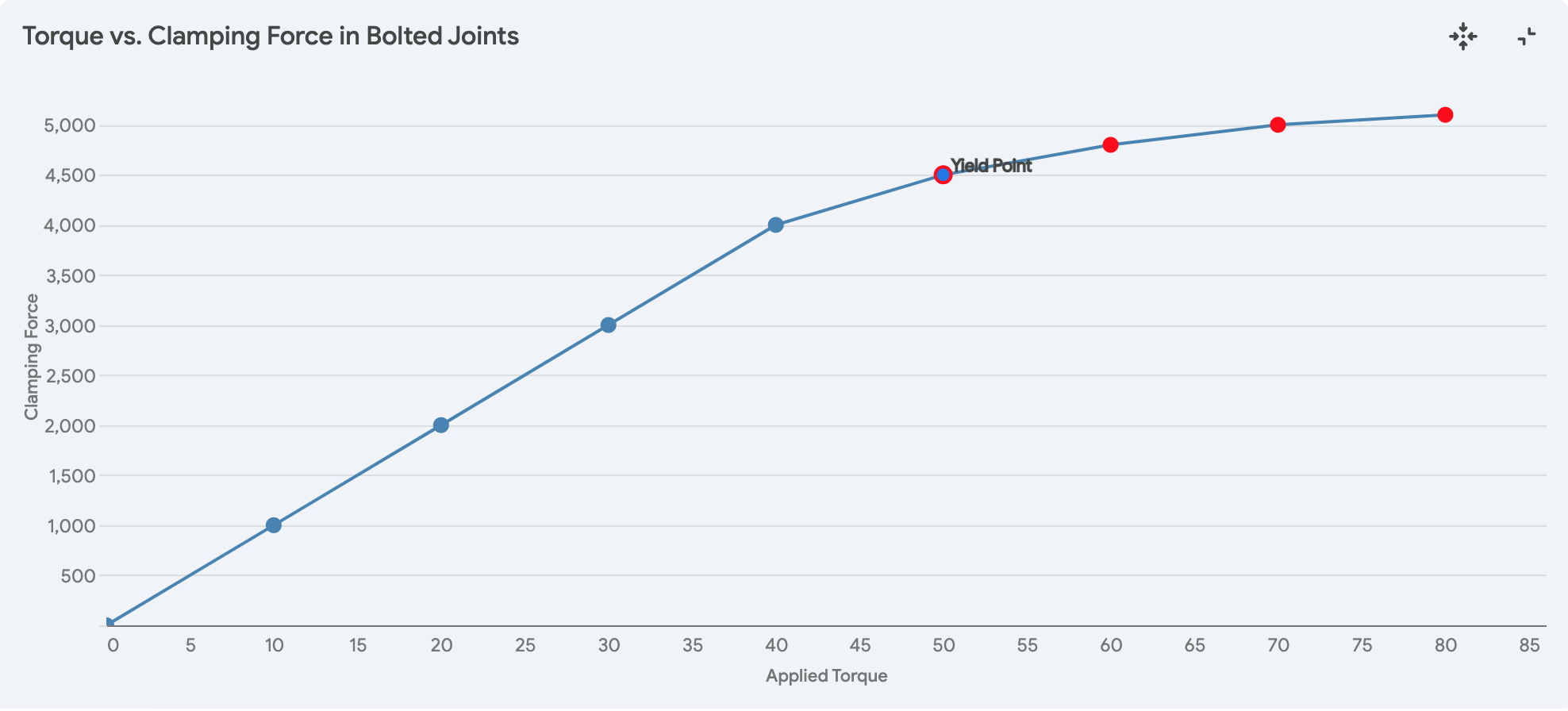

- Understanding Torque and Clamping Force

- How to Calibrate a Torque Wrench

- Common Mistakes to Avoid When Using a Torque Wrench

- What Are the Ten Best Automotive Repair Tools for DIY Projects?