Innovative Air Compressor Solutions: Boosting Productivity in 2025

Air compressors continue to be the backbone of modern pneumatic systems, driving everything from high-performance impact wrenches to versatile spray guns in industrial settings and home garages alike. In 2025, a new wave of innovative air compressor solutions is revolutionizing how we power our tools, emphasizing energy efficiency, smart technology, and enhanced durability. This comprehensive guide explores the latest breakthroughs and strategies for upgrading your air compressor systems. Whether you’re a professional in an industrial environment or a DIY enthusiast working in your home garage, you’ll find the insights you need to transform your operations with cutting-edge technology.

Table of Contents

- Introduction

- Key Takeaways

- Innovative Technologies Driving Air Compressor Solutions

- Smart Connectivity and IoT Integration

- Variable Speed Drives (VSD) and Energy Efficiency

- Advanced Cooling Systems and Noise Reduction

- Hybrid Power Options and Eco-Friendly Materials

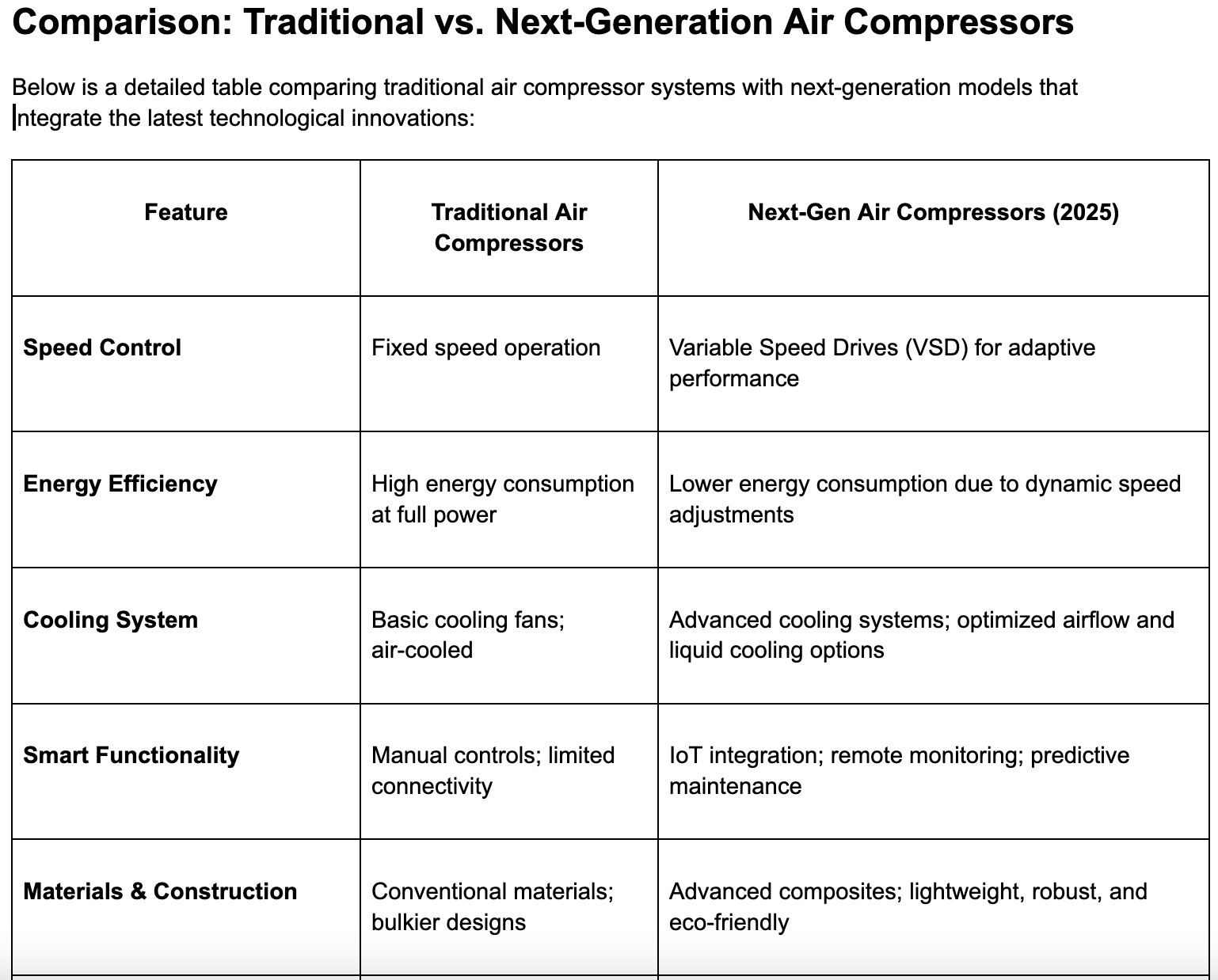

- Comparison: Traditional vs. Next-Generation Air Compressors

- Practical Applications and Benefits

- Maintenance, Durability, and Safety Best Practices

- Frequently Asked Questions (FAQs)

- Related Articles

- Specific Product Recommendations

- Call to Action

- Conclusion

- Affiliate Disclosure

Intro

Air compressors have evolved significantly in recent years, driven by rapid advancements in technology. Today’s air compressors are no longer simple machines that compress air—they are sophisticated, high-performance systems equipped with smart features and innovative designs. In 2025, the focus has shifted to solutions that deliver higher energy efficiency, improved durability, and smarter operation through integrated digital controls. This guide provides a detailed exploration of these innovative air compressor solutions, highlighting how they can boost productivity, reduce energy costs, and extend equipment life.

Whether you’re looking to upgrade your existing system or investing in a new one, this guide offers a wealth of information, technical insights, and practical recommendations to help you stay ahead in a competitive market.

Key Takeaways

- Enhanced Efficiency: Next-generation air compressors feature variable speed drives and smart control systems that dynamically adjust performance, reducing energy consumption.

- Smart Connectivity: IoT integration allows for remote monitoring, real-time diagnostics, and predictive maintenance, ensuring reliable operation.

- Advanced Cooling & Noise Reduction: Innovative cooling systems and sound-dampening technologies help maintain optimal operating temperatures while creating a quieter workspace.

- Hybrid and Eco-Friendly Solutions: Hybrid power options and eco-friendly materials are reducing both environmental impact and operational costs.

- Improved Productivity: Modern designs offer increased performance, durability, and user comfort, making them ideal for both industrial and home applications.

Innovative Technologies Driving Air Compressor Solutions

Smart Connectivity and IoT Integration

Modern air compressors are embracing digital transformation with built-in smart connectivity. These systems now come equipped with sensors and WiFi modules that enable:

- Remote Monitoring: Track critical performance metrics like pressure, temperature, and airflow from your smartphone.

- Predictive Maintenance: Advanced analytics identify potential issues before they become serious, reducing downtime.

- Automated Adjustments: Systems can automatically adjust operational parameters to maintain peak efficiency.

- User-Friendly Interfaces: Digital dashboards and mobile apps provide intuitive control and real-time feedback, simplifying management.

This connectivity not only improves operational efficiency but also allows for proactive maintenance, ensuring your compressor runs reliably at all times.

Variable Speed Drives (VSD) and Energy Efficiency

Variable Speed Drives (VSD) are revolutionizing air compressor efficiency by allowing the motor to operate only at the necessary speed based on current demand:

- Adaptive Performance: VSD adjusts motor speed in real time, which means the compressor only uses as much energy as needed.

- Energy Savings: This adaptive approach significantly lowers energy consumption and reduces utility bills.

- Reduced Wear: Running at lower speeds when full power is not required minimizes mechanical stress and extends the life of motor components.

- Consistent Output: VSD technology helps maintain steady pressure and airflow, which is critical for high-performance pneumatic operations.

Advanced Cooling Systems and Noise Reduction

Efficient cooling is essential for maintaining motor performance and longevity:

- Optimized Airflow: Redesigned internal ducting improves airflow and heat dissipation.

- High-Performance Fans: Modern compressors use advanced fans or liquid cooling systems to keep temperatures in check.

- Noise Dampening: The incorporation of sound-absorbing materials and innovative design techniques significantly reduces operational noise, making compressors more suitable for residential use.

- Enhanced Durability: Better cooling and lower noise levels help maintain the integrity of motor components, prolonging system life.

Hybrid Power Options and Eco-Friendly Materials

Environmental sustainability and operational flexibility are driving the development of hybrid and eco-friendly air compressors:

- Hybrid Systems: Some compressors now offer multiple power sources (electric, battery, and even solar), providing versatility for off-grid or remote applications.

- Eco-Friendly Materials: The use of recycled plastics, biodegradable lubricants, and oil-free designs minimizes environmental impact while simplifying maintenance.

- Reduced Operational Costs: Energy-efficient designs and eco-friendly systems lead to lower utility and maintenance costs over time.

- Sustainable Manufacturing: These innovations align with global sustainability trends, making them attractive to eco-conscious consumers.

Practical Applications and Benefits

Industrial Applications

Upgraded air compressor systems are critical in high-demand industrial environments:

- Continuous Operation: High-duty cycle systems ensure reliable performance in manufacturing plants, automotive assembly lines, and heavy machinery maintenance.

- Cost Savings: Energy-efficient motors and smart controls reduce power consumption, resulting in lower operational costs.

- Predictive Maintenance: IoT-enabled features minimize unexpected downtime by alerting operators to potential issues before they escalate.

- Consistent Performance: Advanced cooling and optimized airflow maintain stable PSI and CFM levels, essential for precision and heavy-duty applications.

Home and Workshop Applications

For home garages and small workshops, next-generation air compressors offer:

- Compact and Space-Saving Designs: Smaller, efficient models fit easily into limited spaces without sacrificing performance.

- Quiet Operation: Enhanced noise reduction technologies make these compressors ideal for residential areas.

- User-Friendly Interfaces: Digital controls and smart features simplify operation and maintenance, making them perfect for DIY enthusiasts.

- Cost Efficiency: Reduced energy consumption and maintenance needs translate into long-term savings.

Overall Benefits

- Increased Productivity: Enhanced performance means tasks are completed faster, boosting overall efficiency.

- Lower Operating Costs: Energy savings and reduced maintenance requirements lead to significant cost reductions over time.

- Enhanced User Experience: Improved ergonomics, quieter operation, and smart connectivity contribute to a more comfortable and efficient workspace.

- Extended Equipment Lifespan: Upgraded components and proactive maintenance extend the life of your air compressor system, providing a better return on investment.

Maintenance, Durability, and Safety Best Practices

Maintenance Best Practices

- Routine Inspections: Regularly inspect hoses, filters, and connections to detect leaks or signs of wear.

- Clean and Drain: Keep the compressor and its components clean; drain moisture from tanks to prevent rust and buildup.

- Proper Lubrication: Follow manufacturer guidelines for lubricating moving parts to ensure smooth operation.

- Firmware and Software Updates: For IoT-enabled systems, regularly update software to maintain optimal performance.

- Scheduled Servicing: Establish a maintenance schedule based on usage to prevent unexpected downtime.

Durability Enhancements

- Premium Materials: Next-gen compressors use advanced composites and recycled materials that are both lightweight and durable.

- Robust Construction: Ergonomic and compact designs not only enhance user comfort but also increase the overall robustness of the system.

- Automated Diagnostics: Smart monitoring systems provide early warnings of potential issues, allowing for timely maintenance and extended equipment life.

Safety Best Practices

- Personal Protective Equipment (PPE): Always wear safety glasses, gloves, and hearing protection when operating air compressors.

- Proper Installation: Follow all manufacturer guidelines during installation to ensure safe and optimal operation.

- Adequate Ventilation: Operate compressors in well-ventilated areas to prevent overheating.

- Regular Training: Ensure operators are trained on the latest features and safety protocols of next-generation systems.

Frequently Asked Questions (FAQs)

-

What are the main benefits of upgrading an air compressor motor?

Upgraded motors provide higher energy efficiency, reduced noise, improved cooling, and advanced smart features, resulting in lower operational costs and enhanced performance. -

How do Variable Speed Drives (VSD) improve compressor efficiency?

VSD technology adjusts the motor speed in real time based on load demand, leading to significant energy savings and reduced wear on the compressor. -

What advantages does IoT integration offer in air compressors?

IoT connectivity allows for remote monitoring, predictive maintenance, and automated adjustments, ensuring consistent performance and reducing unexpected downtime. -

How often should I maintain my upgraded air compressor system?

Routine inspections and scheduled servicing every 3-6 months are recommended, depending on usage, to ensure optimal performance and longevity. -

Where can I find more detailed information on air compressor optimization?

For further insights, explore our related articles on compressor selection, sizing, and workshop setup available on Tend Industrial Supplies.

Related Articles

Enhance your knowledge and optimize your workspace with these valuable resources from Tend Industrial Supplies:

-

Ultimate Guide to Choosing the Best Air Compressor for Your Home Garage in 2024 A comprehensive guide for selecting the ideal air compressor tailored to your home workshop.

-

How to Choose the Perfect Air Compressor for Your Workshop Detailed strategies to build an efficient workshop with the right power tools.

-

Understanding the Right Size of Air Compressor for Your Pneumatic Air Tools in 2024 Learn how to match your air compressor’s output with your specific tool requirements.

-

Quiet Air Compressors: The Best Options for Home Garages and Small Workshops Explore compressor models that offer powerful performance with minimal noise.

-

VEVOR Air Compressors: Choosing the Right Size for Your Projects

Insights into selecting a VEVOR compressor that meets your project's unique needs.

Specific Product Recommendations

For those ready to upgrade, consider these top-rated air compressors available on Amazon:

-

EMAX Industrial Smart Air Silent Compressor:

Featuring ENERGY STAR Certified Smart Compressor technology, this model offers variable speed operation and ultra-quiet performance—ideal for heavy-duty industrial use.

Buy on Amazon -

Ingersoll Rand Variable Speed Rotary Screw Compressor:

Engineered for continuous operation, this compressor is renowned for its advanced motor controls and robust design, making it perfect for industrial applications.

Buy on Amazon -

California Air Tools Quiet & Oil-Free Smart Compressor:

Designed for home garages and small workshops, this compressor combines quiet operation with an oil-free design, reducing maintenance and operating costs.

Buy on Amazon

Always verify the latest specifications and reviews to ensure these products meet your specific needs.

Call to Action

Upgrade your air compressor system today with the latest innovative solutions that boost efficiency, reduce energy consumption, and enhance productivity. Whether you’re in a busy industrial setting or a compact home workshop, Tend Industrial Supplies offers a premium selection of next-generation air compressors engineered for peak performance in 2025.

VisitTend Industrial Supplies or contact our expert team at sales@tendsupplies.com for personalized recommendations and exclusive deals that will transform your operations.

Conclusion

Innovative air compressor solutions in 2025 are transforming how we power our pneumatic systems. With advancements in motor optimization, variable speed drives, smart connectivity, and enhanced cooling systems, next-generation compressors offer significant improvements in efficiency, reliability, and user comfort. By understanding these innovations and implementing strategic upgrades, you can reduce operating costs, extend equipment life, and boost overall productivity—whether for industrial applications or home workshops.

This guide has provided in-depth analysis, practical strategies, and detailed comparisons to help you make informed decisions about upgrading your air compressor system. Embrace these cutting-edge technologies and experience the future of air compressor efficiency.

For more expert advice and detailed product reviews, be sure to explore our related articles on Tend Industrial Supplies. Equip your workspace with the latest technology and take your productivity to the next level.

Affiliate Disclosure

Some links on this article are affiliate links, which means we may earn a commission if you make a purchase at no extra cost to you.