Air vs. Electric Impact Wrenches: A Detailed Comparison for Professionals and DIY Enthusiasts

Air vs. Electric Impact Wrenches

Impact wrenches are essential tools in both professional and DIY toolkits. Whether you're working on automotive repairs, construction projects, or home improvement tasks, choosing the right impact wrench can significantly improve efficiency, productivity, and safety. In this comprehensive guide, we delve into the differences between air (pneumatic) and electric impact wrenches, offering an in-depth comparison that covers performance, cost, durability, maintenance, and suitability for various applications.

This article is designed to help professionals and DIY enthusiasts make informed decisions when purchasing an impact wrench. We’ve included detailed sections, an information-rich table, actionable lists, six answered FAQs, five related articles for further reading, and a clear call to action for Tend Industrial Supplies.

Table of Contents

- Introduction

- Understanding Impact Wrenches

- Air (Pneumatic) Impact Wrenches

- Electric Impact Wrenches

- Detailed Comparison Table

- Pros and Cons of Each Type

- Usage Scenarios and Applications

- Maintenance, Durability, and Safety

- FAQs

- Related Articles

- Call to Action

- Conclusion

Introduction

Impact wrenches deliver high torque output with minimal effort, making them indispensable for loosening or tightening bolts and nuts in demanding applications. However, with two main types on the market—air (pneumatic) and electric impact wrenches—the choice can be confusing.

This guide will provide you with:

- An overview of each type’s working principles.

- A detailed comparison including performance, cost, maintenance, and usability.

- A side-by-side table summarizing key specifications.

- Practical recommendations based on various use cases.

- Answers to frequently asked questions.

- Internal resources and related articles to explore further.

By the end of this guide, you’ll have the knowledge you need to select the ideal impact wrench that suits your needs and budget.

Understanding Impact Wrenches

Impact wrenches use rapid bursts of torque to loosen or tighten fasteners. They work by delivering impacts at high speeds through a rotating hammer mechanism. This design minimizes user fatigue while maximizing output power.

There are two main categories of impact wrenches:

- Air Impact Wrenches: Powered by compressed air, these tools are commonly used in professional settings like automotive repair shops and construction sites.

- Electric Impact Wrenches: These come in both corded and cordless versions and are increasingly popular among DIY enthusiasts and professionals who require portability and ease of use.

Before diving into the specifics of each, it's essential to understand the basic features that all impact wrenches share:

- Torque Output: Measured in foot-pounds (ft-lbs), torque is the primary indicator of an impact wrench’s power.

- Impacts Per Minute (IPM): This shows how frequently the tool delivers an impact, affecting both performance and efficiency.

- Ergonomics and Weight: A comfortable design and manageable weight can reduce fatigue during extended use.

- Durability and Build Quality: Impact wrenches must withstand heavy use and harsh conditions.

Air (Pneumatic) Impact Wrenches

How They Work

Air impact wrenches are powered by compressed air supplied from an air compressor. The compressed air drives a piston mechanism that creates rapid, high-torque impacts. The simplicity of the pneumatic system results in high reliability and consistent performance, particularly in heavy-duty environments.

Key Features

- High Torque Output: Air wrenches typically deliver more torque, making them suitable for the most challenging jobs.

- Lightweight Design: Because the power source is external (the air compressor), the tool itself is often lighter and more ergonomic.

- Continuous Operation: Ideal for workshop settings where a steady, high-performance tool is required.

- Durability: With fewer electronic parts, these tools are robust and can withstand prolonged heavy use.

- Cost Efficiency: Compressed air systems are a standard tool in many shops, so the overall cost of operation can be lower for industrial and high-volume use.

Common Applications

- Automotive repair and maintenance

- Heavy machinery assembly

- Construction and industrial assembly

- Situations requiring rapid and repeated use over extended periods

Electric Impact Wrenches

How They Work

Electric impact wrenches use an electric motor to generate the impact mechanism. They are available in corded and cordless (battery-powered) versions, making them versatile for both indoor and outdoor tasks.

Key Features

- Portability: Cordless models offer the freedom to work in areas without access to a power outlet.

- Ease of Use: Electric models are generally simpler to operate, with less setup time compared to pneumatic systems.

- Consistent Power: Modern electric impact wrenches deliver a stable power output, suitable for many light- to medium-duty tasks.

- Low Maintenance: With no need for an air compressor or hoses, electric wrenches require less upkeep.

- Quiet Operation: Electric models tend to be quieter than their air counterparts, which is beneficial in residential or noise-sensitive environments.

Common Applications

- Home garage projects and DIY tasks

- Light to medium automotive work

- Assembly and maintenance tasks in confined spaces

- Projects where portability is a key factor

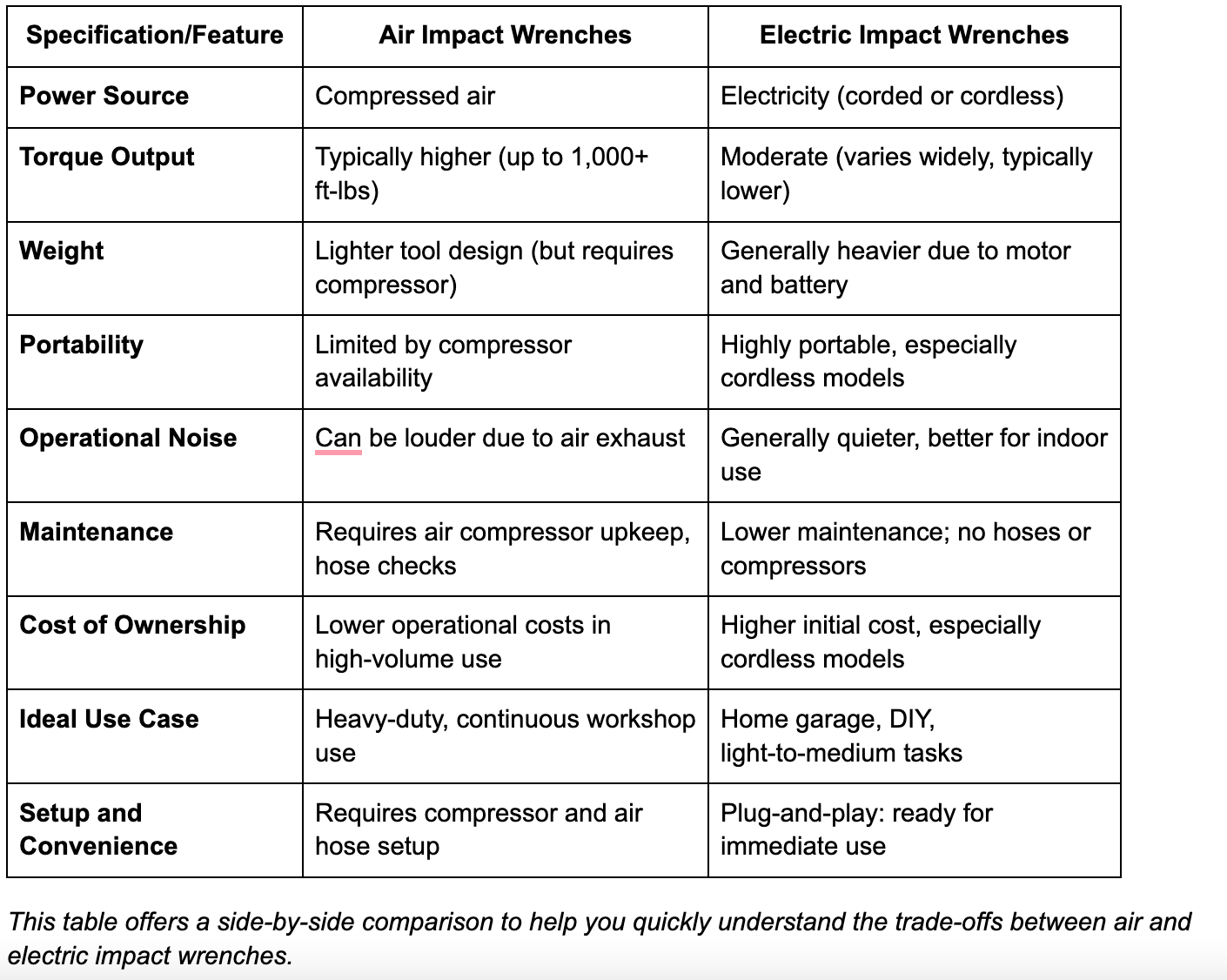

Detailed Comparison Table

Below is an information-rich table that summarizes the key specifications and features of air and electric impact wrenches:

This table offers a side-by-side comparison to help you quickly understand the trade-offs between air and electric impact wrenches.

Pros and Cons of Each Type

Air Impact Wrenches

Pros:

- High Performance: Delivers higher torque for heavy-duty applications.

- Lightweight Tool: Ergonomic design reduces user fatigue.

- Durability: Fewer electronic components mean fewer points of failure.

- Cost-Effective for Workshops: Lower per-use cost when a compressor is already in place.

Cons:

- Requires an Air Compressor: Additional equipment increases overall setup cost and complexity.

- Less Portability: Tethered by hoses and the compressor’s location.

- Noise Levels: Can be louder, making them less ideal for residential use.

Electric Impact Wrenches

Pros:

- Portability: Cordless models provide freedom to work anywhere.

- Ease of Use: Quick setup and operation, ideal for occasional tasks.

- Quiet Operation: Lower noise levels suitable for home garages and indoor use.

- Low Maintenance: No hoses or compressor systems required.

Cons:

- Lower Torque: Generally deliver less power compared to air models.

- Battery Life Limitations: Cordless models may require frequent recharging during prolonged use.

- Higher Initial Cost: Advanced battery technology and motors can drive up the price.

Usage Scenarios and Applications

When to Choose an Air Impact Wrench

- Professional Workshops: Ideal for automotive repair shops or construction sites where high torque and continuous operation are needed.

- Heavy-Duty Applications: This tool is used when working with stubborn bolts, large machinery, or multiple fasteners that need to be addressed quickly.

- High-Volume Operations: The cost efficiency of compressed air becomes more beneficial in industrial settings.

When to Choose an Electric Impact Wrench

- Home Garage and DIY Projects: Perfect for occasional use, such as light automotive repairs or assembly tasks.

- Portability is Key: Choose electric if you frequently move between job sites or have limited workspace.

- Noise-Sensitive Environments: Use electric models in residential areas or indoor projects where lower noise is a priority.

- Quick Setup: Ideal when you need a tool that’s ready to work without the hassle of setting up an air compressor.

Maintenance, Durability, and Safety

Maintenance Tips

Air Impact Wrenches:

- Regular Compressor Maintenance: Keep the air compressor in good condition, checking for leaks and maintaining proper pressure.

- Hose and Fitting Inspections: Regularly inspect and replace worn air hoses and fittings.

- Lubrication: Some air wrenches may require periodic lubrication; refer to the manufacturer’s guidelines.

Electric Impact Wrenches:

- Battery Care: For cordless models, maintain battery health by following proper charging practices.

- Clean and Inspect: Regularly clean the tool to remove dust and debris, which can affect performance.

- Motor Maintenance: Ensure the motor and other electronic components are not exposed to moisture.

Durability and Build Quality

Both impact wrenches are designed to withstand demanding use; however, the build quality can vary between brands and models. Professional-grade air impact wrenches tend to have a more rugged construction suited for heavy-duty work. Electric models, especially premium cordless options, also boast high durability but may be more sensitive to extreme conditions due to their electronic components.

Safety Considerations

- Personal Protective Equipment (PPE): Always wear safety glasses, gloves, and hearing protection when using any impact wrench.

- Proper Handling: Follow manufacturer instructions for safe operation. Impact wrenches deliver high torque, so ensure you are securely positioned.

- Ventilation: For air-powered tools, make sure the compressor is in a well-ventilated area to avoid overheating.

- Electrical Safety: For electric models, inspect cords and batteries regularly to prevent shocks or short circuits.

FAQs on Air vs. Electric Impact Wrenches

Which type of impact wrench delivers higher torque?

Air impact wrenches generally deliver higher torque due to the power of compressed air, making them better for heavy-duty applications.

Are electric impact wrenches suitable for professional use?

Electric impact wrenches are ideal for light-to-medium tasks, especially in home garages and DIY projects. However, for heavy-duty or continuous industrial use, air impact models are often preferred.

What are the main maintenance differences between the two types?

Air impact wrenches require maintenance of both the tool and the air compressor (including hoses and fittings). In contrast, electric models focus primarily on battery care and cleaning of the tool itself.

How does portability compare between air and electric impact wrenches?

Electric impact wrenches, especially cordless models, are more portable and easier to use in remote locations since they do not require an air compressor or hoses.

Which type is quieter in operation?

Electric impact wrenches tend to operate more quietly than air impact wrenches, making them better suited for noise-sensitive environments such as residential areas.

What factors should I consider when choosing between air and electric models?

Consider the torque requirements, frequency of use, portability, noise levels, maintenance needs, and overall cost of ownership. Your specific application—whether it’s for heavy-duty professional use or occasional DIY tasks—will determine the best choice.

Related Articles

For further insights into tool selection and maintenance, consider exploring these related articles:

How to Choose the Perfect Air Compressor for Your Workshop

- Learn detailed strategies for selecting an air compressor tailored to workshop use.

Quiet Air Compressors: The Best Options for Home Garages and Small Workshops

- Discover models designed for low noise without sacrificing performance.

Understanding the Right Size of Air Compressor for Your Pneumatic Air Tools in 2024

- A guide to ensuring your compressor’s capacity meets your tool requirements.

Vevor Air Compressors: Choosing the Right Size for Your Projects

- Insights on selecting the perfect Vevor compressor based on project demands.

New Jersey's Guide to Choosing Compact and Efficient Portable Air Compressors

Call to Action

Ready to upgrade your toolkit? Whether you’re a professional or a DIY enthusiast, Tend Industrial Supplies has a wide range of high-quality impact wrenches and related tools designed to meet your specific needs.

Visit our website atTend Industrial Supplies to explore our selection and find the perfect tool for your projects. For personalized advice or if you have any questions, please contact our expert team at sales@tendsupplies.com.

Elevate your performance today with tools that deliver power, precision, and durability!

Conclusion

Choosing between air and electric impact wrenches depends on your application, work environment, and personal preferences. Air impact wrenches offer superior torque and are ideal for heavy-duty and professional environments. In contrast, electric impact wrenches provide excellent portability, ease of use, and quieter operation—perfect for home garages and DIY projects.

This detailed comparison has highlighted the strengths and weaknesses of both options, providing you with all the information you need to make an informed decision. By considering factors such as performance, maintenance, cost, and safety, you can select an impact wrench that perfectly aligns with your requirements.

Remember to leverage our related guides for additional insights and recommendations on other essential tools and equipment. With the right impact wrench, you can tackle even the toughest tasks confidently and efficiently.

Tend Industrial Supplies, your trusted partner for premium tools and industrial equipment has brought you this guide. For more expert advice and top-tier products, visitTend Industrial Supplies or contact us at sales@tendsupplies.com.