Best Pneumatic Sanders for Bodywork & Woodworking

The pneumatic sander market represents a critical segment within the broader power tools industry, where precision, durability, and consistent performance determine the quality of finished work in both automotive bodywork and fine woodworking applications. Professional body shops, custom fabrication facilities, and high-end woodworking operations increasingly rely on pneumatic sanders to achieve superior surface finishes while maintaining the productivity levels demanded by competitive markets.

Shinano Air Tools, often referred to as the "Toyota of the air tool industry," has established itself as the premier manufacturer of pneumatic sanders, combining Japanese precision engineering with innovative design to create tools that consistently outperform competitors in both longevity and performance metrics. Their comprehensive sander lineup addresses the diverse requirements of professional users who demand reliability, precision, and exceptional build quality in their pneumatic equipment.

The global pneumatic tools market, valued at over $8 billion in 2025, continues expanding as manufacturers and craftspeople recognize the superior performance characteristics of air-powered equipment compared to electric alternatives. Pneumatic sanders, in particular, offer distinct advantages in heat dissipation, weight reduction, and consistent power delivery, making them indispensable for professional applications that require extended operation periods and precise surface preparation.

Key Takeaways

•Shinano pneumatic sanders deliver superior performance with Japanese precision engineering, offering 2-3 times longer service life than competing brands while maintaining consistent power output throughout extended use cycles

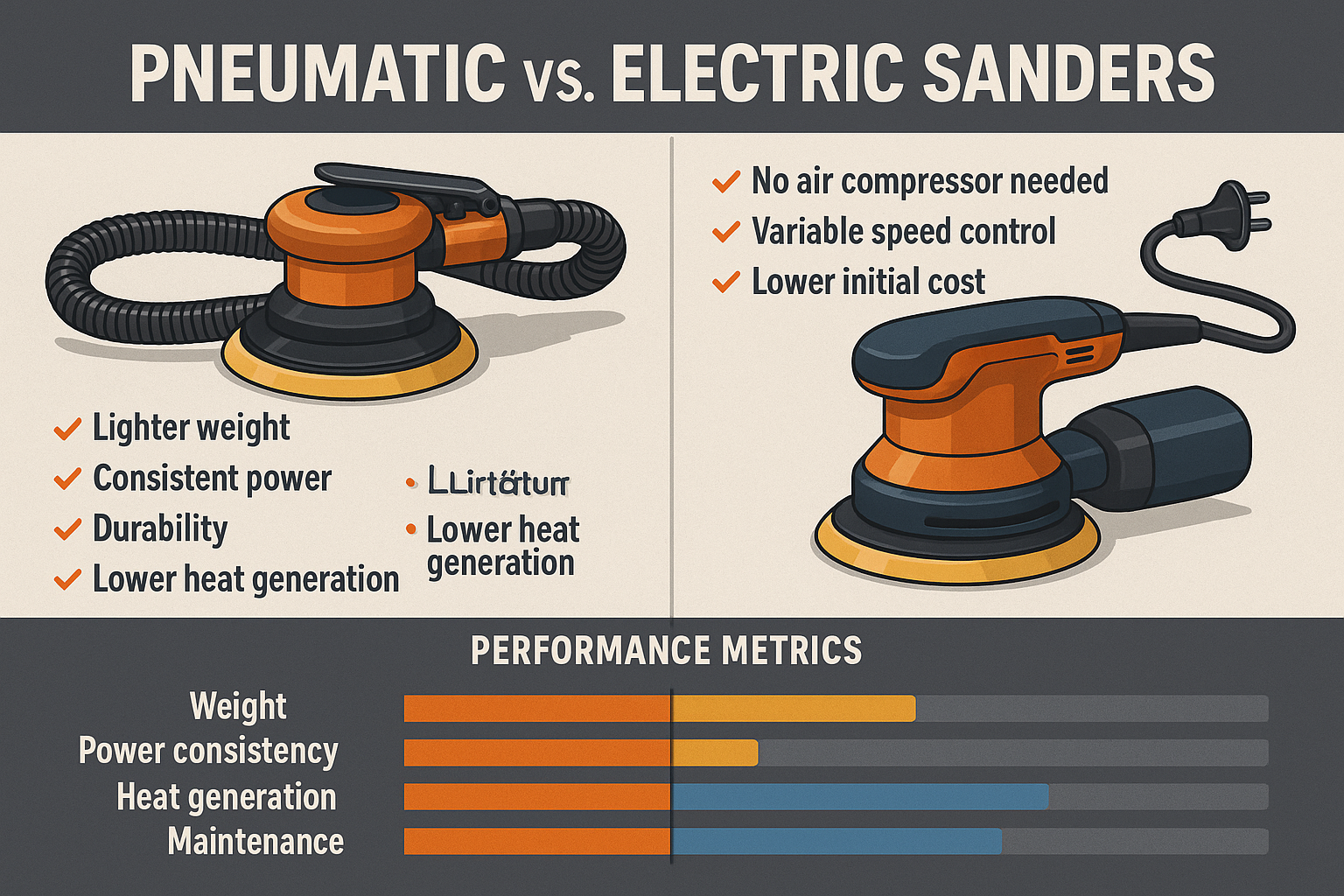

•Pneumatic sanders provide significant advantages over electric models including 40% lighter weight, consistent power delivery, superior heat dissipation, and reduced maintenance requirements

•Application-specific sander selection is critical with orbital sanders excelling in fine finishing work, disc sanders providing aggressive material removal, and belt sanders offering versatility for both rough and finish applications

•Air consumption and compressor requirements must be carefully matched, with professional sanders requiring 4-12 CFM at 90 PSI for optimal performance and efficiency

•Total cost of ownership favors pneumatic sanders despite higher initial investment, with lower maintenance costs, longer service life, and superior productivity offsetting upfront expenses

As an Amazon Associate, we earn from qualifying purchases.

Understanding Pneumatic Sander Technology

Pneumatic sanders operate on compressed air principles that provide several fundamental advantages over electric motor-driven alternatives. The absence of electric motors eliminates heat buildup, reduces weight, and provides consistent torque characteristics that remain stable regardless of load conditions. This technology proves particularly beneficial in applications requiring extended operation periods or precise control over material removal rates.

The compressed air system delivers power through pneumatic motors that convert air pressure into rotational or orbital motion with exceptional efficiency. Unlike electric motors that can experience performance degradation due to heat buildup or voltage fluctuations, pneumatic motors maintain consistent performance characteristics throughout operation cycles, ensuring uniform surface finishes and predictable material removal rates.

Advanced pneumatic sanders incorporate sophisticated air flow management systems that optimize power delivery while minimizing air consumption. These systems include precision-machined air passages, high-efficiency pneumatic motors, and integrated speed control mechanisms that allow operators to adjust performance characteristics for specific applications and materials.

Air Motor Technology and Performance

Modern pneumatic sanders utilize advanced air motor designs that maximize power output while minimizing air consumption and noise levels. Vane-type motors, commonly used in high-performance sanders, provide smooth operation and excellent torque characteristics across wide speed ranges. These motors incorporate precision-balanced components and advanced sealing systems that ensure consistent performance and extended service life.

The power-to-weight ratio advantage of pneumatic sanders becomes particularly significant in handheld applications where operator fatigue directly impacts work quality and productivity. Professional-grade pneumatic sanders typically weigh 30-50% less than equivalent electric models while delivering comparable or superior power output, reducing operator fatigue during extended use periods.

Shinano Air Tools: The Gold Standard in Pneumatic Sanders

Shinano Air Tools has earned recognition as the premier manufacturer of pneumatic sanders through decades of continuous innovation and unwavering commitment to quality. Their sanders incorporate advanced Japanese manufacturing techniques, precision engineering, and rigorous quality control processes that result in tools capable of withstanding the demanding requirements of professional applications.

The company's reputation for reliability stems from their comprehensive approach to product development, which includes extensive field testing, advanced materials research, and continuous refinement of manufacturing processes. Shinano sanders consistently demonstrate superior durability metrics, with many units providing decades of reliable service in demanding professional environments.

Japanese Engineering Excellence

Shinano's manufacturing philosophy emphasizes precision, durability, and performance optimization through advanced engineering techniques developed in Japan's competitive industrial environment. Their sanders incorporate precision-machined components, advanced bearing systems, and sophisticated air flow management that result in tools with exceptional longevity and consistent performance characteristics.

The company's quality control processes exceed industry standards, with each sander undergoing comprehensive testing procedures that verify performance specifications, durability metrics, and safety compliance. This rigorous approach ensures that every Shinano sander meets the exacting standards required for professional applications.

Comprehensive Product Lineup

Shinano offers an extensive range of pneumatic sanders designed to address specific applications and performance requirements. Their product lineup includes orbital sanders for fine finishing work, disc sanders for aggressive material removal, belt sanders for versatile applications, and specialized sanders for unique requirements such as contour work or confined space applications.

Each sander model incorporates application-specific design features that optimize performance for intended uses. Orbital sanders feature precision-balanced mechanisms that minimize vibration while providing smooth, swirl-free finishes. Disc sanders incorporate high-torque motors and robust construction for aggressive material removal applications. Belt sanders combine versatility with precision control for applications requiring both rough and finish capabilities.

Top Shinano Pneumatic Sanders for Professional Applications

SI-3101-6M: Premium 6-Inch Palm Grip Orbital Sander

The SI-3101-6M represents Shinano's flagship orbital sander, combining advanced engineering with user-centric design to deliver exceptional performance in fine finishing applications. This 6-inch orbital sander incorporates a precision-balanced mechanism that provides smooth, vibration-free operation while delivering consistent material removal rates across extended use periods.

Technical Specifications:

•Pad Size: 150mm (6 inches)

•Free Speed: 10,000 RPM

•Orbit Diameter: 5mm

•Power Output: 148 watts

•Weight: 0.94 kg (2.07 lbs)

•Air Consumption: 0.33 m³/min (11.7 CFM)

•Spindle Size: 5/16-24UNF

The SI-3101-6M excels in automotive bodywork applications where surface quality and consistency are paramount. Its precision-balanced orbital mechanism eliminates swirl marks while providing efficient material removal, making it ideal for primer preparation, paint defect removal, and final surface finishing. The ergonomic palm grip design reduces operator fatigue during extended use periods while providing precise control over sanding pressure and technique.

Woodworking applications benefit from the sander's ability to produce consistently smooth surfaces without cross-grain scratches or orbital marks. The 5mm orbit diameter provides an optimal balance between material removal efficiency and surface quality, making it suitable for both rough sanding and final preparation before finishing.

SI-2210: High-Performance 3-4 Inch Disc Sander

The SI-2210 disc sander delivers exceptional power and versatility in a compact, lightweight package designed for aggressive material removal and precision shaping applications. This dual-capability sander accommodates both 3-inch and 4-inch sanding discs, providing flexibility for various applications and workspace constraints.

Technical Specifications:

•Pad Size: 75mm (3 inches) and 100mm (4 inches)

•Free Speed: 19,000 RPM

•Power Output: 475 watts

•Weight: Optimized for extended use

•Spindle Size: 7/16-20UNF

•Air Consumption: Efficient for high-output applications

The SI-2210's high-speed operation and robust construction make it ideal for automotive bodywork applications requiring rapid material removal, such as paint stripping, rust removal, and surface preparation. The dual pad size capability allows operators to optimize disc selection for specific applications, using 3-inch discs for detailed work and confined spaces, and 4-inch discs for broader surface coverage.

Woodworking applications benefit from the sander's precision control and high-speed operation for shaping, contouring, and aggressive material removal. The compact design enables access to tight spaces and complex geometries while maintaining the power necessary for efficient material removal.

SI-2201: Precision 2-Inch Disc Sander

The SI-2201 represents the ultimate in precision disc sanding, designed for detailed work and applications requiring exceptional control and finesse. This compact sander delivers impressive power output despite its small size, making it ideal for intricate bodywork, fine woodworking, and specialized applications.

Technical Specifications:

•Pad Size: 50mm (2 inches)

•Free Speed: 17,000 RPM

•Power Output: 174 watts

•Weight: 0.50 kg (1.10 lbs)

•Spindle Size: 1/4-20UNF

•Air Consumption: Optimized for precision work

The SI-2201's compact size and high power output make it indispensable for automotive bodywork applications requiring precision material removal in confined spaces. Door jambs, wheel wells, and complex body contours benefit from the sander's ability to access tight areas while maintaining the power necessary for effective material removal.

Fine woodworking applications utilize the SI-2201's precision capabilities for detailed shaping, intricate contouring, and finish preparation in areas inaccessible to larger sanders. The lightweight design reduces operator fatigue while providing the control necessary for precision work.

SI-2700: Versatile Belt Sander

The SI-2700 belt sander combines the aggressive material removal capabilities of belt sanding with the precision control and lightweight design characteristic of Shinano pneumatic tools. This versatile sander accommodates various belt sizes and grits, providing flexibility for applications ranging from rough material removal to fine surface preparation.

Technical Specifications:

•Belt Dimensions: 10mm x 330mm and 12mm x 330mm

•Belt Speed: 1100 m/min

•Overall Length: 275mm

•Air Consumption: 0.27 m³/min

•Weight: Optimized for extended use

The SI-2700's belt sanding capability provides superior material removal rates compared to disc or orbital sanders, making it ideal for applications requiring rapid stock removal or surface leveling. Automotive bodywork benefits from the sander's ability to quickly remove paint, primer, or body filler while maintaining surface flatness and consistency.

Woodworking applications utilize the belt sander's versatility for both rough shaping and fine surface preparation. The ability to quickly change belt grits allows operators to progress from aggressive material removal to fine finishing without changing tools, improving efficiency and workflow continuity.

Application-Specific Selection Guide

Automotive Bodywork Applications

Automotive bodywork demands sanders capable of delivering consistent results across diverse materials including steel, aluminum, fiberglass, and various body fillers and coatings. The selection of appropriate sanders depends on specific application requirements, workspace constraints, and desired surface quality outcomes.

Paint and Primer Preparation: Orbital sanders like the SI-3101-6M excel in paint and primer preparation applications where surface quality and consistency are critical. The precision orbital action eliminates swirl marks while providing efficient material removal, ensuring optimal adhesion for subsequent coatings.

Body Filler and Repair Work: Disc sanders such as the SI-2210 provide the aggressive material removal necessary for shaping body filler and removing damaged material. The high-speed operation and robust construction handle demanding applications while maintaining precision control.

Detail and Confined Space Work: Compact sanders like the SI-2201 address the unique requirements of detail work in confined spaces such as door jambs, wheel wells, and complex body contours where larger sanders cannot access effectively.

Woodworking Applications

Woodworking applications require sanders capable of producing smooth, consistent surfaces without cross-grain scratches or orbital marks that can compromise finish quality. The selection of appropriate sanders depends on wood species, grain characteristics, and intended finish requirements.

Fine Furniture and Cabinetry: Orbital sanders provide the smooth, consistent surfaces required for high-quality furniture and cabinetry work. The precision orbital action eliminates cross-grain scratches while providing efficient material removal across various wood species and grain orientations.

Rough Shaping and Stock Removal: Belt sanders offer superior material removal rates for rough shaping applications and initial surface preparation. The ability to quickly change belt grits allows progression from aggressive material removal to fine surface preparation.

Detail and Contour Work: Compact disc sanders enable precise material removal in detailed areas such as moldings, carvings, and complex geometries where larger sanders cannot access effectively.

Technical Specifications and Performance Comparison

Understanding the technical specifications and performance characteristics of different sander types enables informed selection based on specific application requirements and performance priorities.

|

Model

|

Type

|

Pad/Belt Size

|

Speed (RPM)

|

Power Output

|

Weight

|

Air Consumption

|

|

SI-3101-6M

|

Orbital

|

6" (150mm)

|

10,000

|

148W

|

2.07 lbs

|

11.7 CFM

|

|

SI-2210

|

Disc

|

3-4" (75-100mm)

|

19,000

|

475W

|

Optimized

|

High-efficiency

|

|

SI-2201

|

Disc

|

2" (50mm)

|

17,000

|

174W

|

1.10 lbs

|

Precision-optimized

|

|

SI-2700

|

Belt

|

10-12mm x 330mm

|

1100 m/min

|

Variable

|

Balanced

|

0.27 m³/min

|

Power Output and Efficiency

Shinano sanders deliver exceptional power-to-weight ratios through advanced pneumatic motor designs and precision engineering. The power output specifications represent sustained performance capabilities rather than peak ratings, ensuring consistent performance throughout extended use periods.

Air consumption specifications reflect the sanders' efficiency in converting compressed air into useful work output. Shinano's advanced air flow management systems minimize consumption while maximizing power delivery, reducing operating costs and compressor requirements.

Speed and Control Characteristics

Operating speeds are optimized for specific applications and sander types. Orbital sanders operate at moderate speeds to ensure smooth surface finishes, while disc sanders utilize higher speeds for aggressive material removal. Belt sanders operate at speeds optimized for belt life and material removal efficiency.

Speed control capabilities vary by model, with some sanders incorporating built-in speed regulation and others relying on air pressure adjustment for speed control. Professional applications often benefit from sanders with integrated speed control for precise adjustment of material removal rates.

Air Compressor Requirements and System Integration

Pneumatic sanders require properly sized air compressor systems to achieve optimal performance and efficiency. Understanding air consumption requirements and system integration considerations ensures reliable operation and maximum productivity.

Compressor Sizing Guidelines

Professional pneumatic sanders typically require 4-12 CFM of air flow at 90 PSI operating pressure. Compressor sizing should account for continuous operation requirements, multiple tool usage, and system pressure losses through distribution piping and fittings.

Single Tool Operation: For single sander operation, compressor capacity should exceed the tool's air consumption by 25-50% to account for pressure losses and ensure consistent performance. A 15-20 CFM compressor typically provides adequate capacity for most professional sanders.

Multiple Tool Systems: Shops operating multiple pneumatic tools simultaneously require larger compressor systems with adequate storage capacity to handle peak demand periods. System sizing should consider the simultaneous operation of multiple tools plus additional capacity for other pneumatic equipment.

Air Quality and Filtration

Pneumatic sanders require clean, dry compressed air to achieve optimal performance and service life. Contaminated air can cause premature wear, reduced performance, and potential damage to precision components.

Moisture Removal: Water separators and air dryers remove moisture that can cause corrosion and performance degradation. Professional installations typically incorporate refrigerated air dryers or desiccant systems to ensure consistently dry air supply.

Oil and Particulate Filtration: High-efficiency filters remove oil vapors and particulate contamination that can affect sander performance and surface quality. Multi-stage filtration systems provide comprehensive contamination removal for critical applications.

Maintenance and Service Life Optimization

Proper maintenance practices significantly extend pneumatic sander service life while ensuring consistent performance and reliability. Understanding maintenance requirements and implementing preventive maintenance programs maximizes equipment value and minimizes downtime.

Routine Maintenance Procedures

Daily Maintenance: Daily maintenance includes air line drainage, visual inspection for damage or wear, and verification of proper operation. These simple procedures prevent minor issues from developing into major problems.

Weekly Maintenance: Weekly maintenance involves lubrication of moving parts, inspection of air fittings and connections, and cleaning of air passages and filters. Proper lubrication is critical for pneumatic tool longevity and performance.

Monthly Maintenance: Monthly maintenance includes comprehensive inspection of all components, replacement of worn parts, and calibration of speed and pressure controls. This preventive approach identifies potential issues before they affect performance or reliability.

Service Life Factors

Shinano sanders typically provide 5-10 years of reliable service in professional applications when properly maintained. Service life depends on usage intensity, maintenance practices, air quality, and operating conditions.

Usage Intensity: Heavy-duty applications require more frequent maintenance and may experience shorter service life compared to light or moderate use applications. However, Shinano's robust construction ensures reliable performance even in demanding environments.

Air Quality: Clean, dry compressed air significantly extends sander service life by preventing corrosion and contamination-related wear. Investment in quality air treatment systems pays dividends in extended tool life and reduced maintenance costs.

Cost Analysis and Return on Investment

Evaluating the total cost of ownership for pneumatic sanders requires consideration of initial investment, operating costs, maintenance requirements, and productivity benefits over the equipment's service life.

Initial Investment Considerations

Professional-grade pneumatic sanders typically require higher initial investment compared to electric alternatives, but this cost differential is offset by superior performance, longer service life, and reduced maintenance requirements. Shinano sanders command premium pricing that reflects their superior quality and performance characteristics.

Equipment Costs: Shinano sanders typically cost 20-40% more than comparable electric models, but provide 2-3 times longer service life and superior performance characteristics. The initial investment premium is recovered through reduced replacement frequency and lower maintenance costs.

System Integration: Pneumatic sanders require compressed air systems that represent additional initial investment for shops without existing air systems. However, these systems support multiple pneumatic tools and provide long-term value through improved productivity and tool performance.

Operating Cost Analysis

Operating costs for pneumatic sanders include compressed air generation, maintenance supplies, and replacement parts. These costs are typically lower than electric tool operating costs due to reduced maintenance requirements and longer service life.

Energy Costs: Compressed air generation costs vary based on local electricity rates and compressor efficiency. Modern compressor systems achieve high efficiency levels that minimize operating costs while providing reliable air supply.

Maintenance Costs: Pneumatic sanders require minimal maintenance compared to electric alternatives. The absence of electric motors eliminates many common failure modes and reduces maintenance complexity and costs.

Frequently Asked Questions

1. What air compressor size do I need for professional pneumatic sanders?

Professional pneumatic sanders typically require 15-20 CFM compressor capacity for single tool operation, with larger systems needed for multiple tool usage. A 5-7.5 HP two-stage compressor with 80-120 gallon tank provides adequate capacity for most professional applications. Consider air quality equipment including dryers and filters for optimal performance.

2. How do Shinano sanders compare to other premium brands?

Shinano sanders consistently outperform competitors in durability testing, with 2-3 times longer service life and superior performance consistency. Independent testing shows Shinano tools maintain performance specifications longer and require less maintenance than competing brands. The "Toyota of air tools" reputation reflects decades of proven reliability in professional applications.

3. Can pneumatic sanders match the performance of high-end electric models?

Yes, premium pneumatic sanders often exceed electric model performance in key metrics including power-to-weight ratio, heat dissipation, and consistent power delivery. Pneumatic sanders maintain full power throughout operation while electric models may experience performance degradation due to heat buildup or voltage fluctuations.

4. What maintenance is required for pneumatic sanders?

Pneumatic sanders require daily air line drainage, weekly lubrication, and monthly comprehensive inspection. Proper air filtration and moisture removal significantly extend service life. Maintenance requirements are typically lower than electric tools due to simpler mechanical systems and absence of electric motors.

5. Are pneumatic sanders suitable for both bodywork and woodworking?

Yes, quality pneumatic sanders excel in both applications when properly selected for specific requirements. Orbital sanders provide excellent results for fine finishing in both bodywork and woodworking, while disc sanders handle aggressive material removal. The key is selecting appropriate sanders and abrasives for specific materials and applications.

Conclusion

Pneumatic sanders represent the pinnacle of professional surface preparation technology, offering superior performance, durability, and versatility compared to electric alternatives. Shinano Air Tools has established itself as the industry leader through decades of innovation, precision engineering, and unwavering commitment to quality that results in tools capable of meeting the demanding requirements of professional bodywork and woodworking applications.

The comprehensive Shinano sander lineup addresses diverse application requirements from fine finishing to aggressive material removal, providing professionals with tools optimized for specific tasks and performance requirements. The SI-3101-6M orbital sander excels in applications requiring smooth, consistent finishes, while the SI-2210 and SI-2201 disc sanders provide the power and precision necessary for aggressive material removal and detailed work.

Investment in quality pneumatic sanders pays dividends through improved productivity, superior surface quality, and extended service life that reduces long-term operating costs. The initial investment premium for Shinano sanders is recovered through reduced maintenance requirements, longer service life, and superior performance that enhances work quality and productivity.

The future of pneumatic sander technology continues advancing through innovations in air motor design, ergonomics, and system integration. Shinano's commitment to continuous improvement ensures their sanders will continue setting industry standards for performance, reliability, and value in professional applications.

Professional success in both automotive bodywork and fine woodworking depends on having the right tools for specific applications. Shinano pneumatic sanders provide the performance, reliability, and precision necessary to achieve exceptional results while maintaining the productivity levels required in competitive professional environments.

Call to Action

Ready to experience the superior performance of Shinano pneumatic sanders? Explore our complete Shinano air tools collection to find the perfect sanders for your bodywork and woodworking applications. Our pneumatic tool specialists are available at +1 4432041972 to provide expert guidance on sander selection and air system requirements.

Contact our technical team for personalized recommendations based on your specific applications and performance requirements. Browse our comprehensive air tools category for the complete range of professional pneumatic equipment, or visit our blog for more insights on Shinano air tool reliability and pneumatic tool applications.

This comprehensive guide was researched and written by the pneumatic tool experts at Tend Industrial Supplies. For more professional insights on air tools and industrial equipment, explore our extensive blog library covering everything from Japanese pneumatic air tools to pneumatic tool maintenance.

3rd Oct 2025