Beyond Brute Force: Why Japanese Air Impact Wrenches Are the Smart Choice for Pros

Why Japanese Air Impact Wrenches Are the Smart Choice for Pros

Key Takeaways:

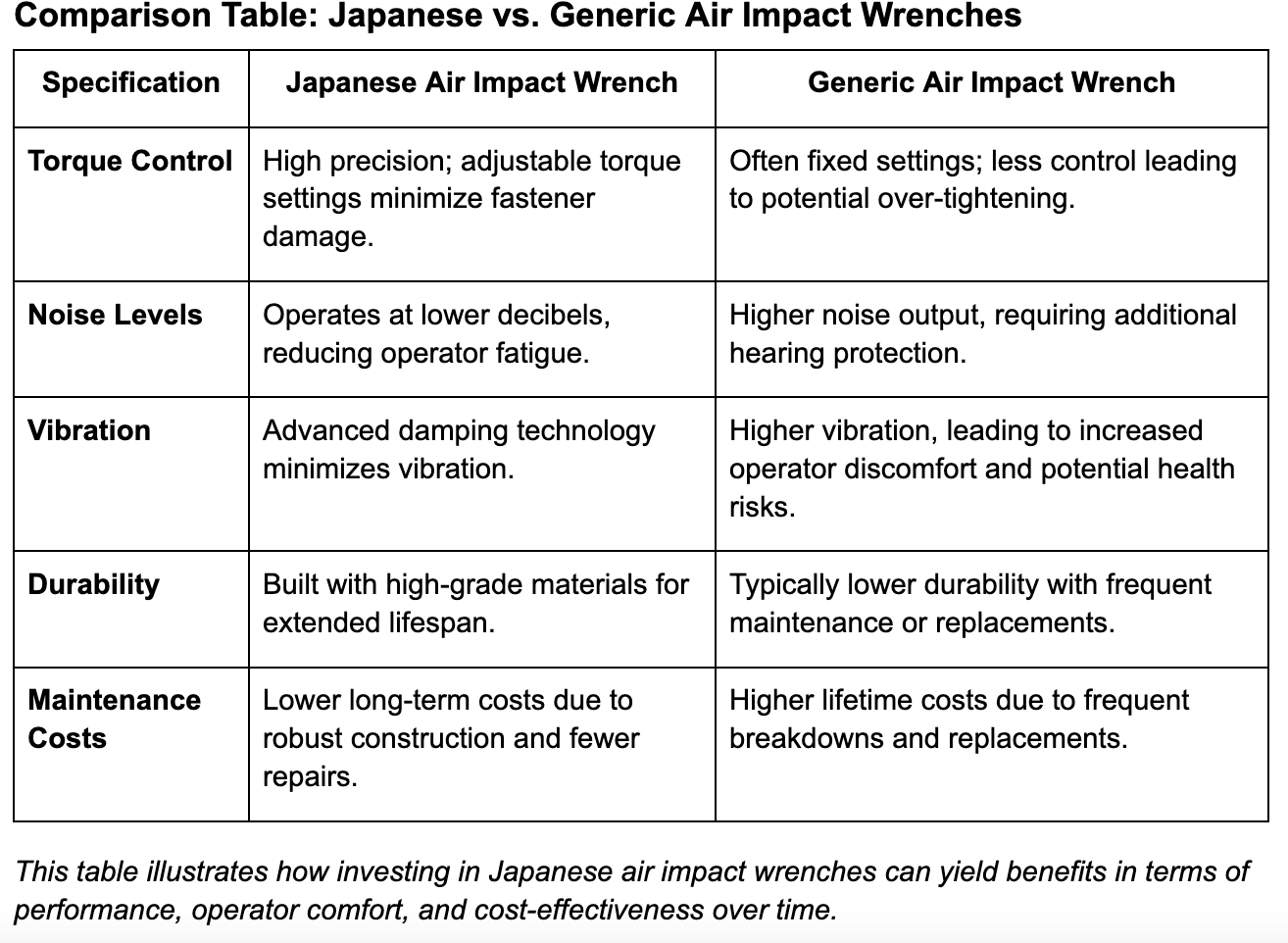

- "Brute force" is not enough: Focusing solely on power in air impact wrenches leads to problems like vibration, noise, fastener damage, and short tool lifespans.

- Japanese air impact wrenches offer a smarter approach: They are engineered for precision, quality, and durability, providing superior performance and long-term value.

- Key benefits include: enhanced torque and control, superior durability, improved ergonomics, long-term cost savings, and reduced noise and vibration.

- Professionals across various industries can benefit from the advantages of Japanese air impact wrenches.

- Investing in Japanese air impact wrenches is an investment in quality, efficiency, and your professional success.

Are you tired of air impact wrenches that promise power but deliver nothing but frustration? Wrenches that vibrate your hands numb, struggle with stubborn bolts, and seem to break down just when you need them most? In the demanding world of professional mechanics, manufacturing, and construction, relying on "brute force" alone simply isn't enough. It leads to wasted time, damaged fasteners, and ultimately, compromised quality. There's a smarter way to work. It's time to move beyond the limitations of generic, power-focused impact wrenches and discover the world of Japanese Air Impact Wrenches. These aren't just tools; they're precision-engineered instruments designed for professionals who demand performance, durability, and a level of control that "brute force" can never offer.

The Problem with "Brute Force" Alone: Power Isn't Everything

For years, the marketing around air impact wrenches has focused on one thing: torque. More torque equals more power, right? While torque is undoubtedly important, relying solely on raw power is a recipe for problems. Think about it:

- Vibration Fatigue: High vibration from poorly designed wrenches leads to operator fatigue, reduced precision, and even long-term health issues like Hand-Arm Vibration Syndrome (HAVS). This translates to decreased productivity and increased worker downtime.

- Excessive Noise: Cheaply made impact wrenches are often incredibly loud, contributing to noisy and potentially unsafe work environments. Hearing protection becomes essential, and communication on the job site suffers.

- Fastener Damage: "Brute force" often means uncontrolled power. This can easily lead to over-tightening, stripped threads, and broken bolts, resulting in rework, material waste, and compromised structural integrity.

Short Tool Lifespan: Wrenches built with low-quality materials and minimal engineering simply don't last. Frequent breakdowns and replacements become the norm, eating into your budget and disrupting workflow

Brute Force Thread accident-Hidden Cost of Brute force

Brute Force Thread accident-Hidden Cost of Brute force

These issues aren't just inconveniences; they are real costs that impact your bottom line and the quality of your work. Professionals need tools that are not just powerful, but also smart, efficient, and reliable. This is where the Japanese approach to tool manufacturing shines.

The Japanese Approach: Precision Engineering for Professional Results

Japanese manufacturing has long been synonymous with quality, precision, and innovation. This reputation isn't built on hype; it's rooted in a deep-seated philosophy of craftsmanship and continuous improvement (Kaizen). When it comes to air impact wrenches, this translates into tools engineered for:

- Uncompromising Quality: Japanese manufacturers prioritize high-grade materials, from specially formulated steels to durable composites. This ensures components can withstand the rigors of demanding industrial environments and deliver consistent performance over time.

- Precision Engineering: Every component, from the rotor to the anvil, is meticulously designed and manufactured to exacting tolerances. This precision minimizes vibration, maximizes power transfer, and ensures smooth, controlled operation.

- Rigorous Testing: Japanese tools undergo stringent quality control processes and testing at every stage of production. This commitment to quality assurance means you can rely on your Japanese air impact wrench to perform flawlessly, day in and day out.

- Focus on User Experience: Ergonomics and user comfort are paramount. Japanese designs often incorporate features like lightweight housings, balanced weight distribution, and vibration-dampening technologies to reduce operator fatigue and enhance productivity.

This dedication to engineering excellence isn't just about making tools; it's about creating solutions that empower professionals to work more efficiently, safely, and with greater precision.

Modern Japanese Tools factory

Modern Japanese Tools factory

Key Benefits of Japanese Air Impact Wrenches: Work Smarter, Not Harder

Investing in a Japanese air impact wrench is an investment in quality, efficiency, and long-term value. Here's a breakdown of the key benefits you can expect:

Enhanced Torque and Control:

Japanese engineering focuses on efficient power delivery. This means you get maximum torque output with minimal air consumption, and crucially, superior control. This control is vital for preventing over-tightening and fastener damage, especially when working with delicate materials or critical assemblies. You'll experience:

- Faster Bolt Run-Down: Efficient mechanisms deliver power quickly, speeding up your work.

- Consistent Torque Application: Precise engineering ensures consistent torque delivery, reducing errors and improving joint integrity.

- Reduced Fastener Damage: Controlled power minimizes the risk of stripping threads or breaking bolts, saving time and materials.

Superior Durability and Longevity:

Built to withstand the toughest conditions, Japanese air impact wrenches are designed for a long service life. This translates to:

- Reduced Downtime: Fewer breakdowns mean less disruption to your workflow and projects staying on schedule.

- Lower Replacement Costs: Investing in quality upfront means fewer replacements over time, saving you money in the long run.

- Reliable Performance: You can count on your Japanese wrench to perform consistently, even under heavy use, maintaining your productivity and quality standards.

Improved Ergonomics and User Comfort:

Japanese manufacturers understand that operator comfort is crucial for productivity and safety. Features like:

- Lightweight Designs: Reduced weight minimizes fatigue, especially during extended use, allowing you to work longer and more comfortably.

- Balanced Weight Distribution: Well-balanced tools are easier to control and maneuver, reducing strain and improving precision.

- Vibration Dampening: Advanced vibration reduction technologies minimize hand-arm vibration, protecting operators from HAVS and improving overall comfort.

- Ergonomic Grips: Comfortable and secure grips enhance control and reduce hand fatigue

Long-Term Cost Savings:

While the initial price of a Japanese air impact wrench might be slightly higher than a generic alternative, the long-term cost savings are significant. Consider:

- Reduced Replacement Costs: Durability means fewer replacements, saving you money over time.

- Increased Productivity: Efficiency and ergonomics lead to faster work cycles and higher output.

- Lower Repair Costs: Higher quality components and robust construction mean fewer repairs and less downtime.

- Minimized Rework: Precision and control reduce fastener damage and errors, minimizing costly rework.

Reduced Noise and Vibration:

Japanese engineering often prioritizes noise and vibration reduction, creating a more pleasant and safer work environment. This leads to:

- Improved Worker Comfort: Quieter operation reduces noise fatigue and improves overall working conditions.

- Enhanced Communication: Lower noise levels make it easier for workers to communicate on the job site, improving safety and coordination.

- Compliance with Safety Regulations: Reduced noise and vibration can help businesses comply with workplace safety regulations and minimize the risk of noise-related health issues.

Who Benefits Most from Japanese Air Impact Wrenches?

Japanese air impact wrenches are ideal for any professional who demands the best in performance, reliability, and longevity. This includes:

- Automotive Technicians: For everything from routine tire changes to complex engine and transmission work, precision and control are paramount.

- Manufacturing Engineers & Assembly Line Workers: In manufacturing settings, consistency, speed, and durability are crucial for maintaining production efficiency and quality.

- Construction Workers: From bolting steel structures to assembling heavy equipment, the power and robustness of Japanese wrenches are essential for demanding construction tasks.

- Maintenance and Repair Crews: For maintaining machinery, equipment, and infrastructure, reliable tools that can handle diverse tasks and environments are indispensable.

- Heavy Equipment Mechanics: Working on large machinery requires tools that can deliver massive torque and withstand extreme conditions.

No matter your industry, if you rely on air impact wrenches for critical tasks, upgrading to Japanese-engineered tools is a smart investment that will pay dividends in performance, durability, and overall efficiency.

Ready to experience the difference that precision engineering can make?

Contact Tend Industrial Supplies today to learn more about our range of high-quality Japanese Air Impact Wrenches and find the perfect tools to elevate your work.

Email us at: sales@tendsupplies.com

As an Amazon Associate, Tend Industrial Supplies may earn a commission from qualifying purchases through links in this article

Related Articles

Precision in Every Turn: The Evolution of Japanese Air Tools

Explore the history and innovation behind Japanese air tools, detailing how precision engineering has redefined performance in demanding work environments.

Read more on Tend Supplies

What Are the Features of Japanese Air Tools That Make Them Popular Among Professionals

Japanese air tools are popular among professionals due to their precision engineering, high-quality materials, durability, and ergonomic designs

Shinano Air Tools: Unmatched Reliability and Longevity - The Toyota of the Air Tool Industry

Shinano Air Tools: Built to last, like a Toyota. Discover unmatched reliability and longevity in the air tool industry. Learn why professionals trust Shinano.

Ergonomic Considerations in Pneumatic Tool Design- Shinano Air Tools

Ergonomic design is crucial for pneumatic tools. Explore how Shinano Air Tools prioritizes user comfort and safety in their tool design. Learn about features that reduce fatigue and improve productivity.

Why Japanese Air Tools are the Workshop Warriors

Japanese air tools' durability is a key factor behind their popularity. Built to withstand rigorous use in demanding environments, these tools often outlast their counterparts, making them a cost-effective choice over the long run

Frequently Asked Questions (FAQs)

1. What makes Japanese air impact wrenches different from other brands?

Japanese air impact wrenches stand out due to their unwavering commitment to precision engineering, high-quality materials, and rigorous testing. This results in tools that offer superior performance, durability, ergonomics, and a longer lifespan compared to generic alternatives that often prioritize only power at the expense of refinement.

2. Are Japanese air impact wrenches more expensive?

While the initial purchase price of a Japanese air impact wrench might be slightly higher, they offer significant long-term cost savings. Their superior durability reduces replacement frequency, their efficiency boosts productivity, and their precision minimizes rework and material waste. Considering the total cost of ownership, Japanese wrenches often prove to be more economical in the long run.

3. What are the key features to look for in a high-quality air impact wrench?

Key features include: high torque output with good control, durable construction using quality materials, ergonomic design for reduced vibration and fatigue, a balanced weight, and a reputable brand known for quality and reliability. Japanese brands often excel in all these areas.

4. Are Japanese air impact wrenches suitable for DIY or only for professionals?

While designed for the demands of professional use, anyone who values quality and performance can benefit from Japanese air impact wrenches. DIY enthusiasts who want reliable, long-lasting tools and appreciate precision engineering will find them to be a worthwhile investment.

5. Where can I purchase Japanese air impact wrenches from Tend Industrial Supplies?

You can explore our selection of high-quality Japanese air impact wrenches by contacting us directly at sales@tendsupplies.com. Our team can help you find the perfect models to meet your specific needs and applications. You can also check our Products online for more information and product details.