Common Failures in Pneumatic Tools and How to Fix Them

Common Failures in Pneumatic Tools

As an Amazon Associate, we earn from qualifying purchases. When you purchase through our links, we may earn a small commission at no additional cost to you.

Pneumatic tools represent the backbone of modern industrial operations, from automotive service centers to manufacturing facilities and construction sites. However, even the most reliable pneumatic equipment experiences failures that can halt productivity and increase operational costs. Understanding the most common failure modes and their solutions enables maintenance teams to minimize downtime, extend tool life, and optimize performance.

Research indicates that compressed air systems typically operate at only 10-20% efficiency, with pneumatic tool failures contributing significantly to this inefficiency. The global pneumatic tools market, valued at over $8 billion in 2025, continues expanding as industries recognize the superior power-to-weight ratios and durability advantages of air-powered equipment. However, maximizing these benefits requires a comprehensive understanding of failure mechanisms and preventive maintenance strategies.

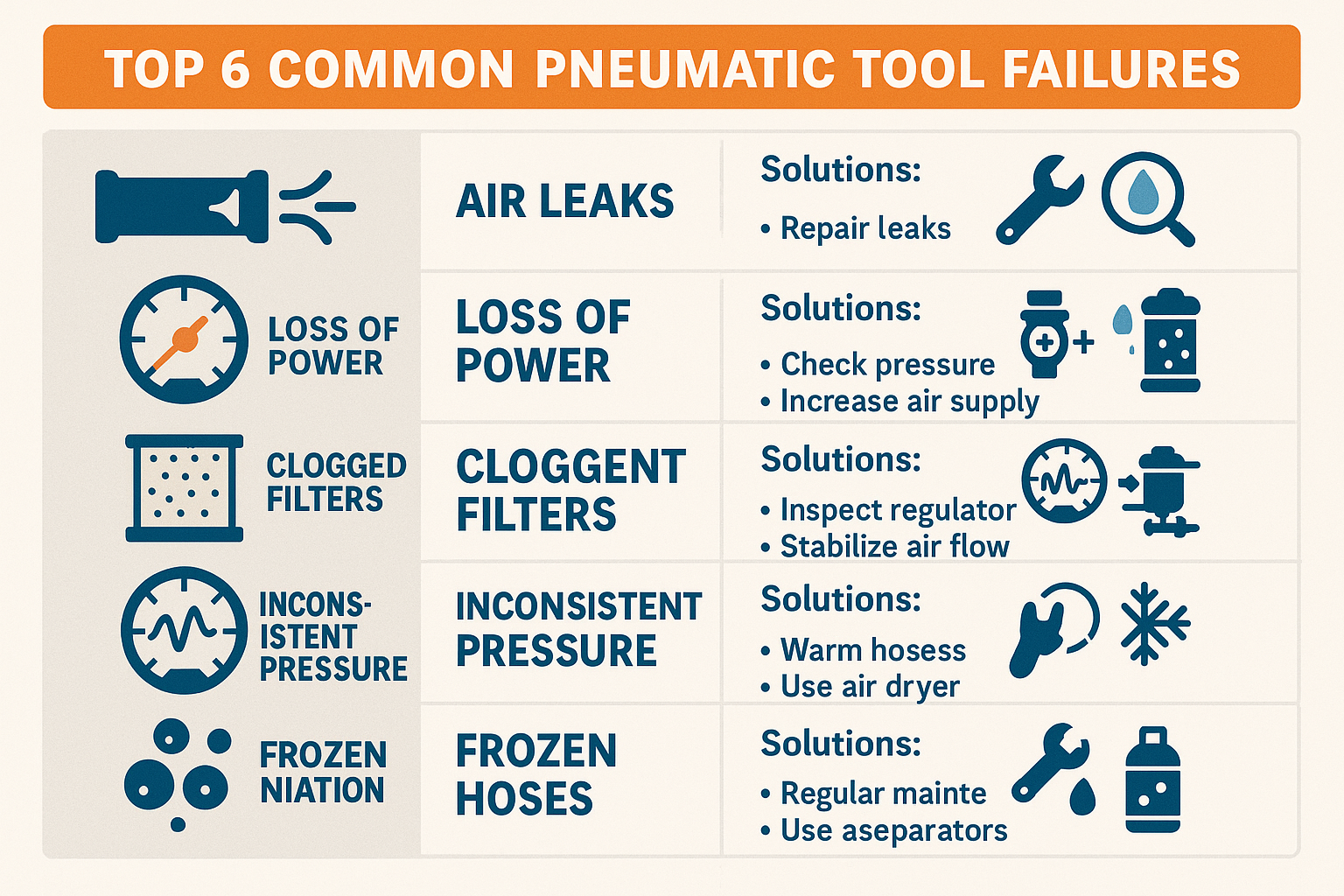

Professional maintenance teams report that 80% of pneumatic tool failures are caused by six primary factors: air leaks, power loss, filter contamination, pressure inconsistencies, environmental factors, and inadequate maintenance practices. Each failure mode presents distinct symptoms and requires specific diagnostic and repair approaches to restore optimal performance and prevent recurrence.

Key Takeaways

•Air leaks account for 35% of pneumatic tool failures and can reduce system efficiency by up to 50%, making leak detection and repair the highest priority maintenance activity

•Proper air filtration prevents 60% of contamination-related failures by removing moisture, oil, and particulate matter that cause premature wear and performance degradation

•Preventive maintenance reduces failure rates by 70% compared to reactive maintenance approaches, significantly improving tool reliability and operational efficiency

•Environmental factors cause 25% of failures through temperature extremes, moisture exposure, and contamination that can be mitigated through proper storage and handling procedures

•Quality air preparation systems extend tool life by 200-300% by providing clean, dry, properly regulated compressed air that optimizes performance and minimizes wear

Understanding Pneumatic Tool Failure Mechanisms

Pneumatic tools operate through complex interactions between compressed air, mechanical components, and control systems. Failure mechanisms typically involve degradation of seals, contamination of internal components, wear of moving parts, or disruption of air flow patterns. Understanding these mechanisms enables the development of targeted diagnostic approaches and effective repair strategies.

The compressed air environment presents unique challenges compared to electric or hydraulic systems. Air compressibility creates dynamic pressure variations that stress seals and gaskets. Moisture condensation can cause corrosion and freeze damage in cold conditions. Contamination from oil vapors, particulate matter, and chemical residues accelerates component wear and degrades performance.

Modern pneumatic tools incorporate sophisticated air motors, precision valves, and advanced materials designed to withstand these challenges. However, even premium tools require proper maintenance and air preparation to achieve their designed service life and performance specifications.

System Integration Factors

Pneumatic tool performance depends heavily on the entire compressed air system, from the compressor output to the point of use. System factors including pressure regulation, air quality, distribution design, and maintenance practices directly impact tool reliability and performance. Failures often result from system-level issues rather than tool-specific problems.

Proper system design includes adequate compressor capacity, effective air treatment, appropriate distribution sizing, and comprehensive maintenance programs. These elements work together to provide the clean, dry, properly regulated compressed air that pneumatic tools require for optimal performance and longevity.

Primary Failure Modes and Diagnostic Approaches

1. Air Leaks: The Silent Performance Killer

Air leaks represent the most common and costly pneumatic tool failure mode, accounting for 35% of all reported issues. Even small leaks can significantly impact tool performance while increasing energy costs and reducing system efficiency. A single 1/8-inch leak at 100 PSI wastes approximately 100 CFM of compressed air, equivalent to the output of a 25-horsepower compressor.

Common Leak Locations:

•O-ring seals and gaskets (40% of leaks)

•Threaded connections and fittings (30% of leaks)

•Quick-disconnect couplers (15% of leaks)

•Valve seats and internal seals (10% of leaks)

•Hose connections and damaged hoses (5% of leaks)

Diagnostic Techniques:

Visual Inspection: Examine all connections, fittings, and hose assemblies for obvious damage, corrosion, or loose connections. Look for oil stains or dirt accumulation that may indicate leak locations.

Auditory Detection: Listen for hissing sounds during quiet periods when background noise is minimized. Many leaks produce audible sounds that can be located through systematic listening.

Soap Solution Testing: Apply soapy water to suspected leak locations and observe for bubble formation. This method provides definitive leak identification and allows precise location determination.

Ultrasonic Detection: Professional ultrasonic leak detectors identify high-frequency sounds produced by air leaks, enabling the detection of leaks that may not be audible to human hearing.

Repair Procedures:

Seal Replacement: Replace worn O-rings, gaskets, and seals using manufacturer-specified materials. Ensure proper installation techniques, including correct compression and lubrication.

Connection Tightening: Tighten loose fittings to the manufacturer's specifications using the appropriate tools. Avoid over-tightening, which can damage threads or sealing surfaces.

Component Replacement: Replace damaged quick-disconnects, valves, or other components that cannot be effectively repaired. Use genuine replacement parts to ensure proper fit and performance.

2. Power Loss and Performance Degradation

Power loss manifests as reduced tool speed, decreased torque output, or inability to maintain operating pressure under load. This failure mode often develops gradually, making early detection challenging but critical for preventing complete tool failure.

Root Causes:

•Insufficient air supply pressure or flow

•Internal component wear reducing efficiency

•Clogged air passages restricting flow

•Worn or damaged air motor components

•Inadequate lubrication causing increased friction

Diagnostic Procedures:

Pressure Testing: Measure air pressure at the tool inlet during operation to verify adequate supply pressure. Compare readings to manufacturer specifications and system design parameters.

Flow Rate Measurement: Determine actual air consumption compared to tool specifications. Excessive consumption indicates internal leakage or component wear.

Performance Testing: Measure tool speed, torque output, or other performance parameters under standardized conditions. Compare results to baseline measurements or manufacturer specifications.

Internal Inspection: Disassemble tools following manufacturer procedures to inspect internal components for wear, damage, or contamination.

Repair Solutions:

Air Supply Optimization: Increase compressor capacity, improve distribution sizing, or reduce system pressure losses to ensure adequate air supply.

Component Replacement: Replace worn air motor components, valves, or other internal parts using genuine replacement parts and proper assembly procedures.

Lubrication System Maintenance: Clean and service automatic lubrication systems or implement proper manual lubrication procedures using manufacturer-specified lubricants.

3. Filter and Air Quality Issues

Contaminated compressed air causes 60% of premature pneumatic tool failures through accelerated wear, corrosion, and performance degradation. Effective air treatment systems remove moisture, oil vapors, and particulate matter that can damage sensitive internal components.

Contamination Types:

•Moisture: Causes corrosion, freezing, and lubrication washout

•Oil Vapors: Create carbon deposits and seal degradation

•Particulate Matter: Accelerates wear and clogs precision components

•Chemical Contaminants: Cause seal swelling and material degradation

Air Quality Standards:

Professional pneumatic tools require air quality meeting ISO 8573 standards:

•Particulate: Class 3 (maximum 5 micron particles)

•Moisture: Class 4 (maximum -40°F pressure dew point)

•Oil: Class 3 (maximum 1 mg/m³ oil content)

Filtration System Design:

Primary Filtration: Removes large particles and bulk moisture using coalescent filters with automatic drains.

Secondary Filtration: Eliminates fine particles and oil vapors through high-efficiency filters with 0.01 micron rating.

Air Drying: Reduces moisture content using refrigerated dryers or desiccant systems to prevent condensation and corrosion.

Point-of-Use Filtration: Provides final air cleaning immediately before tool connection using combination filter-regulator-lubricator units.

4. Pressure Regulation and Consistency Problems

Inconsistent air pressure causes erratic tool performance, reduced efficiency, and accelerated component wear. Proper pressure regulation ensures optimal tool operation while preventing damage from overpressure conditions.

Pressure-Related Issues:

•Fluctuating pressure during operation

•Insufficient pressure for tool requirements

•Excessive pressure causing component damage

•Pressure drop during high-demand periods

Regulation System Components:

Primary Regulation: Reduces compressor output pressure to distribution system requirements using high-capacity pressure regulators.

Secondary Regulation: Provides stable pressure to tool groups or individual tools using precision regulators with appropriate flow capacity.

Pressure Monitoring: Continuous pressure monitoring using gauges or electronic sensors to detect system problems and optimize performance.

Maintenance Procedures:

Regulator Calibration: Verify and adjust regulator settings to maintain proper pressure under varying load conditions.

Component Inspection: Examine regulator internals for wear, contamination, or damage that may affect performance.

System Sizing: Ensure adequate regulator capacity for system demands and proper sizing of distribution components.

Environmental Factors and Seasonal Considerations

Environmental conditions have a significant impact on the performance and reliability of pneumatic tools. Temperature extremes, humidity variations, and contamination exposure require specific preventive measures and maintenance adjustments.

Cold Weather Operations

Freezing Prevention: Install air dryers and heat tracing to prevent moisture freezing in distribution lines and tools. Use synthetic lubricants that maintain viscosity at low temperatures.

Condensation Management: Implement automatic drain systems and moisture separators to remove condensation before it reaches tools.

Material Considerations: Select seals and gaskets rated for low-temperature operation to prevent brittleness and failure.

Hot Weather Challenges

Thermal Expansion: Account for thermal expansion in distribution systems and tool components. Provide adequate clearances and flexible connections.

Lubrication Degradation: Use high-temperature lubricants and increase lubrication frequency to compensate for thermal breakdown.

Cooling Requirements: Ensure adequate ventilation and cooling for compressors and air treatment equipment operating in high-temperature environments.

Contaminated Environments

Ingress Protection: Select tools with appropriate IP ratings for dusty or wet environments. Implement protective covers and regular cleaning procedures.

Filtration Enhancement: Upgrade air filtration systems to handle higher contamination levels. Consider pre-filtration at air intake points.

Maintenance Frequency: Increase inspection and maintenance frequency in contaminated environments to prevent accelerated wear and failure.

Preventive Maintenance Programs

Effective preventive maintenance programs reduce pneumatic tool failures by 70% while extending service life and optimizing performance. Comprehensive programs address both tool-specific maintenance and system-level requirements.

Daily Maintenance Tasks

Visual Inspection: Check for obvious damage, leaks, or unusual conditions. Verify proper tool operation and performance.

Lubrication: Apply appropriate lubricants according to manufacturer specifications. Monitor automatic lubrication systems for proper operation.

Air Quality Check: Drain moisture separators and check filter condition. Verify proper pressure regulation and air flow.

Weekly Maintenance Activities

Detailed Inspection: Examine tools for wear, damage, or performance degradation. Test safety systems and protective devices.

System Monitoring: Check compressor operation, air treatment performance, and distribution system condition.

Performance Testing: Conduct standardized performance tests to establish baseline measurements and detect developing problems.

Monthly Comprehensive Maintenance

Component Replacement: Replace filters, seals, and other wear items according to manufacturer schedules.

Calibration Verification: Check and adjust pressure regulators, flow controls, and monitoring instruments.

System Analysis: Analyze performance data, energy consumption, and failure trends to optimize system operation.

6th Oct 2025