Cordless vs. Pneumatic: Which Tools Last Longer?

Imagine walking into an old auto body shop, the air thick with the smell of oil and compressed air. Tucked away on a shelf sits an air impact wrench, battered, scratched, and still fully functional after 30 years of heavy use. Now, look at a modern construction site: workers zip through framing tasks with cordless nailers, free from hoses, but diligently swapping out battery packs every few hours. This stark contrast perfectly illustrates the central question facing every professional: “Cordless vs. Pneumatic: Which Tools Last Longer?”

The choice between the proven, rugged longevity of pneumatic air tools and the powerful, cutting-edge portability of cordless power tools is more than just a preference, it’s a critical business decision impacting long-term operational costs and job-site efficiency. This comprehensive guide will dissect the durability of each system, examining the tool body, the power source, and the maintenance requirements, to determine which technology truly offers the best return on your investment in tool longevity. We'll provide the definitive answer to help you equip your workshop or job site with the most durable and reliable equipment.

Key Takeaways:

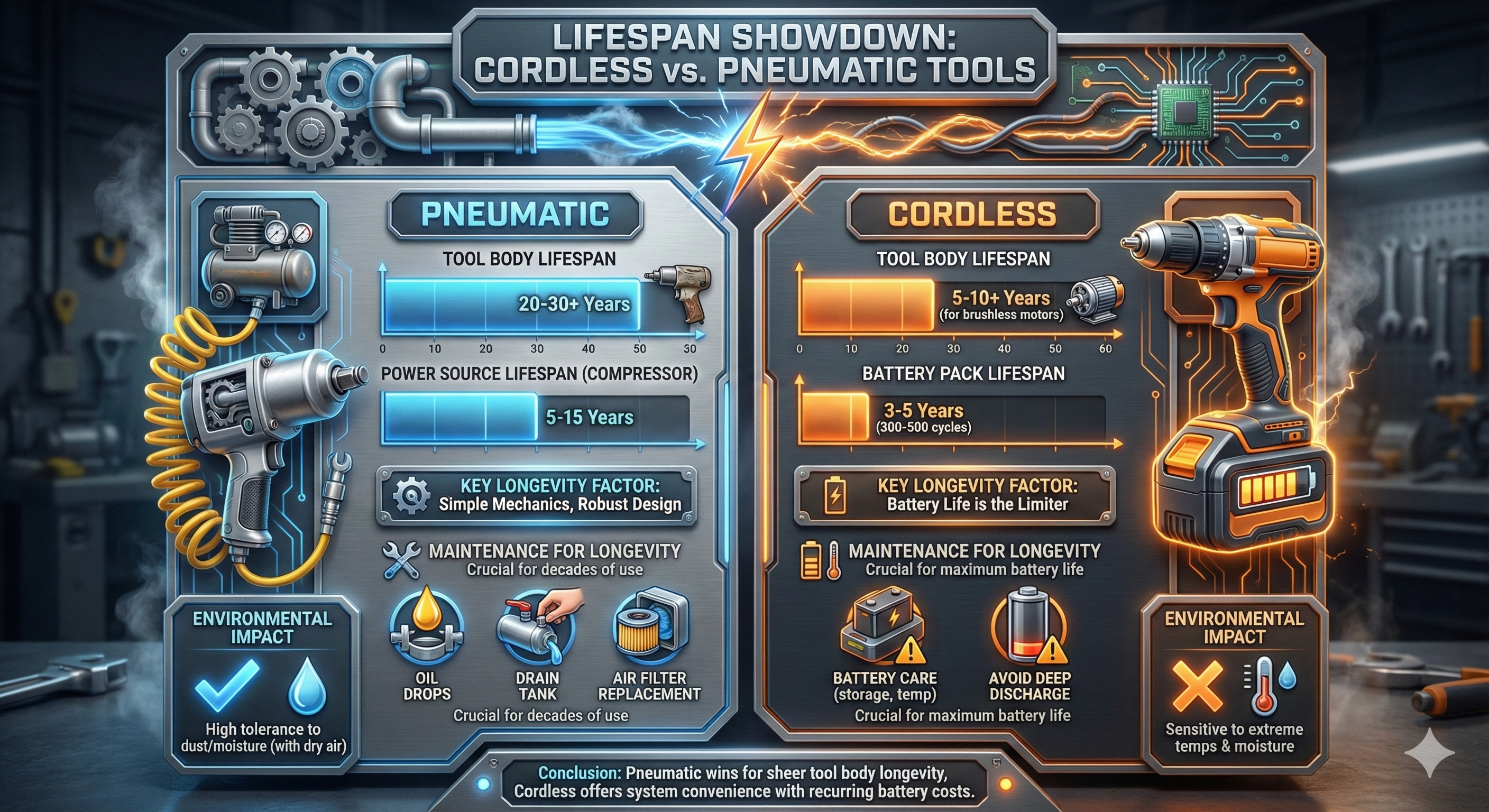

- Pneumatic Tools Win Pure Durability: The simple, gearless internal mechanics of pneumatic tools give the tool body a superior lifespan, often lasting 20 to 30 years or more with basic maintenance, making them the ultimate choice for core longevity.

- Cordless Longevity is Limited by Batteries: The practical lifespan of the entire cordless system is capped by the Lithium-ion battery packs, which typically require replacement every 3 to 5 years (300-500 charge cycles), becoming the main recurring long-term cost.

- The Best Tool for Continuous Use: For sustained, heavy-duty applications (like all-day automotive repair or production framing), the thermal stability and robust design of pneumatic tools make them the most long-lasting and reliable option.

- Maintenance Dictates Lifespan: Proper maintenance is critical for both: Pneumatics require daily oiling and air-system drainage, while Cordless longevity relies heavily on battery care (temperature control and proper storage charge).

- Portability vs. Durability Trade-off: The choice hinges on your primary need: If maximum portability, versatility, and quick setup are key, cordless offers the best system, accepting the battery replacement cost; if absolute decades-long tool-body durability in a fixed location is the goal, pneumatic is the clear winner.

The Longevity Verdict: Pneumatic Tools Win the Durability Race

When we assess which power tool technology will last the longest, the winner for sheer, decades-long durability is the pneumatic system. This is primarily due to its fundamentally simpler, more robust design.

Pneumatic Tool Longevity: Why They Last Decades

Pneumatic tools, such as air impact wrenches, air nailers, and die grinders, rely on an external air compressor to operate. Their internal components are minimal, typically consisting of a few metal vanes and seals that harness compressed air.

- Simple Internal Mechanics: Air tools lack complex electric motors, sophisticated electronics, and, crucially, rechargeable batteries. Fewer moving parts mean fewer potential points of failure.

- Decades-Long Lifespan: With regular maintenance often just a drop of air tool oil before use and keeping the air supply dry a quality pneumatic tool can easily last 20 to 30 years or more. Many mechanics and carpenters still use air tools bought new two decades ago.

- Ease of Repair: The components that do wear out (like O-rings, seals, and vanes) are typically part of inexpensive and widely available rebuild kits. This makes pneumatic tools highly serviceable, allowing a technician to restore an old tool to "like-new" performance for a fraction of the replacement cost.

- The Compressor: While the air tool itself is incredibly durable, its power source the air compressor has a more measurable lifespan. A professional-grade reciprocating compressor may last 5 to 15 years (or 40,000 to 50,000 operational hours) with proper maintenance, but this cost is spread across every pneumatic tool you own.

Cordless Tools: Modern Convenience with a Lifespan Limit

Modern cordless power tools (drills, impact drivers, circular saws, etc.) are marvels of engineering, offering incredible power and unmatched portability. However, their lifespan is intrinsically tied to two complex, high-wear components: the Brushless Motor and the Lithium-Ion Battery.

The Tool Body (Motor and Housing)

- Brushless Motor Durability: Most professional-grade cordless tools now use brushless motors, which have fewer friction points and generate less heat than older brushed motors. This significantly extends the life of the motor itself, often lasting for 5 to 10 years or more with heavy use.

- Electronic Complexity: Cordless tools contain complex circuit boards and electronic systems for performance optimization and battery management. These components are more susceptible to damage from moisture, dust, extreme temperatures, and accidental drops than the simple mechanics of a pneumatic tool.

The Battery Pack (The Longevity Limiter)

This is the Achilles' heel for overall cordless system longevity.

- Finite Charge Cycles: Most Lithium-ion (Li-ion) batteries have a lifespan measured in charge cycles the number of times they can be fully charged and discharged before their capacity drops significantly (usually to 70-80% of original capacity).

- Average Lifespan: A typical professional-grade Li-ion battery will last 300 to 500 charge cycles, translating to an average useful lifespan of 3 to 5 years under regular, demanding use. After this, while the tool body remains functional, the tool is only as good as the (now-diminished) battery.

- Replacement Costs: While the tool body is an initial, long-term purchase, the battery packs are a recurring expense. The need for continuous cordless battery replacement drastically changes the long-term cost and "true" longevity of the system.

Factors That Dramatically Affect Tool Lifespan

Regardless of the power source air or battery the lifespan of any tool is heavily influenced by how it is used and maintained in real-world conditions, whether on a bustling commercial site in New York or a remote DIY project in rural Australia.

Heavy-Duty Use vs. Intermittent DIY

|

Factor |

Pneumatic Tools (Pro) |

Cordless Tools (Pro) |

Global Impact on Longevity |

|

Duty Cycle |

Ideal for continuous, high-volume use (e.g., all-day framing, assembly lines). Minimal internal heat generation. |

Best for intermittent use or punch-list tasks. Heavy, continuous use generates heat, which degrades the motor and rapidly shortens battery life. |

Pneumatics handle constant, strenuous work better; Cordless thrives in mobility and varied, shorter tasks. |

|

Environmental Stress |

Highly tolerant of high dust and humidity if the air is filtered and dried. The all-metal construction is often more durable against drops. |

Susceptible to dust and moisture damage to internal electronics/circuit boards. Extreme heat and cold drastically reduce battery performance and lifespan. |

Extreme temperatures (common in many regions) are a major longevity threat to cordless batteries. |

|

Maintenance |

Crucial: Daily oiling, draining the air compressor's tank (to prevent rust), and replacing air filters. Low cost, high impact on longevity. |

Crucial: Battery care (storage charge, temperature control, avoiding deep discharge). Minimal tool body maintenance. The system's longevity relies on proper battery management. |

Regular lubrication (pneumatic) and temperature control (cordless) are the most critical steps to extend life. |

Selecting Your Long-Term Tool System (Safe Buyer Advice)

When choosing the system with the best long-term value, professionals and home users considering tool longevity for mechanics or long-lasting construction nailers should analyze their typical job profile.

Choose Pneumatic If You Prioritize:

- Maximum Tool Body Longevity: You want a tool that can last for 20+ years.

- Sustained, High-Volume Power: Your work involves continuous, heavy-duty tasks (automotive repair, industrial manufacturing, all-day framing).

- Inexpensive, Simple Repairs: You prefer simple mechanical maintenance and cheap rebuild kits.

- Best Value for Dedicated Shop Work: You work consistently in a single location (a garage, factory, or workshop) where the compressor is stationary and accessible.

Choose Cordless If You Prioritize:

- Portability and Quick Setup: You are a mobile technician or need tools for remote job sites, roofing, or punch-list work where dragging a hose is impractical.

- System Convenience: You prefer the convenience of a single battery platform and are willing to accept the recurring cost of battery replacement.

- Versatile, Varied Tasks: Your tasks are varied, scattered, or require working in tight spaces where the compact size and maneuverability of a lighter, hose-free tool are essential.

- The Best Long-Term Solution for Home DIY: For occasional use, a cordless tool's batteries can last well over the typical 3-5 years, making it an excellent, long-lasting investment for homeowners.

Which Tools Actually Last Longer?

Pneumatic tools last significantly longer, often 20–30+ years because they have simple mechanical internals and no batteries.

Cordless tools deliver superior portability, but their total lifespan is limited by Lithium-ion batteries, which typically need replacement every 3–5 years.

Winner: Pneumatic Tools for Pure Longevity

- Tool body can last a lifetime

- Simple mechanics

- Cheap rebuild kits

But… Cordless Wins for Mobility

Cordless tools make more sense when:

- You work on job sites

- You need fast setup

- You need freedom from hoses

Frequently Asked Questions (FAQs)

Q: Are modern brushless cordless tools closing the lifespan gap with pneumatic tools?

A: Yes, significantly. The introduction of brushless motors has dramatically improved the lifespan of the cordless tool body itself, reducing heat and wear compared to older brushed motors. For the vast majority of intermittent or moderate professional tasks, a high-quality brushless tool will offer equivalent or superior longevity to pneumatic tools in terms of operational hours. However, the pneumatic tool still maintains a decisive edge in multi-decade component durability and in handling continuous, extreme-duty cycles without overheating.

Q: What is the most common reason for a pneumatic tool failing prematurely, and how can I prevent it?

A: The most common cause of premature failure in pneumatic tools is rust and corrosion due to moisture passing through the air line. Air compressors naturally collect water vapor (especially in humid environments). To prevent this, you must regularly drain the air compressor tank and use a proper air line filter-regulator-lubricator (FRL) system to ensure the air delivered to the tool is dry and consistently lubricated. This simple step is the key to maximizing the long-term reliability of air tools.

Q: Does extreme temperature affect cordless or pneumatic tool longevity more severely?

A: Extreme temperatures affect cordless tools far more severely. Cordless performance and lifespan are highly dependent on the stability of the Lithium-ion batteries. Exposure to extreme heat accelerates battery degradation (reducing its total cycle life), and extreme cold drastically reduces the tool's immediate run time and power output. Pneumatic tools, being mechanical, are largely unaffected by temperature extremes, provided the air supply remains dry. This makes them a more durable choice for outdoor work in regions with high climate variance.

Q: When is it more cost-effective for a business to choose the higher initial investment of pneumatic equipment?

A: It is more cost-effective for a business to choose pneumatic equipment when the tools are used constantly for a majority of the workday in a fixed location (e.g., assembly lines, dedicated auto bays, or large-scale manufacturing). The higher initial cost of the compressor and tools is quickly offset by the minimal long-term maintenance costs, the lack of recurring expensive battery purchases, and the extended, decades-long service life, leading to a much lower 10-year total cost of ownership (TCO) for high-volume users.

Q: What are the main long-term cost differences between air and battery tools?

A: Air tools have a higher initial setup cost (tool + compressor), but lower long-term operating costs due to the tool's decades-long lifespan and cheap repair kits. Cordless tools have a lower initial tool-only cost, but a higher long-term recurring cost from regularly replacing expensive Li-ion battery packs every 3-5 years.

Q: Is there a cordless tool that can match pneumatic longevity for heavy-duty applications?

A: For the sheer durability of the core tool body, pneumatic still wins for continuous, extreme use (like running a 1-inch impact wrench all day). However, modern high-voltage cordless tools (40V, 60V, etc.) with advanced battery management systems (BMS) are closing the performance gap, offering impressive tool body longevity in a vast majority of professional tasks, making the best long-lasting power tool choice highly application-dependent.

Q: How does battery technology impact the overall lifespan of cordless tools?

A: The shift from older Nickel-Cadmium (NiCd) and Nickel-Metal Hydride (NiMH) to Lithium-Ion (Li-ion) has increased cordless longevity significantly. Li-ion has no "memory effect" and better power-to-weight ratio. Newer battery advancements, like using LiFePO4 (Lithium Iron Phosphate) or advanced cooling systems, further promise to improve cycle life and thermal stability, making future cordless options even more durable.

Related Articles:

- Maryland's Ultimate Comparison of Corded vs. Cordless Power Tools

- The Ultimate Comparison of Air vs Electric Tools for Professional Contractors

- Why cordless power tools are taking over the market and how to choose the right ones for you

- Pneumatic vs. Electric Tools: A Comprehensive Comparison for Every Job

- Tend to Your Automotive Projects with Top Air Tools from Tend Industrial Supplies in the USA

Conclusion

The definitive answer to which tool system lasts longer is nuanced, resting on a crucial distinction: pneumatic tools offer superior core machine longevity, while cordless tools deliver superior system convenience and versatility.

For a heavy-duty, fixed operation like an industrial fabrication shop or a dedicated automotive garage, investing in the robust mechanical simplicity of air impact wrenches and pneumatic nailers offers the best long-term value, with tool bodies engineered to last two decades or more through simple, low-cost rebuild kits. This system provides the consistent, uninterrupted power required for repetitive, high-volume work.

However, for the modern, mobile professional, the on-site electrician, the roofer, or the remote technician, the unmatched convenience and job-site portability of modern brushless cordless tools are the decisive factors. While users must accept the recurring cost of Lithium-ion battery replacement every 3 to 5 years, the gains in setup time, maneuverability, and overall productivity often outweigh this financial trade-off, solidifying the cordless system as the superior power tool longevity solution for fieldwork.

Ultimately, the wisest investment strategy for professionals globally is often a balanced tool arsenal: leveraging the decades-long durability of pneumatic tools in the workshop and relying on the efficiency and cordless freedom of battery-powered options on site.

Whether you decide to rely on the infinite lifespan of pneumatic systems or the mobility of modern cordless technology, one thing remains constant: Quality matters.

Don't let cheap components stall your projects. At Tend Industrial Supplies, we stock only the most durable, industry-tested tools, from heavy-duty air impact wrenches to the latest brushless battery systems.

Browse our premium selection of air and cordless tools at