How to Choose Insulated Electrician Tools: Certification & Safety Tips

Working deep inside a crowded 480V control panel, a veteran electrician named Mark accidentally slipped, his insulated screwdriver brushing a live busbar. There was no arc, no flash, just the silent, momentary realization that the tool's thick, certified insulation was the only thing standing between him and a fatal shock. He pulled back, heart pounding, the incident a stark, terrifying reminder of the non-negotiable role of his equipment.

For any professional or serious DIY enthusiast working near live electrical currents, tools are a vital piece of personal protective equipment (PPE). The severe danger of non-insulated tools makes the choice of replacement a matter of life or death. This guide cuts through the confusion, providing a global standard for understanding How to Choose Insulated Electrician Tools: Certification & Safety Tips.

Working with live electrical currents, even seemingly low-voltage circuits, demands absolute precision and non-negotiable safety standards. The difference between a routine job and a catastrophic accident often comes down to one thing: the quality and certification of your tools.

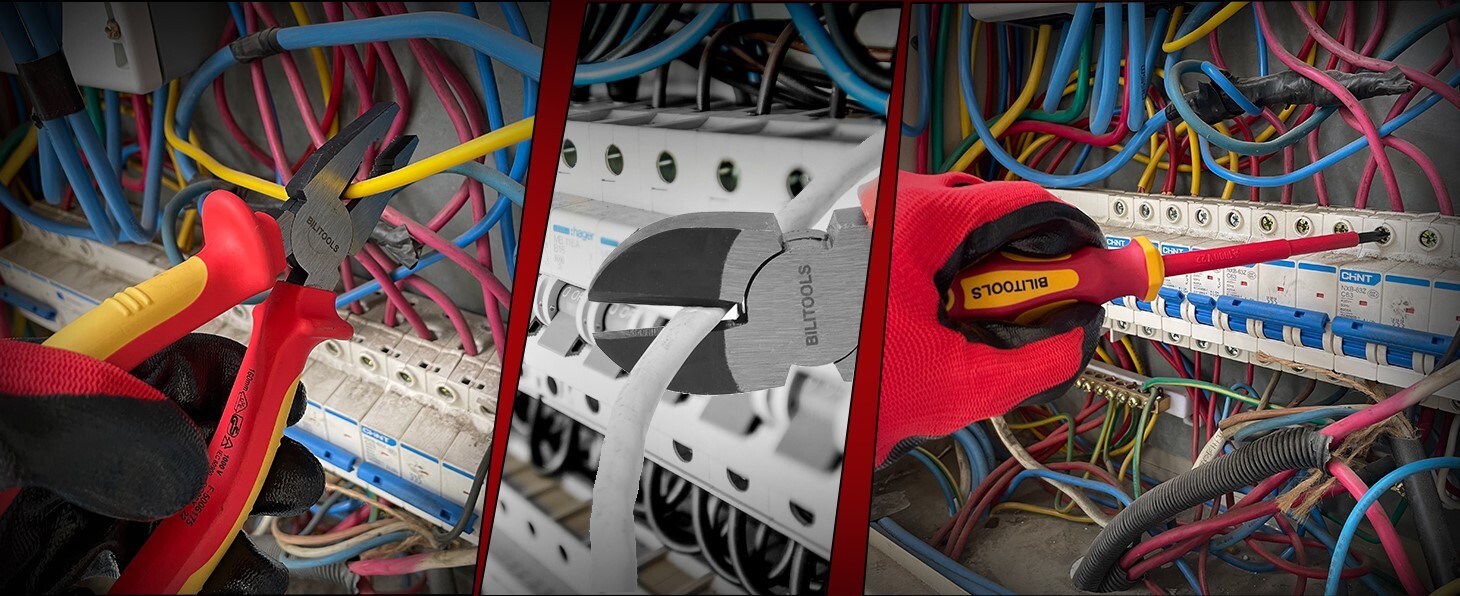

We’ll also highlight why the BILITOOLS 1000V Insulated Electrician Screwdriver & Pliers Set is one of the most trusted options for both home users and professionals, combining 1000V safety rating, VDE certification, and ergonomic design in one reliable kit.

Whether you’re rewiring a socket or upgrading your electrical toolkit, choosing the right insulated tools isn’t just smart, it could literally save your life.

Amazon Affiliate Disclosure:

Tend Supplies is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn fees by linking to Amazon.com and affiliated sites. As an Amazon Associate, we earn from qualifying purchases. We only recommend products we genuinely believe in, which helps us continue to create valuable content for our readers.

Key Takeaways:

- Certification is Non-Negotiable: Always verify that insulated tools meet the international IEC 60900 standard and are visibly marked with the 1000V rating. Tools marked with the VDE certified label are universally trusted for compliance.

- Insulated Tools are a Secondary Defense: Remember that insulated tools are your backup PPE. The primary rule of electrical safety is always to de-energize, lock out, and test every circuit before any work begins.

- Master the "Red Flag Test": High-quality tools are double insulated (often red over yellow). If the inner yellow layer is visible through any cut, crack, or tear in the outer insulation, the tool is compromised and must be retired immediately.

- The 10x Safety Margin: Certified 1000V tools are dielectrically tested at 10,000 volts (10kV), ensuring a massive safety margin that protects you when working on circuits up to 1,000V AC/1,500V DC.

- Avoid Custom Insulation: Never try to create your own insulated tool using electrical tape. Only use tools with factory-certified, permanently molded insulation that has been individually tested to meet the required safety standards.

The Gold Standard: Understanding Insulated Tool Certification

The moment an electrician's tool touches a live component, the insulation surrounding the handle becomes the only thing protecting the user. This insulation must meet rigorous international standards to guarantee its performance.

The International Requirement: IEC 60900

The single most important standard to look for globally is IEC 60900. This is the international benchmark for insulated tools certification and is recognized by most regulatory bodies across Europe, Asia, and North America (often cross-referenced with ASTM F1505 in the U.S.).

- The 1000V Rating: Tools complying with IEC 60900 are rated for safe use up to 1,000 volts AC (Alternating Current) or 1,500 volts DC (Direct Current).

- The Testing: While rated for 1,000V, every single tool is dielectrically tested in water at 10,000 volts (10kV) for three minutes. This 10x safety margin ensures the tool will not fail under real-world stress.

- VDE Certified Tools: Often, you will see the VDE mark (Verband der Elektrotechnik) alongside the IEC 60900 standard. VDE is a highly respected German testing and certification institute, and the VDE mark is one of the most trusted indicators globally that the tool has met or exceeded the IEC standard.

Also Read: Insulated vs Standard Hand Tools for Electrical Work: Key Safety Differences You Should Know

Beyond Compliance: What the Mark Means on Your Tool

When you are choosing insulated screwdrivers or a best insulated pliers set, always look for these visual confirmations:

- The Rating: The number 1000V must be clearly and permanently marked on the insulation.

- The Double Triangle: A clear symbol of two interlocking triangles often indicates the tool has been approved for live work.

- Manufacturer and Year: The tool must include the manufacturer’s mark and, frequently, the year of production (essential for tracking compliance).

If a tool only says "Insulated" without a visible 1000V or VDE/IEC 60900 mark, do not use it for live work. It does not meet the necessary global safety threshold. Following OSHA insulated tool requirements and IEC 60900 standards ensures both global compliance and field-tested reliability

Key Safety Principles: Choosing the Right Insulated Tool

Once you have confirmed the certification, the next step is examining the specific features that contribute to real-world safety and efficiency during electrical safety work.

Insulation Design: The Critical Barrier

The highest quality tools utilize a design known as double insulated tools explained by the color layers:

- Dual Layer System: The tool is covered with two distinct, colored layers of insulation typically an outer layer of Red (or Orange) and an inner layer of Yellow.

- The Red Flag Test: The contrasting inner layer serves as an immediate visual warning system. If the outer red layer is cut, cracked, or worn, the inner yellow layer becomes visible. This is your "red flag" the tool is compromised and must be immediately removed from service.

When buying, inspect the transition point between the metal shank and the handle this is often the weakest point where cheaper tools fail and the insulation may be thinner or improperly molded.

Tool Type and Application

Every insulated tool kit should include the essentials, each designed with unique safety considerations:

- Insulated Screwdrivers: Look for handles designed for high torque and comfort. The shaft insulation should extend as close to the tip as possible, leaving only the functional part of the driver exposed. Many premium brands test each screwdriver individually at 10kV before it leaves the factory.

- Insulated Pliers and Cutters: Ensure the plier's pivot point does not compromise the insulation. The grips should be contoured to prevent the hand from sliding toward the metal jaws. Look for hardened cutting edges, as frequent use can degrade the metal and, subsequently, the insulation's integrity near the joint.

- Insulated Wrenches and Ratchets: These tools are often bulkier due to the necessary insulation around the head. Ensure the tool's head profile still allows access to confined spaces, a key consideration for maintenance in control panels.

Your Safety Checklist: Maintenance and Usage Tips

Even the highest quality VDE certified 1000V insulated hand tools are only as safe as their user's diligence and maintenance routines. Following this safety checklist for electrical work is non-negotiable for professionals adhering to OSHA requirements for insulated tools and other global safety mandates.

Pre-Use Inspection: The Red Flag Test

Every time you take an insulated tool out of your bag, perform a quick visual inspection:

- Check for Cuts: Run your finger along the entire length of the insulation. Feel for nicks, slices, or abrasions.

- Look for Cracks: Inspect the areas around the handle ends and the joint where the insulation meets the metal shank. Cracks are often caused by dropping the tool or using it to pry.

- Look for the Inner Color: If you see the inner (yellow) insulation color showing through the outer (red/orange) layer, the tool’s protective capability is compromised. Set it aside immediately.

When to Retire Insulated Tools

Insulated tools do not have a hard expiration date like certain electrical gloves, but they must be retired if they fail the visual inspection.

- Heat Damage: Never expose these tools to extreme heat (like leaving them on a hot manifold or welding bench), which can weaken the polymer insulation.

- Damage from Prying/Dropping: Do not use insulated screwdrivers as chisels or levers. Dropping a tool from height onto concrete can cause microscopic cracks, compromising the integrity needed for safe electrical work.

- Compromised Insulation: If the insulation is visibly damaged, cut the tool's metal tip off and discard it to prevent anyone else from accidentally using it for live work.

Remember, the purpose of insulated tools is to act as a secondary defense. The primary rule in any electrical environment is to de-energize, lock out, and test every circuit before work begins.

Frequently Asked Questions (FAQs)

1. What is the single most important certification mark to look for globally?

The most important mark is the IEC 60900 standard, which is the international benchmark. Tools are also frequently marked with VDE certified (a highly respected European testing body) to confirm compliance with this standard.

2. Does "1000V rated" mean the tool was only tested up to 1000 volts?

No. Tools rated for 1000V are actually dielectrically tested at 10,000 volts (10kV) for several minutes. This 10x safety margin ensures the tool's insulation integrity under real-world stress.

3. What is the purpose of the two-color (e.g., red over yellow) insulation?

This design provides a visual warning system called the "Red Flag Test." If the outer insulation (red) is cut or damaged and the inner contrasting color (yellow) is visible, the tool is compromised and must be retired immediately.

4. Can I use insulated tools on circuits higher than 1000 volts?

No. Insulated tools are certified and rated only for use up to a maximum of 1000 volts AC (or 1500V DC). Using them on higher voltages voids the safety rating and puts the user at extreme risk.

5. Should I wrap a regular tool in electrical tape to make it insulated?

Absolutely not. This is extremely dangerous and does not meet any safety standard. Electrical tape is not rated for high voltage and can be easily punctured. Always use factory-certified, tested, and marked tools.

6. Are insulated tools my primary defense against electrical shock?

No. Insulated tools are your secondary defense. The primary rule of safety is to always de-energize, lock out, and test every circuit before any work begins.

7. Do insulated hand tools have an expiration date?

No, unlike some rubber safety equipment (like gloves), insulated hand tools do not have a mandatory retirement date. Their lifespan depends entirely on passing the visual inspection (the "Red Flag Test"). If the insulation is cracked, cut, or the inner color shows, the tool must be retired immediately.

Related Articles:

- The DIY Guide to Safe Electrical Repairs: Why Insulated Electrician Screwdriver & Pliers Set Matter

- Top Hand Tool Sets for Every DIY Enthusiast

- The Resurgence of Hand Tools in the Age of Automation

- Introduction to Hand Tools: Definition, Importance, and Classifications

- Best Budget Tools 2025: Quality Tools That Won't Break the Bank

- Best Hand Tool Brands of 2025: A Complete Guide for Pros & DIYers

Conclusion:

When you are working near live circuits, there is simply no cutting corners. The simple act of choosing your tools is the most critical decision you make for your personal safety.

The definitive global requirement is IEC 60900 standard compliance. You must ensure that every single item, from your best insulated pliers set to your new how to choose insulated screwdrivers, carries the proper markings. Investing in VDE certified 1000V insulated hand tools is a non-negotiable step that confirms the tools have been tested at ten times their working voltage.

But certification is only the first line of defense. True safety is a discipline enforced by your actions. By adhering to a rigorous safety checklist for electrical work and understanding that the unique design of double insulated tools explained their compromised status via the "Red Flag Test," you proactively manage risk.

Always respect the fact that these tools are a backup. If you find damage, adhere strictly to the procedure for retiring damaged insulated tools. By prioritizing certified quality and daily vigilance, you ensure that your tools remain a professional defense against the unseen dangers of electricity.

Call to Action

Don't gamble your safety on uncertified or damaged equipment. Your life depends on the 1000V VDE certification of your tools. Upgrade your kit today to meet the highest global standards for electrical safety and compliance.

Explore our full inventory of IEC 60900 certified insulated hand tools and essential LOTO gear, all built for professional performance and maximum safety, at Tendsupplies.com.

Need expert guidance on choosing the right tools for high-voltage compliance or purchasing bulk insulated screwdrivers for your crew? Contact our safety specialists directly at sales@tendsupplies.com.