How to Choose the Right Endoscope or Borescope for Industrial Use: A Complete Guide

What is the Right Endoscope or Borescope for Industrial Use

Introduction

inspection technology has become a cornerstone of preventive maintenance, diagnostics, and operational safety. Two of the most critical tools for internal visual inspection are the borescope and endoscope. Though originally from different fields, they’re now widely used across automotive, plumbing, HVAC, and manufacturing industries. This article complements our earlier article "Choosing the Right Borescope Camera: A Buyer’s Guide" but in this guide we are given more reasons to make an informed decision and the major difference between an industrial endscope and borescop

Choosing the right tool for your application isn’t just about specs—it’s about selecting the correct diameter, flexibility, resolution, and lighting to match your inspection task.

Get this wrong, and you risk poor diagnostics, equipment damage, or wasted costs.

Key takeaway: Whether you’re peering into a car engine, a pipeline, or a complex piece of machinery, using the right inspection camera helps you work faster, safer, and more efficiently.

What’s the Difference Between a Borescope and an Endoscope?

While the terms are often used interchangeably in online marketplaces, they originally served different purposes:

-

Borescopes are designed for industrial applications and are often rigid or semi-rigid, making them ideal for inspecting machinery, engines, and static structures.

-

Endoscopes, in contrast, are typically more flexible, and while originally used in medical contexts, they’ve become common in inspecting softer pathways like plumbing and HVAC ducts.

Key Differences:

| Feature | Borescope | Endoscope |

|---|---|---|

| Flexibility | Rigid or semi-rigid | Usually flexible |

| Use Case | Industrial, mechanical, automotive | Plumbing, HVAC, internal pathways |

| Probe Diameter | Typically 4mm – 10mm | Typically 5mm – 12mm |

| Original Field | Industrial | Medical (now also industrial) |

Related Product: Grabo PRO-Lifter 20 – Vacuum lifter for surface inspection tasks

Use with endoscope tools to check tile or surface integrity before lifting.

Key Industrial Use Cases

Let’s break down the practical, real-world uses where a borescope or endoscope becomes essential:

Automotive Inspections

-

Cylinder and piston checks

-

Combustion chamber inspections

-

Timing belt and valve assessments

-

Turbocharger diagnostics

Relevant Tool: Shinano SI-1490B Air Impact Wrench – Often used alongside borescopes in engine work.

Plumbing and Pipework

-

Clogged drains and pipe blockages

-

Leak detection inside walls or underground systems

-

Corrosion checks in metallic pipelines

HVAC Systems

-

Ductwork inspections for mold or blockage

-

Coil corrosion and airflow restriction checks

Aircraft and Aviation Maintenance

-

Jet turbine checks

-

Structural inspection of tight compartments

-

Scheduled airframe diagnostics

Inspection Accessory: Maxxeon WorkStar 5000 – Area Light – Ideal for illuminating inspection environments.

Heavy Machinery & Manufacturing

-

Visual diagnostics for gearboxes, bearings, and mechanical systems

-

Routine preventive maintenance

Matching Accessory: Shinano SI-2210 Belt Sander – Surface prep after internal inspection

Important Features to Consider

To choose the right inspection camera, you must understand the technical specs that impact functionality:

Camera Resolution

The higher the resolution, the more detail you'll capture:

-

720p: Basic level for simple diagnostics

-

1080p or 2MP+: Ideal for clear imaging in automotive and manufacturing

-

4MP+ or dual lenses: Professional-grade inspections

If you’re inspecting critical moving parts or corrosion, always opt for HD or above.

Product mention

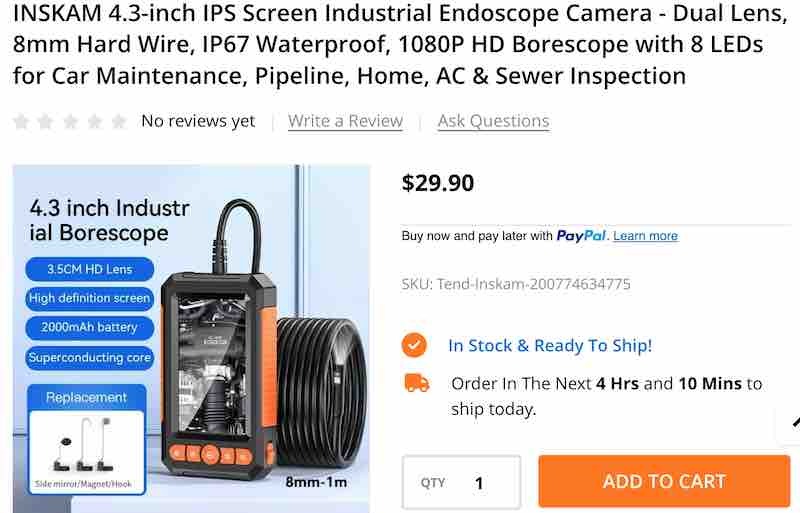

For clear 1080p resolution on a budget, try the

INSKAM 4.3” IPS Screen Dual Lens Borescope – $29.90

Why it works: Cheap, IP67 waterproof, perfect for engine inspections.

Advanced Tool: INSKAM 4.3” IPS Screen Dual Lens Borescope – $29.90

Cable Type & Length

-

Rigid borescopes are great for straight-line access like engine blocks.

-

Semi-rigid cables offer slight flexibility, suitable for most HVAC or pipe jobs.

-

Flexible endoscopes work well for winding plumbing systems or irregular ductwork.

Lengths range from 1 meter (for desktop work) to 15+ meters (for underground pipelines).

Product Mention

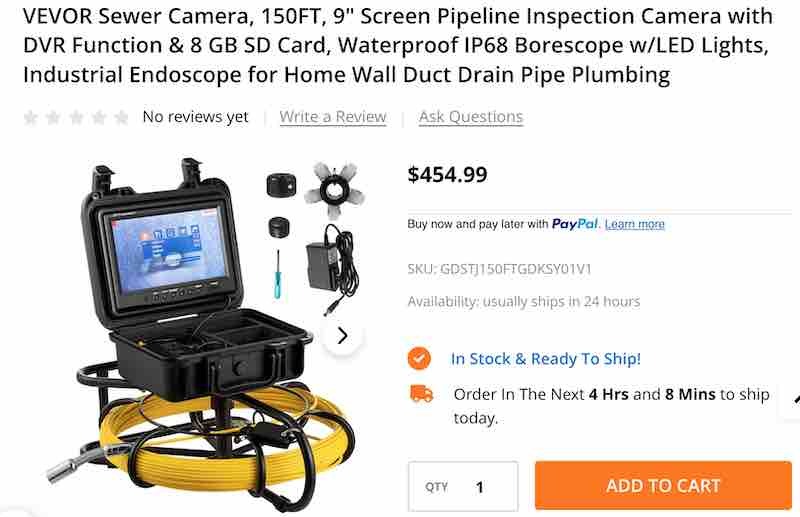

For long-range plumbing inspection,

VEVOR Sewer Camera – 150FT Cable, IP68 Waterproof – $454.99

Why it works: This serves those looking for high-ticket, ultra-long probes like those often listed in Amazon/Reddit forums.

Probe Diameter

Critical for access in tight areas:

-

3.9mm – 5.5mm: Needed for spark plug holes, injectors, or tight cavities

-

6mm – 10mm: Best for general pipe inspections, HVAC ducts, and engine chambers

Lighting & Waterproof Ratings: Why They Matter

LED Lighting

Lighting is non-negotiable since inspections often occur in dark, narrow, or enclosed spaces.

Most modern borescopes and endoscopes come with built-in adjustable LEDs—typically 6 to 12 diodes near the camera tip. Features to consider:

- Adjustable brightness: Prevents glare in reflective surfaces like pipes or engine walls

- Shadow reduction: Ensures even lighting in cylindrical or deep compartments

- Color temperature: White or daylight LEDs yield better detail in video capture

Pair with: Maxxeon WorkStar 620 Technician’s Light – For external task area illumination before or after camera inspection.

Want a tool with dual lens and bright LED lighting for tight machine spaces?

VEVOR 4.3" Dual Lens Endoscope – 16.4FT Cable – $35.00

Waterproof Rating (IP67, IP68)

Make sure your device has a strong IP (Ingress Protection) rating for plumbing, outdoor construction, and marine inspections.

- IP67: Can be submerged in up to 1m of water for 30 minutes – suitable for most indoor pipe checks

- IP68: Deeper submersion, great for wastewater, underground, or rainy environments

4.3” Industrial Endoscope with 10M Cable – $30.98

Display Types: Built-In vs. Wireless

When it comes to monitoring your inspection in real-time, you have two major options:

Built-In Screen

- No need for external devices

- Faster setup and deployment

- Ideal for workshops or field techs who don’t want to depend on smartphones

Wireless (Wi-Fi or USB)

- Camera connects to your smartphone, tablet, or PC

- Offers app-based features like video recording, zoom, and screenshot

- Perfect for mobile inspections or digital documentation

Some high-end models even offer dual modes: screen + wireless streaming.

Recommended Inspection Cameras by Use Case

Here’s a tailored chart to help you match your industry with the right borescope/endoscope type:

|

Industry |

Recommended Tool |

Key Features |

|

Automotive |

Semi-rigid Borescope (5.5mm) |

1080p, built-in screen, short cable (1-2m) |

|

Plumbing |

Flexible Endoscope (8–12mm) |

IP68 waterproof, 15m cable, wireless |

|

HVAC |

Wireless Borescope (6mm) |

LED, WiFi, semi-rigid cable |

|

Aviation Maintenance |

High-res Industrial Borescope (4mm) |

2MP+, rigid shaft, articulating head |

|

Manufacturing Plants |

Rugged Borescope (6–8mm) |

Dual lens, external monitor, rugged housing |

Recommended by Use Case Best Industrial Endoscope 2025

|

Industry |

Recommended Tool |

|

|

Automotive |

||

|

Plumbing |

||

|

HVAC |

||

|

Aviation Maintenance |

||

|

Manufacturing Plants |

Wired vs. Wireless: Which Is Better for You?

Both configurations have their pros and cons depending on your environment and mobility needs:

Wired (Built-in screen):

- No need for additional devices

- Stable and interference-free video feed

- More rugged and durable in field conditions

Wireless (WiFi / USB):

- Great for confined or dynamic spaces

- Can stream to multiple users (e.g., during a group inspection)

- Can store digital inspection logs on your phone

Wireless devices often come with rechargeable batteries, so make sure battery life is suitable for the duration of your inspection cycles (2–4 hours typical).

Brand Guide: Top Options in 2025

Here are some trusted names in inspection technology, available through distributors like Tend Industrial Supplies:

Maintenance & Durability Tips for Long-Term Use

To protect your investment and ensure consistent performance from your industrial borescope or endoscope, follow these expert tips:

- Clean the lens after each use using a soft microfiber cloth and lens-safe cleaning agent

- Avoid kinking flexible cables, especially when coiling or packing the tool

- Store in a shockproof case to protect the camera head and electronics

- Charge batteries after each session to prevent premature battery wear

- Use protective sleeves in corrosive or chemical-rich environments

? Use Epochem Multipurpose Cleaner to safely clean equipment exposed to industrial environments

Conclusion: Making the Right Choice

Choosing the right industrial inspection tool—whether labeled as a borescope or endoscope—boils down to three key factors:

- Your specific use case (e.g., engine inspection vs. pipe blockage)

- Technical requirements (e.g., probe diameter, camera resolution)

- Work conditions (e.g., waterproof needs, light availability, wireless preference)

By evaluating these needs up front, you’ll avoid wasting money on underperforming devices—and instead, you’ll gain accurate visual data, faster troubleshooting, and increased safety.

At Tend Industrial Supplies, we offer only the most reliable, tested solutions for industrial professionals, mechanics, contractors, and inspectors.

FAQs: Frequently Asked Questions

What’s the difference between an endoscope and a borescope?

While similar in function, borescopes are typically semi-rigid and used for mechanical inspections, while endoscopes are more flexible and adapted for plumbing and ductwork.

Can I connect a borescope to my smartphone?

Yes—many modern models come with Wi-Fi or USB connections compatible with both Android and iOS. Just make sure your phone supports OTG or Wi-Fi Direct.

What probe diameter should I choose?

- 3.9–5.5mm for tight spaces (e.g., spark plugs)

- 6–10mm for general industrial inspections

- 12mm+ for wide plumbing and ducts

Are borescopes waterproof?

Only if they have IP67 or IP68 ratings, always check before using near water, waste, or chemical zones.

Can I record and share footage from inspections?

Yes, built-in display and Wi-Fi models often come with photo/video capture, and wireless ones let you share to the cloud or email.

Call to Action

Are you ready to upgrade your inspections with the right tool?

=>Browse our inspection cameras and visual tools collection for vetted, high-quality products.

=> Need help deciding? Email us at sales@tendsupplies.com or call +1 443 204 1972

=>Want our full catalog Download the Industrial Tools PDF Catalog