How to Choose Workshop Air Compressors by CFM: The Ultimate Guide (2025)

Imagine you're deep into a big automotive project, impact wrench in hand, ready to bust a stubborn lug nut when suddenly the steady whir of your compressor turns into a strained, stuttering hiss. The wrench loses power, the nut stays put, and you’re left waiting five minutes for the tank to refill, every time. You bought a compressor with a massive tank and high horsepower, but still, your tools are starving for air.

That moment of stoppage is the painful realization that you chose the wrong machine. You fell for the marketing hype and ignored the single most critical specification: CFM.

This common mistake is exactly why we created this guide. Forget horsepower and forget tank size for a moment. If you want a workshop that runs smoothly and efficiently, you need to understand airflow. In this article, we’ll cut through the confusion and show you exactly how to choose workshop air compressors by CFM, ensuring your tools always have the volume of air they need to perform flawlessly.

Key Takeaways:

- Ignore Horsepower Hype: Prioritize CFM (Cubic Feet per Minute) over HP or tank size, as it is the only metric that effectively determines if your tools will run continuously without stalling.

- The 1.5x Sizing Rule: To prevent underpowering your shop, identify your most "air-hungry" tool (usually a sander or grinder) and multiply its required CFM by 1.5 to calculate your minimum compressor size.

- SCFM vs. CFM Matters: Always verify the SCFM rating (Standard CFM) delivered at 90 PSI. Generic "displacement CFM" is a theoretical number that often exaggerates real-world performance.

- Tanks Don't Create Air: A larger tank acts as a "battery" for short bursts but cannot compensate for a low-CFM pump during continuous tasks like sanding, grinding, or spray painting.

- Know Your Tier: Different workflows demand specific airflow: nail guns generally need just 2–4 CFM, while professional painting or bodywork setups require a minimum of 10–12 SCFM.

What is CFM and Why Does It Rule the Workshop?

CFM stands for Cubic Feet per Minute. It measures the volume of air a compressor can deliver at a specific pressure level.

Think of compressed air like water flowing through a hose:

- PSI (Pressure) is how hard the water pushes out.

- CFM (Volume) is how much water is coming out.

Most workshop tools, especially impact wrenches, grinders, and sanders are "air hungry." They don't just need a burst of pressure (PSI); they need a constant river of air (CFM) to keep spinning.

The Critical Difference: CFM vs. SCFM

When shopping, you will see two acronyms. Knowing the difference is a major authority signal:

- CFM (Displacement/Actual): A theoretical number. It’s often measured at the pump's bore and stroke, assuming 100% efficiency (which never happens in real life).

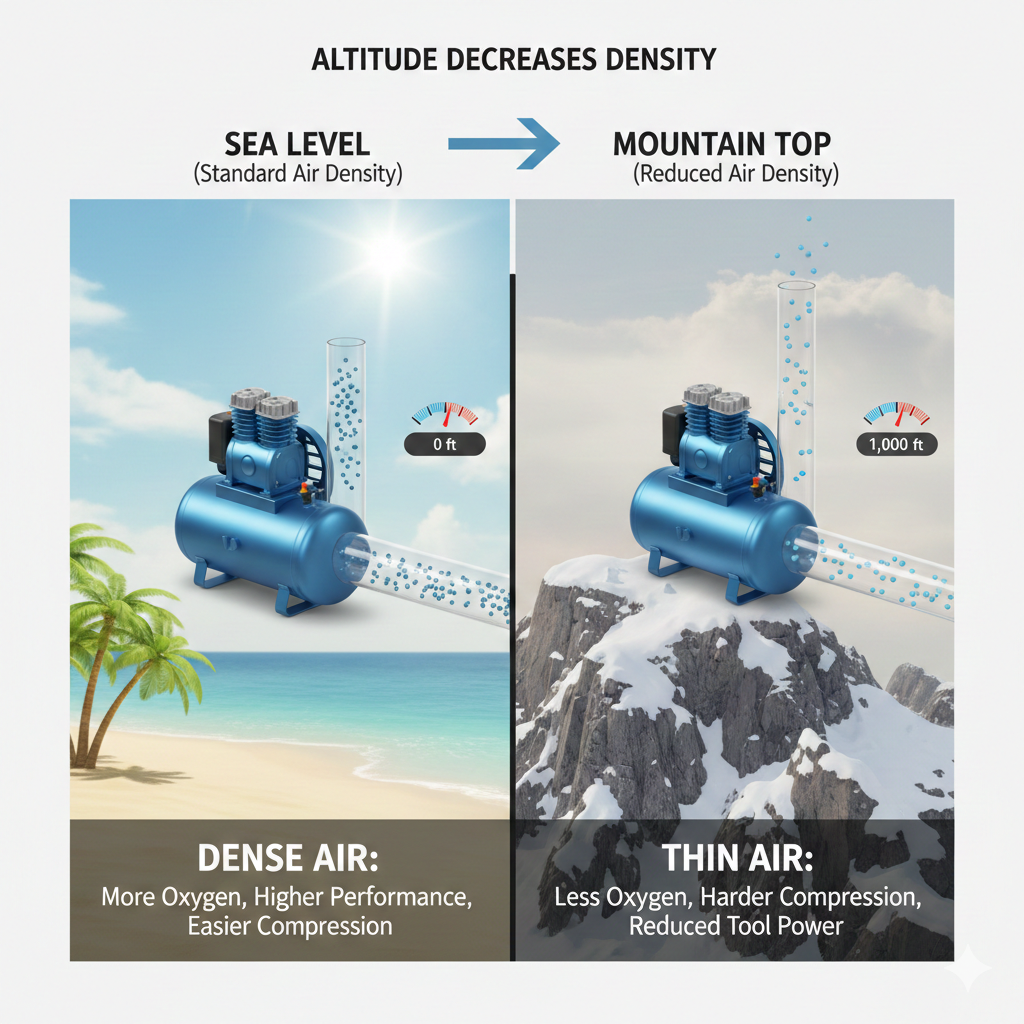

- SCFM (Standard Cubic Feet per Minute): This is the "real" number. It measures airflow under standard conditions (usually 68°F, 36% humidity, at sea level).

Pro Tip: Always look for the SCFM rating delivered at 90 PSI. This is the industry standard benchmark. If a brand only lists "CFM" without pressure context, they may be inflating their numbers.

Step-by-Step: How to Calculate Your Workshop CFM Requirements

Don't guess. Use this three-step formula to determine the exact size you need.

Step 1: Audit Your "Air Hungriest" Tools

You don't need a compressor that powers every tool at once you need one that powers your highest consumption tool. For most workshops, this is usually a sander, grinder, or sandblaster.

Step 2: The 1.5x Safety Rule

Manufacturers rate tools based on a "25% duty cycle" (meaning the tool is only triggered for 15 seconds out of every minute). But in a real workshop, you might sand a table for 5 minutes straight.

The Formula:

$$\text{Tool's Required CFM} \times 1.5 = \text{Minimum Compressor SCFM}$$

- Example: An orbital sander needs 6 CFM.

- Calculation: $6 \times 1.5 = 9 \text{ CFM}$.

- Result: You need a compressor that delivers at least 9 CFM @ 90 PSI.

Step 3: Multi-Tool Math (For Pros)

If you plan to run two tools simultaneously (e.g., you are spraying while a helper is sanding), add the CFM of both tools together and then apply the safety buffer.

Air Tool CFM Chart: Quick Reference Guide

Use this table to estimate your needs. Note that ratings are for continuous use at 90 PSI.

|

Air Tool Category |

Average CFM Required @ 90 PSI |

Compressor Class Needed |

|

Brad / Finish Nailer |

0.3 – 1.5 CFM |

Portable / Pancake |

|

Impact Wrench (1/2") |

4.0 – 5.0 CFM |

DIY Stationary |

|

Air Ratchet |

4.0 – 6.0 CFM |

DIY Stationary |

|

Spray Gun (HVLP) |

6.0 – 12.0 CFM |

Professional Stationary |

|

DA Sander / Orbiter |

8.0 – 12.0 CFM |

Professional High-Flow |

|

Die Grinder |

10.0 – 14.0 CFM |

Industrial 2-Stage |

|

Sandblaster |

15.0 – 25.0+ CFM |

Industrial Rotary Screw |

Does Tank Size Affect CFM?

This is a common misconception. A larger tank does not create more air.

- The Pump produces the CFM (the rate of flow).

- The Tank stores the air (the battery).

If your pump produces 5 CFM but your tool uses 10 CFM, a larger tank will only buy you a few extra seconds of runtime before the pressure drops and you have to stop and wait.

When to prioritize tank size:

- Intermittent bursts: If you only use an impact wrench for 3 seconds to remove a lug nut, a large tank allows you to use a smaller pump.

- Buffering: A large tank (60-80 gallons) helps cool the air and remove moisture before it hits your tools.

Frequently Asked Questions (FAQs)

Can I run a sander on a 6 CFM compressor?

Answer: Barely. Most Dual Action (DA) sanders require 10-12 CFM for continuous operation. A 6 CFM compressor will run the sander for about 30-60 seconds before the pressure drops below 90 PSI, forcing you to stop and wait for the tank to refill. For sanding, aim for a compressor with at least 10 SCFM.

Is higher CFM always better?

Answer: Yes, but it costs more. A higher CFM rating means the compressor pump is larger and works less to keep up with demand. This leads to cooler running temperatures, less moisture in the lines, and a longer lifespan for the motor. However, high CFM units often require 220V power.

How do I convert L/min to CFM?

Answer: Many imported compressors list Liters per Minute (L/min). To convert to CFM, divide the L/min rating by 28.3.

- Example: $280 \text{ L/min} \div 28.3 = 9.9 \text{ CFM}$.

What is the maximum CFM I can get from a standard 110V outlet?

Answer: generally, the limit is 5 to 6 CFM @ 90 PSI. A standard household outlet (110V/120V) is limited by amperage (usually 15 or 20 Amps).

- 15-Amp Circuit: Can support a motor up to ~1.5 - 2 HP, producing roughly 4.0 – 5.0 CFM.

- 20-Amp Circuit: Can support slightly larger motors, topping out around 5.5 – 6.5 CFM. Authority Note: If you see a 110V compressor claiming 10+ CFM, be very skeptical. To achieve true high-volume airflow (10+ CFM), you almost always need a 220V power source to drive the larger motor required.

Do I need a Single-Stage or Two-Stage compressor for high CFM?

Answer: It depends on whether you need volume or pressure.

- Single-Stage: Best for most woodworking and spray painting. They are excellent at producing high CFM at lower pressures (below 100 PSI).

- Two-Stage: Essential for heavy-duty automotive work. They compress air twice, allowing for higher pressures (175 PSI+).

- Verdict: If you just need CFM for sanding or spraying (which happens at 90 PSI), a high-quality Single-Stage unit is often more cost-effective. If you need high pressure and high volume for heavy truck tires or industrial machinery, buy a Two-Stage.

Can I connect two smaller compressors to double my CFM?

Answer: Yes. This is a common workshop "hack" known as daisy-chaining. If you connect two compressors into the same air line, their CFM output is additive, but the pressure (PSI) stays the same.

- Example: Compressor A (4 CFM) + Compressor B (4 CFM) = 8 Total CFM. Safety Requirement: Ensure both compressors are set to similar cut-in/cut-out pressures and use check valves to prevent backflow. This is a great way to run high-consumption tools like sandblasters without buying a massive industrial unit.

Related Articles:

1. How to Choose the Right Size Air Compressor for Your Pneumatic Tools

2. Maximizing Performance: How to Choose the Right Air Compressor for Your Impact Wrench

3. 10 Essential Air Compressor Maintenance Tips to Maximize Performance

4. Air Compressors: Types, Uses, Selection Tips and Understanding the Power Behind Air Tools

5. Enhancing Air Compressor Efficiency: The Ultimate Guide to Motor Optimization

Conclusion

Choosing the right air compressor doesn't have to be a gamble. By shifting your focus from marketing hype (HP) to the empirical data of CFM, you gain the power to select a machine that perfectly matches your workflow.

The most important specification you can remember is the SCFM at 90 PSI. This single number is the true indicator of continuous air delivery, not the confusing CFM ratings often found on the box. Always apply the 1.5x safety buffer to your most demanding tool to ensure smooth operation, a vital step often overlooked in generic air compressor sizing chart guides.

Whether you are looking for the best air compressor for home workshop use perfect for simple nailing and tire inflation or if your projects demand constant high volume, like meeting the high cfm requirements for spray painting, your research must be led by volume. Understanding the difference between a single-stage vs. two-stage compressor ensures you invest in efficiency, not just noise.

Don't buy a machine that disappoints when the pressure drops; buy one that powers your success. Use this guide to shop with authority, confidence, and clarity.

You now possess the authoritative knowledge to cut through manufacturer marketing and select the machine that truly delivers. Don't waste money on an underpowered compressor.

Visit Tendsupplies.com today to browse our expertly curated selection of air compressors, all clearly rated by their verified SCFM at 90 PSI. Find the perfect single-stage or two-stage machine built to meet your specific needs.

If you are still calculating your multi-tool CFM or need advice on upgrading your voltage, don't hesitate to reach out. Email our air tool specialists directly for expert, technical consultation:sales@tendsupplies.com.