How to Maintain and Clean Your Socket Sets for Longevity

Every mechanic or serious DIYer has a tool ghost story, the time a critical repair stalled because a favorite deep-well socket was seized solid with rust, or the trusted ratchet mechanism choked on accumulated grit, slipping and failing at maximum torque. That moment of frustration and lost time is the stark reminder of why neglecting your gear is simply not an option. Your socket set is an investment in precision and strength; its performance directly impacts the safety and efficiency of your work. This is exactly why mastering the techniques outlined in How to Maintain and Clean Your Socket Sets for Longevity is the best defense against premature tool failure and the expensive cycle of rust damage. Following a routine cleaning and storage regimen will ensure your tools are always ready to deliver maximum torque reliably.

Quick Answer

The best way to maintain and clean your socket sets for longevity involves a three-step process: Degreasing, Rust Removal, and Protection. First, soak and scrub all sockets with a strong degreaser to remove surface contaminants. Second, treat rust using white vinegar or a dedicated rust removal solution, focusing on neutralizing the acid afterward. Third, apply a thin coat of light machine oil to all metal components (especially impact sockets) and lubricate the internal ratchet mechanism sparingly before storing the entire set in a climate-controlled, organized container with desiccant packs to mitigate humidity.

Key Takeaways:

-

Rust is the primary enemy: Remove rust promptly and never use abrasive sandpaper on chrome.

-

Ratchets need special care: Disassemble, clean, and apply minimal grease to avoid dirt buildup.

-

Apply a protective barrier: Oil, wax, or VCI coatings prevent oxidation.

-

Control storage environment: Use silica packs, climate-controlled drawers, and socket organizers.

-

Degrease first: Rust removal is ineffective on oily surfaces.

Why Routine Socket Maintenance Matters

Ignoring tool maintenance doesn't just look bad; it costs you money and safety.

- Slippage Risks: Grease buildup can cause the socket to slip off the fastener, leading to rounded bolt heads or hand injuries.

- Rust Corrosion: Oxidation eats away at the metal, weakening the structural integrity of the socket walls.

- Ratchet Failure: Dirt inside your ratchet mechanism can cause the gears to skip or seize when you need torque the most.

Essential Supplies for Tool Cleaning

Before you begin, gather the right materials. You don't need expensive equipment; mostly household items will do the trick for a DIY tool cleaning kit.

- Degreaser: A commercial engine degreaser or strong dish soap.

- Rust Remover: White vinegar (budget-friendly) or a dedicated solution like Evapo-Rust.

- Mechanical Agitation: Brass wire brushes (softer than steel to protect chrome) and steel wool (Grade #0000).

- Lubrication: Light machine oil (like 3-in-One) or a dry lubricant spray.

- Microfiber Towels: For lint-free drying.

Step-by-Step: Deep Cleaning Your Socket Set

1. The Initial Degrease

If your sockets are covered in oil or road grime, rust removers won't work effectively.

- Fill a bucket with hot water and a strong degreasing detergent.

- Soak the sockets (remove them from the rail/case) for 15–30 minutes.

- Scrub them with a stiff nylon brush to remove surface sludge.

- Rinse thoroughly and dry immediately.

2. How to Remove Rust from Chrome Sockets

Rust is the enemy of longevity. For light to medium rust, use the vinegar soak method:

- Submerge: Place rusty sockets in a container of plain white vinegar.

- Wait: Let them sit for 12 to 24 hours. You will see bubbles rising as the acid reacts with the oxide.

- Scrub: Remove the sockets and scrub with a brass wire brush or aluminum foil dipped in water. The rust should wipe away easily.

- Neutralize: Rinse with water and baking soda to stop the acidic reaction.

Pro Tip: Never use heavy-grit sandpaper on chrome sockets. Scratches in the chrome plating allow moisture to penetrate the steel underneath, accelerating future rust.

3. Cleaning the Ratchet Mechanism

The ratchet handle is the heart of your set.

- External: Clean the handle as you would the sockets.

- Internal: If your ratchet is serviceable (has screws or a snap ring), open the faceplate carefully.

- Flush: Use a brake cleaner spray to blast out old, hardened grease and metal shavings.

- Relube: Apply a small amount of fresh dielectric grease or Super Lube. Do not overpack it; too much grease attracts dirt and causes the pawls to stick.

Protection: Lubricating and Rust-Proofing

Once your tools are clean and dry, you must create a barrier against moisture. This is especially vital for impact sockets, which usually have a black oxide finish that is more porous than chrome.

- Chrome Sockets: Wipe them down with a rag lightly dampened with light machine oil or WD-40. Buff off the excess so they aren't slippery.

- Impact Sockets: These benefit from a heavier oil coating. Some mechanics use a paste wax for long-term storage, which provides a dry, hard shell against moisture.

- Silica Gel Packets: Throw a few of these into your toolbox drawers to absorb ambient moisture.

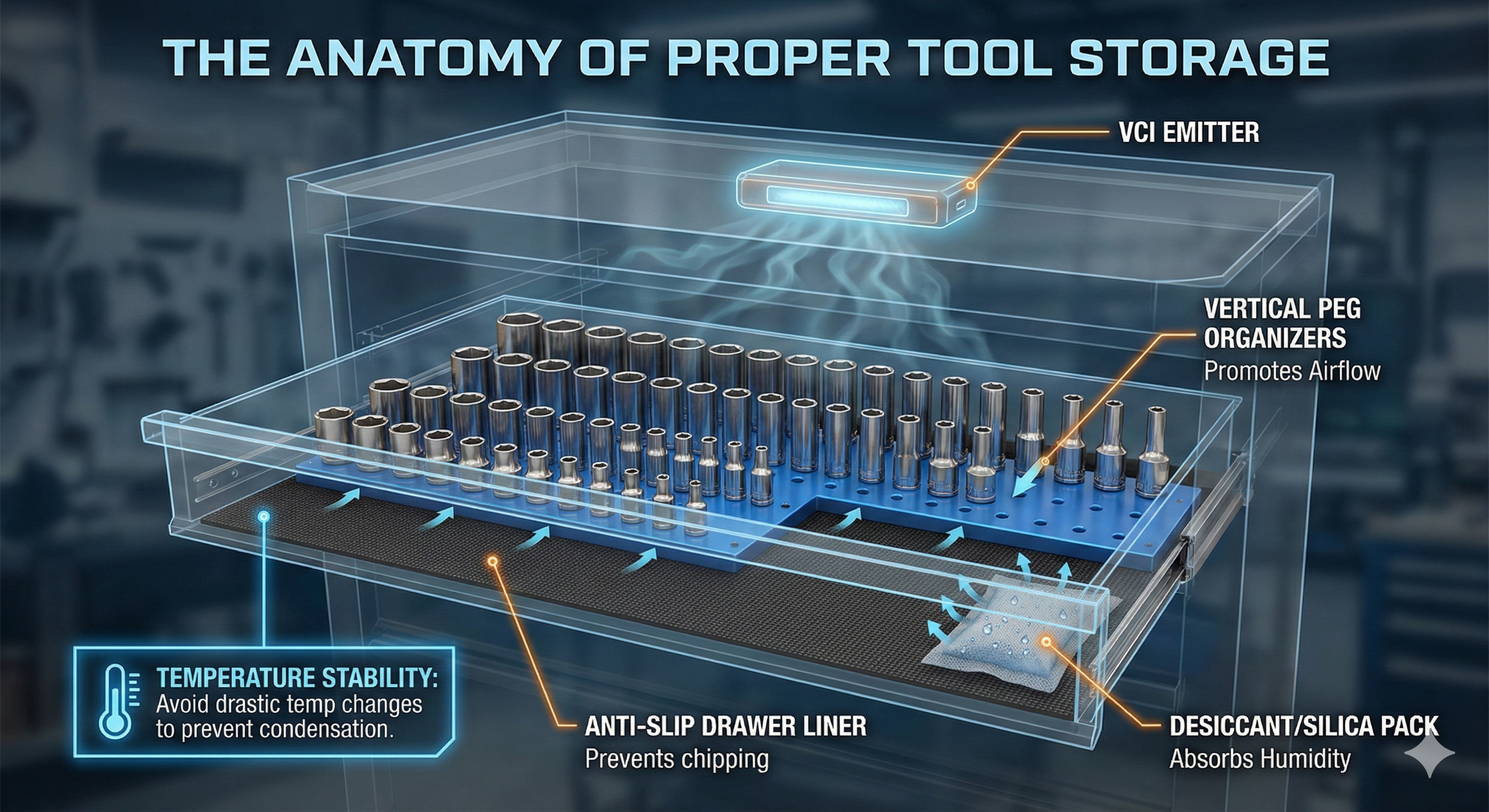

Proper Storage Solutions for Longevity

How you store your tools is just as important as how you clean them. Tossing sockets loosely into a bucket causes them to bang together, chipping the chrome plating.

Socket Organizers and Rails

Investing in a socket rail system or a foam tray organizer keeps tools separated and upright. This allows airflow around the tool, preventing moisture from getting trapped between the socket and the drawer mat.

Climate Control

If you live in a high-humidity area (like Florida or Southeast Asia) or a region with salt air:

- Use Vapor Corrosion Inhibitors (VCI) within your toolbox. These emitters release an invisible vapor that coats metal surfaces and prevents oxidation.

- Avoid storing tools in cardboard boxes, as cardboard absorbs and holds moisture against the metal.

When Should You Replace a Socket?

Even with the best maintenance, tools wear out. Replace a socket if:

- Cracks appear: Usually found at the corners of the drive end. These are safety hazards that can shatter under load.

- Rounded Internal Corners: If the socket no longer grips the flat sides of a bolt but turns on the corners, it will strip your fasteners.

- Loose Fit: If the socket wobbles excessively on the ratchet anvil.

Frequently Asked Questions (FAQs)

1. What is the most effective DIY method for removing light rust from chrome sockets?

The most reliable DIY solution is a white vinegar soak. Submerge the rusted sockets for 12 to 24 hours. The acetic acid will dissolve the oxidation. Authority Tip: Immediately rinse the tools with a baking soda and water solution after scrubbing to neutralize the acid, preventing further corrosion.

2. How do I properly lubricate the internal mechanism of a professional ratchet handle?

Ratchet lubrication requires precision. Never over-grease.

- Flush: Open the faceplate and use a specialized degreaser (like brake cleaner) to flush out old lubricant and debris.

- Re-lube: Apply a minimal amount of high-quality dielectric grease or light machine oil directly onto the pawls and gears. Excess grease attracts dirt and causes the mechanism to seize.

3. Do impact (black oxide) sockets require different maintenance than standard chrome sockets?

Yes, significantly. Chrome sockets rely on plating for protection, but impact (black oxide) sockets have a porous finish. They require a heavier protective coating. Wipe them down with a thin layer of machine oil or a paste wax after every cleaning to create a barrier against moisture, as they are highly susceptible to flash rust.

4. How often should a socket set be deep-cleaned and lubricated?

A complete deep cleaning and lubrication should be performed at least every six months for tools in constant use. However, you must clean and dry them immediately after any exposure to high humidity, salty air (coastal environments), or corrosive chemicals.

5. What are the key elements for long-term, rust-free tool storage?

The three key elements are Organization, Airflow, and Climate Control.

- Store sockets vertically on rails or in foam trays.

- Use a Vapor Corrosion Inhibitor (VCI) emitter or silica gel packs inside your toolbox or drawers to actively mitigate ambient humidity.

6. What kind of lubricant is best for general socket set protection?

Use a light machine oil (such as 3-in-One oil) or a specialized dry lubricant spray. Apply it to a cloth and buff the sockets until they are protected but not slippery. Avoid heavy, thick grease, which will attract and trap abrasive grit.

7. What should I avoid using to clean or scrub my valuable socket sets?

Avoid using highly abrasive materials like coarse sandpaper or aggressive wire brushes on chrome sockets, as they will scratch the protective plating and accelerate rust formation. Also, avoid using flammable liquids like gasoline to clean the internal ratchet mechanisms.

Related Articles:

6 BEST Socket Set Brands: Which Are Worth the Money in 2025

Enhance Safety and Productivity: Impact Socket Essentials for Industrial Applications

How a Drain Plug Socket Set Makes Oil Changes Faster & Cleaner

Vevor 3/4" Drive Socket Set Review & Specs (Heavy Duty Impact)

Conclusion

We've covered the crucial steps necessary to protect your valuable tool investment, from initial deep degreasing to securing your hardware against the silent killers of moisture and grime. Mastering the techniques for the best way to clean rusty sockets and implementing proper ratchet maintenance are not complicated tasks, they are simple, recurring steps that drastically extend the life of your equipment.

Ultimately, preventing rust on professional tools is far cheaper and less frustrating than constantly replacing seized or failing items. By committing to routine cleaning and utilizing climate-controlled storage solutions, you ensure that when you reach into your toolbox, every single piece, from the smallest hex driver to the heaviest impact socket, is ready to deliver reliable, safe performance for decades to come. Your clean, well-maintained tools are a testament to your professionalism and attention to detail.

Are your sockets beyond saving, or do you need the high-quality cleaning supplies mentioned in this guide? Don't settle for tools that let you down!

Visit Tendsupplies.com today to browse our full selection of premium-grade socket sets, professional-grade degreasers, and climate-control storage solutions engineered for durability.

Need Advice on Upgrading Your Set? Our industrial tool experts are ready to assist. Contact our sales team directly for personalized recommendations and volume quotes:

Email Us: sales@tendsupplies.com