How to Use a Thermal Imaging Camera for Water Damage & Electrical Inspections (Rental Guide)

The maintenance call came in after hours: a building manager reported flickering lights on the third floor and a faint water stain spreading across the ceiling, yet no visible leaks or exposed wiring. Tearing open walls would mean downtime, dust, and unnecessary cost. Instead, the inspector reached for a thermal imaging camera and within minutes identified both a hidden moisture path and an overheating electrical connection. This real-world scenario highlights why non-destructive diagnostics matter, and it’s exactly what “How to Use a Thermal Imaging Camera for Water Damage & Electrical Inspections (Rental Guide)” is designed to help you master, accurate detection, faster decisions, and smarter use of rental equipment.

Quick Answer

To use a thermal imaging camera effectively, scan surfaces systematically to detect temperature differences that indicate moisture intrusion or electrical overheating. Renting a thermal imaging camera is ideal for short-term inspections, emergency diagnostics, or when advanced features are needed without the cost of ownership.

Key Takeaways:

- Thermal imaging cameras reveal hidden problems without invasive work, making them essential for detecting concealed water damage and electrical overheating.

- Using a thermal imaging camera correctly requires methodical scanning and verification, as thermal images show temperature differences, not moisture levels or faults directly.

- Renting a thermal imaging camera is ideal for short-term inspections and emergency diagnostics, providing access to advanced features without high upfront costs.

- Thermal imaging improves safety, accuracy, and documentation, especially for restoration projects, electrical inspections, and insurance reporting.

- Choosing the right thermal camera and following best practices ensures reliable results, helping professionals reduce repair time, prevent failures, and control project costs.

What Is a Thermal Imaging Camera?

A thermal imaging camera (infrared camera) detects surface temperature variations and converts them into visual heat maps. These cameras do not “see through walls,” but they reveal thermal anomalies that point to underlying issues.

Common Professional Uses

- Water damage detection behind walls and floors

- Electrical inspections for overheating components

- Preventive maintenance in commercial buildings

- Insurance and restoration documentation

Why Use a Thermal Imaging Camera for Water Damage Inspections?

Detect Hidden Moisture Early

Moisture causes evaporative cooling, creating colder thermal patterns that cameras can identify long before mold becomes visible.

Reduce Destructive Testing

Thermal scans pinpoint affected areas, minimizing unnecessary demolition.

Support Insurance & Restoration Reports

Thermal images provide visual proof of moisture paths and drying progress.

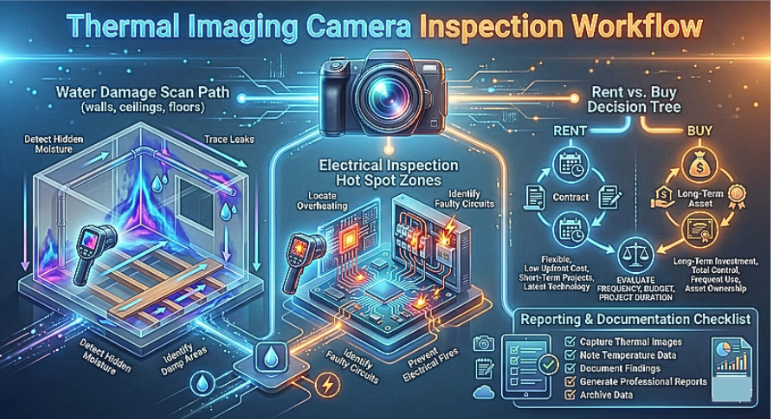

How to Use a Thermal Imaging Camera for Water Damage Detection

Step 1: Establish Baseline Conditions

Scan unaffected areas first to understand normal temperature patterns.

Step 2: Scan Methodically

Move the camera slowly across:

- Walls and ceilings

- Floors and baseboards

- Around plumbing fixtures and HVAC systems

Step 3: Identify Thermal Anomalies

Look for:

- Cold spots or irregular shapes

- Patterns following gravity or plumbing lines

Step 4: Verify with Moisture Meters

Thermal imaging indicates where to test, not moisture content itself.

Using a Thermal Imaging Camera for Electrical Inspections

Why Thermal Imaging Is Critical for Electrical Safety

Electrical resistance creates heat. Abnormal heat often signals:

- Loose connections

- Overloaded circuits

- Failing breakers or panels

How to Perform an Electrical Inspection with a Thermal Camera

Step 1: Inspect Under Load

Electrical systems must be energized and under normal operating load for accurate results.

Step 2: Scan Key Components

Focus on:

- Breaker panels

- Switchgear

- Transformers

- Motors and control panels

Step 3: Compare Similar Components

Temperature differences between identical breakers often reveal faults.

Step 4: Document Hot Spots

Capture thermal images for maintenance records and compliance reports.

Why Rent a Thermal Imaging Camera Instead of Buying?

Advantages of Renting

Lower Upfront Cost

Ideal for:

- One-off inspections

- Emergency water damage calls

- Small contractors and facility teams

Access to Advanced Technology

Rental units often include:

- Higher resolution sensors

- Adjustable emissivity settings

- Wi-Fi image sharing

No Maintenance or Calibration Hassle

Rental providers handle calibration, updates, and servicing.

When Buying Makes More Sense

- Daily or weekly inspections

- Large facility maintenance teams

- Specialized in-house diagnostics programs

Choosing the Right Thermal Imaging Camera (Rental Tips)

Key Features to Look For

- Resolution suitable for building diagnostics

- Temperature range appropriate for electrical systems

- Visual + thermal image overlay

- Easy image export for reports

Recommended Use Cases

- Water damage restoration professionals

- Electrical contractors and inspectors

- Facility managers and insurers

Global Compliance & Safety Considerations

Across regions, thermal imaging cameras support:

- Indoor building assessment standards

- Preventive electrical safety inspections

- Non-destructive testing best practices

While regulations vary globally, thermal inspections are widely recognized as a best practice for risk reduction and documentation.

Common Mistakes to Avoid When Using Thermal Cameras

- Scanning too quickly

- Ignoring surface materials and emissivity

- Using thermal images without verification tools

- Inspecting electrical systems without proper load

Using Thermal Imaging Cameras with Confidence

Learning how to use a thermal imaging camera for water damage and electrical inspections gives professionals a powerful, non-invasive diagnostic edge. For most contractors and facility teams, renting a thermal imaging camera offers the fastest, most cost-effective way to access advanced inspection capabilities without long-term commitment.

By combining proper scanning technique, verification tools, and clear documentation, thermal imaging helps detect problems earlier, reduce repair costs, and improve safety, whether you’re managing a single property or inspecting facilities worldwide.

Get professional-grade thermal imaging cameras delivered fast from Tendsupplies.com.

Frequently Asked Questions (FAQs)

- What is a thermal imaging camera and how does it work?

A thermal imaging camera detects infrared radiation and converts it into visible heat maps, revealing temperature differences on surfaces. It does not see through walls but identifies anomalies caused by water intrusion, electrical overheating, or insulation issues. - How can a thermal imaging camera help detect water damage?

Thermal cameras detect cooler areas caused by moisture evaporation, which appear as distinct thermal patterns. By scanning walls, ceilings, floors, and plumbing areas, inspectors can pinpoint hidden leaks without destructive testing. - Can thermal imaging cameras detect electrical problems safely?

Yes. Thermal imaging identifies hot spots, overloaded circuits, and failing components without physical contact. Electrical systems must be under normal load during inspection for accurate readings. - Should I rent or buy a thermal imaging camera for inspections?

Renting is ideal for short-term projects, emergency inspections, or infrequent use. Buying makes sense for daily or weekly inspections, large facility management, or companies needing long-term access to advanced thermal imaging features. - What are the common mistakes to avoid when using a thermal camera?

Common errors include scanning too quickly, ignoring surface emissivity differences, failing to verify anomalies with moisture meters or electrical tests, and inspecting systems without proper load or safety precautions. - How do I choose the right thermal imaging camera for water and electrical inspections?

Look for cameras with high resolution, appropriate temperature range, visual overlay capability, and multiple output ports. Ensure the model fits the type of inspection, whether for water damage detection, electrical safety, or building diagnostics.

Related Articles:

- Thermal Imaging Camera Rentals (Guide & Options)

- VEVOR Thermal Imaging Camera, 320 x 240 Pixels Super Resolution

- VEVOR SC240M Thermal Imaging Camera – 320x240 Super Resolution

- Industrial Equipment Rentals

- Measuring Tools and Equipment

Conclusion

Mastering “How to Use a Thermal Imaging Camera for Water Damage & Electrical Inspections (Rental Guide)” is a game-changer for restoration professionals, facility managers, and contractors. By detecting hidden moisture, identifying overheating electrical components, and documenting issues without invasive work, thermal imaging cameras improve inspection accuracy, safety, and project efficiency.

For most short-term or emergency jobs, renting a thermal imaging camera for inspections is cost-effective, giving access to advanced features without the burden of ownership. Meanwhile, companies conducting frequent or large-scale inspections may benefit from buying a professional thermal imaging camera for water damage and electrical detection.

By combining systematic scanning techniques, verification tools like moisture meters, and proper documentation practices, professionals can reduce repair costs, prevent failures, and maintain compliance with global building and electrical safety standards. Whether you choose to rent or own, following the guidance in “How to Use a Thermal Imaging Camera for Water Damage & Electrical Inspections (Rental Guide)” ensures faster, safer, and more accurate restoration and maintenance outcomes worldwide.

Ready to enhance your inspections and detect hidden issues faster with thermal imaging cameras? Whether you need to rent a thermal imaging camera for water damage or electrical inspections or are looking to purchase professional-grade thermal cameras for long-term use, Tendsupplies.com has the right solution for your project.

Visit Tendsupplies.com to explore our rental options, compare advanced thermal imaging cameras, and find expert guidance for your restoration and inspection needs.

Have questions or need personalized recommendations? Contact our specialists at sales@tendsupplies.com today for professional support tailored to your projects.