Insulated vs Standard Hand Tools for Electrical Work: Key Safety Differences You Should Know

One Saturday morning, Tom decided to replace a flickering ceiling light in his living room. Confident in his DIY skills, he reached for his regular pliers, thinking it was a quick fix. But the moment he touched the wire, a sudden jolt shot through his hand. Shaken but unharmed, Tom learned a lesson that many overlook: not all hand tools are safe for electrical work.

Electricity doesn’t forgive small mistakes, and using the wrong tool can turn a simple task into a life-threatening accident. That’s where insulated tools come in. Designed with non-conductive handles tested to withstand up to 1000 volts, these tools act as your first line of defense against electric shock. This dangerous incident highlights the single most critical difference in any electrician's arsenal.

If you’ve ever wondered whether insulated tools are worth it or what makes them different from standard hand tools, this guide, Insulated vs Standard Hand Tools for Electrical Work: Key Safety Differences You Should Know will help you make the safest choice. It is dedicated to ensuring you never experience that jolt. Working around live wires, even when the power is supposed to be off, demands certified protection. This crucial distinction isn't about aesthetics; it’s about the difference between a minor setback and a life-threatening accident.

Throughout this guide, we will clarify exactly when to use an insulated tool versus a standard one, eliminating dangerous guesswork. Ultimately, we’ll show you how choosing the right set, like the BILITOOLS 1000V Insulated Screwdriver & Pliers Set, is not just a purchase, it's an investment that can literally save your life. Whether you’re a homeowner handling light switches or a professional electrician, understanding the right tool for the job is the smartest safety move you can make.

Amazon Affiliate Disclosure:

Tend Supplies is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn fees by linking to Amazon.com and affiliated sites. As an Amazon Associate, we earn from qualifying purchases. We only recommend products we genuinely believe in, which helps us continue to create valuable content for our readers.

Key Takeaways:

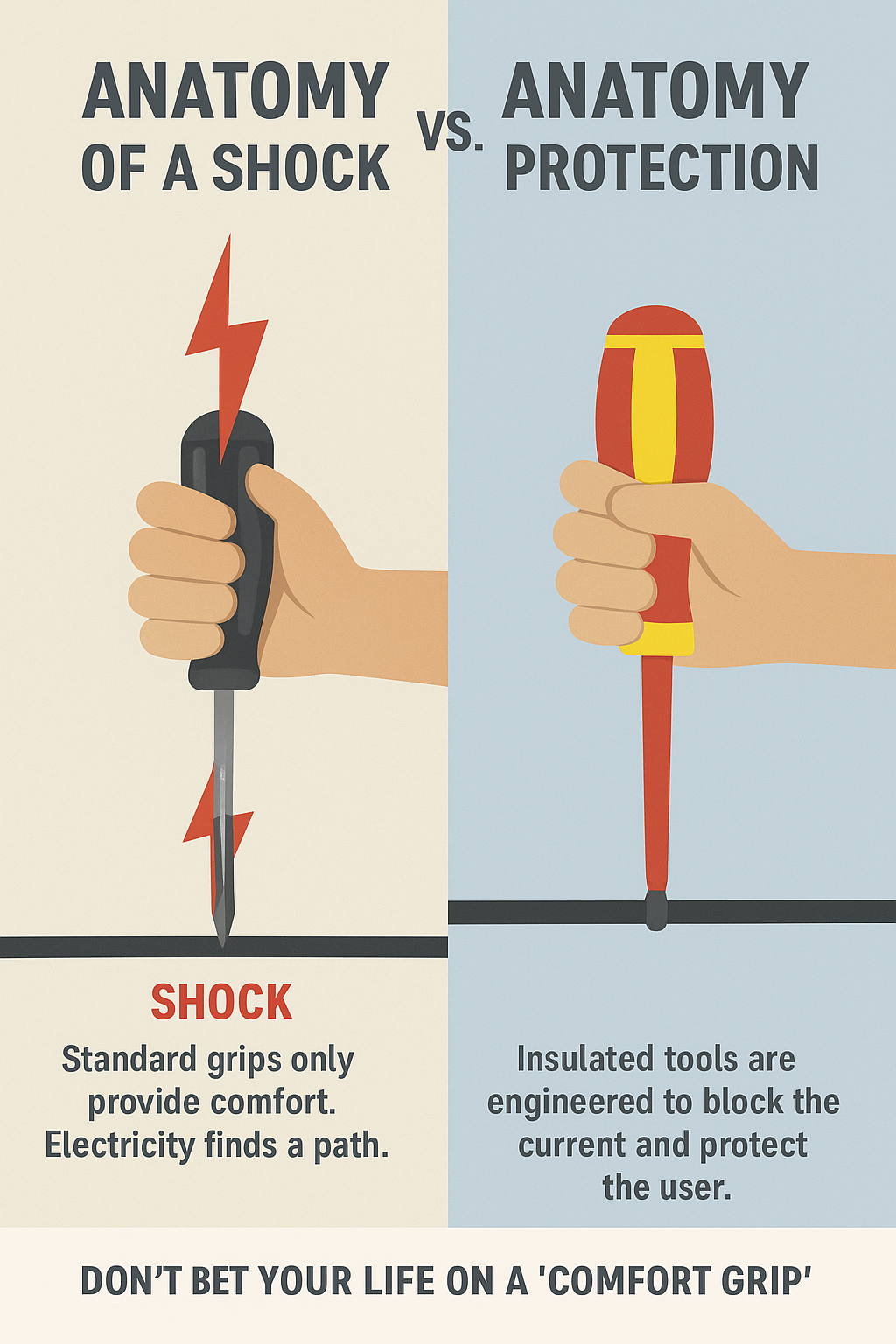

- Standard "Comfort Grips" Offer ZERO Protection: A standard rubber or plastic handle is designed only for grip and comfort, not electrical safety. It will not protect you from a live current.

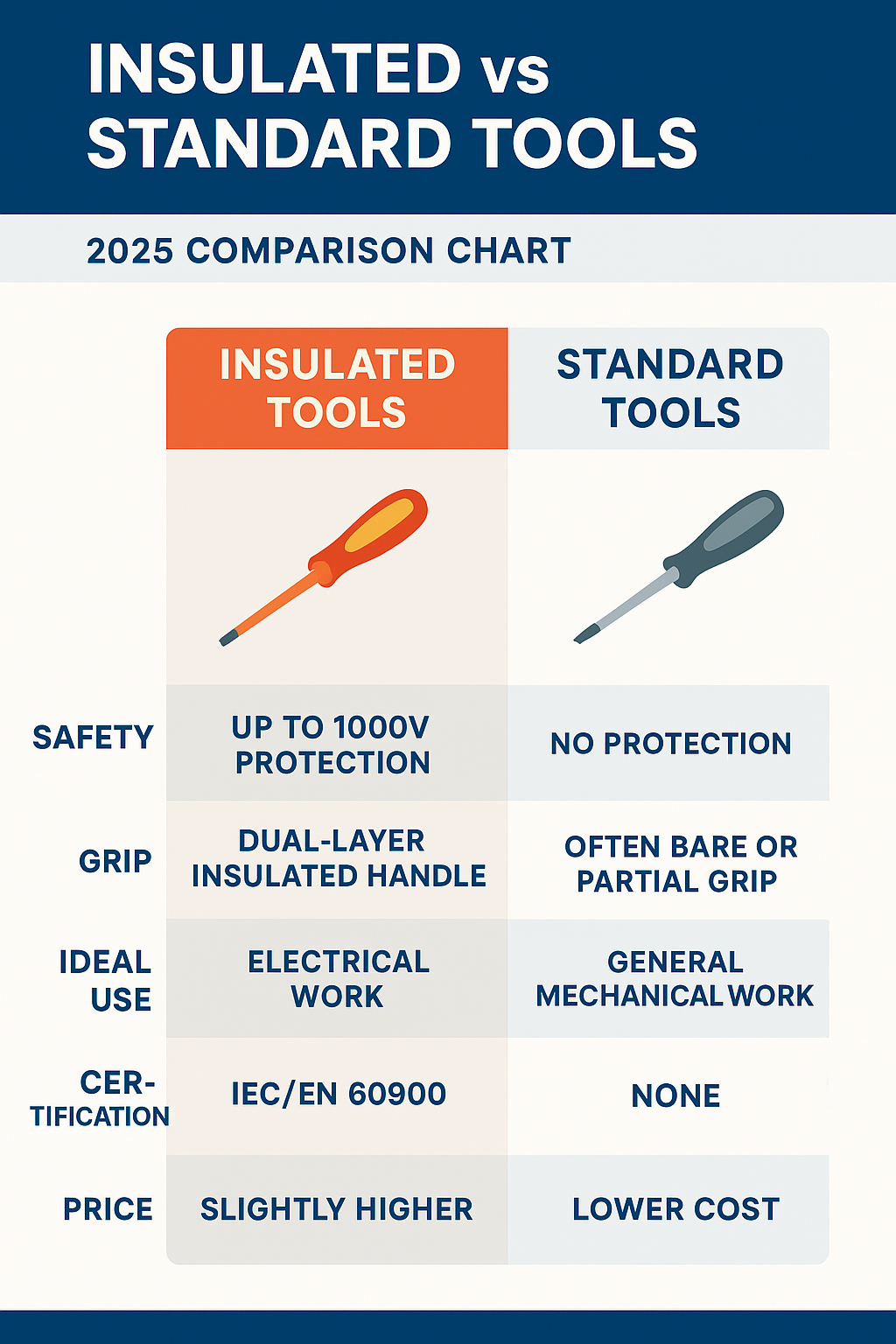

- Look for Official 1000V & IEC 60900/VDE Ratings: True insulated tools are certified. If a tool doesn't have the "1000V" rating and the official "double-triangle" (IEC 60900) or "VDE" mark, it is not safe for live electrical work.

- Insulated Tools Are Your "Last Line of Defense": The first rule is to always turn the power off and verify it with a voltage tester. Insulated tools are your non-negotiable "seatbelt" or backup in case a circuit is mislabeled or a mistake is made.

- "Low Voltage" is a Deadly Myth: Home voltages (110V/120V/240V) carry more than enough amperage to kill you. Never try to "insulate" a standard tool with electrical tape, this provides a false and fatal sense of security.

- Inspect Before Every Use: Your life depends on the tool's integrity. If an insulated tool has any cracks, deep nicks, or (if two-layered) the inner warning color is visible, STOP and discard the tool immediately.

What's the Real Difference? Standard vs. Insulated Tools

At a glance, a standard tool and an insulated tool might look similar. The difference isn't in the grip's comfort, but in its engineering.

Standard "Rubber-Grip" Tools: The Great Misconception

Almost every modern hand tool, from hammers to pliers, has a plastic, rubber, or dual-material grip.

- Their Purpose: These grips are designed for comfort, grip, and torque. They help you hold the tool securely and reduce hand fatigue.

- The Danger: They are NOT designed to protect you from electricity. The metal of the tool (e.g., the screwdriver shaft) runs all the way through the handle. If your hand slips, or if the voltage is high enough, a shock can easily pass through the thin grip, through your body, and to the ground. They offer zero-rated electrical protection.

Insulated Tools: Your Last Line of Defense

Insulated tools are purpose-built for one job: to protect you from electric shock if you make accidental contact with a live circuit.

- Their Purpose: They are engineered with multi-layered, non-conductive materials that are bonded directly to the tool's metal components. The insulation covers the entire tool except for the very tip.

- The Protection: This insulation system is designed to stop electrical current from flowing to your hand.

- Key Features:

- Flame-Retardant: The materials resist catching fire from an arc flash.

- Impact-Resistant: They are tested to withstand drops, even in cold temperatures, without cracking.

- Two-Layer Insulation (Often): Many high-quality insulated tools feature two layers of insulation in different colors (e.g., a red outer layer and a yellow inner layer). If you see the inner yellow layer, it means the tool is damaged and must be retired immediately.

Decoding Insulated Tool Ratings (What You MUST Look For)

This is the most critical part. Not all "insulated" tools are created equal. To be trusted, they must be officially tested and certified to international standards.

The "1000V" Rating: What Does It Really Mean?

You will see "1000V" or "1000V AC / 1500V DC" printed on all certified insulated tools.

- What it means: This is the maximum working voltage the tool is certified to protect you against. This covers residential and most commercial voltages worldwide (110V, 120V, 220V, 240V, 400V, etc.).

- What it doesn't mean: It doesn't mean the tool was only tested to 1000V. To get this rating, the tools are subjected to a much more rigorous test, typically, they are tested in a water bath at 10,000 volts to ensure there are absolutely no weak points.

Global Safety Standards: IEC 60900 and VDE

How do you know a tool is legitimate? According to IEC 60900, insulated tools must pass rigorous dielectric, flame, and adhesion tests to ensure electrical safety. Look for these symbols.

- IEC 60900: This is the key international standard. It's used globally (in Europe, Australia, Asia, and recognized in North America) and specifies the rigorous testing for insulated tools. This includes dielectric tests (the 10,000V test), cold-impact tests, flame-retardancy tests, and insulation-adhesion tests.

- The Double-Triangle Symbol (IEC): This is the official symbol (two triangles, one inside the other) that, along with the 1000V rating, confirms the tool is "suitable for live working."

- VDE (Verband der Elektrotechnik): You will often see a "VDE-GS" mark. This is a highly respected, independent German testing institute. VDE tools are certified to meet (and often exceed) the IEC 60900 standard. Seeing the VDE mark is widely considered a "gold standard" of quality and safety.

If a tool just looks insulated but lacks these official ratings (1000V, IEC 60900, or VDE), do not trust it with your life.

When to Use Insulated vs. Standard Tools (A Practical Guide)

So, do you need to throw out all your old tools? No. You just need to use the right tool for the right job.

Use Insulated Tools (Non-Negotiable) When...

- You are working on any circuit that is or might be live.

- You are replacing an outlet, light switch, or light fixture.

- You are working inside a breaker panel or junction box.

- You are working on or near high-voltage systems, like hybrid and electric vehicles (EVs), which use high-voltage DC power.

- You are in a situation where you cannot 100% guarantee the power is off (e.g., a complex building, a mislabeled panel).

Use Standard Tools When...

- You have 100% confirmed the power is off at the breaker and have verified it with a voltage tester.

- You are doing any non-electrical work (e.g., assembling furniture, general auto repair, plumbing).

- You are working on very low-voltage, de-energized electronics (like computer or hobbyist circuits).

Safety-First Policy: Many professionals adopt a "safety-first" rule: If the work is electrical, use insulated tools. Period. This eliminates the risk of human error, like forgetting to flip a breaker or testing the wrong wire.

Why Insulated Tools Are Non-Negotiable for Electrical Work

- Prevent electric shocks and burns.

- Comply with safety standards.

- Reduce tool slips from sweat or current discharge.

- Increase precision and comfort during extended use.

Common Myths and Fatal Mistakes

Let's clear up a few deadly myths about electrical tool safety.

- Myth 1: "I'll just wrap my standard screwdrivers in electrical tape."

- Reality: This is a fatal mistake. Electrical tape is not rated for this, can have tiny holes, rips easily, gets brittle, and creates a false, deadly sense of security.

- Myth 2: "I'm only working with 110V/120V (in North America), it's not that dangerous."

- Reality: It's not the voltage that kills you; it's the amperage (current). As little as 0.1 amps can send your heart into ventricular fibrillation. Your home's 110V/120V circuits operate at 15-20 amps—more than enough to kill you instantly.

- Myth 3: "I always turn the breaker off, so I don't need them."

- Reality: People make mistakes. Breakers are mislabeled. Someone else in the house might flip it back on. A "ghost" voltage might still be present. Insulated tools are your backup, your "seatbelt," for when the "brakes" (turning the power off) fail.

How to Care for Your Insulated Tools

Your life depends on these tools, so treat them that way.

- Inspect Before Every Use: Look for any cracks, nicks, or gouges in the insulation.

- Heed the Warning Layer: If your tool has two-color insulation, if you see the inner (e.g., yellow) color, STOP. The tool is compromised. Discard it.

- Keep Them Clean: Wipe off any dirt, grease, or solvents.

- Store Them Properly: Don't just throw them in a metal toolbox to rattle against sharp objects. Keep them in a dedicated tool roll or case to protect the insulation.

Pro Tips for Safe DIY Electrical Repairs

- Always turn off power at the breaker.

- Double-check with a non-contact voltage tester.

- Inspect your tools for cracks or wear.

- Keep hands dry and use insulated gloves.

- Store insulated tools separately from standard ones.

Frequently Asked Questions (FAQs)

- Are my regular screwdrivers with rubber handles safe for electrical work?

No. This is a common and dangerous misconception. The "comfort grips" on standard tools are made of plastic or rubber designed for ergonomics and grip, not electrical insulation. They offer no rated protection and will not stop a dangerous electric current from passing through you.

- What does the "1000V" rating on an insulated tool actually mean?

The 1000V (or 1000V AC / 1500V DC) is the maximum working voltage the tool is certified to protect you against. To earn this rating, the tools are put through a much more rigorous test, they are typically submerged in water and tested at 10,000 volts to ensure the insulation is free of any defects.

- What are VDE or IEC 60900 certifications, and do they matter?

They are the most important things to look for. IEC 60900 is the key international standard that proves a tool has passed rigorous safety tests (voltage, impact, flame-retardancy). VDE is a respected independent German testing institute that certifies tools to this standard. If a tool lacks these official marks, it should not be trusted for live electrical work.

- Do I really need insulated tools just to change a light switch or outlet at home?

Yes. While you should always turn the power off at the breaker first, people make mistakes. Breakers can be mislabeled, or someone else might unknowingly flip it back on. An insulated tool is your "seatbelt" it's a non-negotiable last line of defense that protects you from an unexpected shock.

- Can't I just wrap my standard metal tools in electrical tape?

Absolutely not. This is extremely dangerous. Electrical tape is not rated for insulation, tears easily, can have tiny pinholes, and becomes brittle over time. It provides a false and potentially fatal sense of security. There is no safe substitute for a properly manufactured and certified insulated tool.

- My insulated tool has two colors on the handle (e.g., red and yellow). What does that mean?

This is a critical safety feature. The outer layer (e.g., red) is the primary insulation. The inner layer (e.g., yellow) is a warning layer. If you see any of the inner yellow color showing through due to a cut, crack, or scrape, the tool's insulation is compromised and it must be retired immediately.

- How do I inspect and care for my insulated tools?

Inspect them before every single use. Look for any cracks, nicks, cuts, or gouges in the insulation. Keep them clean from dirt and solvents. Store them in a dedicated case or tool roll, not in a metal toolbox where they can be damaged by other sharp tools. Your life depends on the integrity of that insulation.

Related Articles:

- The DIY Guide to Safe Electrical Repairs: Why Insulated Electrician Screwdriver & Pliers Set Matter

- Top Hand Tool Sets for Every DIY Enthusiast

- The Resurgence of Hand Tools in the Age of Automation

- Introduction to Hand Tools: Definition, Importance, and Classifications

- Best Budget Tools 2025: Quality Tools That Won't Break the Bank

- Best Hand Tool Brands of 2025: A Complete Guide for Pros & DIYers

Conclusion

Ultimately, the choice between insulated and standard hand tools comes down to a simple, non-negotiable fact: you cannot see electricity, and a "comfort grip" offers zero protection. Relying on a standard rubber-handled tool for electrical work is a gamble you can't afford to take.

For any job involving a circuit, whether you're a professional electrician meeting OSHA and IEC safety standards or a homeowner tackling a DIY light switch, using the right protective gear is essential. This means investing in a high-quality, certified set of insulated tools.

Before you start any project, inspecting your insulated tools for damage is routine, and always look for the official 1000V and VDE/IEC 60900 ratings. These certifications are not marketing ploys; they are your proof of protection, backed by rigorous testing. A non-contact voltage tester will tell you if a circuit is live, but a VDE-certified screwdriver or plier set is the life-saving backup that protects you when the unexpected happens.

Call to Action

Ready to Prioritize Your Safety? Don't compromise your safety for the sake of a few dollars. Your life is the most valuable tool in your box.

Shop Safety Now at TendSupplies.com.

Have specific questions about compliance, bulk orders, or professional requirements? Reach out to our expert sales team today for personalized assistance and pricing.

Email us directly at sales@tendsupplies.com