Maximizing Performance: How to Choose the Right Air Compressor for Your Impact Wrench

Maximizing Performance: How to Choose the Right Air Compressor for Your Impact Wrench

The performance of an impact wrench isn’t solely determined by its internal mechanics—the quality and compatibility of its air supply is equally critical. Whether you’re a professional mechanic, a construction specialist, or a DIY enthusiast, choosing the right air compressor can be the difference between efficient, smooth operation and frustrating downtime. In this comprehensive guide, we explore the critical relationship between air compressors and impact wrenches, providing technical insights, detailed comparisons, and practical advice on maximizing performance.

This guide is an essential resource for anyone looking to optimize their tool performance. We cover key topics such as CFM, PSI, tank size, duty cycle, and maintenance considerations. We also offer actionable tips, an in-depth comparison table, six FAQs, five related articles for further reading, and a clear call to action for Tend Industrial Supplies.

Table of Contents

Introduction

Why the Right Air Compressor Matters

Key Technical Specifications

- CFM: Cubic Feet per Minute

- PSI: Pounds per Square Inch

- Tank Size and Duty Cycle

Matching Your Impact Wrench with an Air Compressor

Detailed Comparison Table

Maintenance and Durability Considerations

FAQs

Related Articles

Call to Action

Conclusion

Impact wrenches are prized for their ability to deliver rapid, high-torque bursts that loosen even the most stubborn fasteners. However, the performance of an impact wrench is intricately linked to the air compressor that powers it. If the compressor fails to meet the required air volume or pressure, even the most advanced impact wrench will underperform. In this guide, we’ll explain how to choose the right air compressor to maximize the efficiency, reliability, and lifespan of your impact wrench.

For those looking to build a comprehensive power tool setup, check out ourUltimate Guide to Choosing the Best Air Compressor for Your Home Garage in 2024 andHow to Choose the Perfect Air Compressor for Your Workshop for additional insights.

Why the Right Air Compressor Matters

An impact wrench’s performance heavily depends on receiving a consistent and sufficient supply of compressed air. A mismatch between your impact wrench and its air compressor can result in:

- Reduced Torque: Insufficient airflow may prevent the tool from reaching its full torque potential.

- Inconsistent Performance: Fluctuating pressure can lead to uneven impacts, which can affect both efficiency and precision.

- Increased Wear and Tear: Operating an impact wrench with inadequate air supply can strain the tool’s internal mechanisms, leading to premature wear.

- Downtime: Frequent interruptions for compressor adjustments or repairs can disrupt productivity.

By selecting an air compressor that is optimally matched to your impact wrench, you ensure peak performance, longevity, and reliability in your tool operations.

Key Technical Specifications

Understanding the technical specifications of both air compressors and impact wrenches is critical to maximizing performance. The most important factors to consider include:

CFM: Cubic Feet per Minute

CFM indicates the volume of air the compressor can deliver per minute. For an impact wrench to operate effectively, the compressor’s CFM must meet or exceed the tool’s requirements.

- Why It Matters: Higher CFM means a steady supply of air, allowing the impact wrench to maintain continuous, high-torque performance.

- Determining Your Needs: Check your impact wrench’s manual to determine its required CFM, then select an air compressor that provides at least 10-20% more than the minimum.

PSI: Pounds per Square Inch

PSI measures the pressure at which air is delivered. Most impact wrenches require a steady operating pressure—typically around 90-120 PSI.

- Why It Matters: Maintaining the correct PSI ensures that the impact wrench delivers the intended torque and impacts per minute.

- Balancing Act: Too low a PSI can lead to subpar performance, while too high a PSI can cause excessive wear.

Tank Size and Duty Cycle

- Tank Size: A larger tank allows for a longer runtime between compressor cycles, ensuring a consistent air supply during continuous operation.

- Duty Cycle: The duty cycle represents the amount of time a compressor can operate continuously before needing a cooldown period. A higher duty cycle is crucial for professional or heavy-duty applications.

For a more detailed discussion on compressor sizing, please visit our articleUnderstanding the Right Size of Air Compressor for Your Pneumatic Air Tools in 2024.

Matching Your Impact Wrench with an Air Compressor

The relationship between an impact wrench and its air compressor is symbiotic. To maximize performance:

-

Check the Impact Wrench Requirements:

Read the user manual for your impact wrench to determine the necessary CFM and PSI. High-torque wrenches, for instance, typically demand higher CFM. -

Select an Appropriately Sized Compressor:

Ensure that the compressor’s output consistently meets or exceeds your tool’s requirements. For example, if your impact wrench requires 5 CFM at 90 PSI, a compressor delivering 6 CFM would provide a healthy margin for efficiency. -

Consider the Duty Cycle:

If you’re using the impact wrench for extended periods, choose a compressor with a high duty cycle and larger tank to prevent frequent cycling and maintain consistent pressure. -

Portability vs. Stationary Use:

For home garages and light applications, a portable compressor may suffice. However, professional shops might benefit from a larger, stationary compressor that can handle continuous heavy use. -

Efficiency and Energy Consumption:

Look for energy-efficient models that not only meet the performance criteria but also reduce operational costs. For additional details on energy efficiency, refer to the Energy Star guidelines (anchor text: Energy Star guidelines for energy efficiency).

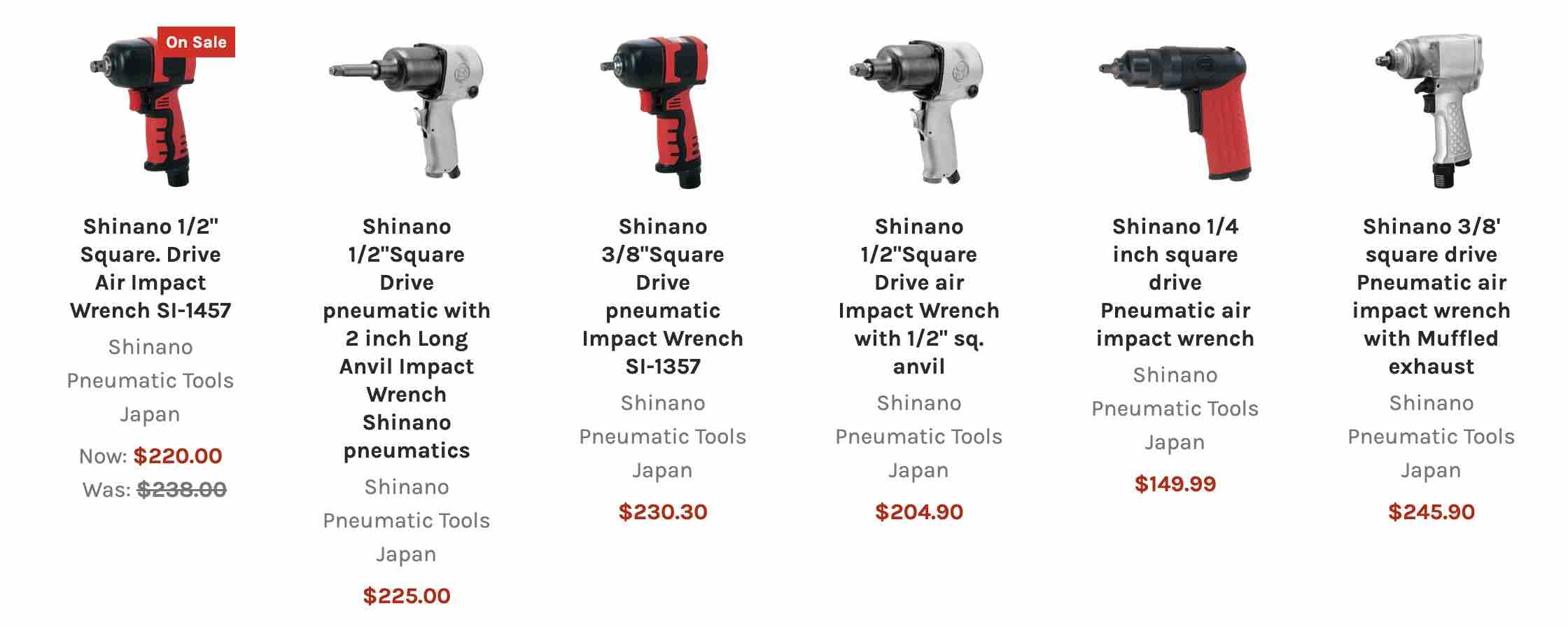

Search For Impact wrench in Tendsupplies.com

Maintenance, Durability, and Safety Considerations

Maintenance Tips

For Air Compressors:

- Regular Inspections: Routinely check hoses, fittings, and the compressor unit for leaks or wear.

- Drain Moisture: Drain the tank after each use to prevent rust and maintain efficiency.

- Lubrication: Follow the manufacturer’s guidelines for lubricating moving parts.

- Filter Replacement: Replace air filters periodically to ensure clean, dry air supply.

For Impact Wrenches:

- Clean After Use: Remove debris and dust to prevent internal wear.

- Check for Wear: Regularly inspect the impact mechanism and replace worn parts as necessary.

- Use Recommended Fluids: If applicable, use the correct lubricants for optimal performance.

Durability and Build Quality

- High-Quality Materials: Premium models—such as the Shinano Air Impact Wrench made in Japan—use high-grade components (e.g., titanium hammers, precision-engineered gears) that extend the tool’s life.

- Ergonomic Design: A well-designed tool reduces operator fatigue and increases productivity over long hours of use.

- Robust Construction: Tools built for heavy-duty environments are designed to withstand continuous use, minimizing downtime.

Safety Considerations

- Personal Protective Equipment (PPE): Always wear safety glasses, gloves, and hearing protection when operating power tools.

- Proper Operation: Follow the manufacturer’s instructions to avoid accidents, particularly when working with high torque.

- Ventilation: Ensure your workspace is well-ventilated, especially when using air compressors that generate heat.

- Electrical Safety: For electric-powered compressors or wrenches, regularly inspect cords and batteries to prevent electrical hazards.

Frequently Asked Questions (FAQs)

-

How does the compressor’s CFM affect my impact wrench’s performance?

A higher CFM ensures that your impact wrench receives a steady and sufficient air supply, maximizing torque output and efficiency. Always choose a compressor with at least 10-20% more CFM than your tool’s minimum requirement. -

What PSI should my air compressor deliver for optimal impact wrench performance?

Most impact wrenches are designed to operate between 90 and 120 PSI. It’s crucial to have a compressor that consistently maintains this pressure range for reliable performance. -

Why is tank size important when selecting an air compressor for an impact wrench?

A larger tank provides a more stable air supply during continuous operation, reducing the frequency of compressor cycling. This is especially important for heavy-duty or professional applications. -

What maintenance routines should I follow to keep my air compressor and impact wrench in top condition?

Regularly inspect your compressor for leaks, drain moisture from the tank, and replace filters as needed. For impact wrenches, clean after each use and inspect for wear, following manufacturer guidelines for lubrication and part replacement. -

Can I use a portable air compressor for my impact wrench in a home garage?

Yes, portable air compressors can be effective for home garages if they meet the necessary CFM and PSI requirements. However, for prolonged or heavy-duty use, a larger stationary compressor may be more efficient. -

Is the Shinano Air Impact Wrench really worth the investment?

Absolutely. Manufactured in Japan with precision engineering and high-quality materials, the Shinano Air Impact Wrench delivers superior torque, durability, and reliability, making it an excellent choice for professionals and serious DIYers.

Related Articles

For additional insights on power tools and air compressor selection, consider these related articles:

-

Ultimate Guide to Choosing the Best Air Compressor for Your Home Garage in 2024

Comprehensive insights into selecting an air compressor that meets your home garage needs. -

How to Choose the Perfect Air Compressor for Your Workshop

Detailed strategies for optimizing your workshop setup with the right compressor. -

Understanding the Right Size of Air Compressor for Your Pneumatic Air Tools in 2024

Guidance on matching air compressor specifications with your tool requirements. -

Top 10 Air Impact Wrenches of 2024: Reviews and Buyer’s Guide

A detailed review of the best air impact wrenches available this year. -

Quiet Air Compressors: The Best Options for Home Garages and Small Workshops

Explore compressor models with low noise levels ideal for residential use.

Call to Action

Maximize the performance of your impact wrench by ensuring you have the right air compressor to match its needs. Whether you’re a seasoned professional or a dedicated DIY enthusiast, Tend Industrial Supplies offers a range of high-quality air compressors designed to deliver consistent power, efficiency, and durability. VisitTend Industrial Supplies today to browse our premium selection of compressors and related power tools. For personalized advice or inquiries, please contact our expert team at sales@tendsupplies.com. Upgrade your workshop and experience the true potential of your impact wrench with a perfectly matched air compressor!

Amazon Affiliate Disclosure: Some links on this site are affiliate links, which means we may earn a small commission if you make a purchase, at no extra cost to you.