Maximizing Safety and Efficiency in Workshops: A Comprehensive Guide to Air Tools and LED Battery-Powered Worklights

A Comprehensive Guide to Air Tools and LED Battery-Powered Worklights

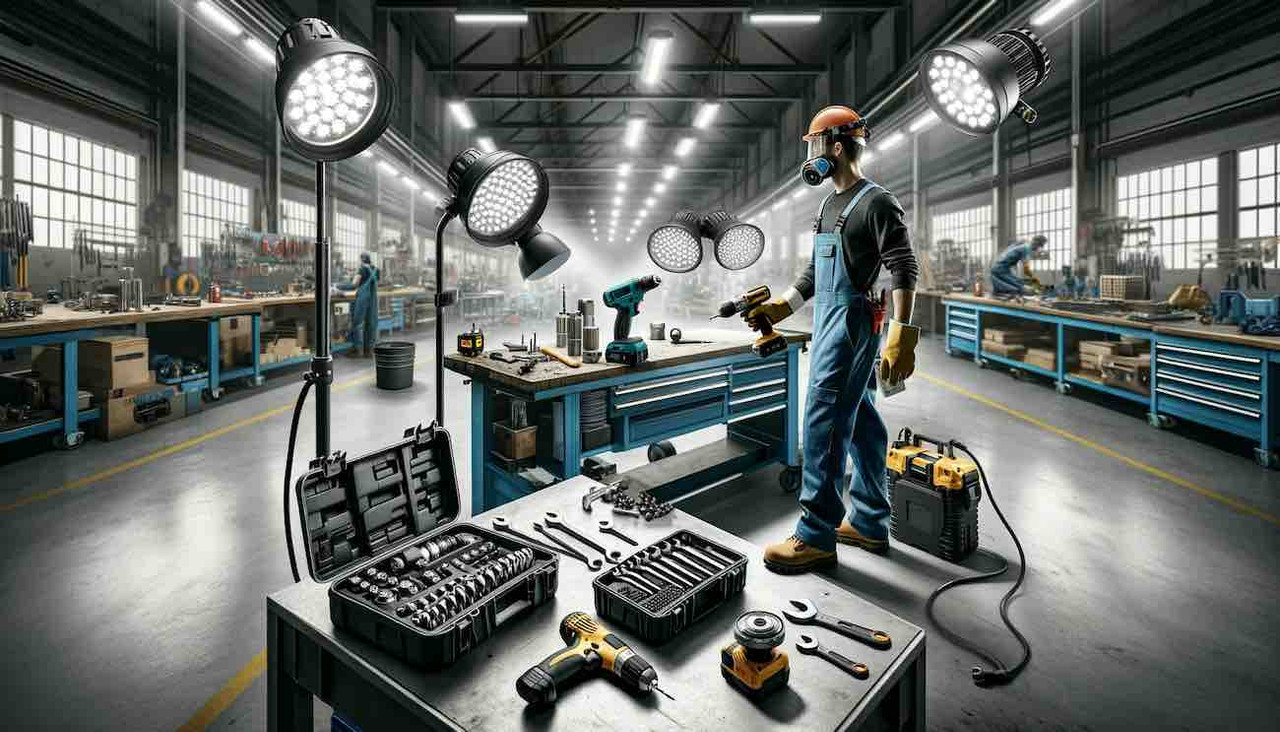

In the ever-evolving landscape of industrial workshops, the twin pillars of safety and efficiency stand as critical determinants of success. As technology advances, the tools and equipment used in these settings have also undergone significant transformations. Among these innovations, air tools and LED battery-powered worklights have emerged as indispensable components in modern workshops. They not only enhance the quality of work but also play a pivotal role in ensuring the safety and well-being of the workforce. This article delves into the evolution of these tools, their types and uses, and the best practices for their selection and maintenance.

The Evolution of Workshop Tools: From Manual to Pneumatic

The history of workshop tools is a testament to human ingenuity and the relentless pursuit of efficiency. Initially, manual tools dominated the workshop landscape, requiring significant physical effort and time. The advent of pneumatic technology, however, marked a paradigm shift. Air tools powered by compressed air offered a new realm of possibilities.

These tools brought with them a slew of advantages over their manual counterparts. Firstly, they reduced the physical strain on workers, directly impacting their health and productivity. Pneumatic tools also offer greater precision and control, crucial in tasks requiring meticulous attention to detail. Moreover, air tools are known for their durability and longevity, making them a cost-effective solution in the long run. They are less likely to overheat and are generally lighter, reducing the risk of fatigue-related errors.

Understanding Air Tools: Types, Uses, and Selection

Air tools come in various forms, each designed to fulfill specific requirements in a workshop setting. Common types include drills,wrenches, and grinders, each serving a unique purpose. Air drills, for instance, are favored for their precision and power, making them ideal for drilling through rigid materials. On the other hand, air wrenches are indispensable for tasks requiring high torque, such as loosening or tightening bolts. Grinders are used for cutting, grinding, and polishing surfaces, offering versatility that is unmatched by manual alternatives.

When selecting air tools, several factors must be considered to ensure they meet the specific needs of a task. The power and speed of the tool should align with the job's requirements. It’s also essential to consider the tool’s weight and ergonomic design, as these factors directly impact user comfort and safety. Additionally, the quality of construction is paramount. High-quality air tools perform better and have enhanced safety features and a longer lifespan.

Integrating air tools and LED battery-powered worklights in workshops is more than just keeping up with technological trends. It is a necessary step towards creating safer, more efficient, and productive work environments. The subsequent sections of this article will further explore the safe and effective use of these tools, shedding light on best practices and innovative applications in modern workshops.

Air Tool Safety: Best Practices and Protocols

Safety in the use of air tools is paramount. Adherence to detailed safety guidelines not only protects the users but also ensures the longevity of the tools themselves. Firstly, personal protective equipment such as goggles, gloves, and ear protection should always be used. It's essential to regularly inspect air tools for signs of wear or damage, particularly the hoses and connectors.

Maintenance is a crucial aspect of air tool safety. Regular lubrication, cleaning, and checking for air leaks can significantly extend the life of these tools while maintaining their performance and safety. Tools should be stored in a dry, clean environment to prevent rust and deterioration.

Common mistakes often stem from misuse or neglect. Overloading the tool beyond its capacity, ignoring maintenance schedules, or using inappropriate attachments can lead to accidents or tool failure. To avoid these pitfalls, users should be trained in adequately using and caring for the tools, and guidelines should be visibly posted in the workshop.

The Role of Lighting in Workshop Safety and Productivity

Adequate lighting is a critical but often overlooked aspect of workshop safety and productivity. Poor lighting can lead to accidents, errors, and strain on the eyes, affecting the overall well-being of the workforce. LED battery-powered worklights have revolutionized workshop lighting by providing bright, focused light that enhances visibility in detail-oriented tasks.

The advantages of using LED worklights are numerous. They are energy-efficient, reducing electricity costs and environmental impact. LED lights also have a longer lifespan than traditional bulbs, meaning less frequent replacements and maintenance. Furthermore, the battery-powered aspect offers mobility, allowing workers to quickly move the light source to where it's needed most without the constraints of cords.

Illuminating Safely: LED Battery-Powered Worklights Explained

LED worklights come in various forms, each suited to different applications. Some are designed for general ambient lighting, while others are meant for focused task lighting. Handheld models offer portability for tasks that require mobility, whereas stand-mounted lights provide steady illumination over a larger area.

The benefits of battery-powered models are particularly significant regarding safety and convenience. These lights eliminate the risk of tripping over cords and can be used in areas without easy access to power outlets. They are also typically designed with sturdy casings to withstand the rigors of a workshop environment.

Optimal Placement and Usage of LED Worklights

Strategic placement of worklights is crucial for maximizing their effectiveness. Task lights should be positioned to illuminate the work area without creating shadows or glare. For general lighting, lights should be evenly distributed to avoid dark spots in the workshop.

Safety tips for using and maintaining LED worklights include ensuring that they are securely placed to prevent them from falling, regularly checking the batteries and replacing them as needed, and cleaning the light covers to maintain optimal brightness. It's also important to select lights with appropriate brightness levels and color temperatures for the workshop's specific tasks and working conditions.

Integrating air tools and LED battery-powered worklights in workshops significantly contributes to these environments' safety, efficiency, and productivity. By adhering to best practices in their use and maintenance, workshops can achieve higher standards of operation and provide a safer, more comfortable working space for their employees.

Case Studies: Real-World Examples of Safe and Efficient Workshops

Exploring real-world applications provides invaluable insights into the practical benefits of air tools and LED worklights. For instance, a renowned automotive repair workshop significantly reduced operational hazards and improved efficiency by integrating advanced pneumatic tools and portable LED worklights. This shift resulted in a noticeable decrease in work-related injuries and increased productivity.

Another case study involves a woodworking shop that transitioned to exclusively using air-powered tools and battery-operated LED lighting. This move improved the precision and quality of their products and created a safer, more energy-efficient work environment. Key lessons from these cases highlight the importance of training staff in correctly using these tools, the benefits of regular maintenance, and the critical role of adequate lighting in reducing workplace accidents.

Future Trends in Workshop Tools and Lighting

Technological innovations are poised to shape the future of workshop tools and lighting. Innovative air tools with sensors for performance monitoring and predictive maintenance are on the horizon. These tools will provide real-time data to optimize their use and predict potential failures, thereby enhancing safety. In lighting, advancements in LED technology are expected to bring even more energy-efficient and durable solutions, possibly integrating solar charging capabilities and IoT connectivity for intelligent control.

Conclusion

This comprehensive exploration of air tools and LED battery-powered worklights underscores their crucial role in enhancing workshop safety and efficiency. The evolution from manual to pneumatic tools represents a significant leap in workshop practices, and the adoption of advanced lighting solutions further amplifies these benefits. As we look to the future, the continued advancement of these tools promises even more significant improvements in workshop environments.

Every workshop's priority should be creating a safe and efficient workspace. Embracing these modern tools is not just a matter of staying current with technological trends; it is a strategic move toward ensuring the well-being of workers and the productivity of operations.

For more information, including detailed product reviews, safety guidelines, and additional air tools and LED worklights resources, visitTend Industrial Supplies. Our team is dedicated to providing high-quality industrial supplies and expert advice to help you optimize your workshop's safety and efficiency. For personalized recommendations and inquiries, reach out to us at sales@tendsupplies.com.

In conclusion, integrating air tools and LED battery-powered worklights in your workshop is an investment in safety, quality, and efficiency. Explore Tend Industrial Supplies’ extensive range of products and resources to take the first step towards a safer, more productive workspace.