Rechargeable Light Bulbs: Why Some Fail Too Early

Why Some Rechargeable Light Bulbs Fail Too Early

The global rechargeable light market has experienced remarkable growth, reaching USD 10.3 billion in 2025 and is projected to expand to USD 17.3 billion by 2035, at a compound annual growth rate (CAGR) of 5.3%. Despite this impressive market expansion and the promise of long-lasting illumination, many consumers and businesses find themselves frustrated when their rechargeable light bulbs fail prematurely. Understanding the root causes of these early failures can save significant money and prevent unexpected lighting outages in critical situations.

Rechargeable light bulbs represent a significant advancement in lighting technology, combining the energy efficiency of LED technology with the convenience of battery backup power. However, when these sophisticated devices fail before their expected lifespan, the consequences extend beyond mere inconvenience. In industrial settings, emergency lighting failures can compromise safety protocols, while in residential applications, premature bulb failure undermines the cost-effectiveness that initially justified the investment.

As an Amazon Associate, we earn from qualifying purchases

Key Takeaways

•Battery degradation accounts for 60% of premature failures in rechargeable light bulbs, often caused by poor charging practices and environmental factors.

•Heat damage significantly reduces lifespan, with temperatures above 85°F accelerating component failure by up to 50%

•Power quality issues, including voltage fluctuations and surges can destroy internal electronics within seconds

•Proper installation and maintenance can extend bulb life by 200-300% compared to neglected units

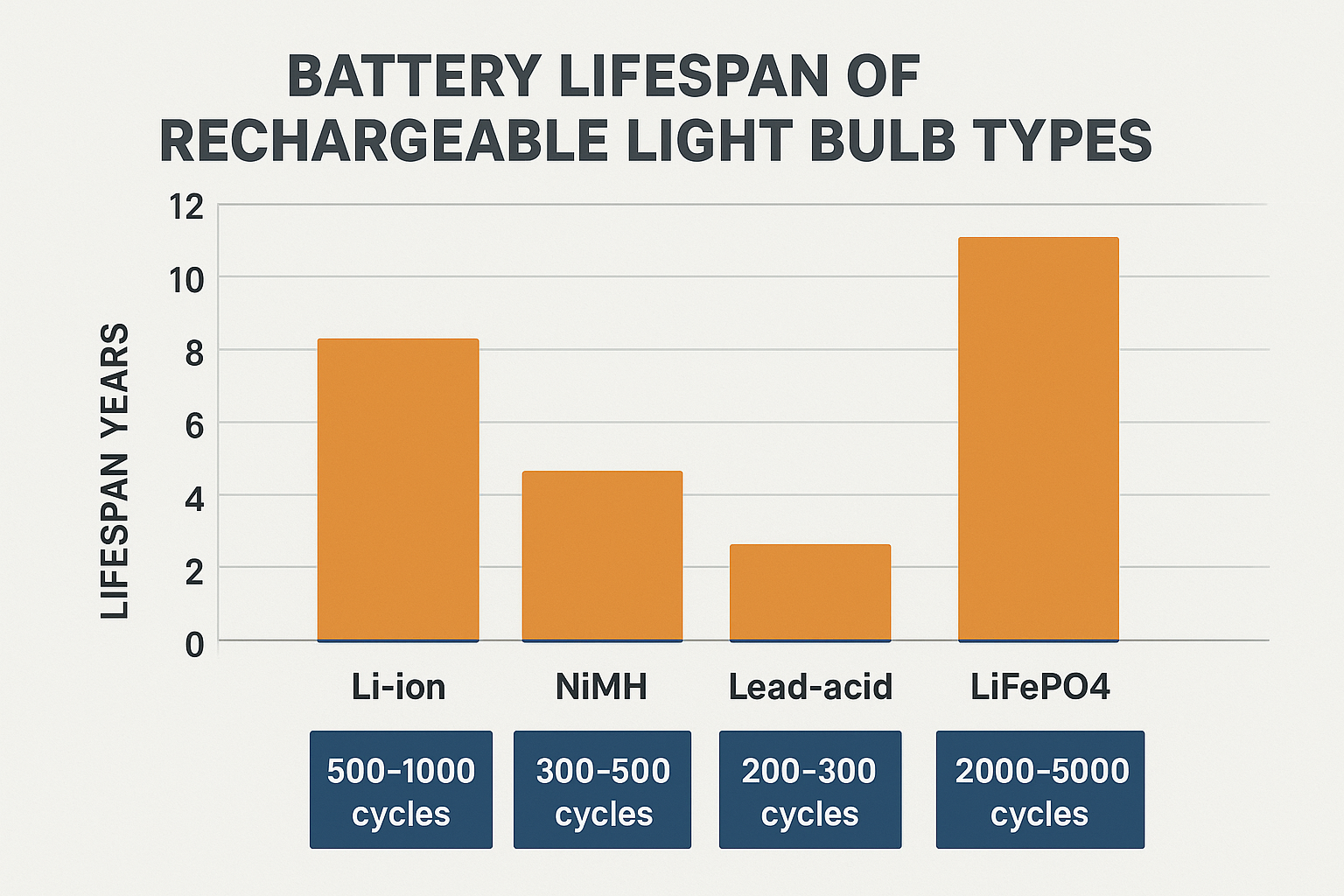

•Quality differences between battery types create dramatic variations in expected lifespan, from 2-3 years for lead-acid to 8-12 years for LiFePO4 technology

Understanding the Anatomy of Failure

Rechargeable light bulbs are complex systems that integrate multiple technologies within a single housing. Unlike traditional incandescent or even standard LED bulbs, these devices contain LED arrays, battery management systems, charging circuits, power conversion electronics, and emergency detection mechanisms. Each component represents a potential failure point, and the interaction between these systems creates additional complexity that can lead to unexpected breakdowns.

The sophistication of modern rechargeable bulbs means that failure rarely stems from a single cause. Instead, cascading failures often occur when one component's degradation places additional stress on other systems. For example, a failing battery may cause the charging circuit to work harder, generating excess heat that accelerates the degradation of LED components and power management electronics.

The Critical Role of Battery Management

Battery management systems in rechargeable bulbs must perform multiple functions simultaneously. They monitor charge levels, regulate charging current, prevent overcharging, manage discharge rates, and detect power outages. When these systems malfunction, the consequences ripple throughout the entire device. Poor battery management can lead to thermal runaway in lithium-ion cells, sulfation in lead-acid batteries, or memory effects in older nickel-cadmium systems.

Primary Causes of Premature Failure

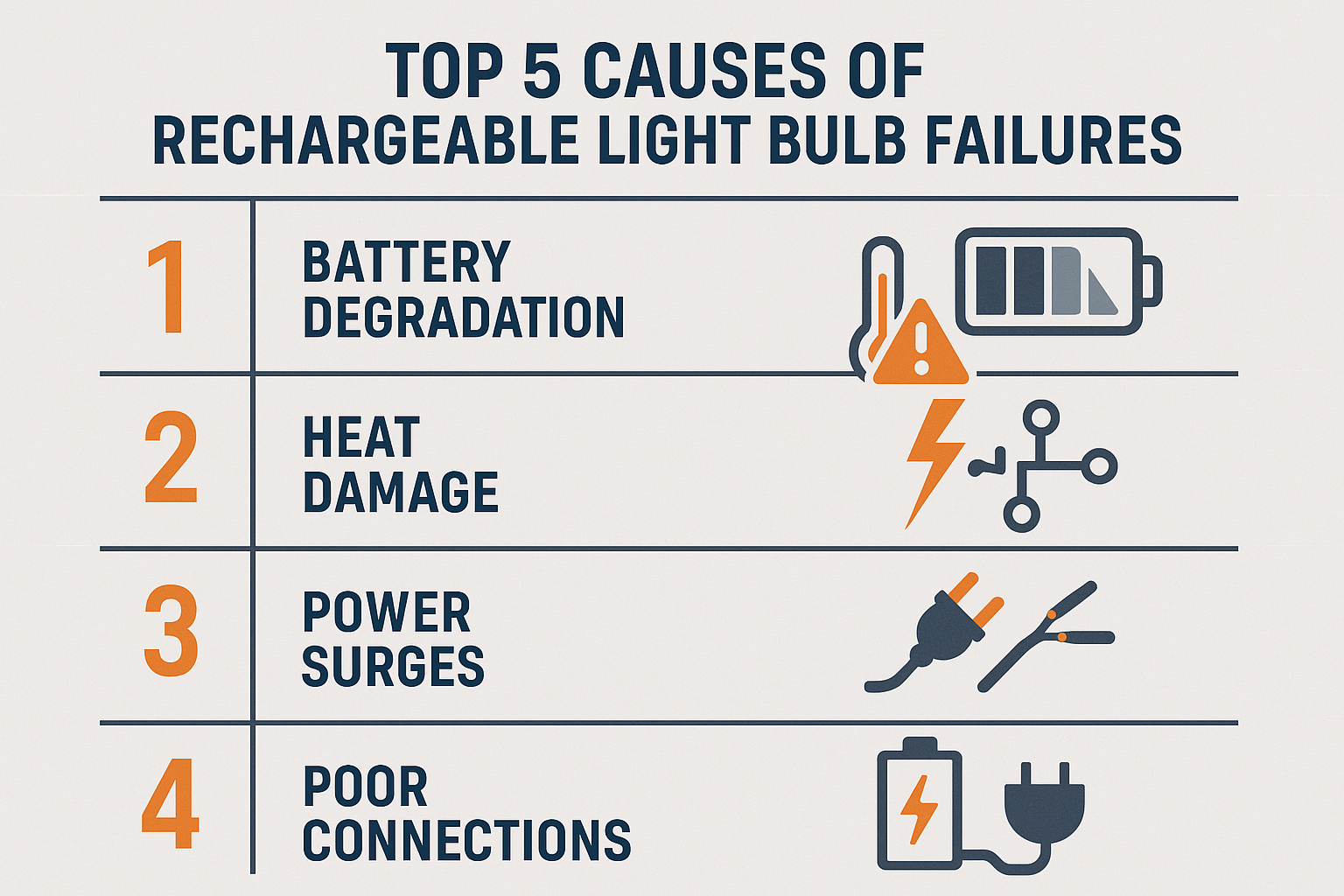

1. Battery Degradation and Chemistry Limitations

Battery degradation represents the most common cause of premature failure in rechargeable light bulbs. The emergency lighting market, valued at USD 7.71 billion in 2024, relies heavily on battery backup systems that must maintain reliable performance over extended periods. However, all battery technologies experience capacity loss over time, and this degradation accelerates under certain conditions.

Different battery chemistries exhibit varying failure patterns and lifespans. Lithium-ion batteries, commonly used in premium rechargeable bulbs, typically provide 500-1000 charge cycles before capacity drops to 80% of original performance. However, exposure to high temperatures, deep discharge cycles, or overcharging can reduce this lifespan dramatically. Nickel-metal hydride (NiMH) batteries offer 300-500 cycles but are more tolerant of temperature variations. Lead-acid batteries, found in budget emergency lighting, provide only 200-300 cycles but are the most cost-effective option for applications with infrequent use.

The emerging LiFePO4 (Lithium Iron Phosphate) technology offers superior longevity with 2000-5000 cycles and enhanced thermal stability. These batteries maintain performance across wider temperature ranges and resist degradation from partial discharge cycles. However, their higher initial cost limits adoption in budget-conscious applications.

|

Battery Type

|

Expected Lifespan

|

Cycle Count

|

Temperature Tolerance

|

Cost Factor

|

|

Lead-Acid

|

2-3 years

|

200-300 cycles

|

Poor (-10°C to 40°C)

|

Low

|

|

NiMH

|

3-5 years

|

300-500 cycles

|

Good (-20°C to 60°C)

|

Medium

|

|

Lithium-Ion

|

5-7 years

|

500-1000 cycles

|

Fair (0°C to 45°C)

|

High

|

|

LiFePO4

|

8-12 years

|

2000-5000 cycles

|

Excellent (-20°C to 70°C)

|

Very High

|

2. Thermal Management Failures

Heat represents the silent killer of electronic components in rechargeable light bulbs. LED chips generate heat during operation, charging circuits produce thermal energy during battery replenishment, and battery cells themselves generate heat during charge and discharge cycles. When thermal management systems fail to dissipate this heat effectively, component degradation accelerates exponentially.

Research indicates that LED lifespan decreases by approximately 50% for every 10°C increase in junction temperature above optimal operating conditions. In rechargeable bulbs, this thermal stress is compounded by the additional heat generated by charging electronics and battery systems. Poor thermal design, inadequate heat sinks, or blocked ventilation can create thermal hot spots that destroy sensitive components within months rather than years.

The problem becomes particularly acute in enclosed fixtures where ambient temperatures can exceed 40°C during normal operation. When combined with the internal heat generation from charging systems, junction temperatures can reach levels that cause immediate damage to LED phosphors and semiconductor junctions.

3. Power Quality and Electrical Stress

Modern electrical systems subject electronic devices to various forms of electrical stress that can cause immediate or cumulative damage. Voltage fluctuations, power surges, electrical noise, and harmonic distortion all contribute to premature failure in rechargeable light bulbs. The charging circuits in these devices are particularly vulnerable to power quality issues because they must continuously monitor and respond to electrical conditions.

Surge events, whether from lightning strikes, utility switching operations, or large motor startups, can destroy power conversion electronics instantly. Even smaller voltage variations can stress components over time, leading to gradual degradation and eventual failure. The emergency lighting industry has documented numerous cases where power quality issues caused widespread failures across entire installations.

4. Installation and Environmental Factors

Improper installation practices contribute significantly to premature failures in rechargeable lighting systems. Loose connections create resistance that generates heat and voltage drops. Incompatible fixtures can restrict airflow or create mechanical stress on bulb components. Environmental factors such as humidity, vibration, and temperature cycling also accelerate component degradation.

Moisture infiltration represents a particularly insidious failure mechanism. Even small amounts of humidity can cause corrosion in electrical connections, create conductive paths that lead to short circuits, and accelerate the degradation of battery systems. Vibration from nearby machinery or traffic can cause mechanical failures in solder joints and component connections.

5. Manufacturing Quality and Design Defects

The rapid growth of the rechargeable lighting market has led to an influx of products with varying quality levels. Budget manufacturers often compromise on component quality, thermal design, or quality control processes to achieve lower price points. These compromises manifest as higher failure rates and shorter lifespans in real-world applications.

Common manufacturing defects include inadequate solder joints, poor component selection, insufficient thermal management, and inadequate quality testing. Design defects may include undersized heat sinks, inadequate surge protection, or battery management systems that lack proper safety features.

Warning Signs of Impending Failure

Recognizing the early warning signs of rechargeable bulb failure can prevent unexpected outages and allow for proactive replacement. These indicators often appear weeks or months before complete failure, providing opportunities for preventive action.

Performance Degradation Indicators

•Reduced backup runtime: Emergency operation time decreases below specified duration

•Dimming during normal operation: LED output decreases noticeably from original brightness

•Slow charging response: Bulb takes longer to reach full charge after power restoration

•Inconsistent switching: Delayed or erratic transition between normal and emergency modes

•Visible flickering: Intermittent light output during either normal or emergency operation

Physical Warning Signs

•Excessive heat generation: Bulb becomes noticeably warmer during operation

•Discoloration: Yellowing or browning of the bulb housing or lens

•Unusual odors: Burning smells or chemical odors during operation

•Mechanical damage: Cracks, bulges, or deformation of the bulb housing

•Corrosion: Visible corrosion on electrical contacts or mounting hardware

Prevention Strategies and Best Practices

Implementing proper prevention strategies can significantly extend the lifespan of rechargeable light bulbs and reduce the frequency of premature failures. These practices address the root causes of failure while optimizing operating conditions for maximum reliability.

Optimal Installation Practices

Proper installation begins with selecting appropriate fixtures that provide adequate ventilation and thermal management. Fixtures should allow unrestricted airflow around the bulb and avoid creating thermal hot spots. Electrical connections must be tight and properly torqued to prevent resistance heating. Using fixtures rated for the specific bulb type ensures compatibility and optimal performance.

Environmental considerations include protecting bulbs from excessive moisture, vibration, and temperature extremes. In harsh environments, consider using bulbs with higher IP ratings or additional protective enclosures. Regular inspection of installation conditions can identify potential problems before they cause failures.

Maintenance and Testing Protocols

Regular maintenance significantly extends bulb lifespan and ensures reliable emergency operation. Monthly testing of emergency function verifies proper operation and identifies developing problems. Annual battery capacity testing can detect degradation before it affects performance. Cleaning of fixtures and bulbs removes dust and debris that can impede heat dissipation.

Documentation of maintenance activities creates a historical record that can identify patterns and predict future maintenance needs. Tracking performance metrics such as backup runtime and charging time can provide early warning of developing problems.

Environmental Optimization

Controlling environmental conditions within acceptable ranges prevents many common failure modes. Temperature control is particularly important, as excessive heat accelerates all forms of component degradation. Humidity control prevents corrosion and electrical problems. Vibration isolation protects mechanical connections and components.

Power quality improvement through surge protection, voltage regulation, and harmonic filtering can eliminate many electrical stress factors that contribute to premature failure. Installing whole-building surge protection provides the first line of defense against major surge events.

Selecting Quality Products for Longevity

The rechargeable light bulb market offers products across a wide range of quality and price points. Understanding the factors that contribute to long-term reliability can guide purchasing decisions and prevent costly premature failures.

Key Quality Indicators

Premium rechargeable bulbs typically feature robust thermal management systems with adequate heat sinks and thermal interface materials. Quality battery management systems include comprehensive protection features such as overvoltage protection, undervoltage lockout, thermal monitoring, and current limiting. Superior electrical design incorporates surge protection, EMI filtering, and robust power conversion circuits.

Certification marks from recognized testing laboratories indicate compliance with safety and performance standards. UL listing, Energy Star certification, and FCC compliance demonstrate that products have undergone rigorous testing and meet established quality criteria.

Brand Reputation and Warranty Coverage

Established manufacturers with strong reputations typically invest more in quality control and product development. Extended warranty coverage indicates manufacturer confidence in product reliability and provides protection against premature failures. Technical support availability ensures that problems can be resolved quickly when they occur.

Cost-Benefit Analysis

While premium products command higher initial prices, their superior reliability and longer lifespans often provide better total cost of ownership. Calculating the total cost including purchase price, installation costs, maintenance expenses, and replacement frequency provides a more accurate comparison between products.

Related

Frequently Asked Questions

1. How long should a rechargeable light bulb last before needing replacement?

Quality rechargeable LED bulbs should provide 20,000 to 50,000 hours of operation with battery backup capability lasting 5-10 years depending on usage patterns and environmental conditions. However, actual lifespan varies significantly based on battery chemistry, operating temperature, and maintenance practices.

2. Can I replace just the battery in a rechargeable light bulb?

Most consumer rechargeable bulbs have sealed designs that don't allow battery replacement. However, some commercial emergency lighting fixtures feature replaceable battery packs. Check manufacturer specifications and warranty terms before attempting any modifications.

3. Why does my rechargeable bulb get hot during charging?

Some heat generation during charging is normal as the charging circuit converts AC power to DC and manages battery charging current. However, excessive heat may indicate a failing charging circuit, battery problems, or inadequate thermal management requiring professional evaluation.

4. What's the difference between emergency lighting and rechargeable bulbs?

Emergency lighting systems are designed specifically for life safety applications and must meet strict codes and standards. Rechargeable bulbs provide convenience backup lighting but may not meet emergency lighting requirements for commercial buildings.

5. How can I test if my rechargeable bulb is working properly?

Turn off the wall switch while the bulb is on - it should continue operating on battery power. How long does it take to verify backup duration meets specifications? Monthly testing ensures reliable emergency operation when needed.

Conclusion

Understanding why rechargeable light bulbs fail prematurely empowers consumers and businesses to make informed purchasing decisions and implement proper maintenance practices. The primary failure modes - battery degradation, thermal stress, power quality issues, installation problems, and manufacturing defects - are largely preventable through proper product selection, installation, and maintenance.

The growing market for rechargeable lighting reflects increasing demand for reliable backup illumination in both residential and commercial applications. As technology continues to advance, newer battery chemistries and improved thermal management systems promise even greater reliability and longer lifespans. However, the fundamental principles of proper installation, regular maintenance, and quality product selection remain essential for achieving optimal performance and longevity.

Investing in quality rechargeable lighting products and implementing proper maintenance practices provides reliable emergency illumination while minimizing the frustration and expense of premature failures. As the technology continues to evolve, staying informed about best practices and emerging technologies ensures optimal performance from these increasingly sophisticated lighting systems.

Call to Action

Ready to upgrade to reliable rechargeable lighting solutions? Contact our lighting experts for personalized recommendations based on your specific needs. Call us at +1 4432041972 for technical guidance on selecting the right emergency lighting systems. Browse our comprehensive selection of heating and lighting equipment to find quality solutions that deliver long-term reliability. For technical support and maintenance guidance, reach out to our team at support@tendsupplies.com.

This article was researched and written by the technical experts at Tend Industrial Supplies. For more insights on industrial equipment and lighting solutions, explore our comprehensive blog covering everything from pneumatic tools to automotive diagnostic equipment.

2nd Oct 2025