Rechargeable vs Non-Rechargeable Work Lights – What to Buy?

As an Amazon Associate, we earn from qualifying purchases.

The work light market has experienced substantial growth, reaching USD 35.69 billion in 2025 and projected to expand to USD 41.07 billion by 2029 at a compound annual growth rate of 3.6%. This expansion reflects the increasing demand for portable, high-performance lighting solutions across industrial, automotive, and construction sectors. However, with the proliferation of both rechargeable and non-rechargeable options, selecting the optimal work light for specific applications has become increasingly complex.

Professional contractors, mechanics, and industrial workers face a critical decision when investing in work lighting: should they prioritize the mobility and convenience of rechargeable units, or the consistent power and unlimited runtime of corded alternatives? This comprehensive analysis examines the technical specifications, real-world performance, and cost considerations that determine which type of work light delivers superior value for different applications.

The LED work light segment, valued at USD 12.6 billion in 2025 and expected to reach USD 18.0 billion by 2032, demonstrates the market's shift toward energy-efficient illumination technologies. Both rechargeable and non-rechargeable work lights have adopted LED technology, but their implementation and performance characteristics differ significantly due to variations in power delivery methods and design constraints.

Key Takeaways

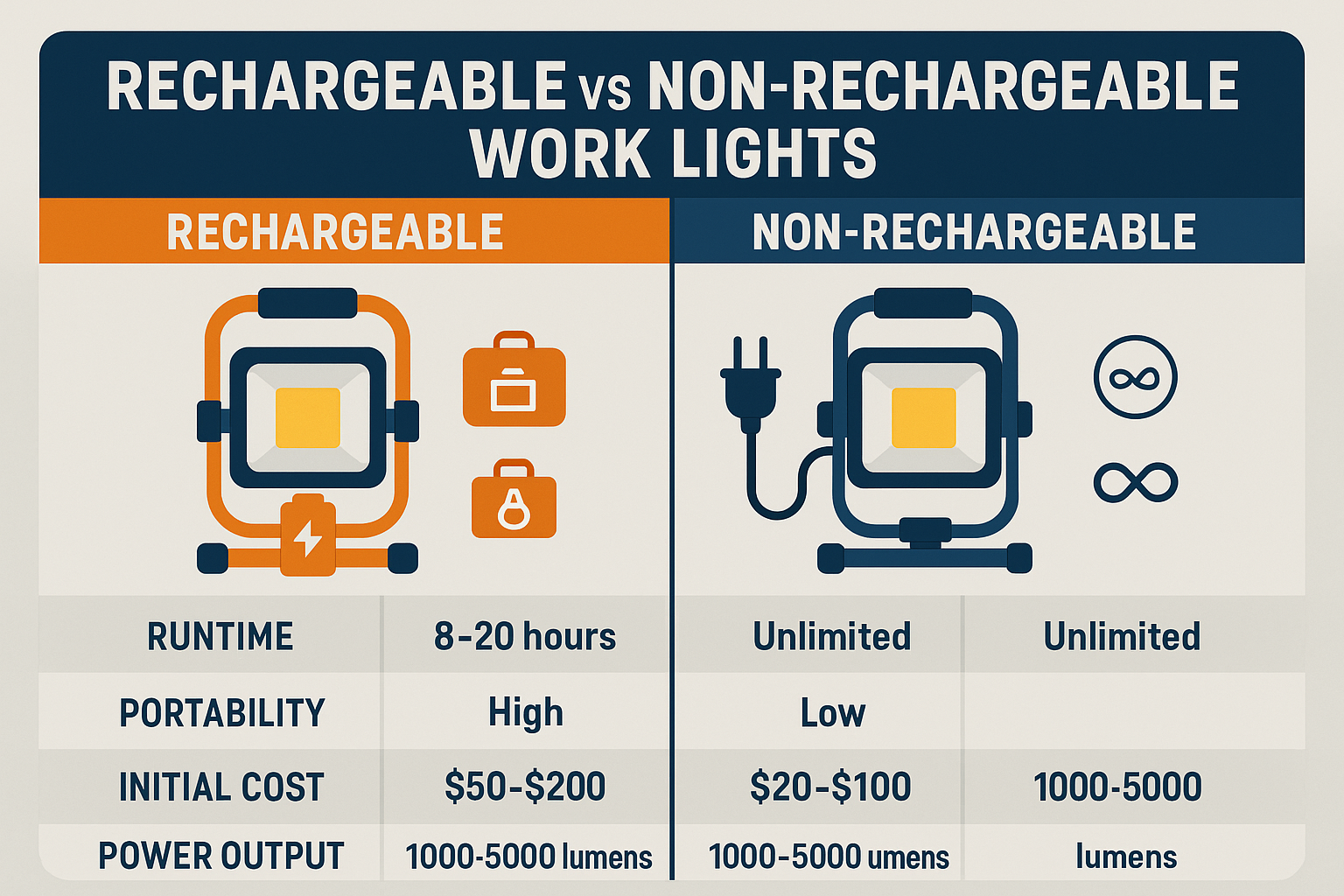

•Rechargeable work lights excel in mobility applications with 8-20 hour runtime capabilities and elimination of cord management issues, making them ideal for automotive work, field service, and confined space applications.

•Non-rechargeable corded lights provide unlimited runtime and consistent power output, making them superior for extended workshop tasks, production environments, and applications requiring maximum brightness

•Initial investment costs favor corded lights ($20-100) over rechargeable units ($50-200), but total cost of ownership depends heavily on usage patterns and replacement frequency

•Power output capabilities are comparable between both types, with premium models in each category delivering 1000-5000+ lumens of illumination

•Battery technology advancements have significantly improved rechargeable light performance, with lithium-ion systems now providing professional-grade reliability and longevity

Understanding Work Light Technology Evolution

Modern work lights represent a significant advancement from traditional incandescent and halogen units that dominated the market for decades. The transition to LED technology has fundamentally altered the performance characteristics and design possibilities for both rechargeable and corded work lights. LED chips generate significantly less heat while producing more lumens per watt, enabling manufacturers to create more compact, efficient, and durable lighting solutions.

The integration of advanced battery management systems in rechargeable work lights has addressed many historical limitations such as memory effects, thermal runaway, and rapid capacity degradation. Contemporary lithium-ion battery packs incorporate sophisticated charging algorithms, temperature monitoring, and cell balancing technologies that extend operational life and maintain consistent performance throughout the discharge cycle.

Non-rechargeable work lights have simultaneously evolved to incorporate intelligent power management systems, surge protection, and enhanced thermal dissipation capabilities. These improvements ensure stable light output and protect sensitive LED components from voltage fluctuations and electrical noise commonly encountered in industrial environments.

Rechargeable Work Lights: Mobility and Convenience

Rechargeable work lights have revolutionized portable illumination by eliminating the constraints and safety hazards associated with power cords. These units incorporate high-capacity battery systems, typically lithium-ion technology, that provide substantial runtime while maintaining compact form factors and manageable weight distributions.

Performance Characteristics

Modern rechargeable work lights deliver impressive performance metrics that rival their corded counterparts in many applications. Premium units achieve light outputs ranging from 1000 to 5000+ lumens, with some specialized models exceeding 10,000 lumens for short-duration applications. Runtime capabilities typically range from 8 to 20 hours depending on brightness settings and battery capacity, with many units offering multiple power modes to optimize performance for specific tasks.

The absence of power cords eliminates several common workplace hazards including trip risks, electrical shock potential, and equipment damage from cord entanglement. This safety advantage becomes particularly significant in automotive service bays, construction sites, and industrial maintenance environments where personnel mobility and workspace organization are critical factors.

Battery Technology and Management

Contemporary rechargeable work lights utilize advanced lithium-ion battery systems that provide superior energy density, reduced self-discharge rates, and extended cycle life compared to older battery technologies. High-quality units incorporate battery management systems that monitor cell voltage, temperature, and charge state to optimize performance and prevent damage from overcharging or deep discharge conditions.

Fast-charging capabilities have become standard in professional-grade rechargeable work lights, with many units achieving 80% charge capacity in 2-4 hours. Some models feature USB-C charging ports that enable charging from vehicle power outlets, portable power banks, or standard wall adapters, providing flexibility in field charging scenarios.

Application Advantages

Rechargeable work lights excel in applications requiring frequent repositioning, confined space access, or operation in areas without readily available electrical power. Automotive technicians particularly benefit from the ability to position lights precisely without cord routing constraints, while maintaining adequate illumination for detailed diagnostic and repair work.

Field service applications represent another area where rechargeable lights provide significant advantages. HVAC technicians, electrical contractors, and maintenance personnel can carry compact, powerful lighting solutions that operate independently of building power systems, ensuring consistent illumination even during electrical system maintenance or emergency repairs.

Non-Rechargeable Corded Work Lights: Consistent Power and Performance

Non-rechargeable corded work lights maintain several fundamental advantages that make them preferred choices for specific applications and work environments. These units draw power directly from electrical outlets, eliminating battery-related limitations and providing unlimited runtime capabilities for extended work sessions.

Unlimited Runtime Capabilities

The primary advantage of corded work lights lies in their ability to provide consistent, unlimited illumination without interruption for battery charging or replacement. This characteristic makes them ideal for production environments, extended repair projects, and applications where continuous lighting is essential for safety or productivity reasons.

Manufacturing facilities, automotive service centers, and construction sites with established electrical infrastructure benefit significantly from corded work lights' reliability and consistency. Workers can focus on tasks without monitoring battery levels or planning charging schedules, reducing workflow interruptions and improving overall productivity.

Power Output and Consistency

Corded work lights can deliver maximum power output continuously without the thermal or electrical limitations imposed by battery systems. This capability enables higher sustained brightness levels and more consistent color temperature throughout operation periods. Professional-grade corded units often incorporate advanced thermal management systems that maintain optimal LED performance even during extended high-output operation.

The direct connection to electrical power also eliminates voltage drop issues that can affect rechargeable units as battery charge decreases. Corded lights maintain consistent brightness and color characteristics throughout operation, ensuring uniform illumination quality for precision work applications.

Cost Effectiveness and Durability

Initial purchase costs for corded work lights typically range from $20 to $100, significantly lower than comparable rechargeable units. This cost advantage stems from the absence of expensive battery systems and charging electronics, allowing manufacturers to focus resources on light output, durability, and thermal management.

Long-term operating costs for corded lights are generally lower due to the absence of battery replacement requirements. Quality corded work lights can operate for thousands of hours with minimal maintenance, while rechargeable units eventually require battery replacement or complete unit replacement when battery systems reach end-of-life conditions.

Technical Specifications Comparison

Understanding the technical differences between rechargeable and non-rechargeable work lights enables informed decision-making based on specific application requirements and performance priorities.

|

Specification

|

Rechargeable Work Lights

|

Non-Rechargeable Corded Lights

|

|

Light Output

|

1000-5000+ lumens

|

1000-8000+ lumens

|

|

Runtime

|

8-20 hours (battery dependent)

|

Unlimited (power dependent)

|

|

Weight

|

2-8 lbs (including battery)

|

1-5 lbs (excluding cord)

|

|

Initial Cost

|

$50-$200+

|

$20-$100+

|

|

Power Source

|

Lithium-ion battery (typical)

|

120V AC electrical outlet

|

|

Charging Time

|

2-8 hours

|

N/A

|

|

Mobility

|

Excellent (cordless)

|

Limited (cord length)

|

|

Maintenance

|

Battery replacement required

|

Minimal maintenance

|

|

Temperature Range

|

Limited by battery specs

|

Wide operating range

|

|

Surge Protection

|

Built-in (battery buffering)

|

Requires external protection

|

Lumens and Light Quality

Both rechargeable and corded work lights utilize LED technology to achieve high lumen outputs with excellent energy efficiency. However, the sustained power availability in corded units often enables higher maximum brightness levels and more consistent light quality throughout operation periods. Rechargeable units may experience gradual brightness reduction as battery voltage decreases, though quality units incorporate voltage regulation to minimize this effect.

Color temperature consistency represents another technical consideration. Corded lights maintain stable color characteristics throughout operation, while some rechargeable units may exhibit slight color shifts as battery charge decreases. Professional-grade rechargeable lights incorporate advanced LED drivers that maintain consistent color temperature across the full discharge cycle.

Thermal Management

Heat dissipation capabilities differ significantly between rechargeable and corded work lights due to design constraints and power delivery methods. Corded units can incorporate larger heat sinks and more robust thermal management systems without weight or size restrictions imposed by battery integration.

Rechargeable units must balance thermal management with portability and battery protection requirements. Advanced models incorporate intelligent thermal monitoring that reduces power output when excessive temperatures are detected, protecting both LED components and battery systems from thermal damage.

Application-Specific Recommendations

Selecting the optimal work light type depends heavily on specific application requirements, work environment characteristics, and usage patterns. Different industries and work scenarios favor particular light types based on their unique operational demands.

Automotive and Mechanical Applications

Automotive service environments typically favor rechargeable work lights due to the frequent need for light repositioning and the confined spaces common in vehicle service work. Mechanics working under hoods, beneath vehicles, or in engine compartments benefit from cordless operation that eliminates cord routing challenges and reduces workplace hazards.

However, automotive shops performing extensive bodywork or paint preparation may prefer corded lights for their unlimited runtime and consistent brightness during extended sanding, polishing, or detail work sessions. The choice often depends on the specific service focus and workspace configuration.

Construction and Field Service

Construction applications present diverse lighting requirements that may favor either rechargeable or corded solutions depending on project phases and site conditions. Early construction phases with limited electrical infrastructure strongly favor rechargeable lights, while finished construction with established power systems may benefit from corded solutions.

Field service technicians typically prefer rechargeable work lights for their portability and independence from customer electrical systems. HVAC, plumbing, and electrical contractors often work in areas where power access is limited or where connecting to customer electrical systems is impractical or prohibited.

Manufacturing and Production

Manufacturing environments with established electrical infrastructure and continuous operation requirements typically favor corded work lights. Production lines, quality control stations, and maintenance areas benefit from unlimited runtime and consistent brightness that corded units provide.

However, maintenance applications within manufacturing facilities may favor rechargeable lights for their mobility and safety advantages when working on energized equipment or in areas where cord routing presents hazards or operational constraints.

Cost Analysis and Total Ownership Considerations

Evaluating the true cost of work light ownership requires analysis beyond initial purchase price to include operational costs, replacement requirements, and productivity impacts over the equipment's useful life.

Initial Investment Comparison

Rechargeable work lights typically require 2-4 times the initial investment of comparable corded units due to battery systems and charging electronics. However, this cost differential has decreased as battery technology has matured and manufacturing volumes have increased.

Premium rechargeable units in the $150-$200 range often provide performance and durability comparable to corded lights costing $50-$75, making the cost differential less significant when evaluated against performance capabilities and application suitability.

Operational Cost Factors

Corded work lights incur minimal operational costs beyond electricity consumption, which is typically negligible for LED-based units. Maintenance requirements are limited to occasional cleaning and lamp replacement for units using replaceable LED modules.

Rechargeable work lights incur battery replacement costs every 3-5 years depending on usage patterns and battery quality. Replacement battery costs typically range from $30-$80, representing a significant portion of the original unit cost. However, improved battery technology and longer cycle life have extended replacement intervals and reduced long-term operational costs.

Productivity and Efficiency Impacts

The productivity impact of work light selection can significantly influence total cost of ownership calculations. Rechargeable lights that eliminate setup time, reduce cord management requirements, and improve workspace safety can provide substantial productivity benefits that offset higher initial costs.

Conversely, corded lights that eliminate charging downtime and provide consistent brightness for quality-critical work may improve work quality and reduce rework requirements, providing value that exceeds their lower initial cost.

Maintenance and Longevity Considerations

Understanding maintenance requirements and expected service life helps optimize work light selection and budgeting for long-term lighting needs.

Rechargeable Light Maintenance

Rechargeable work lights require regular attention to battery health and charging practices to maximize service life. Proper charging procedures, temperature management, and storage practices significantly impact battery longevity and overall unit performance.

Modern lithium-ion battery systems incorporate protection circuits that prevent overcharging and deep discharge damage, but optimal practices still extend service life. Avoiding extreme temperatures, maintaining partial charge during storage, and using manufacturer-specified charging equipment help maximize battery performance and longevity.

Corded Light Maintenance

Corded work lights require minimal maintenance beyond periodic cleaning and inspection of electrical connections. Power cords represent the primary wear item, requiring inspection for damage and replacement when insulation or conductor integrity is compromised.

LED components in quality corded work lights typically provide 25,000-50,000 hours of service life, far exceeding the service life of traditional incandescent or halogen alternatives. This longevity reduces replacement frequency and long-term operational costs.

Safety Considerations and Best Practices

Work light safety encompasses electrical safety, workplace hazard reduction, and proper equipment selection for specific environments and applications.

Electrical Safety

Corded work lights require attention to electrical safety practices including proper grounding, GFCI protection in wet environments, and regular inspection of power cords and connections. Extension cord selection and routing must consider current capacity, voltage drop, and physical protection requirements.

Rechargeable work lights eliminate many electrical safety concerns but introduce battery-specific safety considerations including proper charging practices, temperature monitoring, and protection from physical damage that could compromise battery integrity.

Workplace Hazard Reduction

Cord management represents a significant safety consideration in work environments. Proper cord routing, protection from damage, and elimination of trip hazards require careful planning and ongoing attention. Rechargeable lights eliminate these concerns but introduce the need for charge level monitoring to prevent unexpected power loss during critical work.

Both light types require consideration of heat generation and potential ignition sources in environments with flammable materials or vapors. LED technology significantly reduces heat generation compared to traditional lighting, but thermal management remains important for both safety and performance reasons.

Frequently Asked Questions

1. How long do rechargeable work light batteries typically last?

Quality lithium-ion batteries in rechargeable work lights typically provide 3-5 years of service life with regular use, equivalent to 500-1000 charge cycles. Battery life depends on charging practices, operating temperature, and discharge depth. Proper maintenance can extend battery life, while extreme conditions or poor charging practices can reduce it significantly.

2. Can rechargeable work lights match the brightness of corded models?

Yes, premium rechargeable work lights can achieve brightness levels comparable to corded models, with some units exceeding 5000 lumens. However, sustained high-brightness operation may reduce battery runtime. Corded lights can maintain maximum brightness indefinitely, while rechargeable units may reduce output as battery charge decreases.

3. What are the main advantages of corded work lights over rechargeable models?

Corded work lights provide unlimited runtime, consistent brightness throughout operation, lower initial cost, and minimal maintenance requirements. They excel in applications requiring extended operation periods, maximum brightness, or continuous use without interruption for charging.

4. Are rechargeable work lights suitable for professional use?

Modern rechargeable work lights meet professional performance standards and are widely used in automotive, construction, and maintenance applications. Quality units provide adequate brightness, runtime, and durability for professional use, though application-specific requirements should be evaluated carefully.

5. How do I choose between rechargeable and corded work lights?

Consider your primary applications, workspace characteristics, and usage patterns. Choose rechargeable lights for mobility, confined spaces, and applications without convenient power access. Select corded lights for extended operation, maximum brightness, and applications with established electrical infrastructure.

Conclusion

The decision between rechargeable and non-rechargeable work lights ultimately depends on specific application requirements, work environment characteristics, and usage patterns. Rechargeable work lights excel in applications requiring mobility, flexibility, and operation in areas without convenient electrical access. Their cordless design eliminates workplace hazards and enables precise positioning for optimal illumination.

Non-rechargeable corded work lights provide unlimited runtime, consistent performance, and lower initial costs that make them ideal for extended operation periods and applications requiring maximum sustained brightness. Their reliability and minimal maintenance requirements suit production environments and continuous-use applications.

The work light market's continued growth and technological advancement ensure that both rechargeable and corded options will continue improving in performance, efficiency, and value. LED technology adoption has benefited both categories, while battery technology improvements have particularly enhanced rechargeable light capabilities and value propositions.

Professional users often benefit from maintaining both rechargeable and corded work lights to address different application requirements and provide backup capabilities. This approach maximizes flexibility while ensuring optimal performance for diverse work scenarios.

As battery technology continues advancing and charging infrastructure becomes more prevalent, rechargeable work lights will likely capture increasing market share. However, corded lights will remain essential for applications requiring unlimited runtime and maximum sustained performance.

Call to Action

Ready to upgrade your work lighting setup? Explore our comprehensive selection of work lights to find the perfect solution for your specific needs. Our lighting experts are available at +1 4432041972 to provide personalized recommendations based on your applications and requirements.

For technical guidance on selecting between rechargeable and corded options, contact our team for detailed consultations. Browse our heating and lighting category for the latest in professional work lighting technology, or visit our blog for more insights on workshop lighting solutions and industrial equipment guidance.

This comprehensive guide was researched and written by the technical experts at Tend Industrial Supplies. For more professional insights on industrial equipment and lighting solutions, explore our extensive blog library covering everything from pneumatic tools to emergency lighting systems.

3rd Oct 2025