The Ultimate Guide to Automotive Lifting: Choosing the Right Jacks, Stands, and Lifts for Your Workshop (2025)

In any automotive workshop, from a home garage to a sprawling dealership service center, every task—from a simple brake job to a complete engine overhaul—begins with one critical action: lifting the vehicle. The equipment used for this task is the most vital safety hardware in the entire shop. A quality jack, adequately supported by robust jack stands, is the literal foundation upon which safe, efficient, and profitable work is built. An automotive lift represents the pinnacle of that efficiency.

Yet, the market for lifting equipment is vast and characterized by significant technical differences. What is the real-world difference between a 2-ton and a 3-ton floor jack? Why is an aluminum "racing" jack not always the best choice for a professional shop? What are the non-negotiable safety features of a jack stand? And when is it time to make the ultimate investment in a two-post or four-post vehicle lift?

At Tend Industrial Supplies, we believe that safety and knowledge are inseparable. This guide is designed to empower you with the technical understanding needed to choose the right lifting equipment for your needs. We will explore the mechanics of hydraulic floor jacks, dissect the critical safety designs of jack stands, and demystify the world of professional vehicle lifts. This is your definitive guide to ensuring every vehicle you work on is lifted safely, securely, and efficiently.

Key Takeaways

- Jacks Lift, Stands Hold: This is the most important rule of lifting. Never work under a vehicle supported only by a jack. A jack is a lifting device; jack stands are holding devices. Hydraulic failure in a jack can be sudden and catastrophic.

- Tonnage is a Safety Margin: The "tonnage" rating of a jack or stand indicates the maximum weight it can safely support. Always choose equipment with a rating significantly higher than the weight you plan to lift. For a pair of jack stands, their combined rating should exceed the vehicle's total weight.

- Steel vs. Aluminum Jacks: Steel floor jacks are the durable, heavy-duty workhorses for a workshop environment. Aluminum jacks are lightweight and portable, making them ideal for mobile use, roadside assistance, or motorsports, but they may be less durable under constant shop abuse.

- Look for Safety Certifications: When buying jacks and stands, look for ASME/PASE certification marks. This ensures the equipment has been tested and meets rigorous industry safety and performance standards.

- A Vehicle Lift is an Investment in Efficiency: While a significant expense, a two-post or four-post lift can revolutionize a workshop's workflow, improving ergonomics, safety, and the speed at which jobs can be completed, providing a powerful return on investment.

Part 1: The Workhorse - Hydraulic Floor Jacks

The floor jack is the most common piece of lifting equipment in any shop. It uses hydraulic fluid and a pump mechanism to multiply a small amount of effort on the handle into thousands of pounds of lifting force.

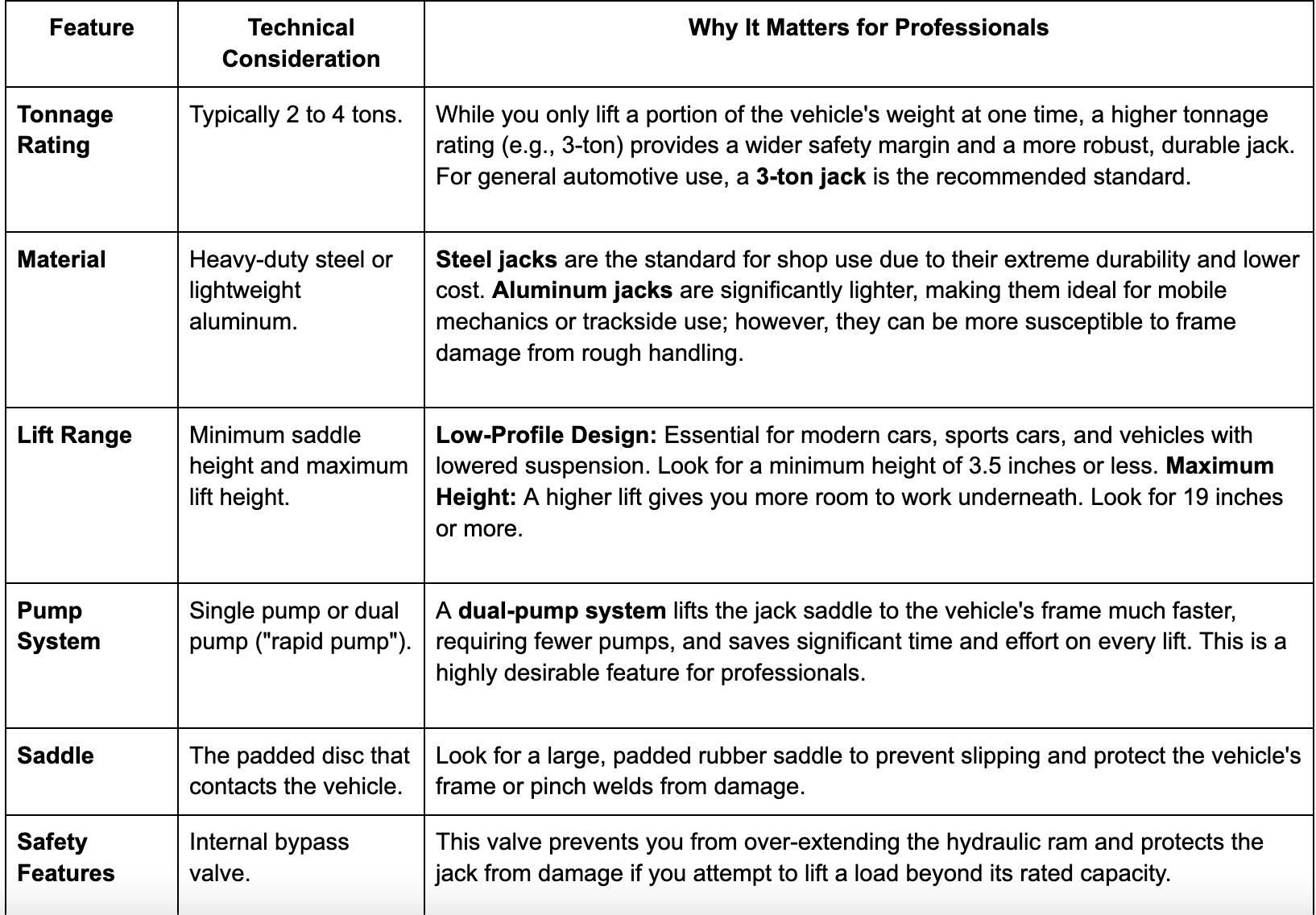

Key Features to Evaluate in a Floor Jack

Part 2: The Lifesaver - Jack Stands

This is the most critical safety section of this guide. Once a vehicle is lifted with a jack, it must be immediately supported by a pair of appropriately rated jack stands before any work begins.

heavy-duty jack stands correctly positioned under the reinforced frame points of a vehicle,

Anatomy of a Safe Jack Stand

- Tonnage Rating: Like jacks, stands are rated in tons. This rating is for a pair of stands. A pair of 3-ton stands can support 6,000 lbs. To be safe, the combined rating of your stands should be at least the full gross weight of the vehicle you are working on. A 3-ton or 6-ton pair is a versatile choice for most cars and light trucks.

- Base Construction: Look for a wide, welded steel base, preferably with a square or pyramid shape. A wider base provides more stability and is less likely to tip or sink into softer surfaces like asphalt on a hot day.

- Locking Mechanism: This is a crucial feature.

- Ratcheting Style: This is the most common type. A lever engages with teeth on a cast iron support column. It allows for fast, easy height adjustment.

- Pin-Lock Style: This design uses a heavy-duty steel pin that passes through a hole in the outer frame and a corresponding hole in the support column. While slower to adjust, many professionals prefer this design as it provides a positive, visible mechanical lock that cannot slip.

- Saddle: The top of the stand should have a deep "V" or "U" shaped saddle to cradle the vehicle's frame or subframe securely.

Safe Jack Stand Procedure:

- Lift the vehicle with your floor jack at a manufacturer-approved lift point.

- Raise the jack stand to the desired height and place it under a substantial, solid part of the vehicle's frame, as specified in the vehicle's service manual.

- Slowly and carefully lower the jack until the vehicle's weight is fully supported by the jack stand. Watch and listen to ensure it settles securely.

- Give the vehicle a firm push to ensure it is stable on the stands before you get underneath.

Part 3: The Ultimate Upgrade - Investing in a Vehicle Lift

For a professional workshop, a vehicle lift is the ultimate investment in efficiency, ergonomics, and safety. It elevates the entire vehicle, providing unrestricted access to the undercarriage and allowing technicians to work comfortably at standing height.

1. The Two-Post Lift

This is the most common type of lift found in automotive repair shops due to its versatility and relatively small footprint.

- How it Works: Two powerful columns are bolted to the concrete floor. Four adjustable arms extend from the columns to lift the vehicle by its frame.

- Pros: Provides complete access to the wheels, brakes, suspension, and underbody of the vehicle. Excellent for all types of repair work.

- Cons: Requires a specific concrete floor thickness (typically 4-6 inches of reinforced concrete) for safe installation. Vehicle must be carefully balanced on the arms.

- Types:

- Symmetrical: The columns are directly opposite each other, and the arms are of equal length. Good for long-wheelbase trucks.

- Asymmetrical: The columns are rotated, and the front arms are shorter than the rear arms. This allows the vehicle to be positioned further back, improving door-opening clearance. This is the most popular choice for general auto shops.

2. The Four-Post Lift

This type of lift is essentially a drive-on ramp.

- How it Works: The vehicle is driven onto two runways, which are then lifted by four columns.

- Pros: Extremely stable and easy to use; no need to position arms. Ideal for oil changes, exhaust work, and vehicle storage. They are also excellent as alignment racks when properly equipped.

- Cons: Takes up more floor space and does not allow the wheels to hang free for brake or suspension work without the use of additional rolling bridge jacks.

3. The Scissor Lift

Scissor lifts use an accordion-like mechanism to raise the vehicle.

- Pros: Can be flush-mounted into the floor, saving a tremendous amount of space. Excellent for quick service bays, tire shops, and detailers.

- Cons: The mechanism underneath can sometimes obstruct access to the center of the vehicle's undercarriage.

Conclusion: Lift with Confidence

Your ability to lift thousands of pounds of metal safely and efficiently is the bedrock of your professional service. It's an area where cutting corners is never an option. By investing in high-quality, properly rated floor jacks, pairing them with robust jack stands on every single job, and considering the long-term efficiency gains of a professional vehicle lift, you are investing in the safety of yourself, your staff, and the integrity of your work. Always prioritize equipment that is certified to meet or exceed industry safety standards.

Building a world-class workshop starts with having the right tools for the job, from a complete mechanic's tool kit to a powerful air compressor system. Your lifting equipment is the critical piece that brings it all together.

Don't leave safety to chance. Upgrade your workshop with professional-grade jacks, stands, and vehicle lifts from Tend Industrial Supplies. Contact our equipment specialists at sales@tendsupplies.com or visit tendsupplies.com to find the perfect lifting solution for your needs.

Frequently Asked Questions (FAQs)

- Can I use just one jack stand? No. Jack stands should always be used in pairs to provide a stable, level base of support for either the front or rear of the vehicle. Using a single stand can create an unstable pivot point.

- What is the difference between a bottle jack and a floor jack? A bottle jack is a vertical, piston-style jack. It is very powerful for its small size but has a narrow base, making it less stable than a floor jack. Bottle jacks are excellent for lifting heavy machinery or as part of a shop press, but floor jacks are far superior for lifting vehicles.

- How do I know where the correct lift points are on a vehicle? The vehicle owner's manual will show the factory-recommended lift points, which are typically reinforced areas on the pinch welds or frame. Never lift a vehicle by the engine's oil pan, the transmission, or the floor pan, as this will cause severe damage.

- Does my concrete floor need special preparation for a two-post lift? Yes, and this is critically important. Most two-post lifts require a minimum of 4-6 inches of high-strength (3000+ PSI) reinforced concrete that has had at least 28 days to cure. Installing a lift on inadequate concrete is extremely dangerous. Always consult the lift manufacturer's specific requirements and have your floor professionally assessed if you are unsure.

- How often should I inspect my lifting equipment? You should perform a quick visual inspection of your jacks and stands before every use. Check for cracks in welds, bent metal, hydraulic fluid leaks, and damaged or worn parts. A more thorough inspection should be conducted at least annually. Never use a piece of lifting equipment that you suspect may be damaged.