The Ultimate Tap and Die Set Buying Guide: Professional Recommendations for 2025

Tap and Die Set Buying Guide

You must be familiar with this. Whether you're a seasoned machinist, a dedicated auto mechanic, or a DIY enthusiast, a high-quality tap and die set is an indispensable part of any workshop. These precision tools allow you to create, repair, and clean threads with accuracy, saving you time, money, and frustration when working on automotive repairs, machinery maintenance, or custom fabrication projects. But with a vast array of options available, choosing the right set can be a daunting task. This comprehensive guide will demystify the world of tap and die sets, providing you with the expert knowledge to select the perfect one for your specific needs and budget.

Key Takeaways

What is a Tap and Die Set?

|

Tool

|

Function

|

Application

|

|

Tap

|

Cuts internal threads

|

Creating or repairing threads inside a hole

|

|

Die

|

Cuts external threads

|

Creating or repairing threads on a rod or bolt

|

How to Choose the Right Tap and Die Set

Material Quality and Construction

Thread Type Considerations (SAE vs. Metric)

Set Size and Configuration Options

Case Design and Organization

Top Brands to Consider

VEVOR Tools

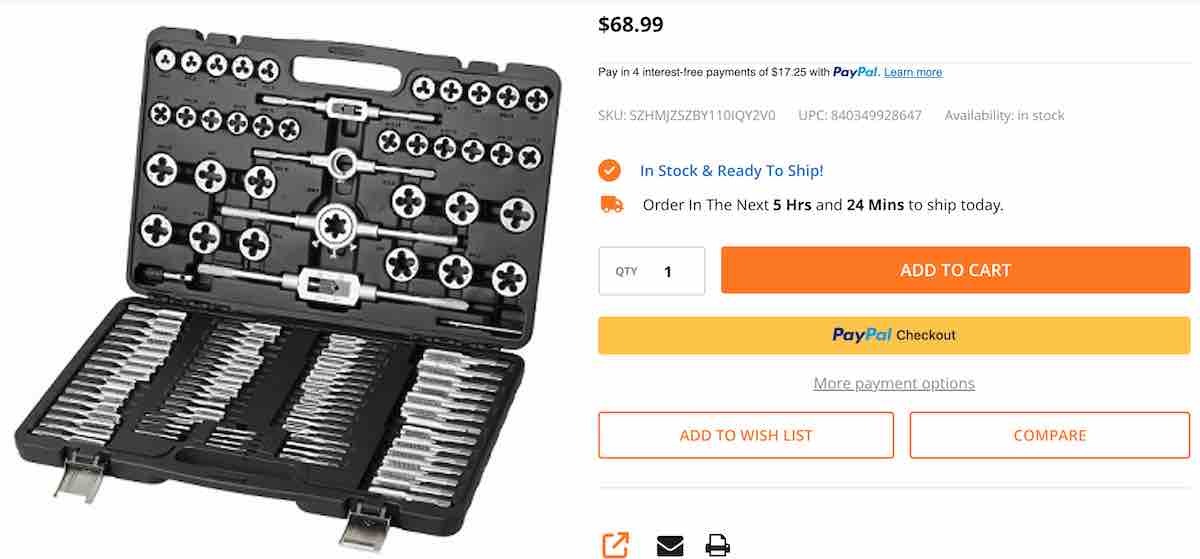

VEVOR Tap and Die Set, 116-Piece Include Metric and SAE Size, Bearing Steel Taps and Dies

Buy from Amazon