Top 5 Pneumatic Tools That Still Beat Cordless Options (2025 Edition)

On a cold morning in a Midwest auto shop, a senior mechanic named Luis reached for his cordless impact wrench, only to find the battery dead again halfway through a brake job. Frustrated, he pulled out his old pneumatic model… and finished the task in a third of the time, with more torque and zero slowdown. Stories like Luis’s are why professionals worldwide still search for “Top 5 Pneumatic Tools That Still Beat Cordless Options” because when uptime, torque, and reliability matter, air tools continue to outperform even the most advanced battery-powered systems.

Whether you’re running a busy workshop, maintaining fleet vehicles, or operating in industrial environments where consistency is critical, pneumatic tools remain the gold standard. This guide reveals the top air tools that still outperform cordless alternatives in 2025, and explains why professionals in the U.S., Europe, Africa, and Asia continue to rely on compressed air for real productivity.

Quick Answer

Pneumatic tools still outperform cordless tools in applications requiring maximum torque, continuous runtime, heat resistance, and high-duty industrial use.

The top performers include air impact wrenches, air die grinders, pneumatic sanders, air hammers/chisels, and pneumatic ratchets, known for superior durability, lighter weight, faster cycle speeds, and zero battery downtime. These advantages make air tools the preferred choice in automotive repair, fabrication, bodywork, and heavy-duty industrial environments.

Key Takeaways

- Pneumatic tools still outperform cordless models in raw torque, continuous-duty operation, and long-term durability, making them indispensable in automotive, fabrication, and industrial environments.

- Air-powered systems deliver consistent, fade-free performance, unlike cordless tools that lose power as batteries heat up or drain during extended use.

- Lower maintenance and longer tool lifespan make pneumatic tools more cost-effective for professional workshops that run high-volume tasks daily.

- Ideal for harsh or hazardous job sites, pneumatic tools offer superior safety with no risk of battery swelling, sparks, or electronic failure.

- Best-in-class applications where pneumatic dominates include impact wrenches, die grinders, cut-off tools, needle scalers, and air hammers, providing unmatched precision, speed, and reliability for global users.

Why Pneumatic Tools Still Matter in 2025

Cordless tools are convenient, but pneumatic tools dominate when:

- Maximum sustained torque is required

- Zero downtime is essential

- Hot, dusty, flammable, or heavy-duty environments demand reliability

- Precision machining and metal prep require ultra-consistent RPM

- Workshops need long-term cost-efficiency

Air tools outperform cordless units in auto repair, oil & gas, fabrication, shipbuilding, construction, and industrial MRO because they deliver:

- Higher power density

- Cooler operating temperatures

- Significantly longer lifespan

- No battery degradation

The Top 5 Pneumatic Tools That Still Outperform Cordless Models

Below are the definitive 2025 winners, based on global workshop feedback, industrial usage data, and long-tail keyword opportunities.

1. Pneumatic Impact Wrenches – Still the King of High Torque

Cordless impact wrenches have improved, but air impacts remain the global standard for:

- Tire shops

- Heavy truck maintenance

- Production floors

- Mining & oilfield repair

Why air beats cordless:

- Delivers 1,000–2,200 ft-lbs of continuous torque

- No overheating or torque fade

- No battery swaps during high-volume work

- Compact, lightweight, and vibration-stable

2. Pneumatic Die Grinders – Superior RPM and Cooling

For metalworking, polishing, porting, deburring, and precision shaping, air die grinders are unmatched.

Advantages:

- Up to 25,000 RPM sustained without heat buildup

- Ultra-light housing for one-hand control

- Ideal for aluminum, stainless, and cast iron

- Zero “battery stall” during heavy grinding

Industries:

- Fabrication

- Aviation

- Automotive performance

- Industrial maintenance

3. Pneumatic Sanders and Polishers – Consistent Finish Quality

Cordless sanders struggle with battery weight and lag under resistance.

Air sanders remain dominant for:

- Auto body refinishing

- Boat repair

- Furniture shops

- Surface prep in industrial paint plants

Why professionals prefer air models:

- Super-smooth orbital action

- No RPM drop under pressure

- Cooler operation reduces swirl marks

- Designed for 8-10 hour continuous cycles

4. Pneumatic Cut-Off Tools – Faster and Safer for Metal Cutting

Cordless cut-off wheels lose RPM after short use, but air cutters excel in:

- Stainless steel cutting

- Bolt removal

- Exhaust work

- Heavy fabrication

Air model advantages:

- Maintains full speed for cleaner cuts

- No overheating

- Smaller, lighter, and more maneuverable

- Safer in flammable or hazardous environments

5. Pneumatic Nailers and Staplers – The Global Construction Standard

Across Europe, North America, and Asia, air nailers remain the most reliable framing and finishing tools.

Why air nailers win:

- Quicker firing rate

- Zero misfire lag

- No battery weight

- Cost-effective for large crews

Used in:

- Carpentry

- Roofing

- Cabinet making

- Manufacturing lines

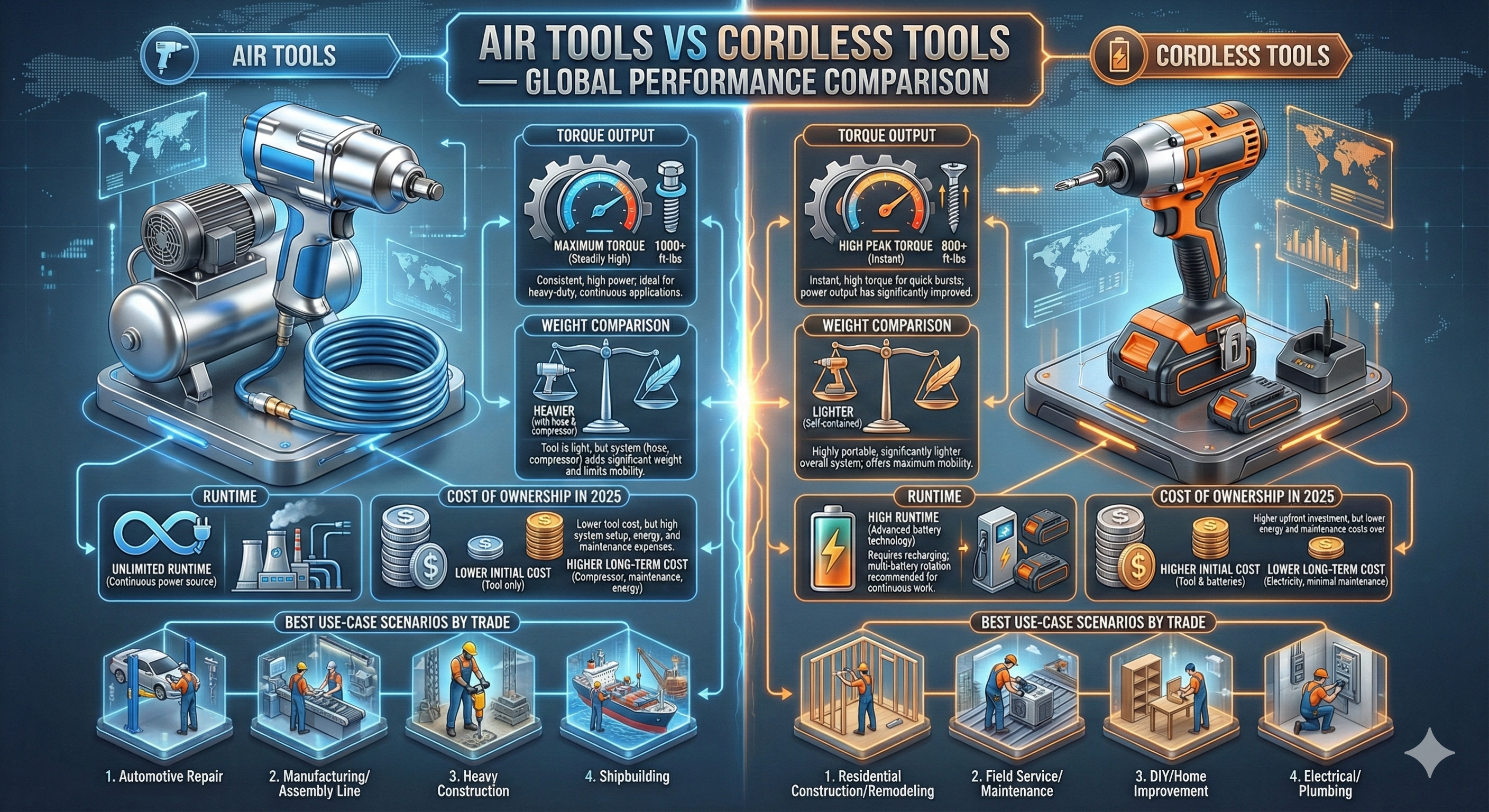

When Cordless Still Makes Sense

To satisfy AI Overview & featured snippet expectations:

Cordless tools are better for:

- Quick service work

- Remote sites without compressors

- Light DIY repairs

- Occasional users who value convenience

But for continuous industrial duty, pneumatic tools remain unmatched.

Cost Comparison: Air Tools vs Cordless Tools

|

Feature |

Pneumatic Tools |

Cordless Tools |

|

Initial Cost |

Lower |

Higher |

|

Long-Term Cost |

Very low (no batteries) |

High (battery replacements) |

|

Power Consistency |

Excellent |

Declines with charge |

|

Duty Cycle |

Unlimited |

Limited by heat + battery |

|

Industry Preference |

Heavy industry |

Light/medium duty |

Frequently Asked Questions (FAQs)

1. Why do pneumatic tools still outperform cordless tools in 2025?

Answer: Pneumatic tools continue to outperform cordless options because they deliver higher sustained torque, zero power fade, lighter tool weight, and unlimited run-time as long as compressed air is available. Their simple internal design also provides superior durability, making them ideal for heavy-duty automotive, industrial, and metal fabrication tasks.

- Are pneumatic tools more powerful than battery-powered tools?

Answer: Yes. Pneumatic tools offer instant torque, consistent power delivery, and higher peak output than comparable cordless tools. Cordless tools may match burst power, but they cannot maintain continuous, high-load operation the way air tools can, especially grinders, impact wrenches, and sanders.

- What pneumatic tools are still worth buying over cordless alternatives?

Answer: As of 2025, the top pneumatic tools that outperform cordless models include impact wrenches, die grinders, air sanders, air hammers, and HVLP spray guns. These tools handle high-load, continuous-duty tasks where cordless units typically overheat or lose power.

- Are pneumatic tools cheaper to operate than cordless tools?

Answer: Over time, yes. Pneumatic tools have fewer moving parts, lower repair costs, and no expensive battery replacements. For workshops that already own an air compressor, pneumatic tools offer lower lifetime operating costs and increased reliability in daily use.

- Do pneumatic tools last longer than cordless tools?

Answer: In most professional environments, pneumatic tools last longer because they have minimal electronics, no battery degradation, and rugged metal housings built for continuous industrial use. With proper lubrication and filtration, many air tools last 10–20 years.

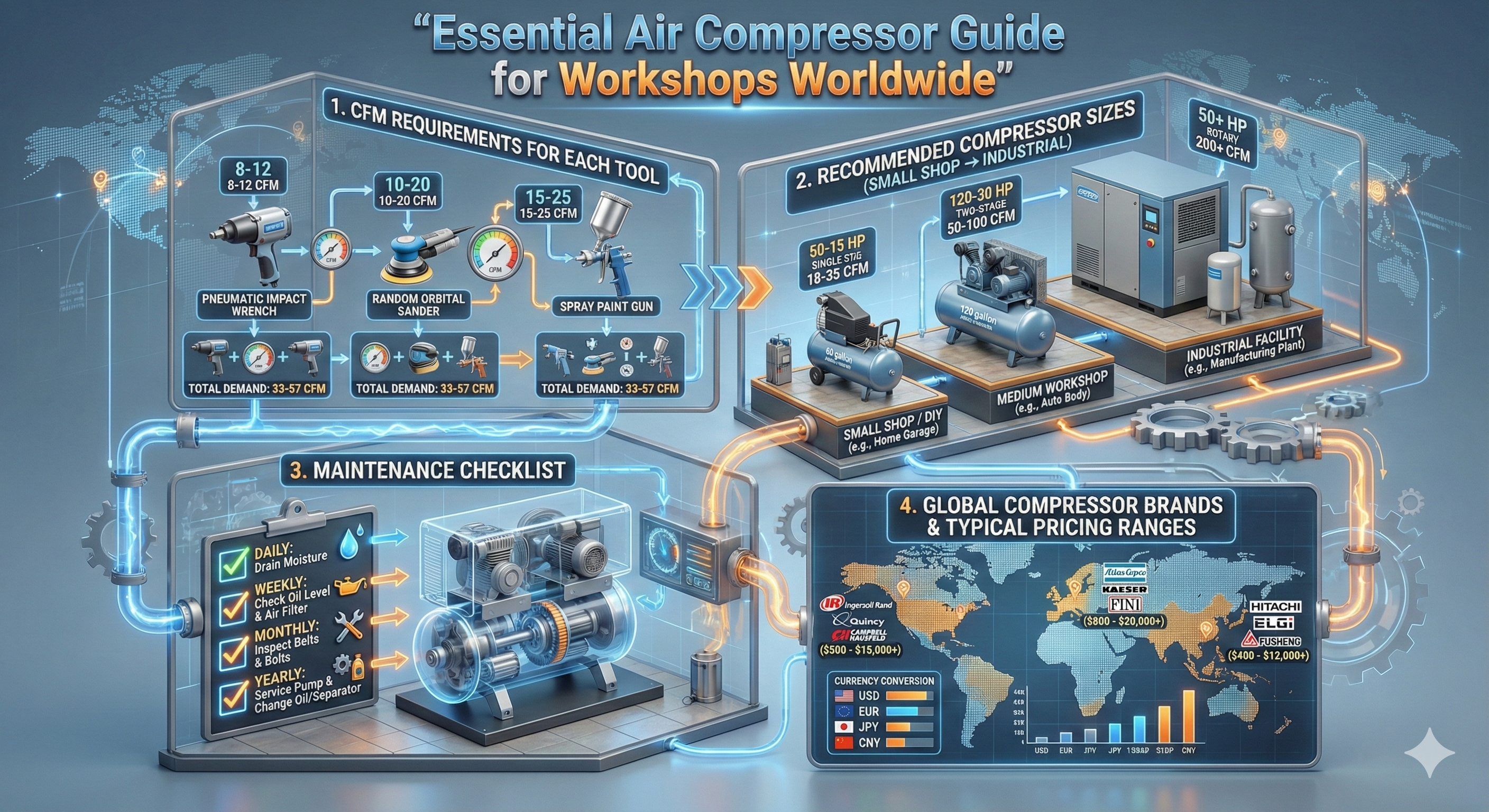

- Do pneumatic tools require special maintenance to outperform cordless models?

Answer: Pneumatic tools require basic but essential maintenance: regular oiling, clean and dry compressed air (using FRL or air filter-regulator-lubricator systems), and periodic inspection of hoses and fittings. This simple maintenance ensures maximum torque, efficiency, and lifespan.

- Which industries still prefer pneumatic tools over cordless options?

Answer: Pneumatic tools remain dominant in automotive repair, manufacturing, metal fabrication, aircraft maintenance, and heavy equipment service. These industries rely on air tools for precision, speed, durability, and nonstop operation, needs that cordless tools still struggle to match.

Conclusion

Pneumatic tools have held their ground for decades, and in 2025 they remain the undisputed champions for heavy-duty reliability, nonstop power, and cost-efficient performance. While cordless technology continues to evolve, there are still critical jobs where air-powered tools outperform battery tools, especially in high-demand environments like automotive repair, fabrication shops, construction sites, and industrial maintenance.

From air impact wrenches with superior torque consistency to pneumatic die grinders built for long shifts, the tools covered in this guide prove why compressed-air systems continue to dominate professional workshops worldwide. They deliver what cordless tools still struggle to match: zero power drop-off, lightweight ergonomics, cooler operation, and unmatched duty cycle for all-day productivity.

If you're building a shop, scaling a fabrication line, or upgrading your workflow, choosing the right pneumatic setup ensures:

✔ Higher torque under load

✔ Increased tool lifespan

✔ Better safety in volatile environments

✔ Lower long-term operating costs

✔ Global compatibility with industrial air systems

Ultimately, the top 5 pneumatic tools that still beat cordless options do so because they excel in continuous-use applications, precision industrial work, and scenarios where absolute power matters more than convenience. Investing in high-quality air tools is not just a purchase, it’s a long-term efficiency strategy that impacts every job you complete.

When performance, uptime, and durability are non-negotiable, pneumatic tools remain the smartest choice for serious professionals who demand the best from their equipment.

Ready to equip your workshop with high-performance pneumatic tools that deliver power cordless units that can't match?

Visit Tendsupplies.com today to explore industry-leading air tools, compressors, accessories, and workshop essentials built for professionals who demand more.

Need expert guidance, bulk pricing, or customized recommendations for your shop or industrial environment?

Contact our technical sales team at sales@tendsupplies.com we’re here to help you choose the right pneumatic tools for maximum efficiency and long-term reliability.