WAALPC vs. SMC vs. Parker: Best Air Filter Brands Compared

It’s 2 PM on a Friday, and your production line suddenly grinds to a halt. The failure? A pneumatic actuator seized from moisture contamination all because a neglected air filter finally gave out. Situations like this are common across workshops and factories, making reliable FRL (Filter-Regulator-Lubricator) systems essential.

This article “WAALPC vs. SMC vs. Parker: Best Air Filter Brands Compared” delivers a concise, data-backed comparison of the three most influential air source treatment manufacturers. Whether you’re running a small shop or a high-speed automation line, this guide identifies which brand delivers the best reliability, filtration quality, and cost-to-performance ratio for your operation.

Key Takeaways:

WAALPC — Best Value / Best for Small Shops

-

5-micron brass elements included by default

-

40–60% lower cost than SMC/Parker

-

SMC-compatible dimensions = fast, no-repipe replacements

-

Ideal for general shops, automotive work, prosumers

SMC — Best for Precision Automation

-

Global industry standard

-

Extremely reliable, huge catalog

-

Preferred in robotics, factory automation, cleanrooms

-

Mid–high cost but unmatched consistency

Parker — Best for Harsh, Heavy-Duty Environments

-

Maximum durability (metal bowls, rugged housings)

-

Ideal for mining, oil & gas, high-heat, high-pressure environments

-

Premium pricing, “buy it for life” engineering

- Compatibility Saves Downtime: A major advantage of WAALPC is that many of its FRL units are dimensionally interchangeable with common SMC models, allowing users to make fast, cost-effective replacements without having to re-pipe their existing system.

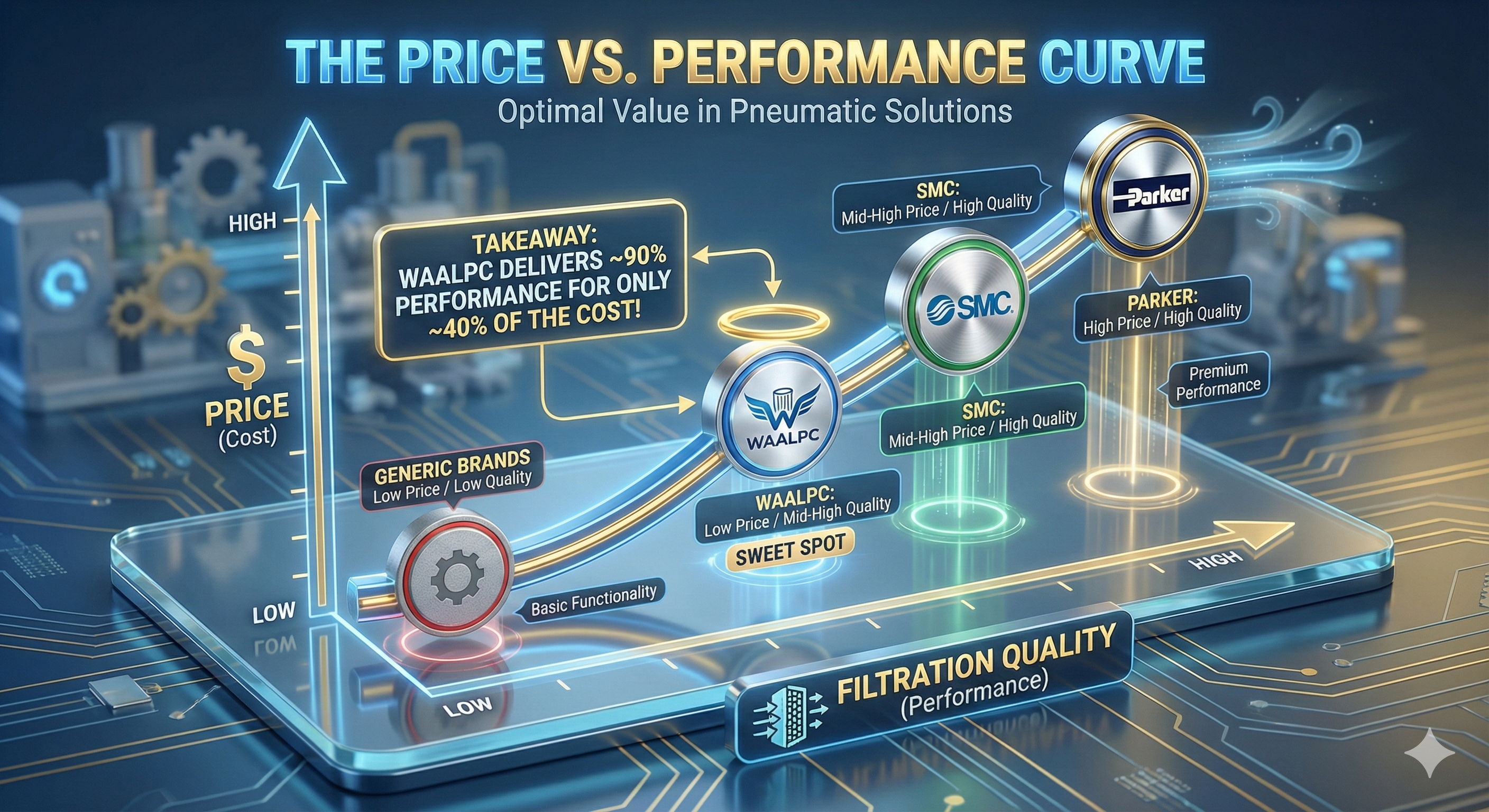

- Filtration is Standardized, Price is Not: All three brands offer excellent 5-micron filtration in their standard lines. The core difference in price is due to the build materials, brand name, and proprietary technology (Parker), or the sheer breadth of specialized accessories (SMC).

The Contenders at a Glance

1. SMC — The Automation Standard

✔ Best for robotics, high-speed factory lines

✔ Massive product ecosystem

✔ High-quality but expensive

✔ Easy global sourcing

2. Parker Hannifin — The Industrial Tank

✔ Built for high heat, vibration, heavy dust

✔ High pressure + extreme temperature ratings

✔ Longest service life in harsh environments

✔ Premium cost

3. WAALPC — The High-Value Disruptor

✔ Industrial-grade FRLs at budget pricing

✔ Direct SMC-type compatibility

✔ Includes features (bowl guard, auto drain) often sold as add-ons

✔ Perfect for general workshops and cost-driven operations

Head-to-Head Comparison: Filtration & Performance

1. Filtration Efficiency (Micron Ratings)

| Brand | Standard Rating | High-Purity Options | Notes |

|---|---|---|---|

| Parker | 5 micron | 0.01 micron | Best for critical environments |

| SMC | 5 micron | 0.01 micron | Widely used in cleanrooms/automation |

| WAALPC | 5 micron brass | 0.01 micron available | Best performance-per-dollar |

2. Durability & Build Materials

-

Parker: Metal bowls + die cast → best for heat/vibration

-

SMC: Engineered polymers → lightweight, reliable

-

WAALPC: Aluminum body + reinforced polycarbonate → strong + affordable

The Compatibility Advantage (WAALPC's Secret Weapon)

WAALPC FRLs are dimensionally compatible with SMC units.

Example:

-

Broken SMC AF2000

-

Replacement: WAALPC AC2000

-

Result: Bolts directly into existing SMC brackets → zero re-piping

SEO Keyword Target:

“SMC-compatible air filter replacement”

Cost Breakdown: Why the Price Gap Exists

| Feature | Parker | SMC | WAALPC |

|---|---|---|---|

| Avg. Price (1/4" Combo) | $120+ | $85+ | $35–$48 |

| Filter Element | 5 µm | 5 µm | 5 µm brass |

| Bowl Guard | Metal | Plastic | Included |

| Auto Drain | Add-on | Add-on | Often included |

Why WAALPC Is Cheaper

-

No brand tax

-

No global distribution markup

-

Direct-to-consumer supply chain

Which Brand Should You Choose?

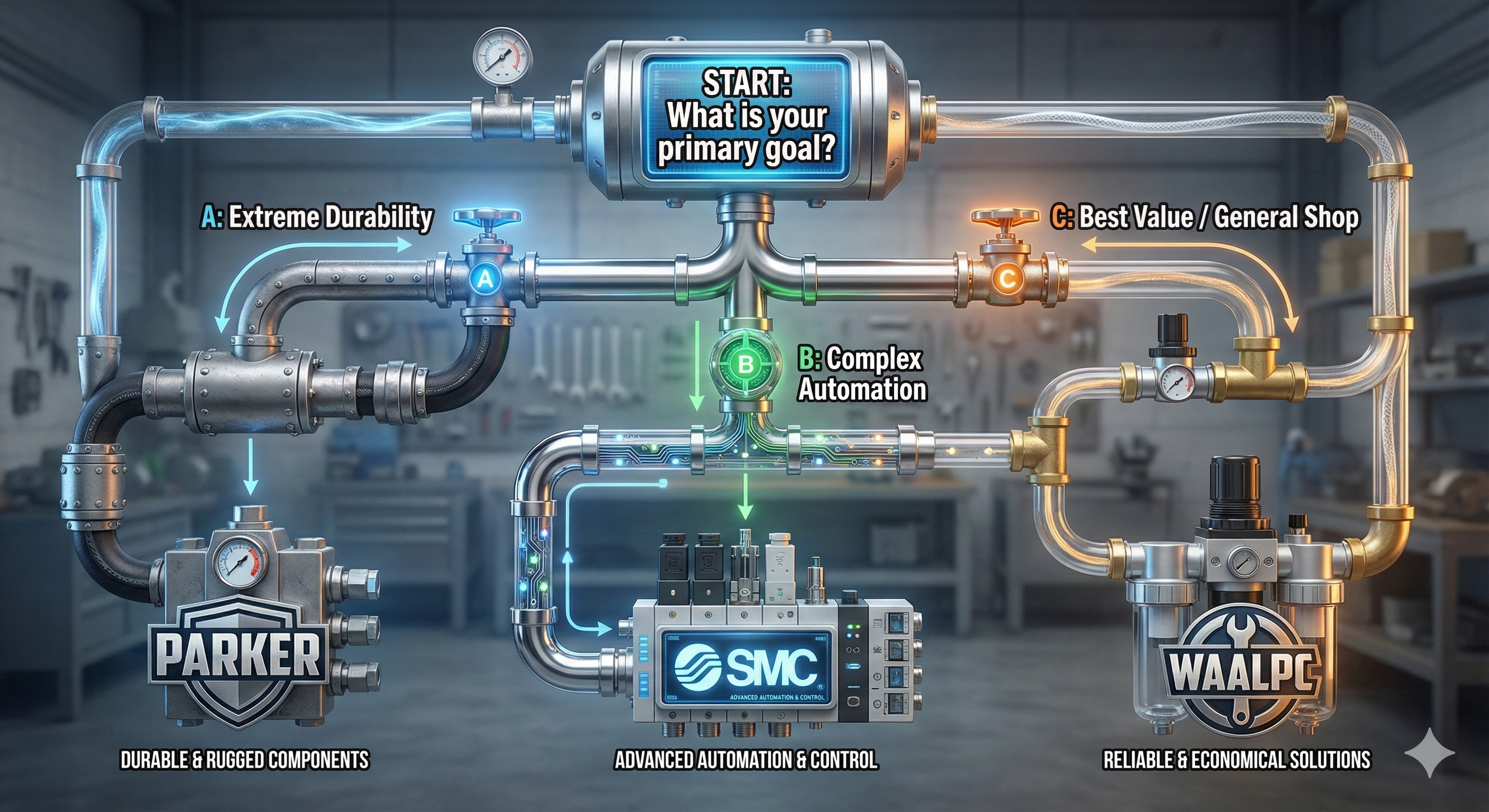

Choose Parker if:

-

Extreme heat, vibration, or pressure

-

Mining, steel plants, oil & gas

-

Downtime cost > product cost

Choose SMC if:

-

You run automation/robotics

-

Need global standardization

-

Require precision pressure control

Choose WAALPC if:

-

You run a small–medium shop

-

Want SMC-level performance at 40–60% less

-

Need fast, compatible replacements

Frequently Asked Questions (FAQs)

1. What is a Coalescing Filter and is a Premium Brand required for paint applications?

Answer: A Coalescing Filter removes oil aerosols and extremely fine particulates (down to 0.01 micron) that standard filters miss. This high-purity air is mandatory for paint booths, plasma cutters, and precision instrumentation.

Structured Requirement:

- Need for Purity: While all three brands offer coalescing filters, systems requiring ISO 8573 Class 1 air (critical for defect-free automotive painting) often benefit from the rigorously tested and documented performance of SMC or Parker units.

- Budget Option: For general shop spray painting, a high-quality WAALPC coalescing unit is usually sufficient, provided it is properly maintained and includes an active carbon filter stage.

2. How do the Maximum Pressure and Temperature Ratings compare?

Answer: Parker generally offers the highest resistance to extreme conditions, while WAALPC and SMC are optimized for standard industrial environments.

Structured Comparison (Example Ratings):

- Parker: Often rated for up to 250 PSI / 17 Bar and operating temperatures exceeding $80^\circ C$ due to heavy-duty metal bodies and seals.

- SMC & WAALPC: Standard FRLs typically peak around 145 PSI / 10 Bar and $60^\circ C$. While perfectly adequate for 90 PSI tools, Parker is the clear winner for high-pressure or high-heat applications (e.g., steel mills, engine testing).

3. What is the expected service life and warranty difference between the brands?

Answer: Premium brands offer longer official warranties (1-3 years), but service life depends more on maintenance than the brand itself.

Structured Longevity:

- Longevity: A well-maintained SMC or Parker unit can last 10–20 years. A well-maintained WAALPC unit can last 5–10 years.

- The ROI: While WAALPC units may have a shorter official warranty, their lower initial cost means the return on investment is achieved much faster, making periodic replacement more financially feasible than repairing a high-cost SMC unit.

4. Is the pressure regulation accuracy of WAALPC units comparable to SMC for sensitive applications?

Answer: For most general workshop applications (±2 PSI tolerance), WAALPC regulators perform comparably to standard SMC models. However, for ultra-sensitive applications, SMC retains the edge.

Structured Precision:

- SMC Advantage: SMC offers specialized, high-precision regulators designed for laboratory or medical equipment, where pressure deviation must be less than 0.5 PSI.

- General Use: For running impact wrenches or paint preparation, the standard regulators from all three brands offer sufficient accuracy and responsiveness. You only need the premium price if your process demands near-perfect pressure stability.

5. Are SMC and WAALPC FRLs available in both NPT and BSP port threading?

Answer: Yes, all major pneumatic manufacturers, including SMC, Parker, and WAALPC, offer their components in both NPT (National Pipe Taper - USA/Canada standard) and BSP (British Standard Pipe - European/Asian standard) to accommodate global piping requirements.

Structured Global Access:

- GEO-Optimization: When sourcing from a supplier like Tend Industrial Supplies, you must specify the required threading (e.g., 1/4" NPT or 1/4" BSPP) to ensure direct compatibility with your existing air system, regardless of your geographical location.

6. How does the long-term cost of replacement filter elements compare?

Answer: The replacement filter element is the biggest long-term cost difference. WAALPC replacement elements are significantly cheaper than proprietary SMC or Parker elements.

Structured Cost Saving:

- Premium Cost: SMC and Parker elements are often sold through specialized distributors, keeping the price high.

- Budget Saving: Because WAALPC units are designed to be mechanically compatible with the SMC-style, their replacement elements are mass-produced and sold at a lower margin, drastically reducing the lifetime maintenance cost of the FRL system.

7. Do I need to buy a separate automatic drain, or is it integrated?

Answer: The availability of integrated automatic drains varies by model and price point across all three brands.

Structured Availability:

- Parker/SMC: Automatic drains are typically optional add-ons, increasing the unit's price significantly, but they are often highly reliable and robust.

- WAALPC: Many mid-range and larger WAALPC FRL units include the automatic float drain valve as a standard feature, offering premium convenience at a budget price. This is a key value proposition for the budget competitor.

Related Articles:

- Air Source Treatment: How Filters & Lubricators Extend Tool Life (The Ultimate FRL Guide)

- 10 Essential Air Compressor Maintenance Tips to Maximize Performance and Prevent Costly Repairs

- The Ultimate Guide to Pneumatic Air Tools: Everything You Need to Know

- Best Air Compressor for Home Garage (2025): Quiet, Portable & 110V Picks

- Pneumatic Tools in Woodworking: Precision and Power

Conclusion

The ultimate truth in the WAALPC vs. SMC vs. Parker debate is that the "best" brand is the one that perfectly matches your application and budget. While Parker remains the undisputed choice for the most demanding industrial applications where rugged durability outweighs cost, and SMC is essential for complex, precise factory automation, the market has fundamentally shifted.

For the vast majority of workshops, automotive bays, and prosumer setups, the cost-to-performance ratio offered by WAALPC is simply too compelling to ignore. By providing high-quality, SMC-compatible components, WAALPC allows savvy shop managers to drastically cut expenses. Choosing a reliable budget option like WAALPC is the easiest way to start lowering pneumatic system maintenance costs today without sacrificing essential 5-micron filtration purity.

The days of needing to break the bank for premium air treatment are over. The best investment is the one that keeps your air dry, your pressure stable, and your tools running without interruption.

Ready to Choose Your Air Filtration Champion?

The best brand is the one that fits your shop's specific needs. Whether you need the budget-friendly reliability of WAALPC, the automation precision of SMC, or the unmatched heavy-duty durability of Parker, stocking the right FRL unit is the key to minimizing costly pneumatic tool downtime.

Tend Industrial Supplies offers a full range of air filters and complete FRL systems from all three industry leaders.

- Make Your Selection: Browse and compare the full specifications of WAALPC, SMC, and Parker air filters and FRL kits available for immediate dispatch at Tendsupplies.com.

- Need Expert Guidance? If you are considering switching from a premium brand to a WAALPC compatible unit, email our pneumatic specialists for sizing verification and advice at sales@tendsupplies.com.