What Are Industrial Air Bevelers and Cutters Used For? The Global Guide to Precision Metal Preparation

A pipeline welder in northern Canada once spent an entire shift grinding one pipe joint with a manual grinder. The edge quality was inconsistent, the bevel angle was uneven, and the weld ultimately failed X-ray inspection, forcing a costly rework. The root cause? Poor edge preparation.

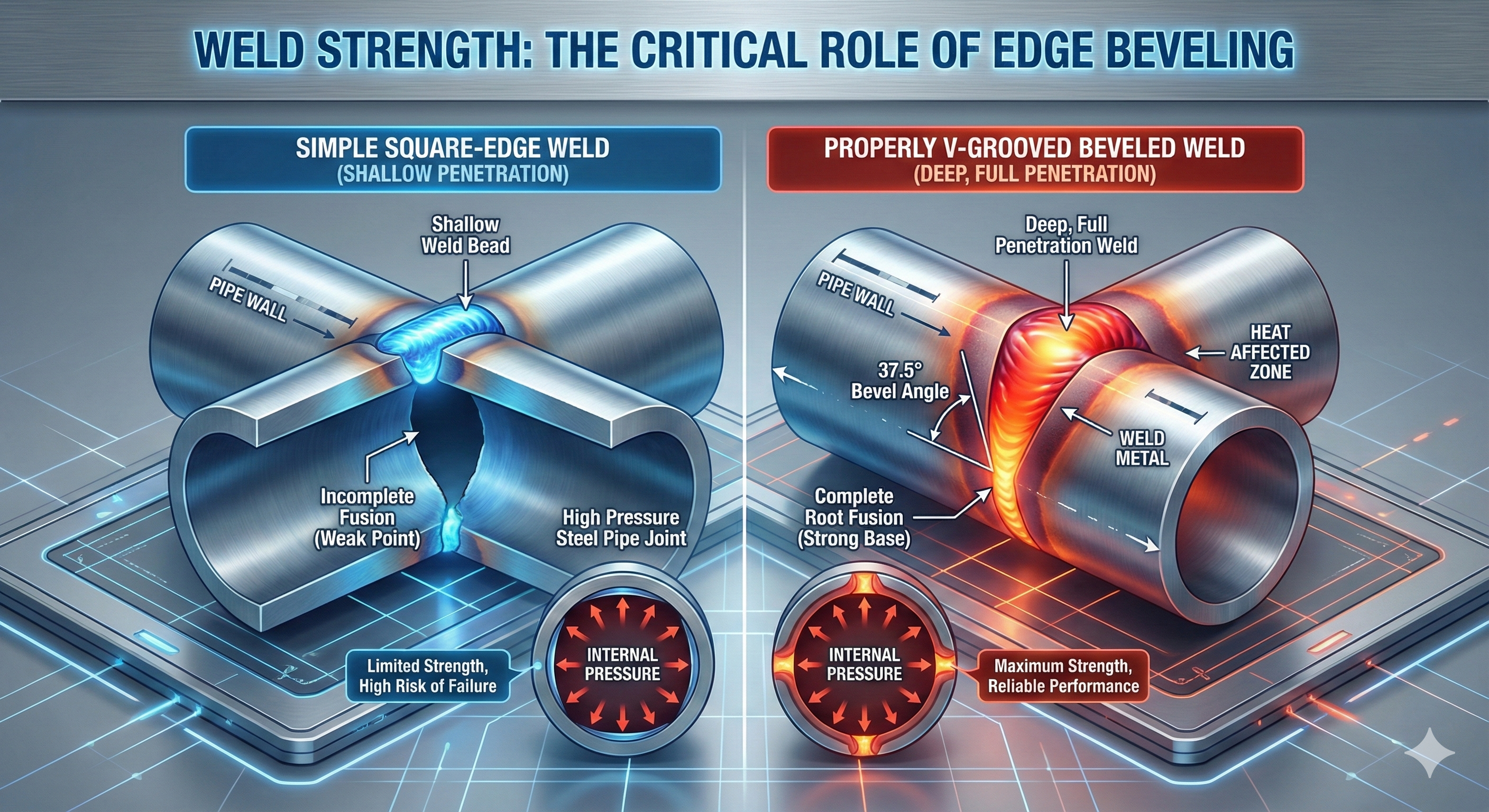

In industries where steel, pressure, and precision collide, oil & gas, shipbuilding, structural fabrication, the quality of the weld always begins with the quality of the bevel.

This expert-driven analysis, What Are Industrial Air Bevelers and Cutters Used For?, explains how pneumatic beveling technology delivers the accuracy, safety, and repeatability required for high-integrity welding in mission-critical environments worldwide.

Quick Answer

Industrial air bevelers and cutters are used to create precise beveled edges on metal plates, pipes, and tubes to ensure full weld penetration and structural integrity. Powered by compressed air, these tools cold-mill the material to produce consistent V-grooves, J-grooves, and other weld profiles without generating sparks, making them essential for heavy fabrication, pipeline construction, refinery maintenance, and shipbuilding.

Key Takeaways:

-

Primary Function: Create bevels for strong, high-integrity weld joints.

-

Safety Advantage: Pneumatic systems are non-sparking, ideal for volatile environments.

-

Global Industrial Use: Pipelines, refineries, shipyards, structural steel, boiler fabrication.

-

Cold Milling Benefits: No Heat-Affected Zone (HAZ), preserving alloy strength.

-

Bevel Profile Versatility: V-bevel, X-bevel, J-bevel depending on code and thickness.

The Core Function: Why Beveling Matters in Modern Fabrication

Beveling creates a controlled, angled edge on a metal plate or pipe. This opening allows molten filler metal to penetrate fully, producing a stronger weld with lower risk of cracking, porosity, or failure under pressure. Without proper edge geometry, even the best welder cannot achieve a structurally sound joint.

The Anatomy of the Cut: Bevelers vs. Cutters

Industrial Air Bevelers

-

Cold-mill the metal using carbide inserts

-

Produce precise, repeatable bevel angles

-

Ideal for V-grooves, J-grooves, chamfers

-

Leave clean, contamination-free weld surfaces

Industrial Air Cutters (Split-Frame / Clamshell)

-

Used to cut pipes to length

-

Create perfectly square, perpendicular cuts

-

Many models perform simultaneous cut + bevel

Key Advantages of Pneumatic (Air) Bevelers

While electric models exist, air-powered tools are often preferred in heavy industry due to specific benefits:

| Feature | Pneumatic Advantage | Industrial Outcome |

|---|---|---|

| Safety | No sparks, no electrical failure risk | Approved for refineries & hazardous zones |

| Torque Stability | High torque at low RPM | Superior for thick carbon steel & alloys |

| Durability | No overheating, minimal wear | Long tool life in harsh jobsite conditions |

| Low Weight | Lighter than electric units | Reduced operator fatigue |

Global Applications: Where Industrial Air Bevelers are Indispensable

The demand for accurate edge preparation spans virtually every major industrial sector. The versatility of air beveling equipment, from handheld portable units to heavy-duty stationary machines, allows for their critical use globally, from shipyards in Busan to oil and gas pipelines in the Middle East.

1. Oil & Gas / Petrochemical

-

Pipeline beveling for full-penetration welds

-

Safe in explosive environments due to non-sparking operation

-

Essential for stainless, Duplex, Inconel, and high-nickel alloys

2. Heavy Fabrication, Construction, and Structural Steel

Whether constructing massive infrastructure or pre-fabricating structural beams for a skyscraper, industrial air bevelers ensure components fit together perfectly before welding.

-

Preparing thick steel plates for high-load structures

-

Creating X-bevels and K-bevels to reduce filler metal volume

-

Deburring after plasma or oxy-fuel cutting

3. Boilerwork and Heat Exchanger Manufacturing

This niche application demands extremely high tolerances, often in the order of hundredths of a millimeter.

-

ID-mounted bevelers prep small tubes

-

Ensures precision fit for tube-to-sheet welds

-

Critical for high-pressure, high-temperature conditions

Precision and Consistency: Key Technical Beveling Concepts

To achieve the highest standards required by codes (like ASME and API), operators use air bevelers to achieve specific cut profiles and tolerances.

Common Weld Prep Profiles

The type of bevel cut directly influences the strength and efficiency of the weld:

V-Bevel

-

Standard for sheet metal

-

Good for single-pass welding

X-Bevel

-

Two-sided bevel

-

Reduces warpage and filler usage

J-Bevel

-

Rounded, low-volume profile

-

Preferred for nuclear, petrochemical, and offshore applications

Best Practices for Different Materials

Industrial air bevelers are highly versatile but require the right technique for optimal results:

-

Carbon Steel: High feed rates, efficient removal

-

Stainless Steel: Avoid work hardening; use proper inserts

-

High Alloys (Duplex, Inconel): Low RPM, high torque, cold milling required

Frequently Asked Questions (FAQs)

1. What is cold milling, and why is it preferred over grinding for weld preparation?

Cold milling is the process used by industrial air bevelers where material is precisely removed using hardened carbide inserts without generating significant heat. This is preferred over grinding because cold milling leaves a cleaner, contaminant-free surface, prevents the formation of a Heat-Affected Zone (HAZ) on the metal edge (especially crucial for stainless steel and alloys), and produces a highly consistent bevel angle that grinding cannot match.

2. What is the difference between a V-bevel and a J-bevel, and when should each be used?

The difference lies in the profile:

- A V-bevel is a straight-sided angled cut (like a "V" or $\wedge$), typically used for thinner to medium materials to allow single-pass welding.

- A J-bevel is a rounded, concave cut (like a "J" or hook) that reduces the land area and the amount of filler metal needed. J-bevels are preferred in high-integrity applications (e.g., nuclear or oilfield) on thick materials to minimize heat input and distortion.

3. Why are air (pneumatic) bevelers safer than electric bevelers in oil and gas environments?

Air bevelers are inherently safer because they operate without an electric motor, meaning they do not generate sparks or the risk of motor burnout. This non-sparking feature is mandatory for use in volatile or potentially explosive atmospheres commonly found in refineries, chemical plants, and active pipelines where strict safety protocols prohibit ignition sources.

4. Can industrial air bevelers process high-strength alloys like Duplex or Inconel?

Yes, they are highly effective for processing high-strength alloys. Air bevelers maintain high torque at lower cutting speeds, which is essential for machining difficult materials like Duplex, Super Duplex, and Inconel. The cold milling action, combined with specific tooling, ensures these materials are prepared without work hardening or micro-fracturing, which would compromise the final weld.

5. What is an ID-mounted beveler, and where is it primarily used?

An ID-mounted (Inside Diameter) beveler is a portable machine that locks onto the inner wall of a pipe or tube. It is primarily used for preparing tube sheets in the manufacturing or maintenance of boilers, heat exchangers, and condenser units. These machines are designed for high precision in small-diameter tubes where external access is limited or impossible.

6. What IP rating should I look for if the beveler is used outdoors or on a jobsite?

While IP ratings are less common on pure pneumatic tools than electric ones, you should look for tools or systems rated for resistance to ingress. A basic rating of IP44 provides protection against splashing water and tools should be stored in weatherproof cases. For simultaneous cut and bevel machines used heavily outdoors, the motor components often aim for IP54 or higher for protection against dust and water spray.

7. How do air bevelers minimize warpage when preparing thick steel plates for welding?

Air bevelers minimize warpage by allowing for compound beveling (like the X-bevel), which is crucial for thick metal plate fabrication. By beveling both the top and bottom edges, the resulting weld can be completed in balanced passes. This distributes the weld heat evenly, counteracting the concentrated shrinkage forces that cause severe warpage and distortion when a single-sided (V-bevel) approach is used on heavy material.

Related Articles:

Best Strategies for Pneumatic Tools Safety

The Importance of Safety When Using Pneumatic Air Tools

Conclusion

Consistent, weld-ready edge preparation is no longer optional, it is the foundation of structural reliability in every major fabrication industry. Industrial air bevelers and cutters deliver the precision, safety, and repeatability required for pipelines, pressure vessels, shipbuilding, and large-scale steel construction.

For fabrication teams that demand predictable weld quality, pneumatic beveling tools are the global standard.

Stop compromising on weld integrity with inconsistent cuts and messy manual grinding. The precision and safety offered by industrial air bevelers and cutters are non-negotiable for modern fabrication and high-pressure pipework.

Explore the full range of pneumatic beveling tools and simultaneous cut and bevel machines discussed in this guide by visiting Tendsupplies.com.

Need to equip a fabrication line or a major pipeline project? For bulk pricing, technical specifications, or customized solutions, reach out to our industrial sales experts.

Email us now at: sales@tendsupplies.com to ensure your next project starts with a perfect, weld-ready edge!