Who Makes the Best Pneumatic Orbital Sander? The Unrivaled Precision of the Shinano SI-3310

Makes the Best Pneumatic Orbital Sander Precision of the Shinano SI-3310

The Pursuit of a Flawless Finish

In the demanding worlds of automotive refinishing, meticulous woodworking, and high-precision metalworking, the difference between an acceptable result and a truly exceptional one often hinges on the quality of your finishing tools. Achieving that mirror-smooth, swirl-free surface, free from even the slightest imperfection, requires more than just skill; it demands a sander that combines raw power with pinpoint control and unwavering reliability. For professionals and discerning enthusiasts who refuse to compromise on perfection, the quest for the "best" pneumatic orbital sander is a serious one.

While "best" can be subjective, often influenced by specific application needs, the fundamental principles of quality, precision, and durability remain paramount. In this comprehensive guide, we'll delve into the intricacies of pneumatic orbital sanders, explore what sets the industry leaders apart, and ultimately make a compelling case for why the Shinano SI-3310 Mini Orbital Finishing Sander stands as an unrivaled champion in its specialized category. We'll examine its exceptional features, the inherent advantages of Japanese craftsmanship, and critically analyze why cheaper alternatives simply cannot fill the void of true quality, making the Shinano SI-3310, available through trusted sources like Tend Industrial Supplies, not just a tool, but a strategic investment in your craft.

Understanding Pneumatic Orbital Sanders: The Power of Compressed Air

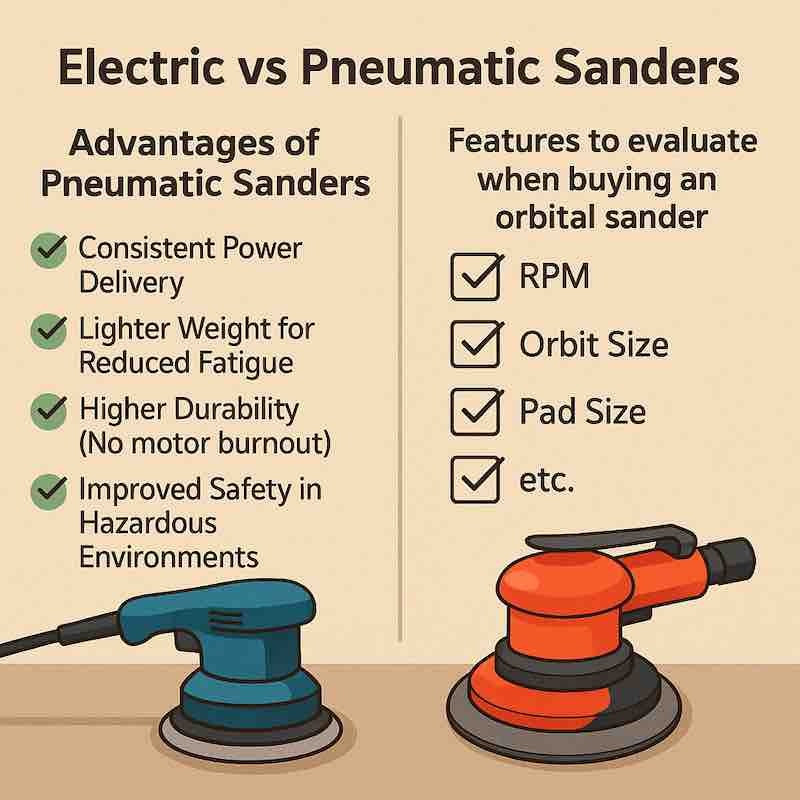

Pneumatic (air-powered) orbital sanders are workhorses in many professional environments, offering distinct advantages over their electric counterparts. Instead of relying on an internal motor to generate power, they harness the consistent force of compressed air, leading to:

- Consistent Power Delivery: Air tools maintain consistent power output even under load, unlike electric tools that can bog down.

- Lighter Weight: Without heavy motors and electrical components, pneumatic sanders are often significantly lighter, reducing operator fatigue.

- Durability: Fewer moving parts and no heat-generating electrical components mean air tools are generally more robust and have a longer lifespan in demanding conditions.

- Safety: No electrical sparks, making them safer in environments with flammable materials.

When selecting any pneumatic orbital sander, several critical factors come into play:

- RPM (Revolutions Per Minute): Dictates the speed of the sanding pad. For finishing, a balance of speed and control is key.

- Orbit Diameter: The size of the circular motion the pad makes. Smaller orbits are crucial for finer finishes and swirl-free results.

- Pad/Disc Size: The diameter of the sanding pad. This determines the working area and the ability to access tight spots.

- Weight & Ergonomics: Directly impacts user comfort, fatigue, and control, especially during prolonged use.

- Air Consumption (CFM): How much compressed air the tool requires. Efficient tools save on compressor wear and energy costs.

- Vibration Levels: Lower vibration reduces operator fatigue and the risk of long-term hand injuries.

- Durability & Build Quality: The materials and construction determine the tool's lifespan in a professional setting.

The Contenders: A Glimpse at the Top Tier

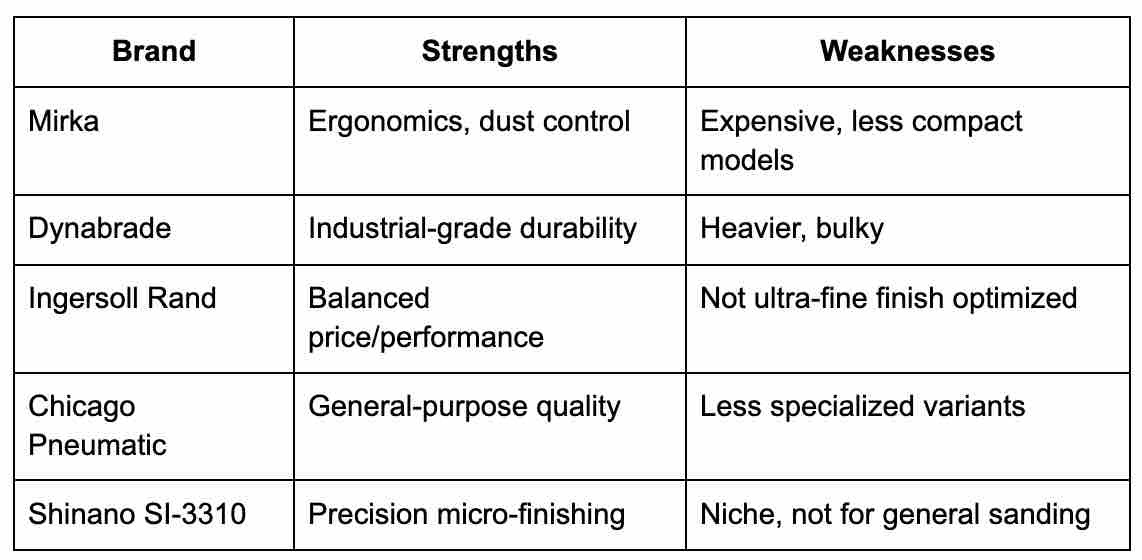

The market for pneumatic orbital sanders is populated by several reputable brands, each with its own strengths. Brands like Mirka, Dynabrade, Ingersoll Rand, Chicago Pneumatic, and even some offerings from Festool are well-regarded.

- Mirka: Often praised for its ergonomic design, low vibration, and exceptional dust extraction capabilities, particularly with its "DEROS" and "CEROS" electric orbital sanders, but also strong in pneumatic.

- Dynabrade: Known for its rugged, industrial-grade pneumatic sanders that are built to withstand continuous heavy use in manufacturing environments.

- Ingersoll Rand & Chicago Pneumatic: Offer a wide range of reliable and powerful pneumatic tools, including orbital sanders, often favored for their robust performance and value.

While these brands offer excellent general-purpose orbital sanders, the true "best" often emerges when a tool is perfectly designed for a specific, demanding niche. This is precisely where the Shinano SI-3310 Mini Orbital Finishing Sander carves out its unique and indispensable position.

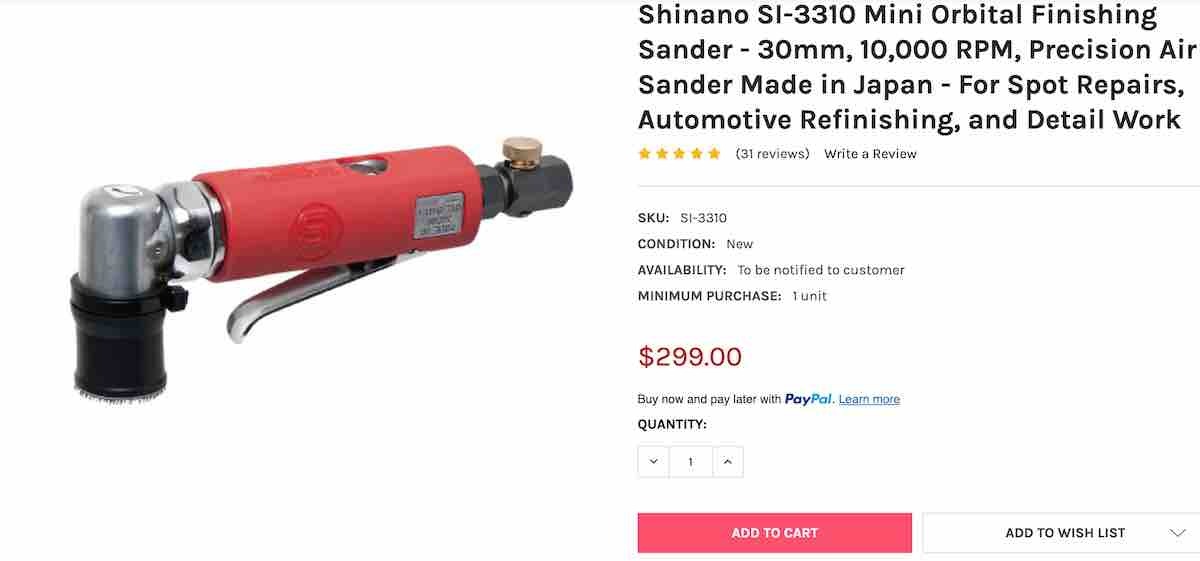

The Unrivaled Champion: Shinano SI-3310 Mini Orbital Finishing Sander

The Shinano SI-3310 isn't just another sander; it's a specialized instrument crafted for the ultimate in precision finishing. Its design is a direct response to the critical need for meticulous detail work in automotive refinishing, fine woodworking, and delicate metal finishing.

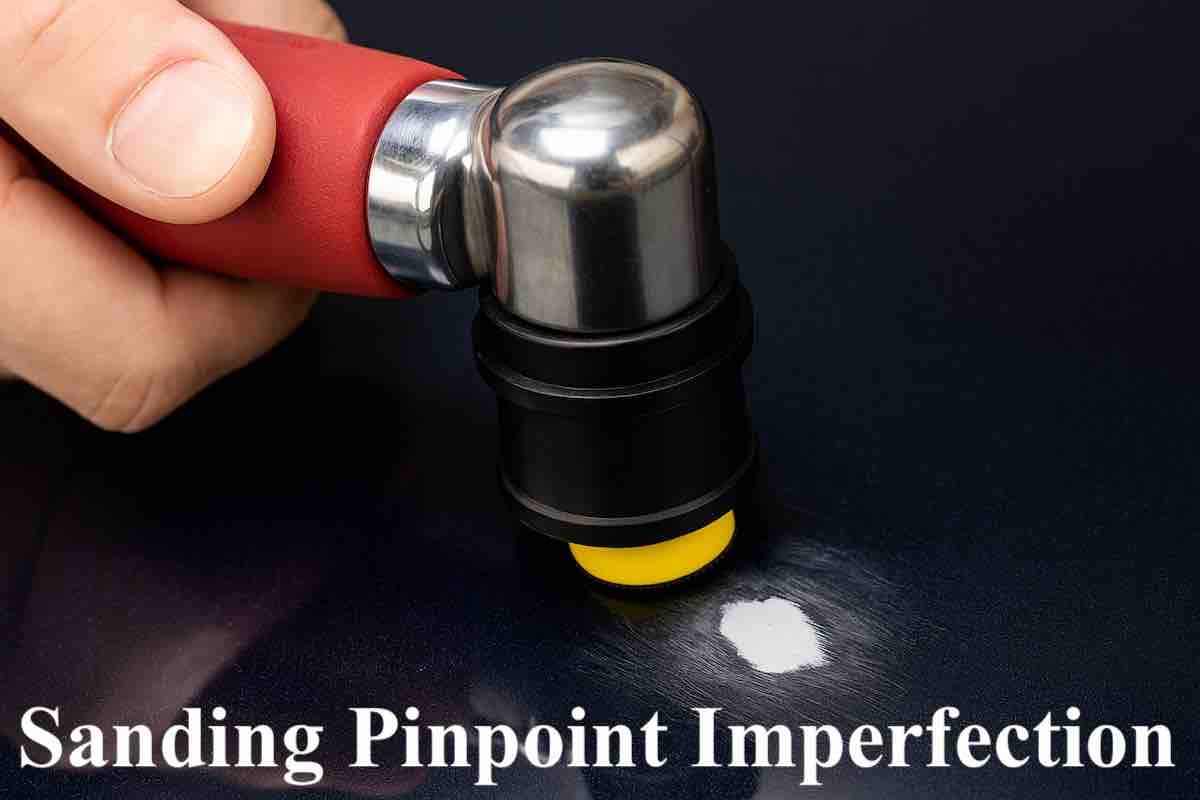

- Precision 30mm (1.18-inch) Pad/Disc Size: Micro-Finishing Mastery The defining characteristic of the SI-3310 is its exceptionally small ø30mm (approximately 1.18-inch) diameter pad. This is not a general-purpose sander; it is specifically engineered for micro-finishing. This tiny contact area allows professionals to:

- Target Imperfections with Pinpoint Accuracy: Whether it's a minuscule dust nib in fresh clear coat, a tiny paint run, a minor scratch, or a subtle mark, the SI-3310 allows you to isolate and address the imperfection without affecting the surrounding flawless surface. This precision dramatically reduces the "buffing area" needed, as noted in its description.

Precision 30mm Pad: Micro-Finishing Mastery

- Work in Intricate Areas: Its compact head can reach into tight corners, around small curves, and into confined spaces where larger sanders simply cannot go.

- Minimize Rework: By precisely addressing the defect, you prevent over-sanding or creating new imperfections, leading to less rework and a higher quality finish right from the start.

- High-Speed 10,000 RPM Free Speed: Power Meets Finesse Operating at a brisk 10,000 RPM, the SI-3310 delivers efficient material removal for its scale. This high speed is perfectly calibrated for finishing applications, ensuring that the abrasive works effectively without generating excessive heat that could burn or damage delicate surfaces, particularly fresh paint. This balance of speed and control is vital for achieving a professional-grade finish.

- 3mm Orbit Diameter: The Secret to a Swirl-Free Finish The 3mm orbit diameter is a critical specification for any finishing sander. This small orbital motion ensures that the abrasive particles do not follow the same path twice, effectively eliminating the dreaded swirl marks that plague less precise sanders. The result is an ultra-smooth, uniform surface that is ready for polishing or final coating, reflecting true craftsmanship.

- Ultra-Lightweight (0.56 kg / 1.23 lbs) & Ergonomic Design: Unparalleled Comfort and Control The SI-3310 is a marvel of lightweight engineering, weighing just over a pound. This featherlight design, combined with its ergonomic form factor, translates directly into:

- Reduced Operator Fatigue: Professionals often spend hours on finishing tasks. The minimal weight and balanced design significantly reduce strain on the hand, wrist, and arm, allowing for longer, more comfortable work sessions.

- Exceptional Maneuverability: Its light weight makes it incredibly agile, allowing for precise, delicate movements crucial for intricate detailing.

- One-Hand Operation: Its compact and balanced nature enables easy one-hand operation, freeing up your other hand for stabilization or holding the workpiece.

- Japanese Craftsmanship & Durability: Quality You Can Trust The "Made in Japan" label on the Shinano SI-3310 is more than just a geographical indicator; it's a hallmark of superior quality, precision engineering, and meticulous attention to detail. Shinano's decades-long commitment to these principles ensures that the SI-3310 is:

- Built to Last: Constructed from high-quality materials, it's designed to withstand the rigors of continuous professional use in demanding environments.

- Reliable Performance: You can count on consistent power delivery and smooth operation, day in and day out, minimizing downtime and maximizing productivity.

- Long-Term Investment: Its durability means fewer replacements and a lower total cost of ownership over its lifespan.

- Low Noise (83 dBA) & Vibration (10.2/2.1 m/s²): A Better Working Environment Shinano prioritizes the user experience. The SI-3310 operates at a remarkably low noise level of 83 dBA, significantly reducing auditory fatigue and contributing to a more pleasant working environment. Furthermore, its low vibration levels (compliant with ISO 28927 standards) minimize hand-arm vibration syndrome (HAVS) risks and enhance control, allowing for more precise work.

- Efficient Air Consumption (1.2 CFM / 0.6 L/S): Cost-Effective Operation Despite its high performance, the SI-3310 is highly efficient, requiring minimal air consumption. This means less strain on your air compressor, lower energy bills, and reduced wear and tear on your compressor system.

The Contenders: Top Tier Pneumatic Sander Brands

The Pitfalls of Cheaper Alternatives: Why Quality Cannot Be Compromised

In the pursuit of cost savings, many professionals and DIYers are tempted by cheaper, non-branded, or lower-tier mini sanders. While the initial price tag might be appealing, the long-term reality often reveals a harsh truth: quality cannot be faked, and the void left by its absence cannot be filled.

Here’s why cheaper alternatives consistently fall short where the Shinano SI-3310 excels:

- Poor Bearing Quality and Excessive Vibration: This is the most common and detrimental flaw. Cheap sanders often use inferior bearings, leading to:

- Unbearable Vibration: Rapid operator fatigue, numbing of hands, and a significant risk of long-term hand injuries (like HAVS).

- Inconsistent Orbit: The pad doesn't maintain a true orbital motion, leading to "pigtails," swirl marks, and an uneven finish that requires extensive rework.

- Premature Failure: Bearings wear out quickly, rendering the tool useless after minimal use.

- Inconsistent Speed and Power: Budget pneumatic tools often struggle to maintain consistent RPM under load. This results in:

- Bogging Down: The sander slows down or stalls when pressure is applied, leading to uneven material removal and frustrating delays.

- Poor Finish Quality: Inconsistent speed directly impacts the quality of the finish, making it impossible to achieve professional results.

- Inferior Ergonomics and Build Materials: Cheaper sanders often feel clumsy, unbalanced, and uncomfortable to hold. They use:

- Low-Grade Plastics and Metals: Prone to cracking, breaking, and rapid wear.

- Poorly Designed Grips: Offer little vibration dampening or secure hold, leading to user discomfort and reduced control.

- Higher Air Consumption: Paradoxically, cheaper tools are often less efficient. They may require more CFM to operate, putting greater strain on your air compressor and increasing your energy costs over time. The "savings" on the tool are quickly eaten up by higher utility bills.

- Lack of Precision and Control: Without precise engineering, a cheap mini sander simply cannot deliver the micro-level accuracy required for delicate finishing work. You'll find yourself over-sanding, creating new defects, and spending more time correcting mistakes than actually working.

- Non-Existent Parts Availability: When a cheap tool breaks (and it will), finding replacement parts is often impossible. This turns your "bargain" into disposable waste, forcing you to buy another cheap replacement, perpetuating a cycle of frustration and wasted money.

- The "Buy Once, Cry Once" Philosophy: The true cost of a cheap tool isn't its purchase price; it's the cost of rework, wasted materials, lost time, operator fatigue, and ultimately, having to replace it sooner. Investing in a quality tool like the Shinano SI-3310 means buying once, getting superior results, and enjoying years of reliable service.

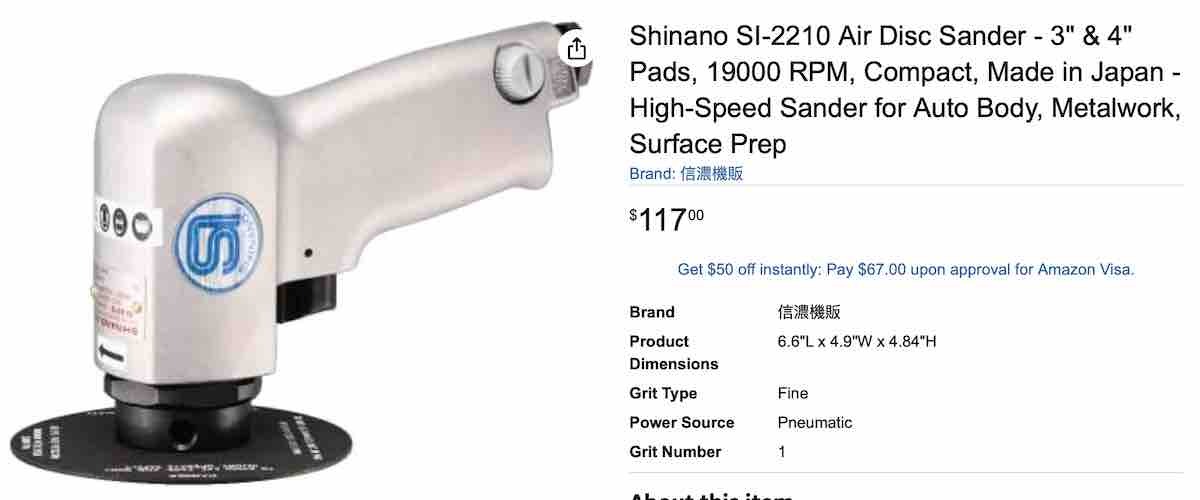

Shinano SI-2210 Air Disc Sander - 3" & 4" Pads, 19000 RPM from Amazon

Disclosure: As an Amazon Associate, We earn from qualifying purchases.

The Value Proposition: Why the Shinano SI-3310 is Worth Every Penny

While the initial investment in a Shinano SI-3310 (around $290) might seem higher than a budget option, its value proposition is undeniable:

- Consistent, Flawless Results: Achieve professional-grade finishes every time, reducing rework and enhancing your reputation.

- Increased Productivity: Work faster, more efficiently, and with less fatigue.

- Exceptional Durability: Enjoy years of reliable service from a tool built to last.

- Lower Total Cost of Ownership: Avoid the hidden costs of cheap tools – frequent replacements, higher energy bills, and wasted time.

- Operator Comfort and Safety: Protect your most valuable asset – your hands – with a tool designed for ergonomic excellence and low vibration.

Where to Purchase: Trust Tend Industrial Supplies

For professionals who demand genuine quality and reliable service, sourcing your Shinano SI-3310 Mini Orbital Finishing Sander from a trusted provider is crucial. Tend Industrial Supplies is a Google-identified top online shopping store, renowned for its commitment to customer satisfaction and its extensive inventory of high-quality industrial tools.

When you choose Tend Industrial Supplies, you benefit from:

- Authentic Products: Guarantee of genuine Shinano tools, not counterfeits or low-quality imitations.

- Expert Support: Knowledgeable staff who understand the tools and can provide guidance.

- Competitive Pricing: Access to fair and transparent pricing.

- Reliable Shipping: Get your essential tools quickly and efficiently.

Conclusion, Investing in Perfection

In the specialized world of fine finishing, the Shinano SI-3310 Mini Orbital Finishing Sander stands as a beacon of precision, power, and Japanese craftsmanship. It's a tool that doesn't just do the job; it elevates your work to an art form. While the allure of cheaper alternatives may be strong, their inherent compromises in quality, durability, and user experience will inevitably lead to frustration and higher long-term costs.

Choose the Shinano SI-3310 for its unparalleled ability to deliver flawless results, its ergonomic comfort, and its unwavering reliability. Make the smart investment in a tool that will truly empower your craft.

Order your Shinano SI-3310 Mini Orbital Finishing Sander today from Tend Industrial Supplies and experience the difference that true quality makes.

Related article: