Why Work Lights Are Shifting to Lithium Power

Work lights are undergoing a major transformation, and tradespeople feel it every day. Picture this: you're deep inside a crawl space diagnosing a faulty wire when your old NiCad-powered work light begins to dim into that familiar orange haze. Minutes later, you're forced to switch to a hot halogen lamp that nearly burns your arm.

This frustration is exactly why the industry has shifted.

In 2025, lithium-ion work lights have become the new standard, replacing halogen, NiCad, and lead-acid models through better safety, longer runtime, higher energy density, and dramatically improved durability.

Below, we explore the engineering and economic factors driving this change, explaining exactly Why Work Lights Are Shifting to Lithium Power and how this transition is setting a new global standard for job site productivity.

Short Answer:

Lithium-ion work lights deliver more energy per gram, maintain full brightness until shutdown, recharge faster, and meet global safety standards like UL, CE, and IECEx. They outperform NiCad, NiMH, halogen, and lead-acid systems in every major category.

Key Takeaways:

- Superior Energy Density & Lightweight Design: Lithium-ion batteries store significantly more power in a smaller, lighter package compared to older NiCad or Lead-Acid batteries, reducing user fatigue during extended use.

- Consistent, Fade-Free Brightness: Unlike older battery types that dim gradually, lithium-ion lights provide a stable, high-intensity light output until the battery is nearly depleted, ensuring maximum visibility when it matters most.

- Elimination of the "Memory Effect": Modern lithium-ion technology allows users to recharge lights at any point without losing future battery capacity, vastly improving workflow efficiency on job sites.

- Enhanced Safety Features are Standard: The shift is driven by safety, with mandatory Battery Management Systems (BMS) preventing overcharge and thermal runaway. Look for certifications like UL, CE, and IECEx (for intrinsically safe models).

- Better Long-Term Value: Despite a higher initial cost, lithium-ion lights offer superior cycle life (more recharges) and extremely low self-discharge rates, meaning they retain power longer and provide a better return on investment than older rechargeable models.

Key Advantages at a Glance:

| Feature | Lithium-Ion | NiCad/NiMH | Halogen / Lead-Acid |

|---|---|---|---|

| Energy Density | ⭐⭐⭐⭐⭐ | ⭐⭐ | ⭐ |

| Weight | Light | Medium | Heavy |

| Brightness Consistency | No dimming | Gradual dimming | Instant drop |

| Memory Effect | None | High | None |

| Safety Systems | BMS + Temp Control | Limited | Heat hazards |

| Runtime per Charge | Long | Short | Short |

| Ideal For | Pro trades & job sites | Budget tools | Legacy setups |

The Power Density Revolution: More Light, Less Weight

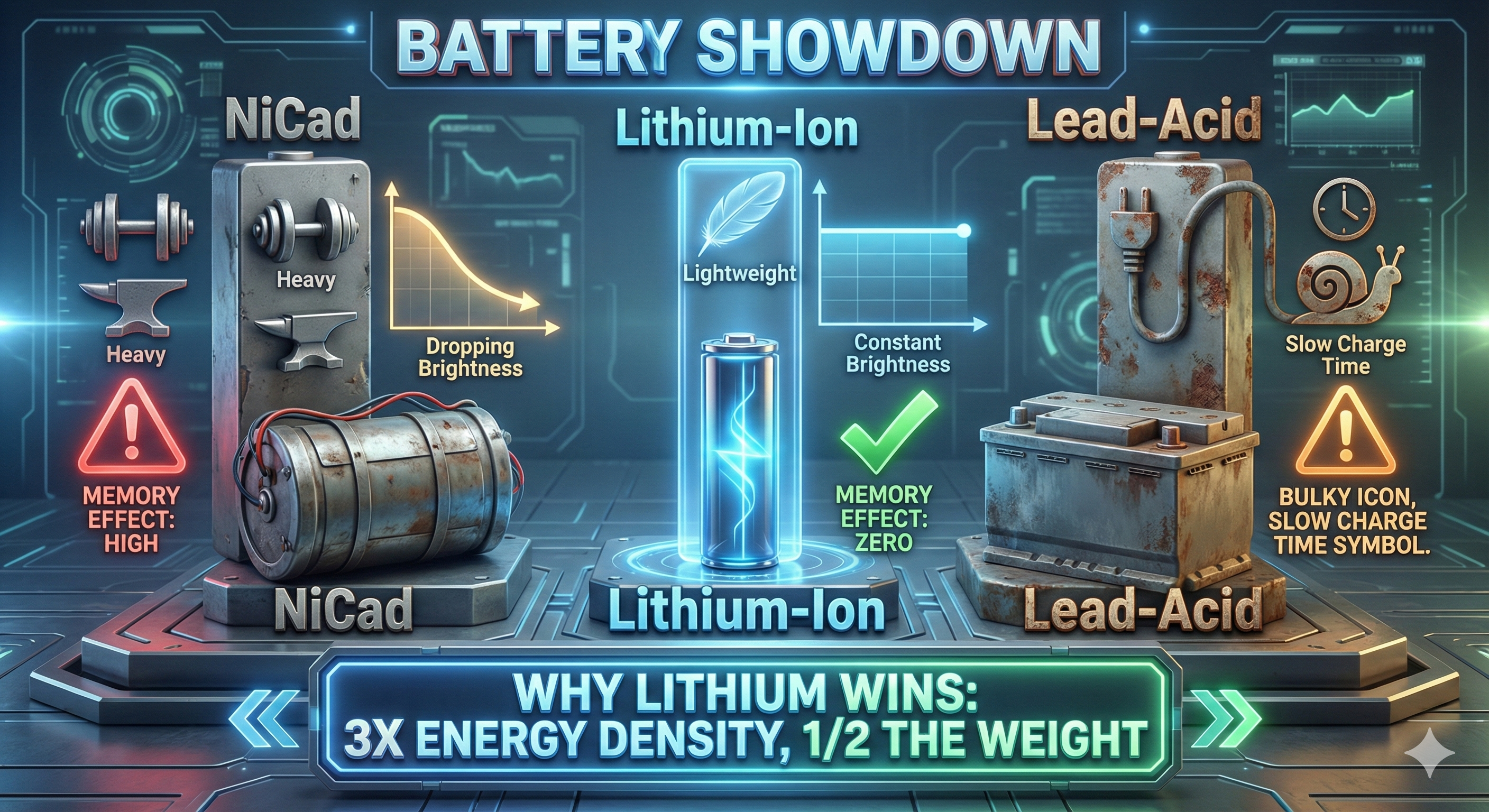

The primary driver behind the shift to lithium is energy density. Traditional Nickel-Cadmium (NiCad) or Lead-Acid batteries are heavy and bulky relative to the power they store.

- Weight vs. Power: A lithium-ion battery can store the same amount of energy as a NiCad battery but at roughly half the weight. For a technician holding a light for hours, that difference prevents fatigue.

- Steady Output: Unlike older batteries that fade gradually (giving you that annoying dimming effect), lithium batteries provide a consistent voltage curve. Your light stays at 100% brightness until the battery is nearly depleted, then shuts off cleanly.

The "Memory Effect" Myth

One of the biggest user complaints with older rechargeable lights was the "memory effect" if you didn't fully drain the battery before charging, it would lose capacity. Lithium-ion work lights have virtually no memory effect. You can charge them for 10 minutes during a coffee break without damaging the battery's long-term health, making them perfect for the stop-and-start nature of trade work.

Global Safety Standards and "Intrinsically Safe" Lighting

As work lights shift to lithium, safety has become a global priority. Early lithium batteries had a reputation for thermal instability, but modern work light safety features have evolved significantly to meet strict international standards (like CE in Europe, UL in the US, and IECEx globally).

Smart Battery Management Systems (BMS)

The secret to safety lies in the BMS. This internal computer monitors every cell in your work light.

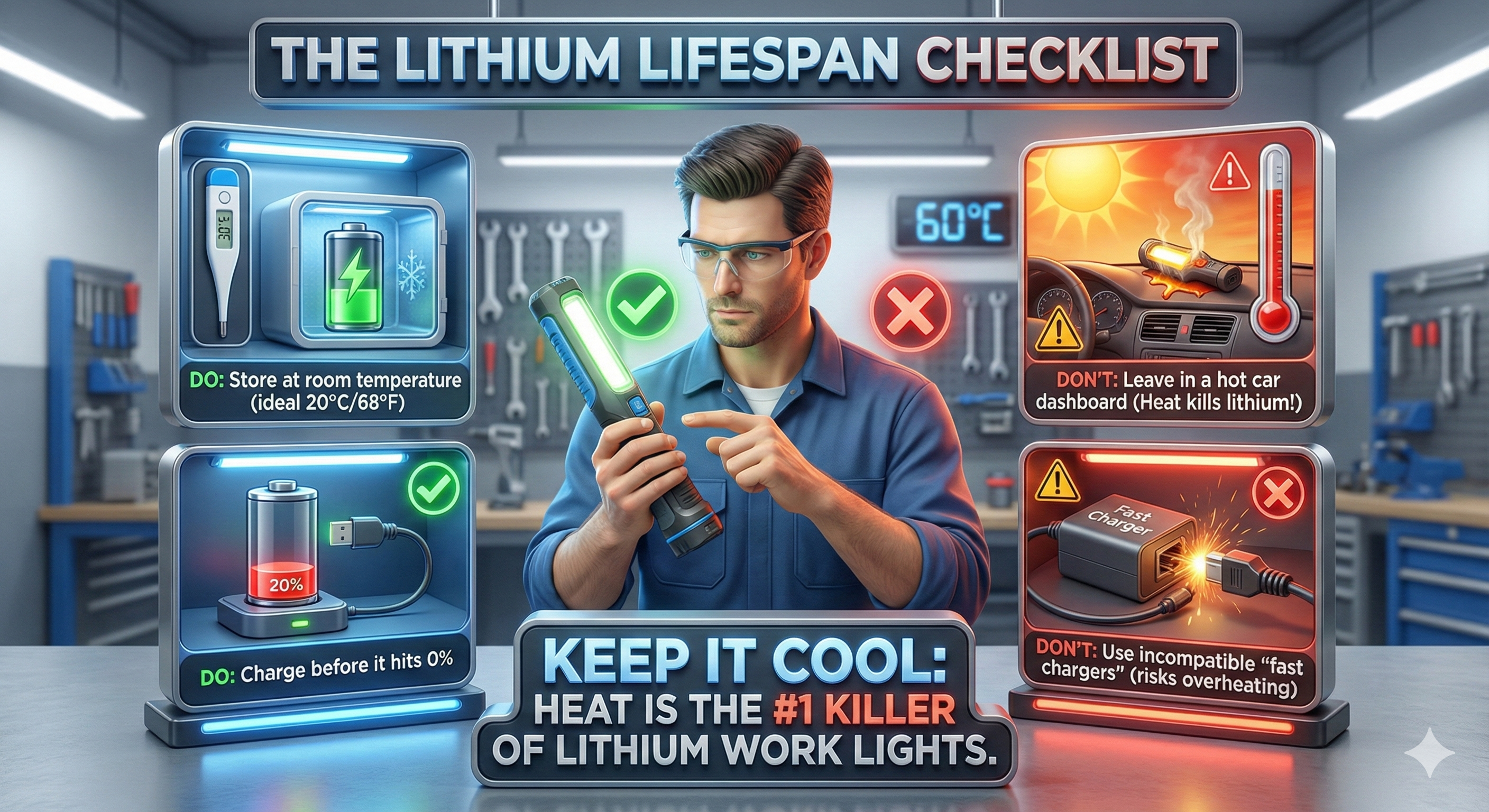

- Thermal Protection: If the light gets too hot (common in tight spaces like attics), the BMS reduces power or shuts down to prevent thermal runaway.

- Overcharge Prevention: You can leave modern lights plugged in overnight without fear of fire, as the BMS cuts the current once the battery is full.

For hazardous environments, like oil rigs or chemical plants, this shift is critical. Manufacturers are now producing intrinsically safe lithium work lights (ATEX/IECEx certified) that are sealed and managed so precisely that they cannot create a spark, allowing high-power cordless lighting in areas where it was previously banned.

Economic and Environmental Impact

While a cordless LED work light with a lithium battery might have a higher upfront cost than a halogen or NiCad model, the Return on Investment (ROI) is undeniable.

- Cycle Life: A quality lithium unit offers 500 to 1,000 charge cycles. A lead-acid alternative often fails after 300 cycles.

- Self-Discharge: If you leave a NiMH light in your truck for a month, it will likely be dead when you reach for it. Lithium batteries lose only about 5% of their charge per month, meaning they are ready when you are.

Sustainability and Disposal

Global users are increasingly asking: Are lithium lights eco-friendly? While lithium mining has an environmental footprint, the longevity of these lights means fewer units end up in landfills compared to disposable alkaline work lights. Furthermore, the EU's new battery regulations are pushing manufacturers toward easier recyclability, making eco-friendly work light choices more accessible.

Troubleshooting Your Lithium Work Light

Even the best tech has hiccups. Here are solutions to common long-tail user queries:

- "Why is my work light blinking red?" This usually indicates a BMS error. It could be due to extreme temperature (too cold or too hot to charge) or a faulty cable. Let the light reach room temperature and try a different cable.

- "Can I leave my lithium work light charging overnight?" Yes, provided you are using the manufacturer's charger. The BMS will stop the charge. However, for maximum lifespan, try to keep the battery between 20% and 80%.

- "My light won't turn on after being stored." Lithium batteries have a "sleep mode" if drained too low. Plug it in for 30 minutes; it may take time for the BMS to "wake up" and accept a charge.

What to Look for in 2025

If you are shopping for the best mechanic work light or a site floodlight, look for these features that define the new standard:

- USB-C Charging: The global standard for convenience.

- Replaceable Batteries: Some pro models now let you swap the lithium cell, extending the tool's life indefinitely.

- IP Ratings: Look for IP65 or higher for water and dust resistance, essential for outdoor cordless lighting.

The shift to lithium isn't just a trend; it's the new baseline for professional efficiency. By understanding the tech, you ensure your tools work as hard as you do.

Frequently Asked Questions (FAQs)

1. What is the main advantage of Lithium-ion over older NiCad work lights?

The primary advantage is energy density and the elimination of the memory effect. Li-ion batteries are significantly lighter while holding more power, and they can be recharged at any time without damaging their capacity, unlike NiCad batteries.

- Is it safe to leave a lithium work light charging overnight?

Yes, it is safe, provided you use the manufacturer's charger. Modern lithium work lights are equipped with a Battery Management System (BMS) that automatically cuts off the current once the battery is full, preventing overcharging and thermal damage.

- What does "intrinsically safe" mean, and why is it important for work lights?

"Intrinsically safe" means the light is designed to be incapable of producing a spark or heat that could ignite flammable gases or dust. This certification (often ATEX or IECEx) is crucial for workers in hazardous environments like chemical plants, mines, or refineries, ensuring the light itself does not cause an explosion.

- Why does my old work light dim before dying, but my new lithium light shuts off instantly?

Older batteries (like NiCad) experience a gradual voltage drop, causing the light to dim slowly. Lithium-ion batteries maintain a consistent, high voltage until they are nearly depleted, thanks to the BMS. This ensures full brightness throughout most of the charge cycle, followed by an immediate shut-off.

- Does extreme temperature (hot or cold) affect lithium work lights?

Yes, extreme temperatures are the biggest killer of lithium-ion batteries. Excessive heat (like leaving it on a car dashboard) permanently degrades capacity, while extreme cold can temporarily halt charging or reduce run time. Always allow the light to reach a moderate temperature before charging or use.

- What safety certification (GEO optimization) should I look for when buying a professional work light?

Globally, look for UL (Underwriters Laboratories) or CE (European Conformity) marks, which signify compliance with fundamental safety standards. For highly sensitive work, look for IECEx or ATEX certifications, indicating suitability for potentially explosive atmospheres.

- Does a lithium work light offer better long-term value than a cheaper halogen model?

Absolutely. While the upfront cost is higher, lithium-powered LED lights consume far less energy, have bulb lifespans measured in tens of thousands of hours, offer up to 1,000 charge cycles, and eliminate the need for costly bulb replacements, providing significant long-term ROI.

Related Articles:

- Rechargeable Lighting vs. Corded Lighting: Which is Best for Your Workshop?

- Top 5 LED Work Lights for Automotive Repair

- Exploring the Pros and Cons of Rechargeable Light Bulbs

- Rechargeable Light Bulbs: Unveiling the Energy Efficiency and Environmental Impact

- Top 5 Best Rechargeable LED Work Lights for Mechanics: Brighten Your Workspace

Conclusion

The transition covered in this guide is not a fleeting trend, but a fundamental industry shift driven by the superior science of lithium-ion chemistry. By adopting cordless LED work light battery life standards, manufacturers have solved the legacy problems of dangerous heat, short runtimes, and the performance-killing "memory effect" associated with older chemistries.

The advantages are clear: from the high energy density that makes your light lightweight and portable, to the sophisticated Battery Management Systems (BMS) that ensure your rechargeable work light is safe from overheating. This focus on technology not only boosts productivity but directly reduces job site hazards.

Moving forward, investing in an intrinsically safe lithium work light (where applicable) is a commitment to the highest standards of efficiency and worker protection. Don't be stuck with the old tech; embrace the new cordless benchmark.

Stop losing time and risking injury with outdated, unreliable lighting. The shift to lithium is about investing in professional-grade efficiency and enhanced safety.

Don't wait for your old light to dim on the critical job.

Explore the latest generation of rechargeable lithium work lights. from intrinsically safe models to high-lumen floodlights. built for long-lasting performance and maximum safety.

Browse the Full Lithium Work Light Catalog Today: Tendsupplies.com

Need expert advice on selecting the perfect cordless LED work light for your specific trade or environment? Our specialists are ready to help you optimize your lighting setup.

Contact Our Sales Team for Bulk Orders or Specialized Consultation: sales@tendsupplies.com

Take advantage of this technology shift by upgrading your gear. Start by identifying the most frustrating light on your job site and replacing it with a modern, lithium-powered unit to immediately experience the difference in brightness, longevity, and safety.