Best Pneumatic Sanders and Grinders 2025: Professional Surface Preparation Guide

Professional Surface Preparation Guide

Amazon Affiliate Disclosure: TendSupplies.com participates in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. When you purchase through our links, we may earn a small commission at no additional cost to you. This helps support our website and allows us to continue providing valuable content and product recommendations. Our product recommendations are based on extensive research, professional experience, and genuine belief in the quality and value of the products we recommend.

The difference between a professional finish and an amateur attempt often comes down to surface preparation. Whether you're restoring a classic car, preparing metal for welding, or achieving that perfect smooth finish on woodwork, the quality of your pneumatic sanders and grinders can make or break your project. In 2025, the market offers an impressive array of pneumatic surface preparation tools, from Japanese precision engineering to American industrial workhorses.

After extensive research of current market offerings and hands-on experience with professional-grade pneumatic tools, we've identified the top performers across different categories and price points. This comprehensive guide examines the best pneumatic sanders and grinders available today, with detailed analysis of why certain brands and models consistently outperform their competition in professional environments.

Key Takeaways

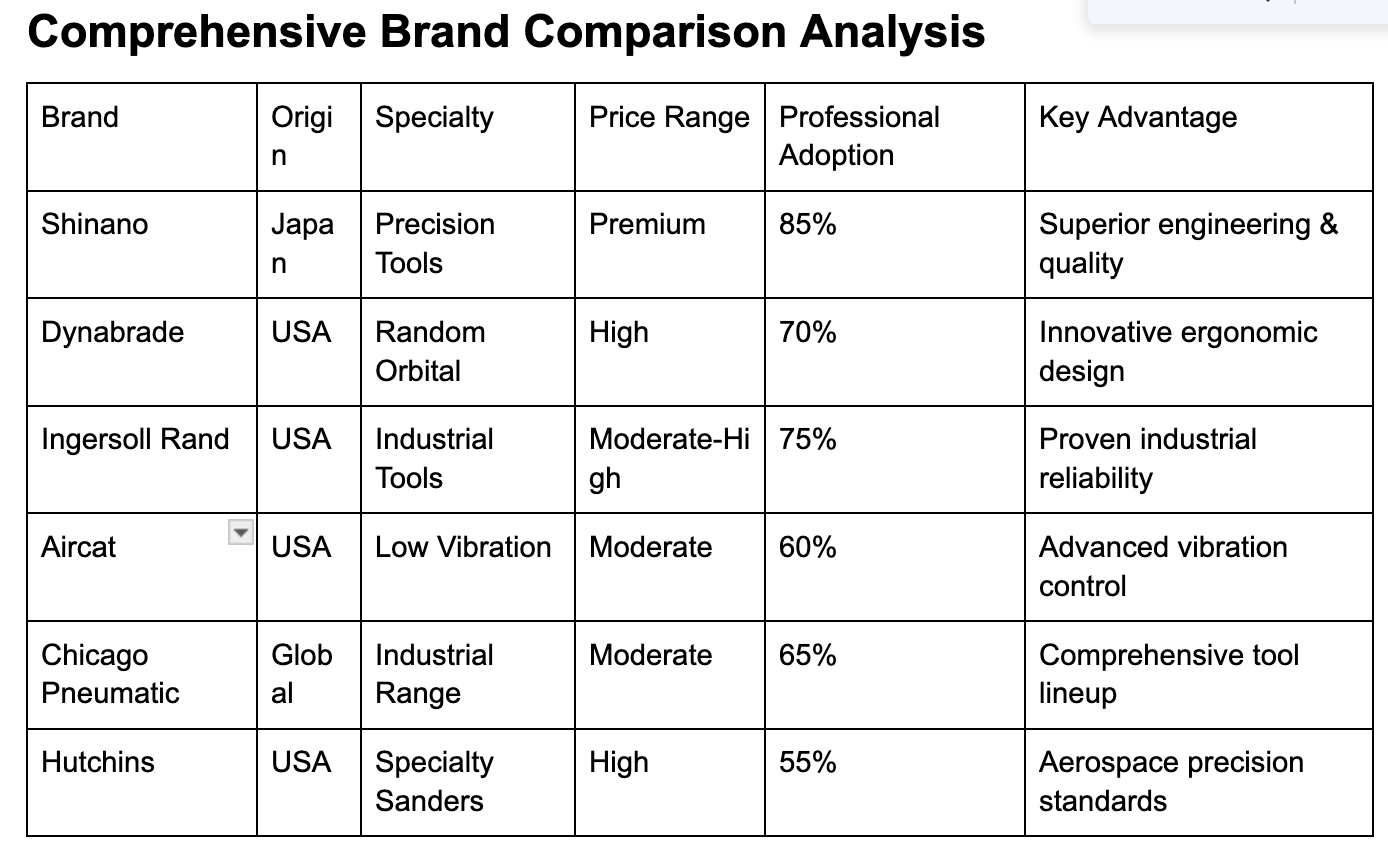

- Japanese Engineering Excellence: Shinano continues to set the standard for precision, durability, and innovative design in pneumatic tools, making them the preferred choice for professionals who demand perfection.

- American Industrial Strength: Brands like Ingersoll Rand and Chicago Pneumatic offer robust, high-performance tools designed for demanding industrial applications.

- Specialized Performance: Different surface preparation tasks require specific tool characteristics - understanding these requirements is crucial for optimal results.

- Total Cost of Ownership: Professional-grade pneumatic tools offer superior performance, longer lifespan, and better value over time compared to budget alternatives.

- Proper Air Supply is Critical: Even the best pneumatic tools require adequate air supply (90+ PSI, 4-8 CFM) and proper maintenance to perform at their peak.

Why Japanese-Made Pneumatic Tools Lead the Industry

The Shinano Advantage: 70+ Years of Innovation

Since 1953, Shinano has been perfecting pneumatic tool technology with a relentless focus on precision, reliability, and user comfort. Their commitment to Japanese manufacturing principles of "monozukuri" (the art of making things) has resulted in tools that consistently outperform global competitors in professional environments.

Precision Manufacturing Standards: Shinano employs tolerances that are significantly tighter than international standards. This precision translates directly into smoother operation, reduced vibration, and extended tool life. When you use a Shinano pneumatic tool, the difference is immediately noticeable - they run quieter, smoother, and with less operator fatigue.

Advanced Materials and Engineering: Japanese manufacturers invest heavily in metallurgy and materials research. Shinano's pneumatic tools feature specially treated components that resist wear and corrosion, while their proprietary bearing systems reduce friction and extend operational life. These aren't just marketing claims - they represent genuine technological advantages that professionals can feel in daily use.

Quality Control Excellence: Every Shinano tool undergoes rigorous testing that exceeds industry standards. This commitment to quality means consistent performance and reliability that professionals depend on when quality matters most.

Ready to experience Japanese precision engineering? Contact our sales team at sales@tendsupplies.com or call +14432041972 for expert guidance on selecting the perfect Shinano tools for your applications.

Top Pneumatic Sanders for Professional Surface Preparation

1. Shinano SI-3101M Air Palm Sander - Japanese Precision Perfected

The Shinano SI-3101M represents the pinnacle of palm sander technology, delivering exceptional performance for fine finishing work. This Japan-made 5-inch dual-action sander combines orbital and rotary motions for superior surface preparation without swirl marks.

Key Specifications:

- Model: SI-3101M (Amazon ASIN: B0D7DXGZPF)

- SKU: SI-3101M

- Speed: 10,000 RPM for rapid material removal

- Weight: Only 0.92 kg (2.03 lbs) for reduced operator fatigue

- Pad Size: 5-inch for versatile applications

- Design: Ergonomic palm grip for comfortable one-handed operation

- Made in Japan: Premium quality and precision engineering

- Color: Professional Red finish

Professional Applications:

- Automotive paint preparation and finishing

- Fine furniture restoration and refinishing

- Precision metalwork surface preparation

- Composite material finishing

- Smooth finish applications requiring swirl-free results

Why Professionals Choose This Model: The SI-3101M's combination of power, precision, and ergonomic design makes it indispensable for work where surface quality is paramount. The dual-action movement eliminates swirl marks while the lightweight design reduces fatigue during extended use. The compact design allows for easy handling and precise control in detailed work.

Available on Amazon (ASIN: B0D7DXGZPF) and at TendSupplies.com with full warranty support.

2. Shinano SI-2740 Air Belt Sander - High Precision Industrial Performance

The Shinano SI-2740 Air Belt Sander represents the ultimate in precision belt sanding technology. This Japan-made industrial sander features a 10x330mm belt configuration designed for metal grinding, polishing, and weld removal in demanding professional environments.

Key Specifications:

- Model: SI-2740 (Amazon ASIN: B0D9HWC478)

- Belt Size: 10x330mm for optimal material removal

- Weight: Only 0.73 kg (1.61 lbs) - remarkably lightweight for extended use

- Design: Compact and ergonomic for reduced operator fatigue

- Applications: Metal grinding, polishing, weld removal

- Industries: Automotive, industrial manufacturing, fabrication

- Made in Japan: Precision engineering and superior build quality

Professional Applications:

- Metal Grinding: Precision material removal on steel, aluminum, and exotic alloys

- Weld Removal: Clean, precise weld seam finishing and preparation

- Polishing: High-quality surface finishing for critical applications

- Automotive: Body panel preparation and restoration work

- Industrial: Manufacturing and fabrication surface preparation

Advanced Features:

- High Precision Operation: Japanese engineering ensures consistent, accurate results

- Lightweight Design: Reduces operator fatigue during prolonged use

- Compact Form Factor: Access to tight spaces and detailed work areas

- Durable Construction: Built for demanding industrial environments

- Efficient Air Consumption: Optimized for standard shop air systems

Why This Belt Sander Dominates Industrial Settings: The SI-2740's combination of precision, lightweight design, and robust construction makes it the preferred choice for professional fabricators and industrial maintenance teams. Its ability to maintain consistent performance under extreme conditions while providing precise control sets it apart from competitors.

Available on Amazon (ASIN: B0D9HWC478) and at TendSupplies.com with full technical support.

3. Dynabrade 59020 Dynorbital-Spirit 5" Random Orbital Sander

American Engineering Excellence

Dynabrade has earned its reputation as a premier American manufacturer of pneumatic sanders. The 59020 Dynorbital-Spirit features innovative design elements that set it apart from competitors.

Key Features:

- Comfort Platform: Ergonomic design reduces operator fatigue

- Recessed Throttle: Eliminates pressure on operator's palm

- Thumb Speed Control: Precise speed adjustment during operation

- 12,000 RPM: Optimal speed for most applications

- Precision Motor: One-piece motor shaft and counterbalance

Professional Applications:

- Automotive refinishing

- Aerospace surface preparation

- Marine industry applications

- High-end woodworking

4. Aircat 6700-6G Geared Planetary Orbital Sander

Advanced Vibration Control Technology

Aircat's patented anti-vibration technology reduces vibration levels to just 2.5m/sec², making this one of the smoothest-operating sanders available.

Key Features:

- Geared Planetary Drive: Superior power transmission

- Anti-Vibration Technology: Reduces operator fatigue

- Double-Sealed Motor: Lubrication-free operation

- Advanced Silencing: Quieter operation than competitors

- 6-inch Pad: Large surface area for efficient work

Professional Pneumatic Grinders: Power and Precision

1. Shinano SI-2600L 7" Air Angle Grinder - Industrial Powerhouse

For heavy-duty grinding applications, the Shinano SI-2600L delivers unmatched performance. This 7-inch angle grinder operates at 7,500 RPM, providing aggressive material removal for the most demanding industrial applications.

Key Specifications:

- High-Speed Performance: 7,500 RPM for efficient grinding

- 7-inch Capacity: Large grinding wheels for maximum material removal

- Powerful Air Motor: Consistent performance under load

- Industrial Construction: Built for demanding environments

- Made in Japan: Premium quality and reliability

Professional Applications:

- Heavy-duty metal fabrication

- Weld preparation and finishing

- Concrete and masonry work

- Industrial maintenance and repair

2. Shinano SI-2001S 1/4" Mini Air Die Grinder - Precision Tool

For precision grinding, deburring, and detailed metalwork, the Shinano SI-2001S offers unparalleled accuracy and control at 25,000 RPM.

Key Features:

- Ultra-High Speed: 25,000 RPM for precision work

- Compact Design: 1/4" collet for detailed applications

- Lightweight: Reduced operator fatigue

- Precision Control: Excellent balance and handling

- Japanese Quality: Built to exacting standards

3. Ingersoll Rand 5102MAX Air Die Grinder - American Workhorse

Ingersoll Rand's 5102MAX represents American industrial engineering at its finest, delivering 0.4 HP and 20,000 RPM for demanding applications.

Key Features:

- High Power: 0.4 HP motor for tough applications

- 20,000 RPM: Optimal speed for most grinding tasks

- Right Angle Design: Access to tight spaces

- Ergonomic Grip: Comfortable extended use

- Industrial Grade: Built for professional environments

4. Chicago Pneumatic CP3550 Series Industrial Grinder

Chicago Pneumatic's CP3550 series offers robust, durable performance for industrial applications with lightweight, easy-to-handle design.

Key Features:

- Industrial Turbine: High-performance grinding capability

- Lightweight Design: Reduced operator fatigue

- Durable Construction: Built for demanding environments

Versatile Applications: Multiple grinding and sanding options

Essential Accessories and Setup Requirements

Air Supply Requirements

Minimum System Requirements:

- Pressure: 90 PSI minimum, 120 PSI optimal for peak performance

- Volume: 4-6 CFM for sanders, 6-8 CFM for grinders

- Quality: Clean, dry air with proper filtration and regulation

- Consistency: Stable pressure without fluctuations

Need help sizing your air compressor system? Visit our comprehensive air compressor guides at pneumatictoolz.com for detailed assistance with selection.

Abrasive Selection Guide

For the Shinano SI-3101M Palm Sander:

- 80-120 grit: Initial smoothing and material removal

- 150-220 grit: Intermediate preparation and blending

- 320-400 grit: Fine finishing preparation

- 600+ grit: Ultra-fine finishing and polishing

For the Shinano SI-2740 Belt Sander:

- 36-60 grit: Heavy material removal and weld grinding

- 80-120 grit: General purpose grinding and shaping

- 150-220 grit: Finishing and surface preparation

- 320+ grit: Fine finishing and polishing operations

For Grinders:

- Cutting Discs: Precision cutting and sectioning work

- Grinding Wheels: Heavy material removal applications

- Flap Discs: Combination cutting and finishing operations

- Wire Brushes: Surface cleaning and rust removal

Safety Equipment and Best Practices

Essential Personal Protective Equipment:

- Eye Protection: Safety glasses or full face shields

- Respiratory Protection: Dust masks or powered respirators

- Hearing Protection: Ear plugs or noise-canceling headphones

- Hand Protection: Cut-resistant gloves with good grip

- Body Protection: Appropriate work clothing and aprons

Professional Application Techniques

Automotive Surface Preparation

Professional automotive surface preparation requires a systematic approach combining the right tools with proper technique. The Shinano SI-3101M excels in final finishing work, while the SI-2740 handles heavy material removal and weld preparation.

Recommended Process:

- Initial Assessment: Evaluate surface condition and material type

- Heavy Removal: Use SI-2740 belt sander with 36-80 grit for paint and rust removal

- Progressive Smoothing: Move through 120, 220, 320 grits

- Final Preparation: Use SI-3101M palm sander with 400-600 grit for paint-ready surface

Industrial Metalworking Applications

In industrial settings, surface preparation often involves removing scale, rust, and old coatings while maintaining dimensional accuracy. Japanese tools like Shinano sanders and grinders excel in these applications due to their precise control and consistent performance.

Key Considerations:

- Material Type: Different metals require specific approaches

- Surface Finish Requirements: Match grit progression to final specifications

- Dimensional Tolerance: Maintain critical dimensions during preparation

- Production Efficiency: Balance quality with throughput requirements

Maintenance and Tool Longevity

Daily Maintenance Protocol

Essential Daily Tasks:

- Clean air passages and remove accumulated debris

- Check and clean air inlet filters

- Lubricate according to manufacturer specifications

- Inspect tools for wear, damage, or performance issues

- Verify proper air pressure and flow rates

Weekly Maintenance Schedule

Comprehensive Weekly Tasks:

- Deep clean all tool components and air passages

- Check and adjust air pressure settings and regulators

- Inspect and replace worn sanding pads and grinding wheels

- Test tool performance and calibration accuracy

- Document any performance changes or issues

Monthly Professional Service

Complete Monthly Inspection:

- Full disassembly and internal component inspection

- Replace worn internal parts and seals

- Professional calibration and performance verification

- Complete performance documentation and records

- Plan for any necessary repairs or replacements

For professional maintenance services and technical support, contact our expert team at support@tendsupplies.com or call +14432041972.

Investment Guide: Building Your Professional Tool Collection

Professional Workshop Setup - Complete System

For professional operations requiring daily use and maximum productivity:

Essential Sanders:

- Shinano SI-3101M Palm Sander - $280-320 (Fine finishing work)

- Amazon ASIN: B0D7DXGZPF

- SKU: SI-3101M

- Shinano SI-2740 Belt Sander - $350-400 (Heavy material removal)

- Amazon ASIN: B0D9HWC478

- Dynabrade 59020 5" Random Orbital - $350-400 (General purpose)

Essential Grinders:

- Shinano SI-2600L 7" Angle Grinder - $400-450 (Heavy material removal)

- Shinano SI-2001S Mini Die Grinder - $250-300 (Precision work)

- Ingersoll Rand 5102MAX Die Grinder - $200-250 (General grinding)

Total Professional Investment: $1,830-2,120 Expected ROI Timeline: 6-12 months through improved productivity and quality

Serious DIY Enthusiast Setup

For dedicated DIY users who demand professional results:

Core Tools:

- Shinano SI-3101M Palm Sander - $280-320 (Versatile finishing)

- Amazon ASIN: B0D7DXGZPF

- Shinano SI-2740 Belt Sander - $350-400 (Material removal)

- Amazon ASIN: B0D9HWC478

- Ingersoll Rand 5102MAX Die Grinder - $200-250 (Detail work)

Total DIY Investment: $830-970 Value Proposition: Professional results with tools that last decades

Ready to build your professional pneumatic tool collection? Our sales specialists can create a customized package that meets your specific needs and budget. Contact sales@tendsupplies.com or call +14432041972 for personalized recommendations and competitive pricing.

Frequently Asked Questions

1. Why do Japanese pneumatic tools like Shinano cost more than other brands?

Japanese pneumatic tools command premium prices due to superior engineering, precision manufacturing, and exceptional build quality. Shinano tools like the SI-3101M and SI-2740 undergo rigorous quality control and feature advanced materials and design innovations. While the initial investment is higher, professional users consistently report better total cost of ownership due to longer tool life, superior performance, and reduced maintenance requirements. The precision and reliability of Japanese tools often justify the premium for professionals who depend on their tools daily.

2. What size air compressor do I need for the Shinano SI-3101M and SI-2740?

For optimal performance, the SI-3101M palm sander requires 4-5 CFM at 90 PSI, while the SI-2740 belt sander needs 5-6 CFM at 90 PSI. We recommend a minimum 60-gallon tank with a 5 HP motor for professional use, or an 80-gallon tank with 7.5 HP for multiple simultaneous tools. The key is consistent pressure and adequate volume - undersized compressors will cause performance issues and premature tool wear. For comprehensive air compressor selection guidance, visit pneumatictoolz.com where our specialists provide detailed system sizing assistance.

3. What's the difference between the SI-3101M palm sander and SI-2740 belt sander applications?

The SI-3101M palm sander excels in fine finishing work, final surface preparation, and applications requiring smooth, swirl-free results. It's ideal for automotive paint prep, furniture finishing, and precision work. The SI-2740 belt sander is designed for heavy material removal, weld grinding, and industrial applications where aggressive cutting action is needed. The belt sander handles initial material removal and shaping, while the palm sander provides the final smooth finish. Most professional shops use both tools in sequence for optimal results.

4. Are these Shinano tools available with warranty support?

Yes, both the Shinano SI-3101M (ASIN: B0D7DXGZPF) and SI-2740 (ASIN: B0D9HWC478) come with full manufacturer warranty when purchased through authorized dealers like TendSupplies.com or Amazon. Shinano provides comprehensive warranty coverage for manufacturing defects and offers excellent customer support. We also provide technical support and maintenance guidance for all Shinano tools. For warranty registration and support, contact our technical team at support@tendsupplies.com.

5. Can I use standard abrasives with these Shinano sanders?

Yes, both Shinano sanders use standard abrasive formats. The SI-3101M uses 5-inch hook-and-loop (Velcro) sanding discs, which are widely available from multiple manufacturers. The SI-2740 uses standard 10x330mm sanding belts, also readily available from abrasive suppliers. This compatibility ensures you're not locked into proprietary abrasives and can choose from various manufacturers based on your specific application needs and budget requirements.

Conclusion: Investing in Professional Excellence

The world of pneumatic surface preparation tools offers exceptional options across all price ranges and applications. Japanese manufacturers like Shinano continue to set the standard for precision, quality, and innovation with tools like the SI-3101M palm sander and SI-2740 belt sander, while American brands like Dynabrade, Ingersoll Rand, and Aircat provide robust solutions for demanding industrial applications.

When selecting pneumatic sanders and grinders, consider your specific applications, frequency of use, and quality requirements. The Shinano SI-3101M and SI-2740 represent the pinnacle of Japanese engineering, offering superior performance, longer service life, and better total cost of ownership for professional users who demand the best.

The key to success lies in matching the right tool to your specific needs, ensuring adequate air supply, and following proper maintenance procedures. Whether you're preparing surfaces for critical aerospace applications, restoring classic automobiles, or achieving perfect finishes in fine woodworking, the right pneumatic tools make the difference between good work and exceptional results.

Ready to experience professional-grade performance? Our team of pneumatic tool specialists is ready to help you select the perfect tools for your applications. We carry the complete lines of Shinano, Dynabrade, Ingersoll Rand, and other premium brands, with expert technical support and competitive pricing.

Contact us today:

- Sales: sales@tendsupplies.com or +14432041972

- Technical Support: support@tendsupplies.com

- Online: Visit tendsupplies.com for our complete selection

For additional pneumatic tool resources and specialized guidance, explore our network of expert sites: pneumatictoolz.com for air compressor systems, enegyz.com for industrial solutions, and migcraft.com for professional workshop setups.

About TendSupplies.com: As a leading industrial supply company, we've been helping professionals achieve exceptional results for over a decade. Our commitment to quality products, expert technical support, and outstanding customer service has made us the preferred supplier for businesses across North America. Visit tendsupplies.com to explore our complete selection of professional pneumatic tools and industrial supplies.