Build Your Dream Workshop: A Step-by-Step Guide with Product Recommendations

A well-equipped workshop is a sanctuary for creativity, a place where DIY projects come to life, repairs are tackled with confidence, and ideas are transformed into tangible realities. Whether you're a seasoned woodworker, a dedicated mechanic, a metalworking enthusiast, or simply someone who enjoys tinkering and building, creating your dream workshop is an investment in your passion and productivity. But embarking on this journey can feel overwhelming. What's the best layout? Which tools are essential, and which can wait? How do you maximize space and ensure safety? This comprehensive guide, brought to you by Tend Supplies, will walk you through the process step-by-step, providing expert advice, practical tips, and product recommendations to help you build a functional, efficient, and inspiring workspace tailored to your specific needs.

Key Takeaway:

Building your dream workshop is an achievable goal, regardless of your space or budget. By carefully planning your layout, prioritizing essential tools, and making informed decisions about storage, lighting, and safety, you can create a personalized workspace that fuels your creativity and empowers you to tackle any project with confidence. This guide provides a structured approach to planning and equipping your workshop, with recommendations from Tend Supplies to help you get started.

Define Your Needs and Vision:

Before you even pick up a hammer, take some time to define your needs and envision your ideal workspace. This crucial first step will guide your decisions throughout the entire process.

- What are your primary activities? What type of projects will you be undertaking? Woodworking, metalworking, automotive repair, electronics, general DIY, or a combination? Each activity has its own set of tools and space requirements.

- What is your skill level? Are you a beginner, intermediate, or advanced maker/builder? This will influence the complexity and cost of the tools you need.

- What is your budget? Determine a realistic budget for your workshop. Remember that you can always start small and gradually expand your tool collection over time.

- What is your available space? How much space do you have to work with? A spare bedroom, a basement corner, a garage, or a dedicated shed? Measure the space accurately and consider its limitations.

- What is your aesthetic? What kind of atmosphere do you want to create? Industrial, minimalist, rustic, or something else entirely?

Plan Your Workshop Layout:

Once you have a clear understanding of your needs and space constraints, it's time to plan your workshop layout. This is where you'll determine the placement of your workbench, tools, storage, and other essential elements.

- The Workbench: The Heart of Your Workshop: Your workbench is your primary work surface, so its size, height, and location are crucial. Consider a sturdy workbench like theVevor Workbench; it is made of durable materials like hardwood or heavy-duty steel.

- Size: Choose a workbench that is large enough to accommodate your projects but doesn't overcrowd your space.

- Height: The ideal height depends on your height and the type of work you'll be doing. A good rule of thumb is to have the workbench top at about waist level.

- Features: Consider features like built-in vises, drawers, and shelves for added functionality.

- Tool Storage and Organization: Efficient storage is essential for keeping your workshop organized and your tools accessible.

- Tool Chests/Cabinets: Invest in a rolling tool chest or cabinet with drawers of various sizes to store your hand tools. Consider the Vevor Tool Chest [invalid URL removed] for a durable and spacious option.

- Pegboards: A classic and versatile solution for hanging frequently used tools.

- Shelving: Install shelves to store larger items, power tools, and supplies.

- Wall-Mounted Organizers: Magnetic strips, hooks, and bins can help maximize wall space.

- Power Tool Placement: If you use stationary power tools (table saw, drill press, band saw, etc.), plan their placement carefully, considering:

- Workflow: Arrange tools in a logical sequence that minimizes movement and maximizes efficiency.

- Space: Ensure sufficient space around each tool for safe operation and material handling.

- Power Outlets: Make sure there are enough outlets near each tool, or plan to install additional ones.

- Lighting: Adequate lighting is crucial for safety and precision.

- Overhead Lighting: Install bright, shadow-free overhead lighting, such as LED shop lights.

- Task Lighting: Use adjustable lamps or work lights to illuminate specific work areas. Consider using the Maxxeon WorkStar 630 Technician's Rechargeable Headlamp for detailed work.

- Natural Light: Maximize natural light whenever possible by positioning your workbench near a window.

- Ventilation: Proper ventilation is essential, especially if you'll be working with materials that produce fumes or dust.

- Exhaust Fans: Install an exhaust fan to remove fumes and dust.

- Dust Collection System: Consider a dust collection system for stationary power tools.

- Open Windows/Doors: Ensure adequate airflow by opening windows and doors when possible.

- Safety Zones: Designate clear pathways and maintain sufficient space around each tool to prevent accidents.

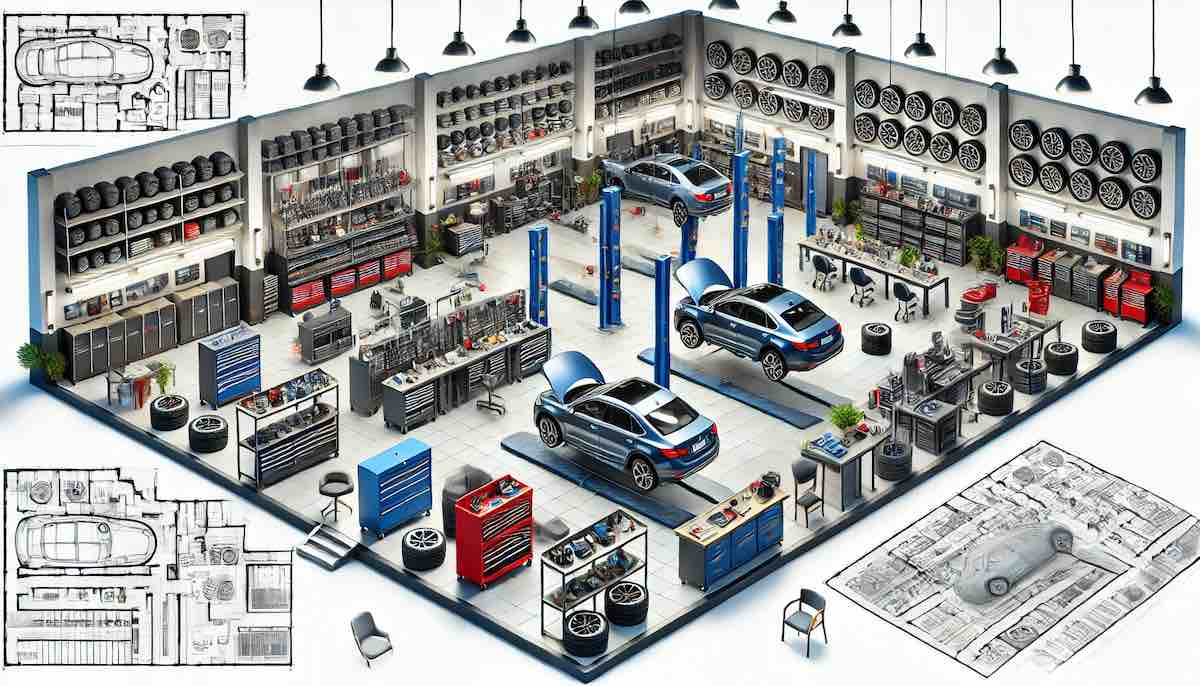

An Automotive workshop Layout in 3D

Essential Hand Tools: The Foundation of Your Workshop

Every workshop, regardless of its specialization, needs a solid foundation of high-quality hand tools.

- Screwdrivers: A comprehensive set, including flathead, Phillips, Torx, and precision screwdrivers. Consider the Wiha Screwdriver Set [invalid URL removed] for a premium option.

- Wrenches: Combination wrenches, ratcheting wrenches, adjustable wrenches, and a set of Allen wrenches (hex keys) are essential. The Gearwrench Ratcheting Wrench Set is a great choice.

- Sockets and Ratchets: A comprehensive socket set with 1/4", 3/8", and 1/2" drive sizes, including both standard and metric sockets. Consider the Tekton Socket Set [invalid URL removed] for its quality and value.

- Pliers: Needle-nose pliers, slip-joint pliers, locking pliers, diagonal cutting pliers, and lineman's pliers are indispensable. Knipex Pliers [invalid URL removed] are renowned for their quality.

- Hammers: A ball-peen hammer, claw hammer, dead blow hammer, and rubber mallet are essential for various tasks. Estwing Hammers [invalid URL removed] are a popular choice.

- Measuring and Marking Tools: Tape measure, ruler, combination square, level, marking pencils, and a scribe.

- Cutting Tools: Utility knife, hacksaw, tin snips, and a good pair of scissors.

- Clamping Tools: C-clamps, bar clamps, spring clamps, and a vise are essential for holding workpieces securely. Consider getting a vise for your Vevor workbench.

Woodworking workshop

Metal working workshop

Power Tools: Enhancing Efficiency and Capabilities

Power tools can significantly expand your capabilities and speed up your workflow. Here are some essential power tools to consider for your dream workshop:

- Cordless Drill/Driver: A must-have for drilling holes and driving screws. Consider a model with at least 18V of power and a 1/2" chuck.

- Impact Wrench: Essential for automotive work and any task involving stubborn fasteners. Check out our article, Upgrade Your Workshop: 5 Essential Air Impact Wrenches Under $100 [invalid URL removed] for budget-friendly recommendations.

- Circular Saw: A versatile saw for making straight cuts in various materials.

- Jigsaw: Ideal for cutting curves and intricate shapes.

- Reciprocating Saw: A powerful saw for demolition and rough cutting.

- Angle Grinder: Used for grinding, cutting, and polishing metal.

- Bench Grinder: For sharpening tools and shaping metal.

- Table Saw: A cornerstone of many woodworking shops, used for making precise rip cuts and crosscuts.

- Drill Press: Provides accuracy and control when drilling holes, especially in metal.

- Miter Saw: For making accurate angled cuts, essential for trim work and framing.

- Air Compressor: Many garages and workshops will want an air compressor. This will allow you to use air tools like the Aircat 1150 or the Shinano SI-1410

Specialty Tools: Tailoring Your Workshop to Your Craft

Depending on your specific interests and the types of projects you undertake, you may need to add specialized tools to your workshop.

- Automotive: OBD-II scanner, torque wrench, brake caliper tool set, ball joint separator, jack stands, creeper.

- Woodworking: Router, planer, jointer, sander, wood lathe, chisels, hand planes.

- Metalworking: Welder (MIG, TIG, or Stick), welding helmet, plasma cutter, metal shear, bending brake.

- Electronics: Soldering iron, multimeter, oscilloscope, wire strippers, breadboard.

Essential workshop Hand tools

Readers Like: Essential Hand Tools for Every Workshop

Safety Equipment: Protecting Yourself in the Workshop

Safety should always be your top priority. Equip your workshop with essential safety gear:

- Safety Glasses: Protect your eyes from flying debris.

- Hearing Protection: Earplugs or earmuffs to protect your hearing from loud tools.

- Work Gloves: Protect your hands from cuts, abrasions, and chemicals.

- Dust Mask/Respirator: Protect your lungs from dust and fumes.

- First Aid Kit: Keep a well-stocked first aid kit readily available.

- Fire Extinguisher: A must-have for any workshop.

Lighting and Electrical: Illuminating and Powering Your Space

Proper lighting and a well-planned electrical system are crucial for a functional and safe workshop.

- Overhead Lighting: Install bright, shadow-free overhead lighting. LED shop lights are an excellent choice due to their energy efficiency and long lifespan. Consider the Flexstar 645W Foldable Dimmable LED Light for your workshop. It is a great option and provides excellent lighting.

- Task Lighting: Use adjustable lamps or work lights for specific tasks. The Maxxeon WorkStar Cyclops and LumaStik are great rechargeable options, while the Maxxeon WorkStar 630 Technician's Rechargeable Headlamp is perfect for detailed work.

- Outlets: Ensure you have enough outlets for all your power tools and equipment. Consider installing dedicated circuits for high-amperage tools.

- Extension Cords: Use heavy-duty extension cords rated for the appropriate amperage.

- Surge Protectors: Protect your valuable tools and electronics from power surges.

Ventilation and Air Quality: Breathing Easy

Good ventilation is essential for removing fumes, dust, and other airborne particles, especially when working with wood, metal, or solvents.

- Exhaust Fans: Install an exhaust fan to vent fumes and dust to the outside.

- Dust Collection System: Connect stationary power tools to a dust collection system to minimize airborne dust.

- Air Filtration System: Consider an air filtration system to further improve air quality.

- Open Windows/Doors: When weather permits, open windows and doors to provide natural ventilation.

Frequently Asked Questions (FAQs)

Q1: What's the best way to store my tools?

A1: The best storage solution depends on your space and the number of tools you have. A combination of a rolling tool chest, pegboards, shelves, and wall-mounted organizers often works well. The Vevor 42-inch Tool Chest [invalid URL removed] is an excellent option.

Q2: How much should I budget for my dream workshop?

A2: The cost of building a workshop can vary widely depending on your needs and the tools you choose. You can start with a basic setup for a few hundred dollars and gradually expand over time. Set a realistic budget and prioritize essential tools first.

Q3: What are the most important safety precautions in a workshop?

A3: Always wear appropriate safety gear (eye protection, hearing protection, gloves, dust mask), keep your work area clean and organized, use tools correctly, and never operate machinery when tired or distracted.

Q4: Should I buy new or used tools?

A4: Both options have pros and cons. New tools come with warranties and are in pristine condition, but they are more expensive. Used tools can be a bargain, but they may require some refurbishment and don't come with warranties. Inspect used tools carefully before purchasing.

Q5: Where can I find high-quality tools for my workshop?

A5:tendsupplies.com offers a wide selection of high-quality tools from reputable brands, carefully curated to meet the needs of professionals and DIY enthusiasts alike. We offer everything from hand tools and power tools to specialized equipment and workshop accessories.

Related Articles:

- Top 10 Essential Power Tools for Every Mechanic Workshop

- Mastering Workshop Safety: A Comprehensive Guide to Protecting Yourself

- Choosing the Right Workbench for Your Needs

- Maximizing Space: Smart Storage Solutions for Small Workshops

- The Ultimate Guide to Air Compressors and Air Tools

Conclusion:

Building your dream workshop is a rewarding endeavor that can significantly enhance your productivity, creativity, and enjoyment of your craft. By carefully planning your layout, selecting the right tools, and prioritizing safety, you can create a personalized workspace that meets your specific needs and inspires you to tackle any project with confidence.

At tendsupplies.com, we're committed to providing you with the tools, equipment, and knowledge you need to bring your workshop vision to life. We offer a wide selection of top-quality products from trusted brands, along with expert advice and exceptional customer service. Whether you're looking for Vevor welder or,Shinano air tools, Maxxeon work lights, or any other essential workshop items, we have you covered.

Ready to start building your dream workshop? Explore our extensive catalog at tendsupplies.com today. Our team is here to help you every step of the way. Contact us at sales@tendsupplies.com for personalized recommendations, expert advice, and answers to all your workshop-related questions. Let Tend Supplies be your trusted partner in creating the ultimate workspace for your passion and productivity!

We hope you find this product helpful! If you decide to buy it, using our link helps support us at no additional cost to you.