Expert Tips for Using Air Sanders in Virginia's Furniture Refinishing Industry

Key Takeaway

Mastering the use of air sanders in furniture refinishing can significantly enhance the quality and efficiency of your work. By understanding the different types of air sanders, proper techniques, and maintenance practices, Virginia's furniture refinishers can achieve superior results while preserving the integrity of valuable pieces. Investing in quality tools and continual skill development is key to success in this competitive industry.

Introduction

Virginia's rich history and appreciation for craftsmanship have fostered a thriving furniture refinishing industry. From restoring antique pieces in Richmond's historic districts to upcycling vintage finds in Norfolk's trendy neighborhoods, air sanders play a crucial role in achieving professional-quality results. This comprehensive guide offers expert tips for using air sanders in Virginia's furniture refinishing industry, helping professionals and enthusiasts alike to elevate their craft and produce stunning results.

Understanding Air Sanders in Furniture Refinishing

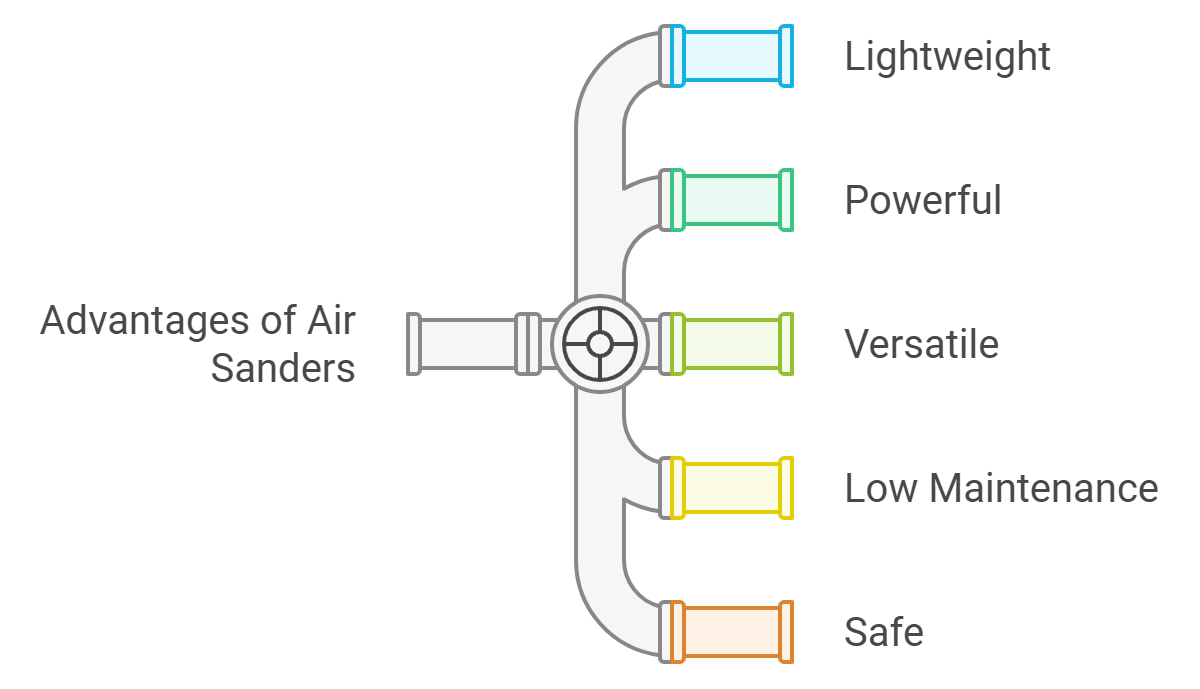

Air sanders, powered by compressed air, offer several advantages over their electric counterparts:

- Lightweight: Reduces user fatigue during extended use.

- Powerful: Provides consistent power for efficient material removal.

- Versatile: Various attachments allow for different finishing tasks.

- Low Maintenance: Fewer moving parts compared to electric sanders.

- Safe: No risk of electric shock, ideal for dusty environments.

Types of Air Sanders for Furniture Refinishing

- Random Orbital Sanders: Ideal for most furniture refinishing tasks, providing a smooth finish.

- Palm Sanders: Perfect for detail work and reaching tight spaces.

- Belt Sanders: Useful for removing large amounts of material quickly.

- Disc Sanders: Great for flat surfaces and edge work.

- Detail Sanders: Designed for intricate areas and corners.

Palm sander

Choosing the Right Air Sander for Virginia's Furniture Refinishing Projects

Consider these factors when selecting an air sander for your Virginia-based furniture refinishing work:

- Project Types: Match the sander to the most common furniture styles in your area.

- Power Requirements: Ensure compatibility with your air compressor.

- Ergonomics: Look for models that are comfortable for extended use.

- Dust Collection: Essential for maintaining a clean workspace and protecting Virginia's indoor air quality.

- Vibration Control: Reduces user fatigue and improves finish quality.

- Versatility: Consider sanders that accept various grit sizes and pad types.

Comparison of Popular Air Sanders for Furniture Refinishing

| Sander Type | Best For | Pros | Cons |

| Random Orbital | All-purpose refinishing | Smooth finish, versatile | May not remove material quickly |

| Palm Sander | Detail work, small areas | Compact, easy to control | Limited coverage area |

| Belt Sander | Rapid material removal | Fast, powerful | Can easily damage wood if not careful |

| Disc Sander | Flat surfaces, edges | Efficient on large areas | Not suitable for curved surfaces |

| Detail Sander | Intricate areas, corners | Reaches tight spaces | Limited to small areas |

Essential Techniques for Air Sanding in Furniture Refinishing

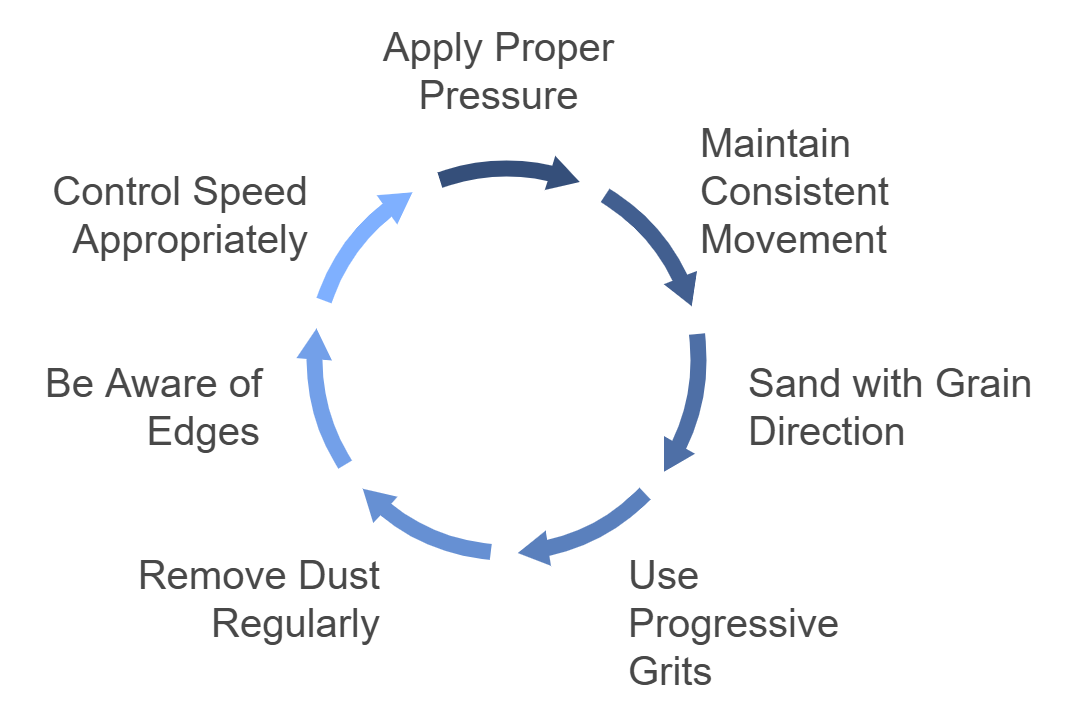

Mastering these techniques will help you achieve professional results in Virginia's furniture refinishing projects:

- Proper Pressure: Apply even, moderate pressure. Let the sander do the work.

- Consistent Movement: Keep the sander moving to avoid creating uneven spots.

- Grain Direction: Sand with the grain whenever possible to avoid scratches.

- Progressive Grits: Start with coarser grits and progress to finer ones for a smooth finish.

- Dust Removal: Regularly clean the surface to check progress and prevent scratching.

- Edge Awareness: Be cautious near edges to avoid rounding them unintentionally.

- Speed Control: Adjust the speed based on the wood type and desired finish.

Air Compressor Considerations for Furniture Refinishing in Virginia

Selecting the right air compressor is crucial for optimal air sander performance:

- CFM (Cubic Feet per Minute): Match or exceed your sander's CFM requirements.

- PSI (Pounds per Square Inch): Ensure your compressor can maintain the required pressure.

- Tank Size: Larger tanks provide more consistent air supply for extended use.

- Portability: Consider a portable compressor for on-site refinishing jobs across Virginia.

- Noise Level: Important when working in residential areas or shared workspaces.

Recommended Air Compressor Specifications for Furniture Refinishing

| Sander Type | Recommended CFM | Minimum Tank Size | Ideal PSI Range |

| Random Orbital | 4-6 CFM | 20+ gallons | 90-100 PSI |

| Palm Sander | 3-5 CFM | 15+ gallons | 90-100 PSI |

| Belt Sander | 5-7 CFM | 30+ gallons | 90-110 PSI |

| Disc Sander | 4-6 CFM | 20+ gallons | 90-100 PSI |

| Detail Sander | 2-4 CFM | 15+ gallons | 90-100 PSI |

Safety Considerations for Air Sanding in Virginia

Prioritize safety when using air sanders in your Virginia-based furniture refinishing projects:

- Dust Protection: Use dust masks or respirators to protect against wood dust, especially important in Virginia's humid climate where dust can linger.

- Eye Protection: Wear safety glasses to guard against flying particles.

- Hearing Protection: Use earplugs or earmuffs to protect against prolonged noise exposure.

- Ventilation: Ensure proper airflow in your workspace to minimize dust accumulation.

- Electrical Safety: Keep air hoses away from potential tripping hazards.

- Fire Safety: Be aware of spark potential, especially when sanding painted surfaces.

- Chemical Safety: Follow proper handling and disposal procedures for refinishing chemicals.

Maintaining Your Air Sander for Optimal Performance

Proper maintenance ensures longevity and consistent performance of your air sanders:

- Regular Cleaning: Remove dust and debris after each use.

- Lubrication: Apply air tool oil as recommended by the manufacturer.

- Pad Inspection: Regularly check and replace sanding pads as needed.

- Air Line Maintenance: Keep air lines clean and free of moisture.

- Compressor Care: Maintain your air compressor according to manufacturer guidelines.

- Storage: Store tools in a dry place to prevent rust, especially important in Virginia's humid climate.

Choosing the Right Abrasives for Virginia's Furniture Refinishing Projects

Selecting appropriate abrasives is crucial for achieving the desired finish:

- Grit Selection:

- Coarse (40-60 grit): For removing old finishes and major imperfections

- Medium (80-120 grit): For smoothing and preparing the surface

- Fine (150-220 grit): For final smoothing before finishing

- Very Fine (320+ grit): For between-coat sanding and ultra-smooth finishes

- Abrasive Types:

- Aluminum Oxide: Versatile and long-lasting

- Silicon Carbide: Ideal for hardwoods and between-coat sanding

- Ceramic: Durable and efficient for tough sanding jobs

- Backing Material:

- Paper: Economical and flexible

- Cloth: Durable and conformable to contours

- Film: Provides a consistent scratch pattern

Advanced Techniques for Furniture Refinishing with Air Sanders

Master these advanced techniques to take your Virginia furniture refinishing projects to the next level:

- Grain Raising: Lightly mist the wood with water between sandings to raise the grain for a smoother final finish.

- Cross-Grain Sanding: Carefully sand across the grain to remove deep scratches, then finish with the grain.

- Burnishing: Use ultra-fine grits (400+) with light pressure to create a glossy surface on dense hardwoods.

- Distressing: Create an aged look by selectively sanding edges and high points.

- Contour Sanding: Use flexible sanding pads to maintain the natural contours of curved furniture pieces.

Virginia's Furniture Refinishing Industry: Trends and Opportunities

Stay ahead in Virginia's competitive furniture refinishing market:

- Eco-Friendly Practices: Embrace low-VOC finishes and sustainable refinishing methods.

- Upcycling: Capitalize on the trend of repurposing and updating vintage furniture.

- Custom Finishes: Offer unique, customized finishes to differentiate your services.

- Historic Preservation: Specialize in restoring furniture from Virginia's rich historical heritage.

- Technology Integration: Utilize digital tools for design visualization and client communication.

Frequently asked Questions

1. How often should I replace the sanding pad on my air sander?

Replace the pad when you notice uneven wear or reduced effectiveness or after approximately 20-30 hours of use, depending on the material being sanded.

2. Can I use an air sander on painted surfaces in historic Virginia homes?

Yes, but start with a coarse grit to remove the paint, then progress to finer grits. Be cautious of lead paint in older homes and take appropriate safety measures.

3. What's the best way to manage dust when sanding indoors in Virginia's humid climate?

Use a sander with built-in dust collection, work near open windows with fans, and consider using air purifiers. Regular cleaning during the sanding process is also crucial.

4. Are there any local regulations in Virginia regarding dust and noise from furniture refinishing?

While regulations vary by locality, many Virginia cities have noise ordinances and air quality regulations. Check with your local government for specific guidelines.

5. How can I prevent over-sanding when working on delicate antique furniture pieces?

Start with a finer grit than you think you need, use light pressure, and check your progress frequently. Consider hand-sanding for extremely delicate areas.

Related Articles

- Understanding the Right Size of Air Compressor for Your Pneumatic Air Tools in 2023

- 15 Essential Pneumatic Tools Every Workshop Must Have

- The Ultimate Guide to Air Impact Wrenches: Reviews, Buying Guides, and Comparisons

- Best Air Compressors for Virginia's DIY Enthusiasts

Conclusion

Mastering air sanders in furniture refinishing is essential for success in Virginia's competitive market. By understanding the types of sanders, proper techniques, and maintenance practices, you can achieve superior results while preserving the integrity of valuable furniture pieces. Remember, investing in quality tools and continually developing your skills are key to thriving in this industry.

Whether restoring antiques in Alexandria's Old Town or creating custom pieces in Virginia Beach, the right air sander, combined with expertise and creativity, can help you produce stunning results that stand out in Virginia's furniture refinishing scene.

For expert advice on selecting the perfect air sanders and accessories for your furniture refinishing projects in Virginia, visit tendsupplies.com or contact sales@tendsupplies.com. Our team of specialists can help you find the ideal equipment to elevate your refinishing work.