Mechanic Tool Kit Checklist: Essential Tools for Every Workshop

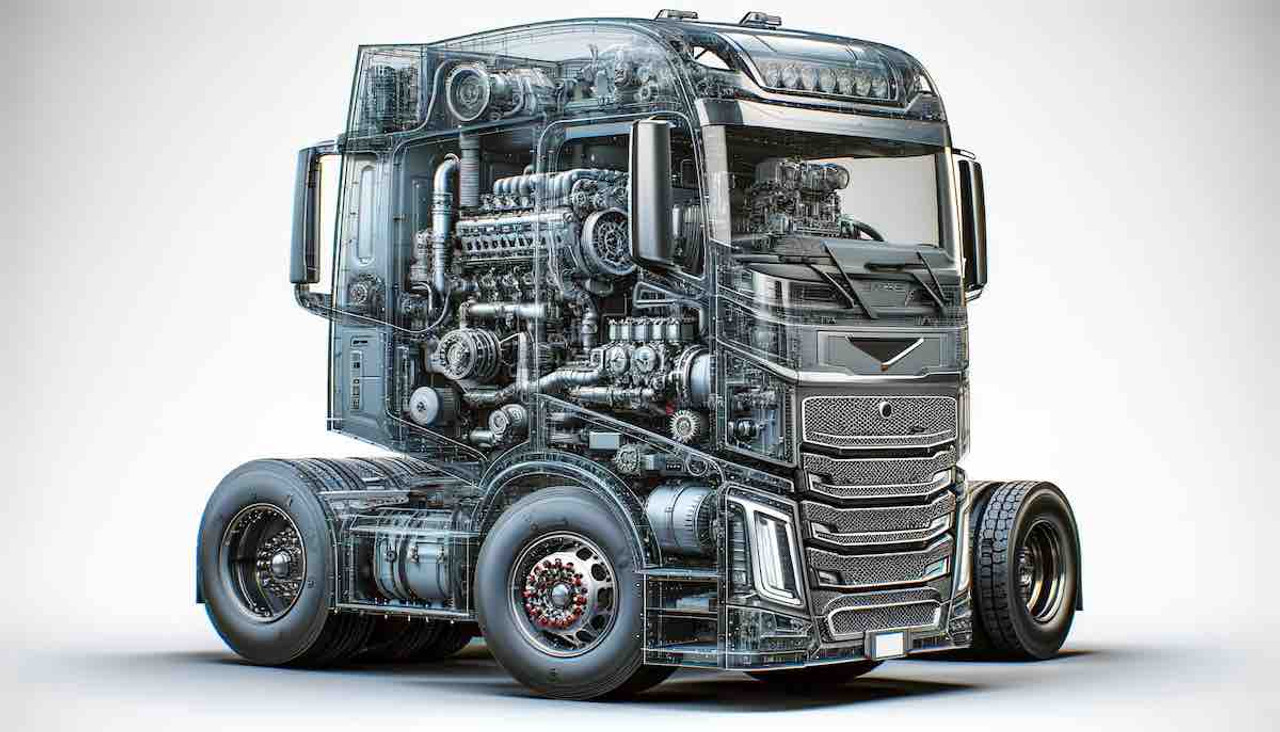

Introduction to Mechanic Tool Kits

Every amateur or professional mechanic understands the Importance of a Complete Mechanic Tool Kit. Not only does it streamline the repair process, but it also ensures you're prepared for various automotive issues. This guide will provide an Overview of Tool Kit Essentials, offering insights into what constitutes a comprehensive mechanic's arsenal.

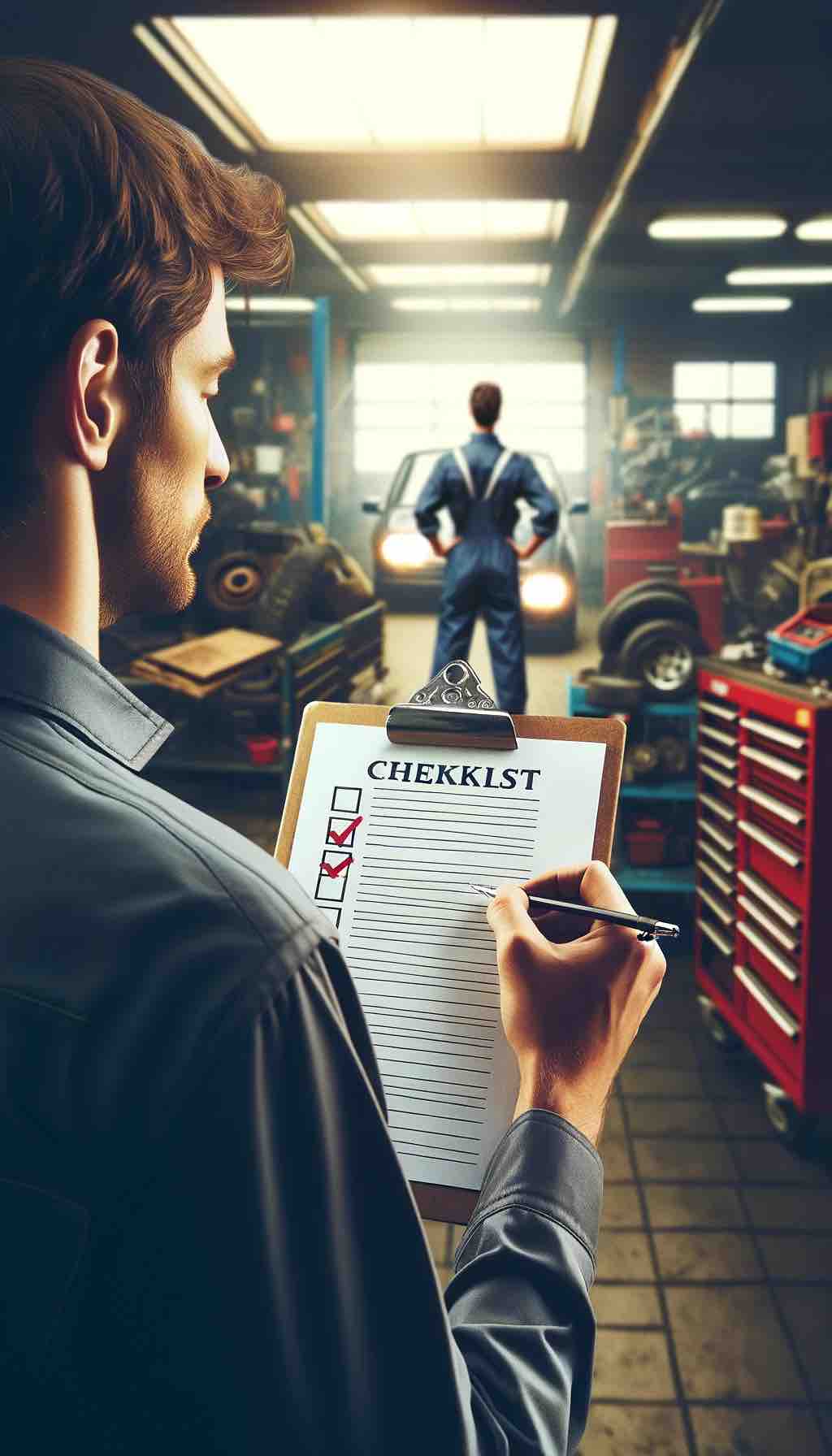

Checklist of mechanic tool kit

We may receive a commission on purchases made from links here, it is at no cost to you

Basic Hand Tools for Every Mechanic

A survey by a leading tool manufacturer polled over 1,000 professional technicians across the US also the Motor & Equipment Manufacturers' Association (MEMA) Market Reports a major automotive industry association, publishes market reports that indirectly shed light on common tools. Their reports on strong sales of specific tool categories like scanners, code readers, and diagnostic equipment indicate their growing importance in professional repair shops. The US Bureau of Labor Statistics (BLS), which represents the US Occupational Employment Statistics program provides data on the tasks performed by mechanics and automotive service technicians. Analyzing this data suggests a strong need for tools that enable basic maintenance (wrenches, screwdrivers), diagnostics (scanners), and some disassembly/reassembly tasks (hammers, specialty pullers).

The results showed that the top 5 most-used hand tools:

- Socket wrenches (both standard and metric)

- Ratchets and extensions

- Combination wrenches

- Screwdrivers (flathead and Phillips)

- Pliers (various types, including slip-joint, needle-nose, and locking pliers)

It is therefore imperative that technicians should focus on ensuring that these are the tools they must always have at hand because These three reports reinforce the recommendations . They all highlight the importance of a strong foundation in basic hand tools like above. Beyond these core tools, the data suggests that professional mechanics increasingly rely on diagnostic equipment like scanners and code readers to identify problems efficiently.

Remember:

- The specific tools needed can vary depending on the mechanic's niche (brakes, electrical, etc.)

- Building a comprehensive kit takes time. Prioritize based on your current projects and gradually expand your collection.

By following these tips and considering the industry trends, you can build a mechanic tool kit that equips you for various tasks, mirroring the approach of many professional workshops.

A well-equipped tool kit begins with the basics. Here are some basic hand tools every mechanic should have:

- Wrenches: Types and Uses: From adjustable wrenches to combination wrenches, each type serves a specific purpose: loosening bolts or ensuring a tight fit. There are different types of wrenches, each with its own purpose. Adjustable wrenches can be used on nuts and bolts of various sizes, while combination wrenches have two heads, one on each end, with different sizes.

- Sockets and Ratchets: Sizes and Varieties: A complete set, ranging from standard to deep sockets and varying ratchet sizes, ensures you can tackle any bolt or nut. This is a versatile tool that can be used to tighten and loosen nuts and bolts of various sizes. It typically includes a ratchet handle, sockets, and extensions.

- Screwdrivers: Essential Types: Flathead and Phillips are just the beginning. Precision screwdrivers and Torx drivers expand your capabilities. Screwdrivers are used for turning screws. There are different types of screwdrivers, such as flat-head screwdrivers and Phillips screwdrivers. Screwdrivers are used for turning screws. There are different types of screwdrivers, such as flat-head screwdrivers and Phillips screwdrivers.

Buy this screw driver from Amazon

- Pliers: Different Models for Different Tasks: Needle-nose pliers for precision work, locking pliers for a secure grip, and wire strippers for electrical tasks are just a few examples. Pliers are used for gripping, twisting, and cutting. There are different types of pliers, such as slip-joint pliers, locking pliers, and needle-nose pliers.

Advanced Hand Tools

As your mechanical skills grow, so should your tool kit. Consider adding:

- Specialty Wrenches and Sockets: Crowfoot wrenches, flare nut wrenches, and torque sockets can help with specific automotive tasks.

- Torque Wrenches: Precision in Tightening: Crucial for ensuring bolts and nuts are tightened to specific torque specs, preventing damage and ensuring safety.

- Impact Drivers: When More Force is Needed: For stubborn bolts or quick removal, an impact driver can save time and effort.

Measuring and Diagnostic Tools

Accurate measurements and diagnostics are key to successful repairs:

- Tape Measures and Calipers: Precision tools like calipers can make all the difference for measuring parts or distances.

- Multimeters and Circuit Testers: Essential for diagnosing electrical issues, from battery checks to identifying short circuits.

- Engine Diagnostic Tools: Code readers and OBD2 scanners can help pinpoint issues, saving time and guesswork.

Equipping your workshop with these essential tools, you'll be prepared to tackle a wide range of mechanical challenges. Remember, a well-stocked mechanic tool kit is the backbone of any successful repair or maintenance task.

Read our Guide to Best Budget Mechanic Tools Kits

Cutting and Fastening Tools

For meticulous cutting and secure fastening, these tools are indispensable:

- Wire Cutters and Strippers: Essential for electrical repairs, ensuring precise wire cutting and insulation removal without damage.

- Hammers and Mallets: A good hammer or rubber mallet is a must-have for tapping parts into place and breaking free stuck components.

- Rivet and Staple Guns: Ideal for bodywork or securing materials, these tools provide a durable solution beyond traditional fastening methods.

Power Tools for the Modern Mechanic

Power tools can significantly enhance efficiency and effectiveness in the workshop:

- Impact Wrenches and Drills: A cornerstone of any mechanic's toolset, they dramatically reduce the time and effort required for removing bolts or drilling holes.

- Air Compressors and Accessories: Power a variety of tools, from pneumatic wrenches to spray guns, making them versatile allies in the garage.

- Grinders and Sanders: Perfect for removing rust, smoothing surfaces, or cutting through metal, these tools are essential for bodywork and fabrication tasks.

Specialty Tools for Specific Tasks

Certain repairs require specialized tools for best results:

- Timing Tools and Belt Tools: Necessary for precise engine work, ensuring timing components are correctly installed and maintained.

- Oil Service Tools: From oil filter wrenches to drain pans, these tools streamline oil changes and help prevent messes.

- Transmission and Alignment Tools: Key for complex jobs like transmission servicing or wheel alignments, ensuring accuracy and saving time.

Safety and Protective Gear

Never underestimate the importance of safety in the workshop:

- Gloves and Eye Protection: Protect your hands from cuts and burns and your eyes from sparks and debris with appropriate safety gear.

- Ear Protection and Respirators: Protect your hearing in noisy environments and your lungs from dust or chemical fumes.

- Protective Clothing and Footwear: Durable, non-slip footwear and flame-resistant clothing can prevent injuries from spills, heat, or falling objects.

Storage and Organization Solutions

A well-organized workshop is a more efficient and safer workspace:

- Toolboxes and Tool Carts: Keep your tools organized, accessible, and mobile for when you need to move around the shop.

- Organizers and Storage Systems: Wall-mounted racks, magnetic holders, and drawer dividers can keep tools visible and within reach.

- Portable Tool Kits and Bags: For jobs on the go, portable kits ensure you have the essentials wherever you need them.

By incorporating these tools, safety gear, and organization solutions into your workshop, you’ll be equipped to handle a wide range of mechanical tasks with efficiency and precision. Remember, investing in the right tools and taking care of them not only makes your job easier but also ensures a safer and more productive working environment.

Storage and Organization Solutions

An organized workshop is a productive workshop. Consider implementing these storage solutions:

- Toolboxes and Tool Carts: Keep your tools secure and mobile. A well-organized toolbox or cart ensures that every tool is just an arm's reach away when needed.

- Organizers and Storage Systems: Wall-mounted racks, pegboards, and drawer organizers can significantly enhance your workspace's efficiency, making it easier to find the right tool quickly.

- Portable Tool Kits and Bags: For mechanics on the move, portable tool kits and bags are essential. They allow you to carry your most-used tools to various job sites without hassle.

Maintenance of Your Mechanic Tool Kit

Proper maintenance is key to extending the life of your tools:

- Cleaning and Lubrication: Regularly clean and lubricate your tools to keep them functioning smoothly and prevent corrosion.

- Regular Check-ups and Replacement: Inspect your tools regularly for signs of wear or damage. Replace any tools that are no longer fit for use to maintain the quality of your work.

- Rust Prevention and Storage Tips: Store your tools in a dry, clean place to prevent rust. Use silica gel packs or a dehumidifier in your storage area to minimize moisture.

Building Your Custom Mechanic Tool Kit

Creating a tool kit that meets your specific needs requires careful planning:

- Assessing Your Needs Based on Specialization: Consider the types of vehicles or machinery you frequently work on and tailor your toolkit accordingly.

- Prioritizing Investments: Start with the essentials and gradually invest in specialized tools as required by your projects.

- Expanding Over Time: As your skills and services expand, so should your tool kit. Add tools that increase your efficiency and ability to take on more complex jobs.

Conclusion: Finalizing Your Mechanic Tool Kit

Compiling the perfect mechanic tool kit is a continuous journey. Review your checklist regularly and ensure each item reflects the Importance of Quality and Care. Quality tools are an investment in your trade, and proper care ensures their longevity. Remember, a well-maintained and carefully curated tool kit is the backbone of any successful mechanic's work. Encourage Continuous Update and Maintenance of your kit to stay ahead in your field.

FAQs

Common Questions About Assembling and Maintaining Mechanic Tool Kits:

- How often should I clean my tools?

- Clean your tools after every use to prevent dirt and grime buildup. A more thorough cleaning and inspection should be done monthly or depending on usage frequency.

- What’s the best way to prevent my tools from rusting?

- Keep your tools dry, use rust-preventative sprays, and store them in a controlled environment. Regularly check for signs of rust and treat them immediately if found.

- Should I buy all my tools at once or gradually?

- It's best to start with essential tools and gradually build your collection based on your needs and budget. This approach allows you to invest in higher-quality tools over time.

- Can I use household items as substitutes for missing tools?

- While household items can temporarily substitute for certain tools, using the right tool for the job is always recommended for safety and effectiveness.

For more tips, guidance, or to explore our range of mechanic tool kits and storage solutions, visit Tend Industrial Supplies at tendsupplies.com or contact us at sales@tendsupplies.com. We're here to help you build and maintain the perfect mechanic tool kit for your needs.

Related Posts