Stop Guessing, Start Proving: Why IAQ Monitoring is the Future of Restoration Jobs

At 6:30 a.m., a restoration crew finished drying a flooded office suite that looked and smelled perfectly clean. The equipment was packed up, the client was ready to sign off, and the job seemed complete. But a week later, complaints came in: headaches, musty air, and lingering discomfort. The problem wasn’t visible on walls or floors it was in the air.

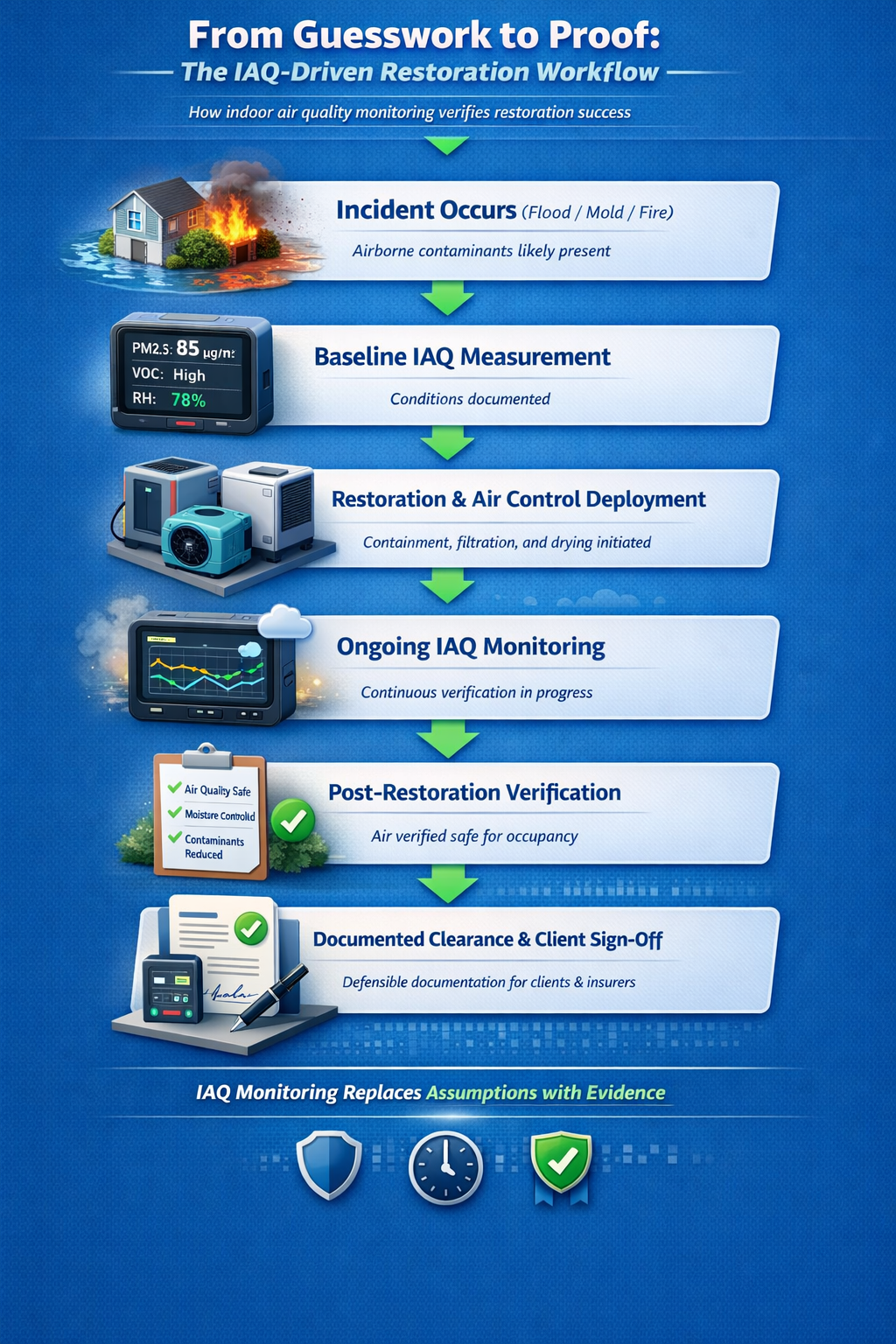

This is exactly why “Stop Guessing, Start Proving: Why IAQ Monitoring is the Future of Restoration Jobs” matters more than ever. In today’s restoration industry, visual inspections and moisture readings alone are no longer enough. Clients, insurers, and regulators now demand measurable proof that indoor air is truly safe. IAQ monitoring turns restoration from assumption-based work into data-backed, defensible results, protecting both occupants and contractors worldwide.

Quick Answer

IAQ monitoring is the future of restoration because it provides measurable, documented proof that indoor air is safe after water damage, mold remediation, or fire restoration. It reduces liability, speeds up approvals, builds client trust, and ensures compliance with modern restoration standards across residential, commercial, and industrial projects.

Key Takeaways:

-

Proof-Based Restoration Is Now the Industry Standard

IAQ monitoring replaces assumptions with measurable data, providing documented evidence that indoor air is safe after water damage, mold remediation, or fire restoration. -

IAQ Data Reduces Liability and Protects Contractors

By capturing before-and-after air quality readings, restoration professionals can defend their work, avoid disputes, and meet increasing insurance and regulatory documentation demands. -

Faster Approvals and Fewer Callbacks Improve Profitability

Verified IAQ results speed up client sign-offs, reduce re-inspections, and eliminate costly return visits, helping restoration businesses close jobs faster. -

IAQ Monitoring Creates a Competitive Advantage

Contractors who offer air quality verification win more commercial and institutional projects, command premium pricing, and stand out in a crowded restoration market. -

The Future of Restoration Is Data-Driven

As standards evolve and clients become more informed, IAQ monitoring will become as essential as moisture measurement, making early adopters better positioned for long-term growth.

What Is IAQ Monitoring in Restoration?

Understanding Indoor Air Quality (IAQ)

Indoor Air Quality refers to the condition of air inside buildings as it relates to occupant health, comfort, and safety. In restoration projects, IAQ focuses on detecting and controlling:

-

Mold spores

-

Particulate matter (PM2.5 / PM10)

-

Volatile Organic Compounds (VOCs)

-

Carbon dioxide (CO₂)

-

Relative humidity and temperature

Why IAQ Matters in Restoration Work

After floods, leaks, fires, or mold events, air contaminants remain long after surfaces look dry. Without IAQ monitoring, contractors rely on assumptions instead of evidence, an approach that increasingly exposes businesses to disputes, failed clearance tests, and legal risk.

Check IAQ Monitor Rental availability at Tendsupplies.com

The Problem With Guesswork in Restoration Jobs

Visual Clean ≠ Air Safe

A building may look restored, smell fine, and still contain harmful airborne contaminants. Mold spores and fine particulates are invisible, and insurance carriers, adjusters, and environmental consultants know it.

Rising Liability and Documentation Demands

Globally, restoration professionals face:

-

Stricter insurance documentation requirements

-

Third-party verification demands

-

Health-related litigation tied to poor air quality

Guessing is no longer defensible. Measured proof is.

Why IAQ Monitoring Is the Future of Restoration

1. Proof-Based Restoration Is the New Standard

IAQ monitoring provides before, during, and after data, proving that:

-

Contaminants were present

-

Controls were effective

-

Air quality meets acceptable thresholds

This documentation protects contractors and builds trust with insurers and clients.

2. Faster Project Approvals & Fewer Callbacks

When you can prove air quality compliance, you eliminate:

-

Re-inspection delays

-

Disputes with adjusters

-

Costly return visits

IAQ data accelerates sign-offs and improves cash flow.

3. Competitive Advantage in Bids & Commercial Contracts

Commercial property managers, hospitals, schools, and industrial facilities increasingly require IAQ verification as part of restoration scope.

Contractors offering IAQ monitoring services:

-

Win higher-value projects

-

Command premium pricing

-

Differentiate from low-bid competitors

4. Compliance With Global Standards

IAQ monitoring aligns restoration work with international best practices, including:

-

IICRC S500 & S520 principles

-

WHO indoor air quality guidelines

-

Regional environmental health standards

This makes IAQ monitoring essential for multi-region and international restoration firms.

Key Applications of IAQ Monitoring in Restoration

Water Damage Restoration

-

Confirms drying effectiveness

-

Detects hidden microbial activity

-

Prevents secondary mold growth

Mold Remediation Projects

-

Establishes baseline spore counts

-

Verifies containment effectiveness

-

Supports clearance documentation

Fire & Smoke Damage Restoration

-

Identifies lingering VOCs and soot particulates

-

Ensures air is safe for re-occupancy

Post-Construction & Renovation Cleanup

-

Confirms dust and particulate removal

-

Protects occupants from respiratory exposure

Essential IAQ Monitoring Tools for Restoration Pros

IAQ Meters

Measure temperature, humidity, CO₂, VOCs, and particulates.

Particle Counters

Detect fine airborne dust and mold-related particulates.

Data Logging & Reporting Software

Creates time-stamped reports for clients and insurers.

How IAQ Monitoring Improves Trust & Transparency

Clients no longer want assurances, they want evidence.

IAQ reports provide:

-

Clear, easy-to-understand data

-

Visual proof of progress

-

Professional documentation that builds credibility

This transparency dramatically improves customer satisfaction and referrals.

The Future: Data-Driven Restoration Businesses

Restoration companies that adopt IAQ monitoring today are building:

-

Stronger insurance relationships

-

Scalable, standardized workflows

-

Legally defensible project records

As AI reporting, smart sensors, and remote monitoring expand, IAQ data will become as essential as moisture readings.

Frequently Asked Questions (FAQs)

1. What is IAQ monitoring in restoration work?

IAQ monitoring in restoration is the process of measuring and documenting indoor air conditions, such as particulate matter, mold spores, VOCs, CO₂, humidity, and temperature, before, during, and after restoration to verify that the air is safe for re-occupancy.

2. Why is IAQ monitoring important after water damage or flooding?

Water damage can release hidden mold spores and airborne contaminants even after surfaces appear dry. IAQ monitoring confirms that drying and remediation efforts have successfully restored safe indoor air quality, reducing health risks and future mold growth.

3. Can IAQ monitoring help with mold remediation clearance?

Yes. IAQ monitoring provides baseline and post-remediation data that supports mold clearance decisions. While it may not replace third-party clearance testing, it strengthens documentation and proves that remediation controls were effective.

4. Do insurance companies require IAQ monitoring?

Many insurers increasingly expect IAQ data, especially for commercial, healthcare, and large-loss restoration projects. While not always mandatory, IAQ documentation often speeds up approvals, reduces disputes, and strengthens claim defensibility.

5. What IAQ parameters should restoration professionals measure?

Restoration professionals typically monitor particulate matter (PM2.5/PM10), VOCs, CO₂, relative humidity, temperature, and sometimes airborne mold indicators, depending on the project type and risk level.

6. Is IAQ monitoring only for large commercial restoration projects?

No. IAQ monitoring is valuable for residential, commercial, and industrial restoration jobs alike. Even small projects benefit from documented proof of safe air quality, improved client trust, and reduced liability.

Related Articles:

- Industrial Equipment Rentals: Complete 2025 Guide for Contractors, Facility Managers & Restoration Pros

- The Complete Guide to Pressure Testing: Methods, Tools, and Best Practices (2025 Edition)

- Industrial Air Compressor Buyer’s Guide: How to Choose the Perfect System in 2025

- Commercial Dehumidifier Rentals: How to Size, Select & Deploy for Flood Restoration

- HEPA Air Scrubber Rentals vs. Buying: Which Is Better for Restoration Projects?

Conclusion

The restoration industry is evolving rapidly, and the days of relying on visual inspections and assumptions are coming to an end. As this article—Stop Guessing, Start Proving: Why IAQ Monitoring is the Future of Restoration Jobs, clearly demonstrates, indoor air quality monitoring has become a critical component of professional, defensible restoration work. From water damage restoration and mold remediation to fire and smoke cleanup, IAQ monitoring provides measurable proof that the indoor environment is truly safe for re-occupancy.

By integrating IAQ monitoring for restoration projects, contractors can reduce liability, improve compliance with modern industry standards, and deliver transparent documentation that insurers and clients trust. Data-driven air quality testing not only supports faster project approvals but also helps prevent costly callbacks and post-job disputes. In an era where air quality verification after flood damage and mold remediation clearance support are increasingly expected, the ability to measure, record, and report IAQ is a powerful competitive advantage.

Looking ahead, the future of restoration belongs to professionals who embrace evidence-based restoration practices. IAQ monitoring is no longer an optional add-on, it is becoming as essential as moisture meters and drying equipment. Contractors who adopt professional indoor air quality monitoring solutions today will be better positioned to win higher-value jobs, protect occupants’ health, and lead the restoration industry with confidence and credibility worldwide.

Ready to stop guessing and start proving your restoration results? Equip your projects with professional IAQ monitoring solutions that deliver measurable proof, faster approvals, and greater client confidence. At Tendsupplies.com, you’ll find industry-grade IAQ monitors, HEPA air scrubbers, and environmental testing equipment available for fast, flexible rental, ideal for water damage restoration, mold remediation, and large-loss recovery jobs.

Visit Tendsupplies.com today to explore IAQ monitoring rentals built for real-world restoration demands, or contact our specialists at sales@tendsupplies.com for expert guidance on selecting the right equipment for your next project. Protect your work, strengthen your documentation, and lead the future of restoration with confidence.