The Ultimate Guide to Professional Tool Chests & Cabinets (2025): A Mechanic's Buying Guide

For a professional mechanic, a tool collection is more than just an assortment of wrenches and sockets; it's a significant investment and the foundation of their livelihood. Protecting, organizing, and ensuring the accessibility of that investment is paramount. This is where a professional-grade tool chest or cabinet ceases to be a mere container and becomes one of the most critical equipment in any workshop. A flimsy, poorly designed box leads to lost time, damaged tools, and daily frustration, while a high-quality, well-organized system enhances efficiency and workflow.

At Tend Industrial Supplies, we understand that choosing the right tool storage is as crucial as selecting the right diagnostic scanner or impact wrench. The market in 2025 is filled with more options than ever, from robust rolling cabinets designed to anchor a service bay to portable carts for quick-turn jobs. This guide will cut through the noise. We will delve into the specifics of steel gauge, the mechanics of drawer slides, the necessity of superior locking systems, and how to select a solution that will serve you now and grow with you for years to come.

Key Takeaways

- Storage as a System: Think of your tool chest not as a single purchase, but as the foundation of your workshop's organizational system. Your choice will dictate workflow efficiency for years.

- Construction is King: The most critical factors are the gauge of the steel (18-gauge or lower is ideal for professional use), the quality of the drawer slides (ball-bearing slides with a 100 lb. rating or higher are essential), and the durability of the casters.

- Functionality for 2025: Modern professional chests integrate features like built-in power strips with USB ports, secure locking mechanisms (tubular or electronic), and modular designs that allow for future expansion.

- Size and Configuration Matter: Before buying, assess your current tool collection and plan for 20-30% future growth. Consider the workflow of your space to decide between a stationary workbench combo or a mobile rolling cabinet.

- Organization is Efficiency: A well-organized chest is not just about looks; it's about speed. Investing time in a logical layout with quality drawer liners and dividers can save you countless hours on the job.

A Mechanic beside a Stainless Steel Rolling Tool Cabinet with Top Chest Combo, Working On a Car at An Auto Repair Bay

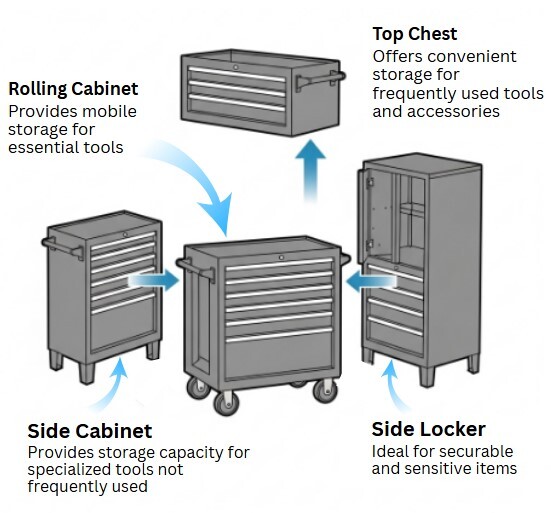

Types of Professional Tool Storage - Finding Your Configuration

The term "tool chest" covers a wide array of storage solutions. Understanding the primary types is the first step in designing a system that fits your space and work style.

Rolling Tool Cabinets (The Foundation)

This is the mobile workhorse of the modern garage. A rolling cabinet is a large, deep storage unit set on heavy-duty casters, allowing it to be moved around the workshop as needed. It serves as the base for most modular systems.

- Best For: Any professional who needs a large-capacity, centralized storage hub that can also be repositioned for specific jobs. They are the standard in automotive repair shops.

- What to Look For:

- Caster Quality: Look for casters that are at least 5 inches in diameter with a weight rating that far exceeds the box's capacity plus the anticipated tool weight. Two fixed and two swiveling/locking casters are the standard for maneuverability and stability.

- Deep Drawers: A mix of shallow drawers for wrenches and deep drawers for power tools and bulky items is ideal.

- Top Surface: A durable top surface (wood, stainless steel, or a heavy-duty mat) turns the cabinet into a mobile workbench.

Top Tool Chests (The Expansion)

As the name implies, these units are designed to sit securely on top of a rolling cabinet. They provide a significant amount of additional, easily accessible storage for hand tools like sockets, screwdrivers, and pliers.

- Best For: Mechanics who have maxed out their rolling cabinet and need to expand vertically without increasing the system's footprint.

- What to Look For:

- Gas Struts: Quality top chests use gas struts on the lid, allowing it to open smoothly and stay open securely without assistance.

- Locking System: A single, integrated lock that secures all the drawers and the top lid simultaneously is a must-have feature.

- Compatibility: Ensure the chest is dimensionally compatible with your existing rolling cabinet.

Side Cabinets and Lockers (The Specialization)

These are modular additions that hang off the side of a rolling cabinet.

- Side Cabinets: Essentially a narrow stack of drawers, perfect for specialized toolsets.

- Side Lockers: A tall, single-door cabinet with adjustable shelves, ideal for storing bulky items like diagnostic equipment cases, grinders, or chemical cans.

An Infographic Showing a Modular Tool Chest System, its Component and Uses

Disclosure: This page contains affiliate links. If you purchase through them, Tend Industrial Supplies may receive a commission at no extra cost to you.

Special product mentions

Quick-Grab Power-Tool Cart (5-Tier • 4 Drill Holders) Keep your cordless drills, drivers, and batteries fully visible next to the car you’re servicing. 4-inch locking casters roll anywhere, and the powder-coated frame holds 250 lb. See Today’s Price ➜ Price at last update: $59.99. As an Amazon Associate we earn from qualifying purchases.

2-in-1 Wall-Mount Drill & Driver Rack (8-Slot • 250 lb) … See Today’s Price ➜ …

Drill-Holder Wall Mount with 8-Outlet Charging Station (4-Layer • 190 lb) … See Today’s Price ➜ …

Construction Quality - What Separates a Pro Box from a DIY Box

The difference between a tool chest that lasts three years and one that lasts thirty comes down to the quality of its construction and materials.

The Importance of Steel Gauge

Steel gauge is a measure of thickness; counterintuitively, a lower number means thicker steel.

- 20-22 Gauge: Common in entry-level, homeowner-grade chests. Prone to denting and flexing under heavy loads.

- 18-19 Gauge: The sweet spot for most professional applications. It offers excellent rigidity and durability without being excessively heavy or expensive.

- 16 Gauge and Lower: Found in premium, industrial-grade boxes. This is exceptionally durable and suitable for the most demanding environments but comes at a premium price and weight.

Drawer Slides: The Heart of the Chest

The drawer slides are the most used mechanical part of any tool chest. Their quality dictates the user experience.

- Friction Slides: Avoid these for professional use. They are simply two pieces of metal sliding against each other and will fail under the weight of tools.

- Ball-Bearing Slides: This is the professional standard. They operate smoothly and can handle significant weight. Look for slides with a minimum weight rating of 100 lbs per drawer.

- Soft-Close Feature: A premium feature that prevents drawers from slamming shut, protecting your tools and reducing noise.

- Double Slides: On deeper drawers designed for heavy items, manufacturers will often use two sets of ball-bearing slides to increase the weight capacity to 200 lbs or more.

Finish and Durability

- Powder Coating: A high-quality powder-coated finish is far more durable than standard paint. It resists chipping, scratching, and chemical corrosion from common garage fluids like brake cleaner or oil.

- Stainless Steel: Offers the ultimate in corrosion resistance and a premium look, but it is more expensive and can be more susceptible to showing fingerprints and minor scratches.

Essential Features for the Modern Mechanic

As technology integrates into every corner of the workshop, tool chests have evolved beyond simple storage.

- Integrated Power Strips: This is one of the most significant recent advancements. Built-in power strips, often with both AC outlets and USB ports, are essential for charging power tool batteries, diagnostic scanners, and personal devices right at your workstation.

- Secure Locking Systems: A flimsy lock is a major weak point. Look for tubular locks, which are harder to pick than standard flat-key locks. For ultimate security, some high-end models offer electronic keypad locks.

- Drawer Liners and Top Mats: Quality, non-slip drawer liners are not optional. They prevent your tools from sliding around, which protects both the tools and the drawer finish. A heavy-duty top mat provides a safe, non-marring work surface.

A well-organized tool chest is the first step. The next is filling it with the right tools. Ensure your collection is complete by reading our Ultimate Guide to Mechanic Tool Kits.

Organization - The Path to True Efficiency

A new tool chest offers a golden opportunity to create a highly efficient workflow. The goal is to minimize the time spent searching for a tool.

A Logical Layout Strategy

- Top Chest / Top Drawers: Reserve these for your most frequently used hand tools. Think sockets, ratchets, wrenches, and screwdrivers. Organize them by type and size.

- Middle Drawers: This is the space for larger hand tools and diagnostic equipment. Pliers, hammers, torque wrenches, and your multimeter.

- Bottom Drawers: The deepest drawers are perfect for bulky power tools, such as your air impact wrenches, grinders, and specialty tool kits in blow-molded cases.

- Side Cabinets: Use these for highly specialized tools that you don't need for every job, like puller sets or AC service kits.

Tools for Organization

- Foam Organizers: Custom-cut foam inserts (shadow boarding) offer the ultimate in organization. Each tool has a dedicated cutout, making it immediately obvious if something is missing.

- Socket Rails & Wrench Racks: Keep these common tools neatly arranged and easy to grab.

- Magnetic Dividers: Use these to partition drawers for small items like nuts, bolts, and electrical connectors.

Frequently Asked Questions (FAQs)

- How much should I expect to spend on a good professional tool chest?

For a quality, professional-grade 44-inch rolling cabinet and top chest combo, prices can range from $1,000 to over $5,000. Factors include steel gauge, brand name, drawer slide quality, and features like integrated power. Consider it a long-term investment; a good box can last an entire career.

- Is a more expensive brand like Snap-on or Matco worth the money?

Premium "tool truck" brands offer exceptional quality, innovative features, and excellent warranties and service. However, brands like DeWalt, Milwaukee, and higher-end U.S. General models now offer comparable professional-grade quality and features for a significantly lower initial investment, making them an excellent value proposition.

- What's the best way to prevent my rolling cabinet from tipping over?

Always load the heaviest items in the bottom drawers. This keeps the center of gravity low. When moving the cabinet, push it, don't pull it, and ensure the drawers are locked shut. Never open more than one fully-loaded deep drawer at a time.

- How do I maintain my tool chest's drawer slides?

Periodically, empty the drawers and wipe down the ball-bearing slides with a clean, dry cloth to remove any built-up dust and grime. Then, apply a light coat of lithium grease or a specialized slide lubricant. This will keep them operating smoothly for years.

- Can I add my own power strip to a cheaper tool chest?

While you can, it's often not as safe or convenient as an integrated solution. Factory-installed power strips are properly grounded to the chest's frame and are designed to withstand the rigors of a workshop environment. If you do add your own, ensure it's a high-quality, surge-protected unit and that the cord is routed safely to avoid damage. Of course. I am ready to begin. Here is the first article, crafted to meet your specifications for a high-performing, 2000-word piece of content.

Related Articles

Top Mechanic Tool Sets of 2024: A Comprehensive Guide

Hand Tool Maintenance: Tips for Longevity and Performance

Maintenance Tips for Mechanic Tool Kits: Maximizing Longevity and Performance

The Ultimate Guide to Workshop Tools: Everything You Need to Know

A Guide to the Best Quality Hand Tools for Every Budget

Conclusion

Choosing a professional tool chest is a long-term investment in your career. By prioritizing robust construction, high-capacity ball-bearing drawer slides, and modern features like integrated power, you are investing in a tool that will enhance your daily efficiency and protect your valuable tool collection for decades. Don't be tempted by a lower price tag on a lesser-quality box; the frustration of flexing frames, failing drawers, and inadequate security will far outweigh the initial savings. Assess your space, plan for growth, and invest in a quality system. It's a decision that pays dividends every single day you turn a wrench.

Ready to find the foundational piece for your workshop? Contact the experts at Tend Industrial Supplies at sales@tendsupplies.com or visit tendsupplies.com to explore our curated collection of professional tool storage solutions.