Top 10 Workshop Essentials for 2025: Tools Every Mechanic, DIYer, and Industrial Tech Needs

On a chilly January morning, a small auto-repair shop in Osaka found itself flooded with customers after a sudden cold snap caused dozens of battery failures across the city. The lead technician reached for his trusted tools, those same workshop essentials he had relied on for over a decade, but this time, something was different. Newer, smarter, more efficient gear had taken the place of outdated equipment, allowing him to diagnose problems twice as fast and finish jobs before competitors opened their doors.

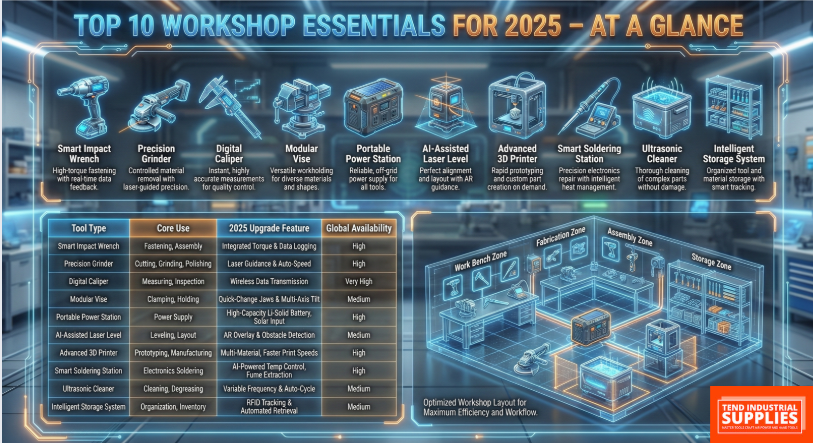

This simple moment captures why staying updated matters. In a world of rapid innovation, the Top 10 Workshop Essentials for 2025 aren’t just tools, they’re what separate efficient, profitable workshops from those struggling to keep up. Whether you're a mechanic, woodworker, engineer, DIY hobbyist, or industrial technician, knowing which tools are truly worth the investment can dramatically improve workflow, safety, and output.

Quick Answer

The Top 10 Workshop Essentials for 2025 include high-torque cordless impact wrenches, multi-material angle grinders, smart digital calipers, heavy-duty workbenches, LED lighting, professional socket sets, bench vises, dust extraction systems, portable power stations, and advanced safety gear. These tools boost productivity, accuracy, and safety for mechanics, DIYers, and industrial technicians.

Key Takeaways

- 2025 workshops require a blend of smart tools and traditional essentials, ensuring faster diagnostics, higher precision, and safer operations in both automotive and industrial settings.

- Power-efficient, long-lasting cordless tools dominate modern workflows, reducing downtime and increasing mobility for professionals and DIY users.

- Digital measurement and diagnostic devices are now must-have tools, helping technicians troubleshoot engines, electronics, and machines with pinpoint accuracy.

- A well-structured workshop layout—Clean Tech Zone, Dirty Zone, and Assembly Zone, maximizes workflow efficiency, cuts clutter, and improves overall productivity.

- Investing in high-durability, future-proof equipment saves money long term, as 2025-ready tools offer better performance, fewer breakdowns, and compatibility with emerging technologies.

Why Your Workshop Needs a 2025 Upgrade

Workshops today must keep up with:

- Higher tool durability requirements

- Faster turnaround expectations

- Smart diagnostics and energy-efficient machines

- Safer handling and noise-reduction features

This list helps you stay ahead with the best workshop tools of 2025, based on performance, affordability, and global availability.

Also Read: Maximize Your Space: Budget Organization Ideas for Small Garages

Top 10 Workshop Essentials for 2025

- High-Torque Impact Wrench (Cordless or Pneumatic)

A must-have for any automotive or industrial workspace.

Best for: Lug nuts, suspension, heavy-duty bolts

Why essential in 2025:

- Brushless motors deliver longer lifespan

- Lightweight designs reduce fatigue

- Smart torque sensors prevent bolt damage

Buying Guide Tips:

-

Torque Rating: Choose one with at least 300–600 ft.lbs for automotive work; industrial use may require 1,000+ ft.lbs.

-

Power Source: Decide between cordless (portable, lithium-ion batteries) and pneumatic (constant high torque).

-

Ergonomics: Look for lightweight, balanced designs with vibration control.

-

Additional Features: Brushless motors, smart torque sensors, and variable speed settings improve efficiency.

2. Multi-Material Angle Grinder (900W–1500W)

Angle grinders remain a universal workshop tool.

Best for: Cutting, grinding, polishing, rust removal

Why essential in 2025:

- Soft-start safety

- Automatic speed control

- Enhanced dustproofing for longer motor life

Buying Guide Tips:

-

Motor Power: 900–1500W is ideal; higher wattage improves cutting speed on tough metals.

-

Disc Size: 4.5–7 inches for flexibility in tight spaces and heavy-duty work.

-

Safety Features: Soft-start, overload protection, and anti-kickback.

-

Dust Protection: Choose grinders with dustproof sealing and debris guards.

- Smart Digital Caliper or Measuring Tool

Best for: Precision engineering, metal fabrication, woodworking

Why essential: 2025 tools now include:

- LCD displays

- Bluetooth measurement syncing

- ±0.001 accuracy for micro-level tasks

Buying Guide Tips:

-

Accuracy: ±0.001 inch / 0.02 mm is recommended for precision tasks.

-

Display: Look for easy-to-read LCD screens and metric/imperial switching.

-

Connectivity: Bluetooth-enabled tools allow syncing with workshop management software.

-

Material: Stainless steel body for durability and resistance to corrosion.

- Heavy-Duty Workbench With Storage

A clutter-free workspace boosts productivity.

What to look for:

- 1000–1500 lb weight capacity

- Lockable drawers

- Pegboard tool organization

- Chemical-resistant surfaces (for auto/machine shops)

Buying Guide Tips:

-

Load Capacity: At least 1,000 lbs for automotive or machinery tasks.

-

Storage Options: Lockable drawers, pegboard panels, and modular shelving maximize efficiency.

-

Surface Material: Chemical-resistant and heat-resistant top for long-term durability.

-

Height & Comfort: Adjustable or ergonomically designed height for prolonged use.

- LED Workshop Lighting + Portable Work Lights

Poor lighting slows down every repair.

2025 improvements:

- Daylight-grade LEDs

- Energy-saving smart sensors

- Magnetic, foldable, and rechargeable options

Buying Guide Tips:

-

Brightness: 3,000–5,000 lumens for large workspaces.

-

Color Temperature: Daylight-grade (5,000–6,500K) for true color visibility.

-

Energy Efficiency: LED with motion sensors or dimmers saves energy.

-

Portability: Magnetic bases, foldable, or rechargeable for flexible lighting positions.

- Professional Socket Set (Cr-V / Cr-Mo Steel)

No workshop is complete without a durable socket kit.

What makes it a 2025 essential:

- 90–120T ratchets for tight spaces

- Metric + SAE full coverage

- Impact-rated sockets for high-torque tasks

Buying Guide Tips:

-

Material: Chrome vanadium or chrome molybdenum for durability and corrosion resistance.

-

Coverage: Full metric + SAE sizes; include deep and standard sockets.

-

Drive Sizes: Commonly 1/4”, 3/8”, 1/2” depending on your typical tasks.

-

Extras: Ratchet with 90–120 teeth for tight spaces and impact-rated for heavy-duty use.

- Bench Vise or Lock-Down Vise

A strong vise provides stability for cutting, filing, welding, and assembly.

Look for in 2025:

- 360° swivel base

- Heat-treated jaws

- 4–6 inch jaw opening

- Integrated pipe jaws

Buying Guide Tips:

-

Jaw Width & Opening: 4–6 inches is versatile; ensure pipe jaws if needed.

-

Swivel Base: 360° rotation allows flexible positioning.

-

Material: Heat-treated steel jaws for long-lasting grip.

-

Mounting: Ensure stable mounting options for heavy-duty tasks.

8. Dust Extraction or Shop Vacuum System

Clean workshops are safer and more efficient.

Ideal for: Woodworkers, metalworkers, auto detailers.

Why essential in 2025:

- HEPA filtration

- Low-noise operation

- Auto-start sync with power tools

Buying Guide Tips:

-

Filtration: HEPA filters capture fine dust, essential for wood or metal shops.

-

Capacity: 20–30L tanks are suitable for most workshops.

-

Noise Level: Look for low-dB models if used indoors.

-

Integration: Auto-start compatible with power tools improves workflow.

9. Portable Power Station or Backup Inverter

Workshops worldwide face unstable power or outdoor job requirements.

2025 features include:

- Pure sine-wave output

- 500W–2000W capacity

- Solar recharging capability

- Power tool compatibility

Buying Guide Tips:

-

Output Capacity: 500–2,000W depending on tools you run simultaneously.

-

Battery Type: Lithium-ion for longevity and portability.

-

Charging Options: Solar, AC, or car charging adds flexibility.

-

Port Types: Ensure AC, USB, and DC outputs match your devices and tools.

10. Safety Gear: Gloves, Goggles, Boots, Ear Protection

Safety remains non-negotiable.

2025 enhancements:

- Cut-resistant gloves

- Anti-fog safety goggles

- Noise-cancelling earmuffs

- Composite-toe anti-slip boots

Buying Guide Tips:

-

Gloves: Cut-resistant, heat-resistant, and anti-vibration options.

-

Goggles: Anti-fog, impact-resistant, and wrap-around design.

-

Boots: Composite-toe, anti-slip, and waterproof.

-

Ear Protection: Noise-cancelling earmuffs rated for high dB exposure.

Frequently Asked Questions (FAQs)

1. What tools are considered essential for a modern workshop in 2025?

A modern 2025 workshop needs a combination of smart diagnostic tools, advanced cordless power tools, precision hand tools, digital measuring devices, safety equipment, and efficient storage systems. These essentials support faster workflow, safer operations, and improved accuracy across all mechanical, automotive, and DIY environments.

2. Why do 2025-ready workshops prioritize cordless power tools?

Cordless tools dominate in 2025 because they offer higher torque, longer battery life, faster charging, and full mobility without compromising performance. Modern lithium-ion and brushless motor technology now match or exceed corded tools in power, making them essential for professional workshops.

3. Do I need smart diagnostic devices in my workshop?

Yes. Smart diagnostic tools, such as OBD-II scanners, thermal cameras, and digital multimeters, provide real-time data, faster troubleshooting, and more accurate repairs. They are especially valuable for automotive, electronics, and machinery maintenance in 2025’s tech-driven environment.

4. How should I organize my workshop for maximum efficiency?

The best setup follows a zoned layout:

- Clean Tech Zone: diagnostics, laptops, testing equipment

- Dirty Zone: welding, grinding, cutting tools

- Assembly Zone: workbench tasks, lighting, fastening, precision work

This layout minimizes cross-contamination, reduces clutter, and increases workflow speed.

5. What safety essentials should every 2025 workshop include?

Every workshop should include upgraded PPE such as smart goggles, heat-resistant gloves, dust masks or respirators, anti-vibration gear, and fire safety tools. Safety equipment is considered a non-negotiable part of the top 2025 workshop essentials.

- Are digital measurement tools really better than traditional ones?

Yes. Digital calipers, laser tape measures, and electronic angle finders offer superior accuracy, faster readings, and consistent results. They also store data, reduce human error, and integrate easily with workshop digital systems.

- How do I choose the right tools for my workshop upgrade?

Choose tools based on durability, task frequency, safety features, battery performance (for cordless tools), and verified user reviews. Prioritizing multi-purpose, high-output, and future-proof equipment ensures your workshop remains competitive and efficient in 2025 and beyond.

Related Articles:

Build Your Dream Workshop: A Step-by-Step Guide with Product Recommendations

The Ultimate Guide to Garage Workshop Layouts: Maximizing Space and Efficiency

Workshop Tool Storage Solutions: Organize and Store Your Tools Efficiently

Mastering Workshop Safety: Essential Tips and Equipment for Tool Handling

Essential Power Tools for Mechanic Workshops: Power Up Your Workshop with These Essentials

Conclusion

Building a future-ready workspace is no longer just about having the right tools, it’s about having the right tools for the way workshops operate in 2025. The Top 10 Workshop Essentials for 2025 highlight how rapidly technology, efficiency demands, and safety standards are evolving across automotive garages, DIY spaces, metalworking shops, and professional fabrication environments.

Investing in smart diagnostic tools, high-output cordless power equipment, digital measurement devices, and professional workshop storage solutions ensures your workspace stays competitive, productive, and safe. The shift toward clean tech zones, efficient assembly stations, and optimized dirty work areas reflects a global movement toward smarter workshop layouts that reduce downtime, improve accuracy, and streamline daily tasks.

Whether you’re upgrading a home garage or managing a high-volume industrial shop, choosing durable, high-precision, future-proof workshop tools will deliver long-term value and better performance. These essentials aren’t simply trends, they’re the new standard for anyone who wants a workshop that can keep up with the speed, technology, and demands of modern work.

If you want your workshop to run smoother, safer, and smarter, start with the essentials, and build the 2025 workspace you’ve always imagined.

Ready to transform your workspace into a smarter, safer, and more efficient 2025-ready workshop? Explore premium tools, professional equipment, and reliable workshop essentials at Tendsupplies.com your trusted partner for high-performance gear that delivers real results.

Whether you’re a mechanic, fabricator, contractor, or DIY creator, our curated selection helps you work faster, reduce downtime, and stay ahead of the technology curve.

Need expert recommendations or bulk order support? Contact us anytime at sales@tendsupplies.com for personalized assistance.