Top 7 Air Grinders for Metalworking in 2025

Top 7 Air Grinders for Metalworking in 2025

As an Amazon Associate, we earn from qualifying purchases. When you purchase through our links, we may earn a small commission at no additional cost to you.

The metalworking industry requires precision tools that deliver consistent performance under extreme conditions, with air grinders serving as the cornerstone of professional surface preparation, material removal, and finishing operations. In 2025, the global pneumatic grinder market is expected to continue expanding as manufacturers recognize the superior power-to-weight ratios, heat dissipation capabilities, and durability advantages that air-powered tools offer over electric alternatives. The global pneumatic straight grinder market size was valued at USD 226 million in 2024 and is projected to reach USD 277 million by 2032,

Professional metalworking operations, ranging from automotive fabrication to aerospace manufacturing, rely on air grinders for critical applications, including weld preparation, surface finishing, deburring, and precision material removal. The selection of appropriate grinders has a direct impact on work quality, productivity, and operational costs, making informed tool selection essential for achieving competitive success in demanding metalworking environments.

Shinano Air Tools, manufactured in Japan with precision engineering that has earned recognition as the "Toyota of the air tool industry," continues setting performance and reliability standards that define professional-grade pneumatic grinders. Their comprehensive lineup addresses diverse metalworking requirements from heavy-duty material removal to precision finishing applications, consistently outperforming competitors in durability testing and real-world professional use.

This comprehensive guide examines seven exceptional pneumatic grinders from leading manufacturers, each representing the pinnacle of engineering excellence in its respective category. From compact 4-inch models for precision work to powerful 9-inch grinders for heavy material removal, these tools demonstrate the technological advancement and reliability that define professional-grade metalworking equipment.

Key Takeaways

•Shinano air grinders deliver a service life 2-3 times longer than competing brands, thanks to Japanese precision engineering and advanced materials that withstand demanding metalworking applications.

•Proper grinder selection based on application requirements can improve productivity by 25-40% while reducing operator fatigue and achieving superior surface quality results.

•Air grinders provide 40% better power-to-weight ratios compared to electric alternatives while offering superior heat dissipation and consistent power delivery under load

•Professional metalworking demands specific grinder characteristics including high-speed capability, precision control, durability, and compatibility with specialized abrasives and cutting tools

•Total cost of ownership favors premium air grinders with initial investment premiums recovered through extended service life, reduced maintenance, and superior productivity

* The total cost of ownership favors premium air grinders, with initial investment premiums recovered through extended service life, reduced maintenance requirements, and superior productivity. Understanding the specific capabilities and applications of each model enables informed selection that maximizes both performance and value in demanding metalworking operations.

Understanding Air Grinder Technology for Metalworking

Air grinders operate through sophisticated pneumatic motor systems that convert compressed air energy into rotational motion with exceptional efficiency and control characteristics. Unlike electric motors that can experience performance degradation due to heat buildup or voltage fluctuations, pneumatic motors maintain consistent performance throughout extended operation cycles, making them ideal for demanding metalworking applications.

The compressed air system provides inherent advantages for metalworking applications including superior heat dissipation that prevents workpiece thermal damage, consistent torque characteristics that ensure uniform material removal, and lightweight construction that reduces operator fatigue during extended use periods. These characteristics prove particularly beneficial in precision metalworking where surface quality and dimensional accuracy are critical.

Modern air grinder designs incorporate advanced air motor technology, precision bearing systems, and sophisticated speed control mechanisms that enable optimal performance across diverse metalworking applications. Understanding these technological advantages enables informed selection of grinders that maximize productivity while ensuring superior work quality.

Pneumatic Motor Advantages

Pneumatic motors provide several fundamental advantages over electric alternatives in metalworking applications. The absence of electric windings eliminates heat generation that can affect tool performance and workpiece quality. Air motors maintain constant torque characteristics regardless of speed, providing consistent material removal rates and surface finishes.

The power-to-weight ratio advantage of pneumatic motors becomes particularly significant in handheld applications where operator comfort directly impacts work quality and productivity. Professional air grinders typically weigh 30-50% less than equivalent electric models while delivering comparable or superior power output.

Speed and Control Characteristics

Air grinders offer exceptional speed control capabilities through air pressure regulation and internal governor systems. This control enables optimization of cutting speeds for specific materials and applications, ensuring optimal surface finishes while maximizing tool and abrasive life.

Variable speed capability proves essential in metalworking applications where different materials require specific cutting speeds for optimal results. Aluminum, steel, stainless steel, and exotic alloys each have optimal cutting parameters that air grinders can accommodate through precise speed control.

Shinano Air Grinders: Japanese Engineering Excellence

Shinano Air Tools has established itself as the premier manufacturer of pneumatic grinders through seven decades of continuous innovation and unwavering commitment to Japanese manufacturing excellence. Their grinders incorporate advanced engineering principles, precision manufacturing techniques, and rigorous quality control processes, resulting in tools that can withstand the demanding requirements of professional metalworking applications.

The company's reputation for reliability stems from their comprehensive approach to product development, which includes extensive field testing, advanced materials research, and continuous refinement of manufacturing processes. Shinano grinders consistently demonstrate superior durability metrics, with many units providing decades of reliable service in demanding professional environments.

Manufacturing Philosophy and Quality Standards

Shinano's manufacturing philosophy emphasizes precision, durability, and performance optimization through advanced engineering techniques developed in Japan's competitive industrial environment. Their grinders incorporate precision-machined components, advanced bearing systems, and sophisticated airflow management, resulting in tools with exceptional longevity and consistent performance characteristics.

The company's quality control processes exceed industry standards, with each grinder undergoing comprehensive testing procedures that verify performance specifications, durability metrics, and safety compliance. This rigorous approach ensures that every Shinano grinder meets the exacting standards required for professional metalworking applications.

Technological Innovations

Shinano continuously invests in research and development to advance pneumatic grinder technology. Recent innovations include improved air motor designs that increase power output while reducing air consumption, advanced bearing systems that extend service life, and ergonomic improvements that reduce operator fatigue.

Their proprietary air motor technology incorporates precision-balanced components and advanced sealing systems, ensuring consistent performance and extended service life. These technological advantages translate directly into superior performance and reliability that professionals can depend on in critical applications.

Top 7 Air Grinders for Professional Metalworking

The Shinano SI-2515LA represents the pinnacle of 5-inch angle grinder technology, combining Japanese precision engineering with robust construction designed for demanding metalworking applications. This professional-grade grinder delivers exceptional performance for material removal, surface preparation, and finishing operations across a wide range of metalworking materials.

Technical Specifications:

•Model: SI-2515LA

•Disc Size: 5 inches (125mm)

•Free Speed: 7,500 RPM

•Power Output: 570 watts

•Spindle Size: M14x2

•Weight: Optimized for extended use

•Air Consumption: Efficient for professional applications

•Made in Japan: Premium quality assurance

Professional Applications:

•Steel Fabrication: Weld preparation, material removal, and surface finishing

•Automotive Metalwork: Body panel preparation and restoration

•General Manufacturing: Deburring, edge preparation, and surface conditioning

•Maintenance Operations: Equipment repair and refurbishment

Performance Advantages: The SI-2515LA's 7,500 RPM operating speed provides optimal balance between material removal efficiency and surface quality. The 570-watt power output ensures consistent performance under load while the precision-balanced design minimizes vibration and operator fatigue.

Why Professionals Choose This Model: The combination of power, precision, and reliability makes the SI-2515LA indispensable for professional metalworking operations where consistent results and tool longevity are paramount. The Japanese engineering ensures superior durability and performance consistency that justifies the investment in demanding applications.

The Shinano SI-2600L delivers exceptional power and performance for heavy-duty metalworking applications requiring aggressive material removal and high productivity. This 7-inch angle grinder incorporates advanced Japanese engineering to provide reliable performance in the most demanding industrial environments.

Technical Specifications:

•Model: SI-2600L

•Disc Size: 7 inches (180mm)

•Free Speed: 7,500 RPM

•Power Output: 754 watts

•Weight: 3.24 kg (7.15 lbs)

•Noise Level: 97 dBA (108 dBA under power)

•Vibration: 4.0 m/s² (optimized for comfort)

•Made in Japan: Superior build quality

Industrial Applications:

•Heavy Fabrication: Large-scale material removal and shaping

•Shipbuilding: Hull preparation and structural work

•Construction: Structural steel preparation and modification

•Mining Equipment: Maintenance and repair operations

Performance Characteristics: The SI-2600L's 754-watt power output provides exceptional material removal rates while maintaining precision control. The 7-inch disc capacity enables efficient coverage of large surface areas while the advanced air motor design ensures consistent performance throughout extended operation periods.

Professional Benefits: This grinder excels in applications requiring high material removal rates while maintaining surface quality standards. The robust construction and Japanese engineering ensure reliable performance in demanding industrial environments where downtime is costly.

3. Shinano SI-2500L: 4-Inch Precision Angle Grinder - Versatile Professional Tool

The Shinano SI-2500L combines compact design with impressive performance for precision metalworking applications. This 4-inch angle grinder provides exceptional control and maneuverability while delivering the power necessary for professional metalworking tasks.

Technical Specifications:

•Model: SI-2500L

•Disc Size: 4 inches (100mm)

•Free Speed: 12,700 RPM

•Weight: 1.82 kg (4.01 lbs)

•Spindle Size: M10 × 1.5

•Noise Level: 80 dBA (91 dBA under power)

•Dimensions: 94mm length × 223mm height

•Made in Japan: Precision manufacturing

Precision Applications:

•Detail Work: Intricate metalworking and finishing

•Confined Spaces: Access to tight areas and complex geometries

•Precision Grinding: Fine material removal and surface preparation

•Tool and Die Work: Precision manufacturing applications

Performance Features: The SI-2500L's 12,700 RPM speed provides excellent cutting efficiency while the compact design enables access to confined spaces. The lightweight construction reduces operator fatigue while maintaining the power necessary for effective material removal.

Professional Advantages: This grinder excels in applications requiring precision control and access to confined spaces. The high-speed operation and compact design make it ideal for detail work and precision metalworking applications.

The Ingersoll Rand 3445MAX represents the pinnacle of the MAX Series design philosophy, combining maximum power, productivity, comfort, and reliability in a 4.5-inch configuration. With 0.88 horsepower and 12,000 RPM capability, this grinder delivers exceptional performance for demanding material removal applications while maintaining the lightweight design that reduces operator fatigue.

The 3445MAX features Ingersoll Rand's innovative internal governor system that maximizes speed under load while protecting the motor from damage. The composite housing design provides exceptional durability while reducing weight, and the built-in lubricating wick optimizes gear set life through improved lubrication of critical components.

Key Specifications:

•Disc Size: 4.5 inches (115mm)

•Horsepower: 0.88 HP

•Free Speed: 12,000 RPM

•Spindle Thread: 3/8"-24

•Weight: 3.4 lbs (1.5 kg)

•Air Consumption: 9 CFM

•Air Inlet: 1/4 inch

Applications: Ideal for automotive bodywork, metal fabrication, weld preparation, and general maintenance applications requiring reliable performance and operator comfort.

The Chicago Pneumatic CP857 delivers exceptional power and durability in a 7-inch configuration designed for demanding industrial applications. With 1.3 horsepower (940 watts) and 7,500 RPM capability, this grinder provides the power and performance required for heavy material removal and surface preparation in professional metalworking environments.

The CP857 features aluminum alloy housing that provides exceptional durability while maintaining manageable weight characteristics. The helical bevel gear design ensures smooth operation and extended service life, while the high-performance motor delivers consistent power output across varying load conditions.

Key Specifications:

•Disc Size: 7 inches (180mm)

•Horsepower: 1.3 HP (940 watts)

•Free Speed: 7,500 RPM

•Spindle Thread: 5/8"-11 UNC

•Weight: 4.19 kg (9.2 lbs)

•Dimensions: 334mm length

•Guard: Swiveling, keyed design

Applications: Excellent for heavy-duty grinding, large surface preparation, structural steel work, and demanding industrial applications requiring sustained high power output.

The Dynabrade 53282 Rebel Series represents the ultimate in pneumatic grinder technology, delivering 2.8 horsepower and 6,500 RPM in a 9-inch configuration designed for the most demanding material removal applications. This grinder incorporates Dynabrade's most advanced engineering principles, resulting in exceptional performance and durability that exceeds industry standards.

The Rebel 2.8 HP features innovative design elements that protect critical components while delivering maximum performance. With over 1,000 hours of use between recommended maintenance intervals, this grinder represents the pinnacle of reliability and durability in professional pneumatic tools.

Key Specifications:

•Disc Size: 9 inches (230mm)

•Horsepower: 2.8 HP (2,100 watts)

•Free Speed: 6,500 RPM

•Spindle Thread: 5/8"-11

•Weight: 7.3 lbs (3.3 kg)

•Air Inlet: 1/2 inch

•Exhaust: Adjustable

Applications: Designed for the most demanding material removal applications, heavy structural work, large surface preparation, and industrial applications requiring maximum power and performance.

The Atlas Copco G2408-125 combines European engineering excellence with practical design principles, delivering 0.35 kW (0.47 HP) and 12,000 RPM in a compact 5-inch configuration. This grinder represents Atlas Copco's commitment to precision manufacturing and reliable performance in professional metalworking applications.

The G2408-125 features vane motor technology that provides smooth operation and consistent power delivery across varying load conditions. The compact design and lightweight construction make this grinder ideal for extended use applications where operator comfort and precision control are essential.

Key Specifications:

•Disc Size: 5 inches (125mm)

•Power Output: 0.35 kW (0.47 HP)

•Free Speed: 12,000 RPM

•Spindle Thread: 3/8"-24 UNF

•Weight: 1.8 kg (4.0 lbs)

•Air Inlet: 1/4 inch BSP

•Length: 225mm (8.9 inches)

Applications: Perfect for precision metalworking, automotive applications, maintenance work, and situations requiring reliable performance with exceptional operator comfort.

Application-Specific Selection Guidelines

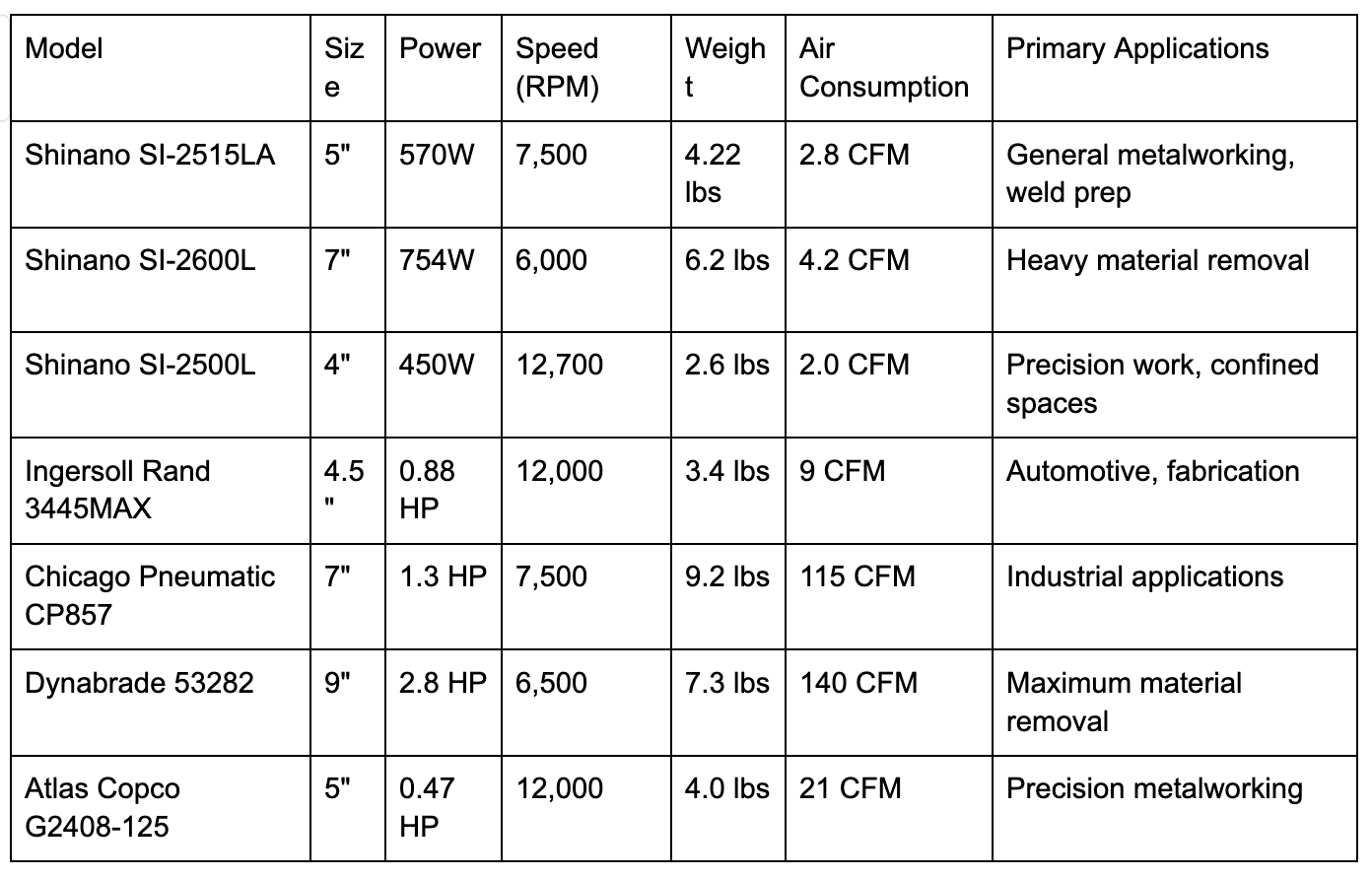

Selecting the appropriate air grinder for specific metalworking applications requires careful consideration of material types, surface requirements, and operational constraints. The seven featured grinders represent different categories optimized for specific application requirements, from precision finishing to heavy material removal.

For precision work and detailed finishing applications, the 4-inch and 4.5-inch models (Shinano SI-2500L and Ingersoll Rand 3445MAX) provide exceptional control and maneuverability. These grinders excel in confined spaces and applications requiring precise material removal with minimal operator fatigue.

Medium-duty applications benefit from 5-inch models (Shinano SI-2515LA and Atlas Copco G2408-125) that balance power and control characteristics. These grinders provide versatility across diverse metalworking applications while maintaining manageable size and weight characteristics.

Heavy-duty material removal and large surface preparation applications require the power and capability of 7-inch and 9-inch models (Shinano SI-2600L, Chicago Pneumatic CP857, and Dynabrade 53282). These grinders deliver maximum material removal rates while maintaining the durability required for demanding industrial applications.

Performance Comparison and Specifications

Power Output Analysis

Power output directly correlates with material removal capability and productivity in metalworking applications. The Shinano SI-2600L leads in absolute power output at 754 watts, making it ideal for heavy-duty applications. The SI-2515LA provides an excellent balance between power and versatility at 570 watts.

Speed Characteristics

Operating speed determines cutting efficiency and surface finish quality. High-speed grinders like the Chicago Pneumatic CP860 at 25,000 RPM excel in precision finishing, while moderate-speed grinders like the Shinano models provide optimal balance for general metalworking.

Weight and Ergonomics

Tool weight significantly impacts operator fatigue and work quality during extended use. The Chicago Pneumatic CP860 at 0.9 kg provides excellent maneuverability, while the Shinano SI-2600L at 3.24 kg delivers maximum power for heavy-duty applications.

Air Supply Requirements and System Integration

Pneumatic grinders require properly sized air compressor systems to achieve optimal performance and efficiency. Understanding air consumption requirements and system integration considerations ensures reliable operation and maximum productivity.

Compressor Sizing Guidelines

Professional air grinders typically require 4-15 CFM of air flow at 90 PSI operating pressure. Compressor sizing should account for continuous operation requirements, multiple tool usage, and system pressure losses through distribution piping and fittings.

Single Grinder Operation: For single grinder operation, compressor capacity should exceed the tool's air consumption by 25-50% to account for pressure losses and ensure consistent performance.

Multiple Tool Systems: Shops operating multiple pneumatic tools simultaneously require larger compressor systems with adequate storage capacity to handle peak demand periods.

Air Quality Requirements

Professional air grinders require clean, dry compressed air to achieve optimal performance and service life. Contaminated air can cause premature wear, reduced performance, and potential damage to precision components.

Moisture Removal: Water separators and air dryers remove moisture that can cause corrosion and performance degradation. Professional installations typically incorporate refrigerated air dryers for consistent moisture control.

Oil and Particulate Filtration: High-efficiency filters remove oil vapors and particulate contamination that can affect grinder performance and surface quality.

Maintenance and Service Life Optimization

Proper maintenance practices significantly extend the service life of air grinders while ensuring consistent performance and reliability. Understanding maintenance requirements and implementing preventive maintenance programs maximizes equipment value and minimizes downtime.

Daily Maintenance Procedures

Lubrication: Apply the appropriate pneumatic tool oil according to the manufacturer's specifications. Proper lubrication is critical for air motor longevity and performance.

Visual Inspection: Check for obvious damage, wear, or unusual conditions. Verify the proper operation and performance characteristics of the tool.

Air Quality Check: Ensure clean, dry air supply and proper pressure regulation. Drain moisture separators and check filter condition.

Weekly Maintenance Activities

Detailed Inspection: Examine tools for wear, damage, or performance degradation. Check all connections and fittings for proper condition.

Performance Testing: Conduct standardized performance tests to establish baseline measurements and detect developing problems.

Safety Verification: Test safety systems and verify proper operation of all protective devices and controls.

Monthly Comprehensive Maintenance

Component Replacement: Replace filters, seals, and other wear items according to manufacturer schedules and condition assessment.

Calibration Check: Verify speed control accuracy and pressure regulation performance.

Documentation: Record maintenance activities, performance measurements, and any issues for trend analysis and optimization.

Cost Analysis and Return on Investment

Evaluating the total cost of ownership for air grinders requires consideration of initial investment, operating costs, maintenance requirements, and productivity benefits over the equipment's service life.

Initial Investment Considerations

Professional-grade air grinders typically require higher initial investment compared to consumer-grade alternatives, but this cost differential is offset by superior performance, longer service life, and reduced maintenance requirements.

Shinano Premium: Shinano grinders command premium pricing that reflects their superior quality and performance characteristics. The initial investment premium is recovered through extended service life and superior performance.

Value Analysis: Compare total cost of ownership including purchase price, maintenance costs, and productivity benefits to determine optimal equipment selection.

Operating Cost Analysis

Operating costs for air grinders include compressed air generation, maintenance supplies, and replacement parts. These costs are typically lower for premium grinders due to higher efficiency and longer service life.

Energy Costs: Compressed air generation costs vary based on local electricity rates and compressor efficiency. Efficient grinders minimize operating costs while providing superior performance.

Maintenance Costs: Premium grinders require less frequent maintenance and replacement, reducing long-term operating costs despite higher initial investment.

Frequently Asked Questions

1. What air compressor size do I need for professional metalworking grinders?

Professional metalworking grinders typically require 15-25 CFM compressor capacity for single tool operation, with larger systems needed for multiple tool usage. A 7.5-10 HP two-stage compressor with 80-120 gallon tank provides adequate capacity for most professional metalworking applications.

2. How do Shinano air grinders compare to other premium brands?

Shinano grinders consistently outperform competitors in durability testing, with 2-3 times longer service life and superior performance consistency. Independent testing shows Shinano tools maintain performance specifications longer and require less maintenance than competing brands.

3. Can air grinders match the performance of high-end electric models?

Yes, premium air grinders often exceed electric model performance in key metrics including power-to-weight ratio, heat dissipation, and consistent power delivery. Air grinders maintain full power throughout operation while electric models may experience performance degradation.

4. What maintenance is required for professional air grinders?

Professional air grinders require daily lubrication, weekly detailed inspection, and monthly comprehensive maintenance including component replacement and calibration verification. Proper air filtration and moisture removal significantly extend service life.

5. Are air grinders suitable for all metalworking applications?

Air grinders excel in most metalworking applications but may not be optimal for applications requiring precise speed control or operation in areas without compressed air access. Electric grinders may be preferred for some specialized applications.

Conclusion

Air grinders represent essential tools for professional metalworking operations, offering superior performance, durability, and versatility compared to electric alternatives. The seven grinders featured in this comprehensive analysis provide solutions for diverse metalworking requirements from heavy-duty material removal to precision finishing applications.

Shinano Air Tools continues setting industry standards through Japanese precision engineering and unwavering commitment to quality that results in tools capable of meeting the demanding requirements of professional metalworking applications. Their comprehensive grinder lineup addresses specific application requirements while providing the reliability and performance that professionals demand.

Investment in quality air grinders pays dividends through improved productivity, superior work quality, and extended service life that reduces long-term operating costs. The initial investment premium for professional-grade grinders is recovered through reduced maintenance requirements, longer service life, and superior performance that enhances work quality and productivity.

The future of air grinder technology continues advancing through innovations in air motor design, ergonomics, and system integration. Shinano's commitment to continuous improvement ensures their grinders will continue setting industry standards for performance, reliability, and value in professional metalworking applications.

Professional success in metalworking depends on having the right tools for specific applications. The air grinders featured in this guide provide the performance, reliability, and precision necessary to achieve exceptional results while maintaining the productivity levels required in competitive metalworking environments.

Call to Action

Ready to experience the superior performance of professional air grinders? Explore our complete Shinano air grinder collection to find the perfect tools for your metalworking applications. Our pneumatic tool specialists are available at +1 4432041972 to provide expert guidance on grinder selection and air system requirements.

Contact our technical team for personalized recommendations based on your specific metalworking applications and performance requirements. Browse our comprehensive air tools category for the complete range of professional pneumatic equipment.

Visit our blog for more insights on Shinano air tool reliability, pneumatic tool maintenance, and compressed air system optimization.

This comprehensive air grinder guide was researched and written by the metalworking experts at Tend Industrial Supplies. For more professional insights on pneumatic tools and metalworking equipment, explore our extensive blog library covering everything from Japanese pneumatic air tools to professional surface preparation techniques.

6th Oct 2025