How Shinano Air Tools Solves Common Pain Points for Professionals and DIYers Alike

How Shinano Air Tools Solves Common Pain Points

Professionals and DIY enthusiasts alike often face frustrating challenges with pneumatic tools. Issues like poor maintenance leading to early failures, insufficient air compressor capacity resulting in weak performance, and excessive noise and vibration causing user fatigue are common pain points. This article explores how Shinano Air Tools, a premium Japanese brand, addresses these issues with durable, ergonomic, and air-efficient solutions. Discover how Shinano Industrial Co., Ltd. reengineers air tools to provide exceptional craftsmanship, unlocking performance, comfort, and reliability where other brands fall short. Discover how specific Shinano tools, ranging from die grinders to impact wrenches, address key challenges in pneumatic tools, providing a smoother and more productive experience for every user.

Key Takeaway

Shinano Air Tools has engineered durable, ergonomic, and air-efficient solutions that directly address the most frustrating challenges users face with pneumatic tools—unlocking performance, comfort, and reliability where other brands fall short.

Introduction: The Hidden Struggles Behind Pneumatic Tools

Air tools have long been praised for their power, longevity, and torque. But if you’ve ever had an impact wrench die mid-job, or a grinder that demands more air than your compressor can supply, you know that reality doesn’t always meet the hype.

At Tend Industrial Supplies, we’ve worked closely with customers in the automotive, construction, and manufacturing trades, and we’ve heard the frustrations firsthand. Fortunately, Shinano Industrial Co., Ltd., a premium Japanese brand known for exceptional craftsmanship, has stepped in to reengineer air tools from the inside out.

In this article, we break down the three most significant pain points in the pneumatic tool world—and show you exactly how specific Shinano tools are solving them.

Pain Point One: Poor Maintenance Leads to Early Tool Failure

The Problem:

The Problem: Over 80% of air tool failures are due to improper or neglected maintenance. Users often forget to oil tools, fail to drain compressors, and neglect to use filters. The result? Internal corrosion, jammed vanes, and a frustratingly short tool lifespan.

Shinano’s Innovation: Self-lubricating design + sealed internals + simplified maintenance

Featured Tool: Shinano SI-1207A 1/4” Straight Die Grinder

- Redesigned for low-maintenance users

- Uses tight-tolerance sealed bearings to resist moisture and dirt

- Accepts lubrication directly through a conveniently placed port

- Lightweight aluminum housing doesn’t trap grime or oil

What it Solves: Shinano builds tools that don’t require constant oiling and meticulous air quality maintenance. They know real mechanics don’t always have time to babysit their tools, and they engineer for that reality.

? Browse Shinano Die Grinders

Pain Point Two: Compressor Can't Keep Up — Tools Feel Weak

The Problem: Most grinders, sanders, and polishers guzzle air—often more than a standard 60-gallon shop compressor can provide. The tool slows down. Tasks take forever. Users blame the tool, but the issue lies at the core with the CFM (airflow) problem.

Shinano’s Innovation: High-torque performance at lower CFM rates

Featured Tool: Shinano SI-3310A 5” Angle Grinder

- Runs efficiently on just 4.5 CFM

- Delivers sustained RPM even under heavy load

- Precision-machined air motor provides top-tier torque

What it Solves: Now small and mid-size shops can enjoy pro-level air tools without needing a 7.5HP industrial compressor. That’s a game changer for auto techs, mobile mechanics, and weekend warriors alike.

? Explore Shinano Angle Grinders

Pain Point Three: Noise, Vibration, and Cold Air Exhaust Fatigue Users

The Problem: Air tools can be brutal on the body. They scream during use, shake your bones, and blow icy air onto your wrist. Long shifts with cheap tools lead to fatigue, hearing loss, and even hand-arm vibration syndrome (HAVS).

Shinano’s Innovation: Noise suppression, vibration dampening, ergonomic grips, and rear exhaust redirection

Featured Tool: Shinano SI-1490EX 3/8” Air Ratchet with Rear Exhaust

- Low-noise exhaust diffuser

- Anti-vibration body construction

- Rear exhaust channels cold air away from the hand

- Lightweight and perfectly balanced for all-day use

What it Solves: Comfort isn’t a luxury—it’s a productivity multiplier. By tackling noise and vibration, Shinano extends user endurance, precision, and tool control..

? See Shinano Air Ratchets

Bonus Pain Point 4 : Lack of Control Leads to Over-Torquing and Damage

The Problem: High-power impact tools often over-deliver—damaging threads, snapping bolts, or warping delicate parts.

Shinano’s Innovation: Advanced torque control, adjustable power settings, and trigger modulation

Featured Tool: Shinano SI-1600S 1/2” Impact Wrench

- 4-position power regulator

- Feather trigger for nuanced torque delivery

- Twin hammer mechanism for smoother torque bursts

What it Solves: Precision where it matters—on aluminum wheels, valve covers, or frame bolts that need finesse over force.

? Shop Shinano Impact Wrenches

Why Mechanics Choose Shinano: A Culture of Craftsmanship

Shinano doesn’t just manufacture tools—they craft them with purpose. Every tool is assembled in Japan under strict quality control, and the company boasts over 50 years of experience in pneumatic innovation.

Here’s what users are saying:

“My SI-1490EX ratchet is the quietest air tool I own—and still kicks like a mule. Been going strong for 3 years with just basic oiling.”

– Andre S., Maryland-based mobile mechanic

“I swapped my cheap die grinder for a Shinano SI-1207A and haven’t looked back. Less air, more grunt, smoother feel.”

– Rich T., automotive restoration expert, NJ

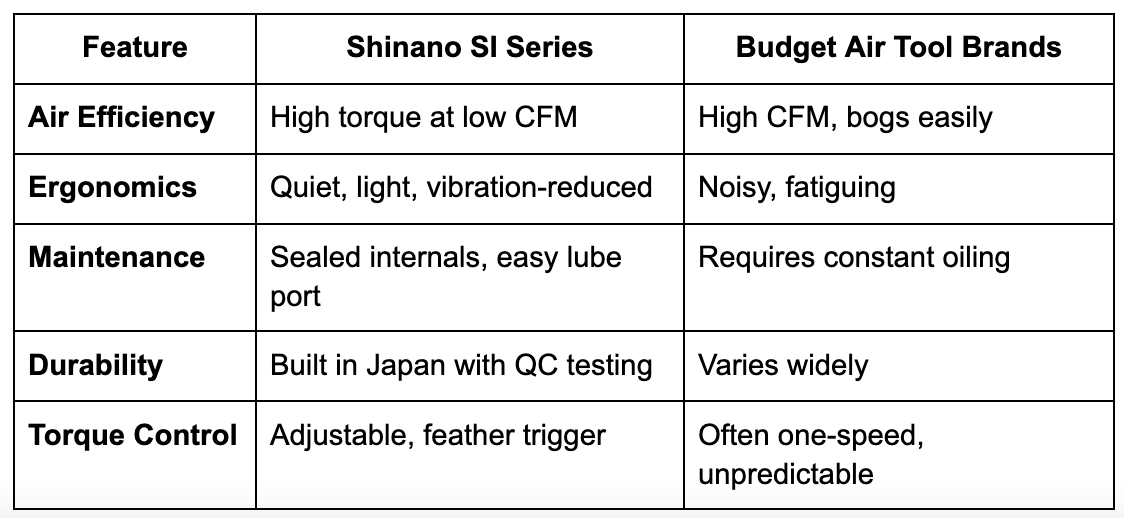

Shinano Tools vs Other Air Tools: A Clear Comparison

Serving Automotive, Industrial & Fabrication Pros Across the U.S.

At Tend Industrial Supplies, we proudly distribute Shinano Air Tools across Maryland, Virginia, Delaware, New York, and nationwide. We’ve seen firsthand how these tools outperform in shops, garages, and manufacturing floors.

Whether you’re restoring vintage cars, maintaining heavy equipment, or running a precision fabrication shop, Shinano gives you confidence in every task.

Related Articles You Should Explore

- Shinano Air Tools: Unmatched Reliability and Longevity — Discover how Shinano became the "Toyota of air tools."

- Top 10 Shinano Air Tools for Professional Mechanics in 2024 — The definitive list of tools pros trust.

- Top 10 Global Air Tool Brands: An Objective Comparison — See how Shinano ranks among the best.

- Shinano Air Tools: The Synonym for Quality and Dependability — A tribute to decades of reliability.

- Best Shinano Air Impact Wrenches in 2024: A Comprehensive Review — Compare torque, speed, and build quality.

- Shinano Pneumatic Tools: Industrial Air Tools for Enhanced Productivity — Built for continuous-use industries.

- In-Depth Review of the Shinano SI-3101M Palm Sander — A specialist's review on finish control.

- Shinano Pneumatic Tools: A Comprehensive Overview — Full brand story and innovation timeline.

Final Thoughts: Invest in Tools That Outlast Your Toughest Jobs

If you're tired of replacing air tools that fail, demand too much air, or fatigue your body—Shinano is your relief. Built for serious professionals, designed to eliminate common frustrations, and supported by a brand with decades of pneumatic expertise.

Call to Action: Order Shinano Air Tools Today

Shop Our Full Shinano Lineup:

https://tendsupplies.com/brand/shinano-pneumatic-tools-japan

Need Help Choosing a Tool?

Call us at (443) 204-1872 or email sales@tendsupplies.com and our experts will help match you to the right model.

Wholesale/B2B Orders Available – Contact for Pricing!

Frequently Asked Questions

Q1. Are Shinano tools compatible with all air compressors?

Yes, especially because their tools are designed for low CFM consumption. Just ensure your compressor can sustain 90 PSI and at least 4–6 CFM for optimal results.

Q2. What warranty do Shinano tools come with?

Shinano air tools come with a 12-month manufacturer's warranty when purchased from authorized dealers like Tend Industrial Supplies.

Q3. Do I need special oil for Shinano tools?

Use any quality pneumatic air tool oil. Shinano tools do well with standard lubricants if used consistently.

Q4. Can I use Shinano tools in mobile setups like service vans?

Absolutely! Many models are air-efficient and compact, perfect for portable compressors in mobile repair units.

Q5. Why choose Shinano over cordless tools?

Shinano excels in continuous operation, higher torque, and longer service life with no battery limitations—ideal for professionals in high-volume environments.