Setting Up Your Professional Automotive Workshop: A Complete Guide to Air Compressors, Hoses, and Essential Pneumatic Tools (2025)

Stepping into a professional automotive workshop, the first sound you’ll likely hear is the rhythmic thrum of an air compressor and the distinct, powerful burst of pneumatic tools at work. Compressed air has been the lifeblood of efficient auto repair for decades, driving everything from high-torque impact wrenches to precision die grinders. Setting up a robust pneumatic system is one of the most critical investments a new technician or growing workshop can make.

However, creating an effective and reliable system goes far beyond simply buying the biggest air compressor you can find. A poorly planned setup can lead to underperforming tools, premature equipment failure, and constant frustration. How do you determine the right compressor size for your needs? What’s the difference between CFM and PSI, and why does it matter? How do you choose the right hoses, reels, and fittings to deliver that power efficiently to your tools?

At Tend Industrial Supplies, we don’t just sell tools; we provide the expertise to help you build the workshop of your dreams. This definitive guide will walk you through the entire process of setting up your professional pneumatic system for 2025. From calculating your air demand and selecting the perfect compressor to designing an efficient delivery system and choosing your core set of air tools, we’ll provide the substantial, technical information you need to get it right the first time.

Key Takeaways

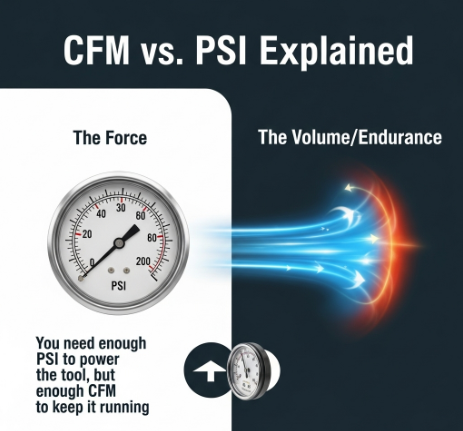

- CFM is King: While PSI (Pounds per Square Inch) is important (most tools require 90 PSI), CFM (Cubic Feet per Minute) is the most critical metric. Your compressor's CFM output at 90 PSI must exceed the total CFM consumption of the tools you plan to run simultaneously.

- Choose the Right Compressor Type: For professional shops, a two-stage, stationary electric compressor is the gold standard, offering higher pressure and greater efficiency for continuous use. A minimum of a 60-gallon tank is recommended, with 80 gallons being ideal for multi-bay shops.

- Don't Skimp on Delivery: The best compressor is useless if the air can't get to your tools efficiently. Invest in 3/8-inch or 1/2-inch hybrid or rubber air hoses, high-quality fittings, and a reliable hose reel to maximize performance and safety.

- Essential Air Tools First: Your initial investment should focus on the "big three" pneumatic tools for mechanics: a powerful 1/2" Air Impact Wrench, a versatile Air Ratchet, and a high-speed Die Grinder.

- Maintenance is Non-Negotiable: The longevity and performance of your entire pneumatic system depend on routine maintenance, including daily draining of the compressor tank, checking oil levels, and regularly lubricating your air tools.

The Heart of the Workshop - Selecting Your Air Compressor

The air compressor is the single most important component of your pneumatic system. It’s a significant investment, so choosing the right one is crucial. Making your decision requires understanding a few key technical specifications.

Understanding Compressor Language: CFM, PSI, and Horsepower

- PSI (Pounds per Square Inch): This measures the amount of pressure, or force, the compressor can generate. Most automotive air tools are designed to operate optimally at 90 PSI. While a compressor might be rated for 175 PSI, its ability to maintain 90 PSI under load is what matters.

- CFM (Cubic Feet per Minute): This measures the volume of air the compressor can deliver at a specific pressure level. This is the most important number to consider. You must match the compressor's CFM output with the air consumption of your tools. If a tool requires 5 CFM at 90 PSI, and your compressor only produces 4 CFM, the tool will be starved for air and will not perform correctly.

- Horsepower (HP): While often used in marketing, HP can be a misleading metric. A high HP rating doesn't guarantee high CFM output. Always prioritize the CFM @ 90 PSI rating over the horsepower.

Types of Compressors for the Professional Shop

|

Compressor Type |

Description |

Best For |

|

Single-Stage |

Air is compressed once. Typically reaches a maximum pressure of around 125-135 PSI. |

Hobbyists, serious DIYers, or very light professional use. Not ideal for continuous operation. |

|

Two-Stage |

Air is compressed twice, with an intercooler pipe cooling the air between stages. This results in higher pressure (175+ PSI) and more efficient operation. |

The professional standard. Ideal for running high-demand tools like grinders and sanders continuously in a multi-technician environment. |

|

Portable |

Smaller, wheeled units, often with smaller tanks (5-30 gallons). |

Mobile detailers, job site contractors. Not suitable as a primary workshop compressor due to low CFM and small tank size. |

|

Stationary |

Large, vertically oriented tanks (60-120 gallons) that are permanently installed. |

Any professional automotive workshop. The large tank acts as a reservoir, allowing the motor to run less frequently. |

Export to Sheets

Recommendation for Professionals: A two-stage, stationary electric (240V) compressor with at least a 60-gallon tank (80-gallon preferred) and a CFM rating of 15 CFM @ 90 PSI or higher will comfortably power a one- or two-bay shop.

The Delivery System - Hoses, Reels, and Fittings

Your compressor's power is useless if it's choked off by a poor delivery system. Investing in quality components here is essential for performance and safety.

A Workshop Bay Showing a Red Retractable Hose Reel Mounted on the Wall with the Hose Extending Down to An Impact Wrench

Air Hoses

The diameter and material of your air hose directly impact airflow. For professional use, a 1/4-inch hose is too restrictive for high-demand tools.

- Diameter: A 3/8-inch inner diameter is the minimum for professional automotive work. For long runs (over 50 feet) or extremely high-consumption tools, upgrading to a 1/2-inch hose will prevent pressure drop and ensure maximum power.

- Material:

- PVC: Inexpensive but becomes stiff and brittle in the cold and can kink easily. Not recommended for professional shops.

- Rubber: Very flexible even in cold weather and extremely durable, but can be heavy.

- Hybrid / Polymer: The best of both worlds. These hoses are lightweight, flexible like rubber, and lay flat without kinking. They are an excellent choice for a busy workshop.

Hose Reels

A retractable hose reel is a massive upgrade in safety and efficiency. It keeps hoses off the floor, preventing a major trip hazard—and protects the hose from being run over or damaged. Look for a heavy-duty steel reel with a reliable retraction mechanism and a quality swivel inlet that prevents leaks.

Fittings, Regulators, and FRL Systems

- Fittings (Couplers & Plugs): Don't use standard "Type M" industrial fittings. Upgrade to high-flow "Type V" style fittings. They have a larger internal diameter and can increase a tool's power output by 10-15% by simply reducing air restriction.

- Regulators: You will need a regulator at the compressor to set the main line pressure and potentially smaller regulators at each workstation. This allows you to dial down the pressure for delicate tools like paint sprayers or airbrushes.

- FRL (Filter-Regulator-Lubricator): This is a three-in-one unit that is essential for a professional setup.

- Filter: Removes water, oil, and particulates from the compressed air, protecting your tools.

- Regulator: Controls the air pressure delivered to the tool.

- Lubricator: Injects a fine mist of air tool oil into the line to automatically lubricate your pneumatic tools as you use them.

The Arsenal - Essential Pneumatic Tools for Mechanics

With your air supply sorted, it’s time to choose your tools. While the list of available air tools is vast, a few are absolutely essential for any automotive technician.

- The 1/2-Inch Air Impact Wrench

This is the quintessential mechanic's air tool, used for everything from changing tires to heavy suspension work. Its high torque output makes quick work of stubborn lug nuts and large bolts.

- What to Look For:

- Torque: Look for a model with at least 1,000 ft-lbs of "nut-busting" torque.

- Mechanism: A twin-hammer mechanism is the industry standard for durability and power.

- Ergonomics: A lightweight composite body reduces fatigue.

- Internal Link: For a deep dive into the top models, check out our comprehensive guide on the Top 10 Air Impact Wrenches of 2025.

- The Air Ratchet

An air ratchet excels at rapidly installing or removing fasteners in tight spaces where an impact wrench won't fit, such as around engine accessories, transmissions, and dashboards. It saves an immense amount of time compared to a manual ratchet.

- What to Look For: A sealed head design for durability, a good balance of speed (RPM) and torque, and a comfortable trigger. They are available in 1/4" and 3/8" drive sizes.

- The Air Die Grinder

A high-speed die grinder is the tool of choice for precision work. Paired with various bits, it can be used for cleaning gaskets, porting cylinder heads, deburring sharp metal edges, and cleaning up welds.

- What to Look For: High RPM (20,000+), a comfortable grip, and a front- or rear-exhaust that directs air away from your work. Both straight and angled models are available.

- The Pneumatic Orbital Sander

For any bodywork or surface preparation, a dual-action (DA) orbital sander is a must. It creates a smooth, swirl-free finish perfect for prepping surfaces for paint or primer.

- What to Look For: A comfortable, low-vibration design and variable speed control.

- Internal Link: To see why precision engineering matters, explore our analysis on Who Makes the Best Pneumatic Orbital Sander.

Frequently Asked Questions (FAQs)

- How do I calculate my shop's total CFM requirement?

Look up the CFM consumption for each air tool you own. Add up the CFM ratings for the tools you expect to use simultaneously. For example, if you have one mechanic using an impact wrench (5 CFM) and another using a die grinder (6 CFM), your simultaneous demand is 11 CFM. It's recommended to choose a compressor with a CFM rating at least 1.5 times your calculated demand to provide a buffer and account for future growth.

- Why do I need to drain the water from my compressor tank every day?

The compression process naturally condenses moisture from the air, which collects as water in the bottom of the tank. If not drained, this water can cause the tank to rust from the inside out, creating a serious safety hazard. It can also be sent down the air lines, damaging your tools.

- What is the difference between oil-lubricated and oil-free compressors?

Oil-lubricated compressors use oil to lubricate the pump, making them quieter, cooler, and significantly more durable. They are the standard for professional shops. Oil-free compressors use a Teflon coating and are often louder and have a shorter lifespan, making them more suitable for light DIY use.

- My impact wrench feels weak, but my compressor is running. What's wrong?

There are several potential culprits: 1) The pressure regulator is set too low. 2) You are using a too long or narrow hose, causing excessive pressure drop. 3) You have air leaks at your fittings. 4) Your tool is dry and needs to be lubricated.

- How often should I oil my air tools?

If you do not have an in-line FRL system, you should put 3-5 drops of air tool oil directly into the tool's air inlet at the beginning of each workday. If you continuously use a tool for several hours, adding another drop or two during your lunch break is a good practice. Proper lubrication is the single most important factor in extending the life of your air tools.

Related Articles

Understanding the Right Size of Air Compressor for Your Pneumatic Air Tools in 2024

Breathe Easy: Maintenance Best Practices for Pneumatic Tools

Best Air Tools: Ultimate Guide to Pneumatic Tools and Impact Wrenches (2025)

15 Essential Pneumatic Tools Every Workshop Must Have

Conclusion

Building a pneumatic system is a foundational step in creating a truly professional and efficient automotive workshop. By starting with a correctly sized, high-quality air compressor and pairing it with a robust delivery system, you create a powerful platform for a wide array of essential air tools. This system will not only save you countless hours of manual labor but will also enable you to perform jobs that would be nearly impossible otherwise.

Remember that this is an integrated system; the performance of your most advanced air tool is only as good as the compressor, hoses, and fittings that support it.

Ready to build your workshop's powerhouse? From industrial-grade air compressors to high-flow fittings and the best pneumatic tools on the market, Tend Industrial Supplies has everything you need. Contact our expert team at sales@tendsupplies.com or visit tendsupplies.com to get started.