The Professional's Powerhouse: An In-Depth Guide to Air Drill Technology, Selection, and the Shinano Advantage

In the demanding worlds of manufacturing, automotive repair, construction, and high-precision crafting, the tools a professional chooses are a direct reflection of their commitment to quality and efficiency. While the market is flooded with various drilling solutions, the pneumatic air drill remains a steadfast favourite for those who require unrelenting power, durability, and control. Unlike their electric or battery-powered counterparts, air drills harness the raw potential of compressed air, offering a unique blend of benefits that make them indispensable for heavy-duty and repetitive tasks.

This comprehensive guide delves deep into the heart of professional air drills. We will dissect their underlying technology, explore the diverse range of types available, and meticulously outline the crucial factors to consider when selecting the perfect tool. Furthermore, we will shine a spotlight on a brand synonymous with quality and innovation in the pneumatic tool industry: Shinano Air Tools from Japan. By understanding the mechanics, exploring the options, and examining top-tier examples like the Shinano lineup, you can equip yourself with the knowledge to choose an air drill that not only meets but exceeds your professional demands.

Key Takeaways

- Air drills offer superior power-to-weight, durability, consistent power, and safety compared to electric drills.

- Understanding your air supply (PSI, CFM) is critical for optimal air drill performance.

- Key components include the air motor, gearing, chuck, and throttle – quality matters.

- Shinano Air Tools from Japan offer high-precision, durable, and ergonomic options across various drill types (Pistol, Reversible, Straight, Angle).

- Selection should be based on power, speed, chuck size, air consumption, and the specific application requirements.

Understanding Air Drills: Beyond the Basics

At its core, an air drill is a power tool that uses compressed air as its energy source to rotate a drill bit. This fundamental difference from electric drills (both corded and cordless) leads to a distinct set of characteristics that are particularly advantageous in professional settings.

The Air Drill Advantage:

- Superior Power-to-Weight Ratio: Air motors are inherently simpler and lighter than electric motors capable of producing equivalent torque. This means air drills can pack a significant punch in a more compact and lighter package, drastically reducing user fatigue during prolonged use, especially in overhead or awkward positions.

- Enhanced Durability & Lifespan: With fewer complex electrical components and typically robust, often all-metal, construction, air drills are built to withstand the rigours of industrial environments. They generate less internal heat during operation, a major factor in tool longevity, and are less susceptible to burnout under continuous heavy loads.

- Consistent Power Output: As long as the air supply is consistent, an air drill delivers steady power. Unlike battery tools that can fade or corded tools that might struggle with voltage drops, air drills maintain their torque and speed, which is crucial for precision tasks and repetitive drilling.

- Intrinsic Safety: The absence of electricity makes air drills inherently safer in environments where flammable materials, vapours, or moisture are present. There's no risk of sparks from motor brushes or electrical shorts, a critical consideration in many industrial and automotive workshops.

- Lower Heat Buildup: Air drills run cooler. The expanding compressed air actually has a cooling effect, meaning the tool remains comfortable to handle even after extended periods of demanding work, and there's less risk of heat damage to delicate workpieces.

- Simpler Maintenance: While they require lubrication, the overall maintenance is often less complex than for sophisticated electric tools with advanced electronics.

The Power Source: Compressed Air Essentials

Understanding an air drill means understanding its power source. These tools don't work in isolation; they require a compressed air system. Key concepts include:

- Air Compressor: The heart of the system, it pressurizes ambient air to the required levels. Its size (tank capacity in gallons) and output (Cubic Feet per Minute - CFM) determine how many tools it can support and for how long.

- PSI (Pounds per Square Inch): This measures the pressure of the air. Most air drills operate optimally around 90 PSI. Consistent pressure is vital for performance.

- CFM (Cubic Feet per Minute): This measures the volume of air the tool consumes. You must ensure your compressor can supply at least the average CFM required by your drill, with enough buffer for peak demand (often listed as Max CFM). Insufficient CFM will lead to a 'starved' tool that underperforms.

- Air Hoses & Fittings: The 'veins' of the system. Proper hose diameter (typically 3/8" or 1/2" for drills) and high-quality, leak-free fittings are essential to deliver adequate air volume and pressure to the tool.

- Filters, Regulators, and Lubricators (FRLs): Often installed in-line, these units ensure the air is clean (filter), at the correct pressure (regulator), and carries a fine mist of oil (lubricator) to keep the drill's internal motor components running smoothly.

Inside an Air Drill: A Mechanical Masterpiece

The apparent simplicity of an air drill belies the precision engineering within. Understanding its key components helps in appreciating its function and selecting the right model:

- Air Inlet: Where the compressed air hose connects, usually a standard NPT (National Pipe Thread) fitting.

- Throttle/Trigger: Controls the flow of compressed air into the motor. Professional models offer variable speed triggers, allowing for precise control over the drilling speed, essential for starting holes accurately and working with different materials.

- Pneumatic Motor: The core of the tool. It typically consists of a rotor with multiple vanes. As compressed air pushes against these vanes, it forces the rotor to spin at high speeds. The design and quality of this motor dictate the tool's power, efficiency, and air consumption.

- Gearing System: The high speed of the air motor is translated into lower speed and higher torque through a system of planetary gears. The quality and construction (often all-metal in professional tools) of these gears are critical for durability and power delivery.

- Spindle: The output shaft, driven by the gearing system, which connects to the chuck.

- Chuck: The mechanism that holds the drill bit. Key considerations include:

- Size: Typically 3/8" or 1/2", indicating the maximum drill bit shank diameter it can accept. 1/2" chucks are standard for heavy-duty professional work.

- Type: Keyed chucks offer a very secure grip but require a key for changes. Keyless chucks allow for quick, tool-free bit changes, but high-quality keyless chucks are needed to match the grip of a keyed version in high-torque situations. Industrial-grade chucks often feature all-metal construction for maximum durability.

- Housing: The outer casing of the drill. Professional models often feature metal gear housings for durability and composite or rubberized grips for comfort and insulation from cold air.

- Exhaust: Where the spent air is vented. This can be through the handle, a port on the side, or sometimes a 360-degree adjustable port to direct air away from the user and workpiece.

Types of Air Drills: Finding Your Fit

Air drills come in various shapes and configurations, each designed for specific applications. Shinano, with its focus on professional-grade tools, offers excellent examples in each category.

- Standard Pistol Grip Drills (e.g., Shinano SI-5500 3/8" Cap. Drill) This is the most common configuration, resembling a standard electric drill. They offer a good balance of ergonomics, power, and control for general-purpose drilling.

- Shinano SI-5500:

- Chuck Size: 10mm (3/8")

- Free Speed: 2,600 RPM

- Output: 258 Watts

- Weight: 0.79 kg (1.75 lbs)

- Avg. Air Consumption: 2.5 CFM

- Profile: A lightweight (0.79kg) and compact tool designed for easy operation in general tasks. Its high free speed (2600 RPM) makes it suitable for drilling smaller holes quickly. It represents an ergonomic and reasonably priced option for standard applications.

- Reversible Drills (e.g., Shinano SI-5305A 3/8" & SI-5305-8A 1/2") These drills feature a switch or mechanism to change the direction of rotation, which is essential for backing out drill bits, removing screws, or even for tapping threads when used carefully.

- Shinano SI-5305A:

- Chuck Size: 10mm (3/8")

- Free Speed: 2,000 RPM

- Output: 326 Watts

- Weight: 1.02 kg (2.24 lbs)

- Avg. Air Consumption: 3.9 CFM

- Profile: A heavy-duty 3/8" reversible drill. It offers a balance of speed (2000 RPM) and power (326W), with a handy reverse mechanism, making it versatile enough for drilling and light tapping work.

- Shinano SI-5305-8A:

- Chuck Size: 13mm (1/2")

- Free Speed: 800 RPM

- Output: 326 Watts

- Weight: 1.45 kg (3.20 lbs)

- Avg. Air Consumption: 4.2 CFM

- Profile: This is the high-torque, heavy-duty option. With its 1/2" chuck and lower speed (800 RPM), it's built for larger holes and tougher materials. The 11.66 Nm max torque and included side handle provide the power and control needed for demanding tasks.

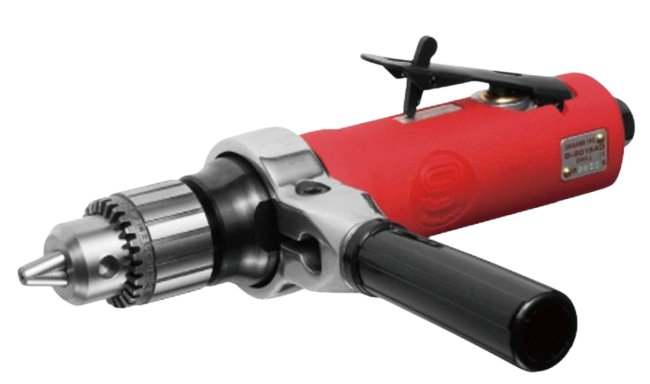

- Straight Drills (e.g., Shinano SI-2015AD 1/4" Cap. Straight Drill) These drills have an 'in-line' design, where the body, motor, and chuck are all aligned. This makes them ideal for working in tight spaces or applying direct, even pressure, often seen in aerospace and fabrication.

- Shinano SI-2015AD:

- Chuck Size: 10mm (3/8") - Note: The name says 1/4" Cap., but specs list a 3/8" chuck with 1/4" drilling capacity.

- Free Speed: 6,000 RPM

- Output: 457 Watts

- Weight: 1.06 kg (2.34 lbs)

- Avg. Air Consumption: 4.2 CFM

- Profile: A high-speed (6000 RPM) straight drill designed specifically for use in narrow places. Its high output (457W) and straight design allow for precision work where access is limited.

- Angle Drills (e.g., Shinano SI-5355 3/8" Cap. Angle Drill) Featuring a chuck mounted at a 90-degree angle to the body, these drills are indispensable for drilling in extremely confined areas, such as inside cabinets, engine bays, or between structural components.

- Shinano SI-5355:

- Chuck Size: 10mm (3/8")

- Free Speed: 1,200 RPM

- Output: 180 Watts

- Weight: 0.94 kg (2.07 lbs)

- Avg. Air Consumption: 3.0 CFM

- Profile: The problem-solver for tight spots. Its 90-degree angle head allows access where other drills can't reach. With a moderate speed (1200 RPM), it provides controlled drilling in confined spaces.

The Shinano Advantage: Precision Engineering from Japan

Shinano Inc. has carved a global reputation for manufacturing high-quality pneumatic tools since its inception. Hailing from Japan, a country renowned for its meticulous engineering and commitment to quality, Shinano tools embody these principles. When professionals choose Shinano, they are investing in:

- Precision Manufacturing: Shinano tools are built to extremely high tolerances, ensuring efficient air usage, high power output, and minimal vibration.

- High-Quality Materials: Components are crafted from top-grade materials, designed to withstand the pressures and demands of continuous professional use, leading to exceptional longevity.

- Ergonomic Design: Shinano places a strong emphasis on user comfort, incorporating features like ergonomic grips, balanced weight distribution, and reduced noise levels to minimize fatigue and enhance safety.

- Reliability: Known for their robust construction and dependable performance, Shinano tools are trusted in workshops and production lines worldwide.

Key Selection Criteria: Choosing Your Professional Air Drill

Selecting the right air drill involves balancing several factors against your specific needs and air supply capabilities.

|

Feature |

Consideration |

Importance |

Shinano Examples |

|

Power/Torque |

Match to materials & hole size. Higher torque for large holes/hard materials. |

High |

SI-5305-8A (High Torque) |

|

Speed (RPM) |

Higher speed for small holes/soft materials; lower speed for large holes/hard metals. |

High |

SI-2015AD (High Speed), SI-5305-8A (Low Speed) |

|

Chuck Size & Type |

3/8" for general, 1/2" for heavy-duty. Keyed for grip, Keyless for speed. |

High |

SI-5305-8A (1/2"), SI-5500 (3/8") |

|

Air Consumption (CFM) |

Must be compatible with your compressor's output. |

Critical |

SI-5500 (Low), SI-2015AD / SI-5305-8A (Higher) |

|

Reversibility |

Essential for backing out bits, removing fasteners, or tapping. |

High |

SI-5305A, SI-5305-8A, SI-5355 |

|

Ergonomics & Weight |

Crucial for comfort and reducing fatigue during long work periods. |

Medium-High |

SI-5500 (Lightweight), SI-5355 (Compact) |

|

Durability |

Look for metal gearing, robust housing, and quality bearings. |

High |

All Shinano models (Professional Grade) |

|

Configuration |

Pistol, Straight, or Angle – based on access and application needs. |

Application-Specific |

SI-5500 (Pistol), SI-2015AD (Straight), SI-5355 (Angle) |

Frequently Asked Questions (FAQs)

- What is the single most important factor when choosing an air drill? While many factors are important, ensuring your air compressor can meet or exceed the drill's Average CFM requirement at the standard 90 PSI is critical. Without enough air, even the best drill will underperform.

- How often do I need to oil my air drill? It's best practice to add a few drops of air tool oil directly into the air inlet before each use if you don't have an in-line FRL system. If you do have an FRL, check its oil level and drip rate regularly according to the manufacturer's guidelines.

- Can I use an air drill for driving screws? While reversible air drills can drive screws, they often lack the fine-tuned clutches found in dedicated screwdrivers or modern cordless drills. They can easily overdrive or strip screws if not used with extreme care. They are primarily designed for drilling.

- Why do some air drills have much lower RPM than others? Lower RPM (Revolutions Per Minute) is generally paired with higher torque. Drills designed for large-diameter holes or hard materials (like the Shinano SI-5305-8A at 800 RPM) need more twisting force (torque) rather than high speed. High RPM drills (like the SI-2015AD at 6000 RPM) are better for smaller holes where speed is preferred.

- Is a 1/2" chuck always better than a 3/8" chuck? Not necessarily. A 1/2" chuck allows for larger bits and is standard on heavy-duty drills. However, it often means a larger, heavier, and sometimes slower drill. If your work primarily involves smaller holes, a 3/8" drill (like the Shinano SI-5500) will be lighter, more compact, and often faster. Choose based on your primary application.

Related Articles:

- The Ultimate Guide to Pneumatic Air Tools: Everything You Need to Know

- 15 Essential Pneumatic Tools Every Workshop Must Have

- 10 Essential Air Tools Every Mechanic Needs for Automotive Excellence

- Shinano Pneumatic Tools Japan - Tend Industrial supplies

- Top 10 Shinano Air Tools for Professional Mechanics in 2024

- The Ultimate Drill Showdown: Optimizing Performance and Extending Lifespan for Air and Electric Drills

Conclusion

The professional air drill remains an unparalleled tool for tasks demanding consistent power, unwavering reliability, and operator safety. By understanding the technology behind them, the nuances of their compressed air requirements, and the specific advantages offered by different types, you can make a truly informed decision. Brands like Shinano Air Tools exemplify the peak of pneumatic design, offering a range of drills like the SI-2015AD, SI-5305A, SI-5305-8A, SI-5500, and SI-5355, each tailored to specific professional needs while upholding a standard of Japanese quality. Investing in a high-quality air drill is an investment in your productivity, precision, and long-term success.

You've explored the depths of air drill technology, understood the nuances of selection, and seen the clear advantages of Shinano tools. Now, it's time to put that knowledge into action and equip your workshop with the powerhouse performance you demand.

Ready to upgrade your air drills or need expert guidance on selecting the perfect Shinano model for your specific professional needs?

Contact Tend Industrial Supplies today! Our specialists are ready to provide the top-tier tools and support that give you the Shinano Advantage.

Email us at sales@tendsupplies.com or visit tendsupplies.com to discover our full range of air drills and accessories.