Mastering Air Grinder Selection & Usage: Top Picks, Applications, Safety, and Accessories

Welcome back to our in-depth exploration of air grinders! In our last Article The Essential Guide to Air Grinders: Types, Features, and Power Fundamentals, we laid the groundwork by examining the core aspects of these powerful pneumatic tools. Now, it’s time to build upon that knowledge and guide you through the practicalities of selecting the perfect air grinder, using it effectively and safely, and understanding the accessories that can unlock its full potential.

At Tend Industrial Supplies, we're committed to not just selling tools, but ensuring you have the expertise to make the best choice for your specific needs. This second article will showcase some of the top air grinders for 2025, discuss budget versus premium considerations, provide a selection guide for various applications, delve into crucial safety protocols, compare air grinders with their electric counterparts, and explore the world of grinding discs and accessories. We'll also touch upon brand insights and the exciting future of air grinder technology.

Key Takeaways:

- The "Top 10 Air Grinders for 2025" list highlights models known for performance, durability, and specific features like noise reduction or precision control, catering to various user needs.

- Air grinders are available from budget-friendly (for occasional use) to premium (for professional, heavy-duty applications), with mid-range options often providing the best value for regular users.

- Select your air grinder based on the specific application: heavy-duty angle grinders for metal fabrication, compact die grinders for automotive, and lower RPM models for woodworking.

- Safety is paramount: Always use appropriate PPE (eye, ear, respiratory, hand protection), ensure guards are in place, and follow safe operating practices.

- Air grinders offer advantages in power-to-weight, durability, and cooler operation over many electric grinders, but require an air compressor; electric cordless grinders offer maximum portability.

- Maximize versatility by choosing the correct grinding discs and accessories (grinding wheels, burrs, flap discs, etc.), ensuring they are rated for your grinder's speed and suitable for the material.

- Reputable brands offer better build quality, support, and often innovative features. Consider long-term value and after-sales service.

- Future air grinder innovations focus on enhanced ergonomics, reduced vibration and noise, smarter features, and sustainable manufacturing.

Top 10 Air Grinders of 2025: Expert Picks for Performance and Value

After extensive market research, considering expert reviews, user feedback, and our own experience, here’s a look at some standout air grinders for 2025. (Note: Availability and specific models at Tend Industrial Supplies may vary; always check our latest catalog.)

1. Shinano SI-2002 (or similar Shinano model): Shinano grinders from Japan are respected for their quality and durability. Models like the SI-2002 often provide high speeds (e.g., 25,000 RPM) in a compact, lightweight package, favored in professional settings.

Japanese Engineering, Durability.

2. Ingersoll Rand 301B Air Die Grinder: A perennial favorite, this straight die grinder is renowned for its durable, ball-bearing construction, 0.33 HP motor delivering 21,000 RPM, and ergonomic design. Ideal for general-purpose grinding, porting, and polishing.

Robust build, Reliable performance.

3. Chicago Pneumatic CP872 Die Grinder: A compact and lightweight (1.3 lbs) die grinder known for its ease of use in tight spaces. It offers up to 22,000 RPM and is a workhorse for deburring and smoothing.

Excellent maneuverability.

4. AIRCAT 6280 Composite Reversible Angle Die Grinder: Features AIRCAT's patented silencing technology for quieter operation (around 82 dBA). Its 0.6 HP motor, 18,000 RPM, and composite housing make it powerful yet comfortable. The reversible feature is a plus for certain applications.

Quiet operation, Powerful.

5. Snap-on FAR7200 (or similar current Snap-on model): Snap-on tools are premium-grade, known for precision engineering, advanced ergonomics, and durability. Their die grinders typically offer high RPMs (e.g., 20,000+), variable speed triggers, and excellent control for professional automotive and industrial use.

Premium quality, Precision control.

6. Milton S-1206 (or similar Milton model): Milton offers good mid-range options that balance performance and affordability. Their die grinders typically feature standard RPMs (around 22,000) and safety locks, suitable for various tasks.

Good value for Money.

7. Campbell Hausfeld TL054500AV (or similar model): Often appealing to DIYers and semi-professionals, Campbell Hausfeld grinders like this angle die grinder can offer good versatility (e.g., 20,000 RPM) and sometimes come with accessory kits.

Versatile, often includes Accessories.

8. Astro Pneumatic Tool 219 (or similar Astro model): Astro Pneumatic provides a range of tools that often hit a sweet spot for performance and price. Their grinders, like the 219 die grinder, can offer powerful motors (e.g., 0.5 HP, 20,000 RPM) and durable housings.

Powerful motor for the price.

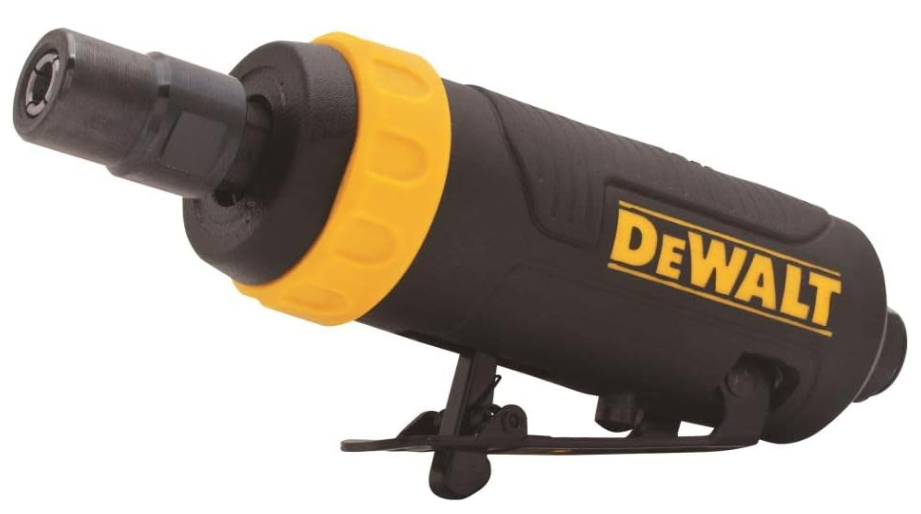

9. DEWALT DWMT70783 (or similar DEWALT air grinder): DEWALT is a trusted name, and their air grinders extend this reputation. The DWMT70783 die grinder, for instance, offers high speed (25,000 RPM), an ergonomic touch control trigger, and robust aluminum body.

Trusted brand, Ergonomic trigger.

10. JET JAT-403 (or similar JET model): JET is known for industrial and woodworking machinery, and their air tools, like the JAT-403 1/4-Inch Right Angle Die Grinder, are built for reliability. Features often include rear exhaust and durable ball-bearing construction.

Industrial reliability, right-angle versatility.

Disclaimer: The "Top 10" list is based on general market perception and common features. Specific needs may lead to different choices. Always verify specs and availability at Tend Industrial Supplies.

Navigating Price Points: Budget-Friendly vs. Premium Air Grinders

Air grinders are available across a wide spectrum of price points. Understanding what you get at each level can help you make a cost-effective decision.

Budget-Friendly Options (e.g., Central Pneumatic, some store brands, entry-level models from known brands):

- Typical Features: Basic construction, standard RPM ranges (18,000-25,000 RPM for die grinders), lightweight design (1-2 lbs), standard 1/4" collets, minimal vibration dampening.

- Pros: Low initial cost, suitable for occasional or light-duty tasks, can be a good entry point for hobbyists.

- Cons: May have shorter lifespan under heavy use, potentially higher noise levels, fewer ergonomic comforts, less consistent performance under load.

- Best For: DIY enthusiasts, occasional users, light tasks where precision and longevity are not paramount.

- Information Gain: When buying budget, look for at least a 1-year warranty and ensure spare parts like collets are readily available.

Mid-Range Options (e.g., many models from Ingersoll Rand, Chicago Pneumatic, AIRCAT, Astro Pneumatic, DEWALT):

- Typical Features: Good balance of durable materials (aluminum or quality composite housings), reliable motors, decent ergonomic grips, some noise reduction features, consistent speed.

- Pros: Offer excellent value, reliable performance for regular professional and serious DIY use, better durability and comfort than budget models.

- Cons: May lack the most advanced features or ultimate refinement of premium tools.

- Best For: Most professionals, serious hobbyists, workshops requiring dependable tools for daily or frequent use.

Premium Selections (e.g., Snap-on, some high-end Ingersoll Rand, Atlas Copco, specialized industrial brands):

- Typical Features: Superior build quality with premium materials (e.g., advanced composites, precision-machined steel), advanced bearing systems, exceptional power-to-weight ratios, sophisticated ergonomic designs, advanced vibration control, enhanced safety features (e.g., automatic shut-offs), often better warranty coverage.

- Pros: Highest performance, durability, and user comfort; designed for demanding, continuous industrial use; often longer service life and better precision.

- Cons: Significantly higher initial investment.

- Best For: Professionals who rely on their tools daily for critical tasks, industrial environments, applications requiring the utmost precision and reliability.

- Tend Supplies Insight: Investing in a premium air grinder can be more cost-effective in the long run for heavy users due to lower downtime, reduced maintenance, and longer tool life.

Application-Specific Selection: Matching the Grinder to the Job

The versatility of air grinders shines across numerous industries. Here’s how to choose wisely for common applications:

1. Metal Fabrication and Welding:

* Tasks: Weld preparation (beveling, cleaning), weld grinding and smoothing, cutting stock, deburring sharp edges, surface finishing.

* Recommended Grinders:

* Angle Air Grinders (4" to 7" discs): For heavy stock removal, cutting, and smoothing large welds. Look for 0.8 HP and above, speeds appropriate for disc size (e.g., 7,000-12,000 RPM).

* Straight Air Die Grinders / Right-Angle Die Grinders: For weld root grinding, reaching into corners, deburring intricate parts. High RPM (20,000+) with carbide burrs is effective.

* Key Features: Robust construction, good guarding, variable speed for different materials/tasks, comfortable grip for control.

2. Automotive Work:

* Tasks: Rust removal, paint stripping, gasket removal, exhaust work, porting and polishing engine components, cutting bolts, body work smoothing.

* Recommended Grinders:

* Straight Die Grinders & Extended Die Grinders: Essential for reaching into engine bays and tight spots for porting, cleaning, and deburring.

* Mini Air Grinders/Pencil Grinders: For precision cleaning of small parts or gasket surfaces.

* Compact Angle Air Grinders (or Right-Angle Die Grinders): Useful for body panel work, rust removal with wire wheels or conditioning discs. Speeds around 15,000-18,000 RPM.

* Key Features: Compact size, good maneuverability, variable speed, good collet system for various bits.

3. Woodworking Applications:

* Tasks: Shaping, carving, pattern sanding, deburring (on harder woods or composites), power carving. * Recommended Grinders:

* Straight Die Grinders: With appropriate carving burrs or sanding drums.

* Mini Air Grinders: For very detailed carving or model work.

* Key Features: Lower RPM capability (e.g., 10,000-15,000 RPM) is often crucial to prevent burning the wood. Excellent dust management considerations are important (use with a dust extraction system if possible). Good throttle control for finesse. * Information Gain: For woodworking, accessory choice is paramount. Use burrs and sanders specifically designed for wood. Test on scrap wood to find optimal speed and pressure.

4. Industrial and Heavy-Duty Usage (Foundries, Shipbuilding, Manufacturing):

* Tasks: Removing risers and gates from castings, heavy weld grinding, surface preparation on large structures, pipeline construction.

* Recommended Grinders:

* Heavy-Duty Angle Grinders (larger disc sizes): High HP (2.0+), robust gearing, durable housings.

* Vertical Grinders: For heavy material removal on flat or large curved surfaces.

* Key Features: Extended duty cycles, superior build quality, enhanced vibration control (e.g., anti-vibration handles), multiple handle positions for better leverage and control, powerful motors (0.5-3 HP+).

Table: Air Grinder Application Recommendations

|

Application |

Primary Grinder Type(s) |

Key Specs/Features |

Recommended Accessories |

|

Metal Fabrication |

Angle Grinder, Die Grinder |

High HP, robust, variable speed |

Grinding wheels, cutting discs, burrs |

|

Automotive Repair |

Die Grinder, Ext. Die Grinder |

Compact, maneuverable, variable speed |

Carbide burrs, wire wheels, abrasives |

|

Woodworking |

Die Grinder, Mini Grinder |

Lower RPM capability, good control, dust management |

Carving burrs, sanding drums |

|

Industrial |

Heavy-Duty Angle/Vertical |

Max HP, extreme durability, vibration control |

Heavy-duty grinding/cutting wheels |

Safety First: Critical Features and Safe Operating Practices

Operating any power tool, including air grinders, demands an unwavering commitment to safety. Modern air grinders incorporate features to protect users, but correct usage and PPE are paramount.

Essential Built-in Safety Features:

- Paddle-Style Switches/Safety Levers: Many grinders have a paddle switch that stops the tool when released, or a safety lock-off lever on the throttle to prevent accidental activation.

- Protective Guards: Angle grinders MUST be used with the correct guard for the disc type and size. Guards help contain debris and fragments if a disc breaks.

- Anti-Vibration Handles: Reduce operator fatigue and improve control, indirectly contributing to safety.

- Burst-Proof Guards (on some models): Designed to contain fragments even if a wheel shatters catastrophically.

- Information Gain: Regularly inspect guards for damage and ensure they are correctly positioned. Never operate a grinder with a damaged or removed guard.

Mandatory Personal Protective Equipment (PPE):

- Eye Protection: Impact-resistant safety glasses are essential. A full-face shield is highly recommended, especially during heavy grinding or cutting, to protect against flying particles and disc fragments.

- Hearing Protection: Air grinders can be very loud (often exceeding 85 dB). Earmuffs or earplugs are necessary to prevent hearing damage.

- Respiratory Protection: Grinding produces dust and fumes. Use a dust mask or respirator appropriate for the material being ground (e.g., N95 for nuisance dust, P100 for more hazardous materials).

- Hand Protection: Heavy-duty work gloves protect against abrasions, cuts, and some heat. However, ensure gloves don't compromise your grip or get caught in moving parts.

- Protective Clothing: Wear durable, close-fitting clothing. Avoid loose sleeves, jewelry, or anything that could get entangled. Leather aprons can offer additional protection.

- Footwear: Steel-toed boots are recommended in workshop or construction site environments.

Safe Operating Practices Checklist:

- Read the Manual: Always understand your specific tool's instructions and warnings.

- Inspect Tool & Accessories: Before each use, check the grinder, air hose, and accessory for damage. Ensure accessories are rated for your grinder's speed.

- Secure Air Connection: Ensure the air hose is securely connected and not a trip hazard. Use the recommended air pressure (90 PSI).

- Secure Workpiece: Clamp your workpiece firmly to prevent it from moving during operation.

- Proper Stance: Maintain a stable, balanced stance. Never overreach.

- Two-Handed Operation: Use two hands to control the grinder whenever possible, especially for angle grinders.

- Direction of Grinding: Control the grinder so debris is directed away from you and others. Be aware of sparks and their potential to ignite flammable materials.

- No Flammable Materials Nearby: Ensure the work area is clear of flammable liquids, gases, or combustible dust.

- Allow Tool to Reach Full Speed: Let the grinder reach its operating speed before contacting the workpiece.

- Apply Steady Pressure: Don't force the tool. Let the grinder and accessory do the work.

- Never Remove Guards: Guards are there for your protection.

- Power Down and Disconnect: Turn off and disconnect the air supply before changing accessories, making adjustments, or servicing the tool. Allow accessories to stop rotating completely.

- Regular Maintenance: Keep the tool clean and lubricated as per manufacturer recommendations. This includes daily oiling for many air tools (a few drops of air tool oil into the air inlet).

Air Grinders vs. Electric Grinders: A Comparative Look

While this guide focuses on air grinders, it's useful to understand their position relative to electric grinders.

|

Feature |

Air Grinders |

Electric Grinders (Corded & Cordless) |

|

Power Source |

Compressed Air |

Electricity (Mains or Battery) |

|

Power-to-Weight |

Generally Higher |

Can be heavier for equivalent power |

|

Durability |

Simpler mechanics, often more robust |

Motors can burn out, more complex electronics |

|

Heat Buildup |

Run cooler (air expansion cools) |

Can overheat with prolonged heavy use |

|

Safety (Wet Env.) |

Generally safer (no direct electricity at tool) |

Higher risk (corded), batteries also have risks |

|

Stall Handling |

Can stall without damage |

Stalling can damage motor/electronics |

|

Portability |

Tethered to air hose/compressor |

Corded: tethered to outlet. Cordless: highly portable |

|

Initial Cost |

Tool may be cheaper, but compressor adds cost |

Tool cost varies; batteries add to cordless cost |

|

Operating Cost |

Air compressor energy consumption |

Electricity cost; battery replacement cost |

|

Maintenance |

Simpler, daily oiling common |

Brushes (on brushed motors), less frequent typically |

Information Gain: The choice often comes down to the work environment and existing infrastructure. If you already have a capable air compressor, air grinders are an excellent choice for power and durability. For ultimate portability where no power or air is available, cordless electric grinders are superior.

Maximizing Versatility: Essential Grinding Discs and Accessories

The true power of an air grinder is unlocked by the vast array of accessories available. Selecting the right one is critical for efficiency, finish quality, and safety.

Types of Grinding Discs & Accessories:

- Grinding Wheels (Bonded Abrasives): For heavy material removal, shaping metal, sharpening. Various grains and bond strengths for different materials (steel, stainless, aluminum). Usually for angle grinders.

- Cutting Discs (Cut-Off Wheels): Thin, abrasive discs for cutting metal stock, bolts, sheet metal. Usually for angle grinders or specialized cut-off tools.

- Flap Discs: Abrasive flaps arranged on a backing. Excellent for grinding and finishing in one step, providing a smoother finish than hard wheels. Good for blending welds, deburring. Usually for angle grinders.

- Carbide Burrs (Rotary Files): For die grinders. Come in many shapes (cylinder, tree, ball, cone) and cut types (single, double/diamond cut) for shaping, deburring, and enlarging holes in metals, plastics, and wood.

- Mounted Points: Small bonded abrasive stones on a shank, for die grinders. Used for precision grinding and deburring in tight areas.

- Wire Wheels and Brushes: For cleaning, rust removal, paint stripping, and light deburring. Available in cup or wheel shapes, with crimped or knotted wires. For both angle and die grinders.

- Sanding Discs/Pads (e.g., Roloc™ type): For surface preparation, sanding, and finishing. Require a backing pad. For both angle and die grinders.

- Polishing Bonnets and Buffs: For achieving a high shine on metals, plastics, or painted surfaces. Used with polishing compounds. Typically lower speeds on die or angle grinders.

- Diamond Discs/Wheels: Specialized for cutting or grinding very hard materials like concrete, stone, tile, and ceramics.

Selecting the Right Disc/Accessory - Key Factors:

- Material Compatibility: Choose accessories designed for the material you are working on (e.g., aluminum oxide for steel, silicon carbide for cast iron/non-ferrous, ceramic for aggressive grinding on alloys).

- Task Requirement: Grinding, cutting, finishing, polishing, cleaning – each needs a specific accessory type.

- Speed Rating (RPM): Crucially important! The RPM rating of the accessory MUST be equal to or greater than the maximum RPM of your air grinder.

- Size and Arbor/Shank: Ensure the disc diameter and arbor hole (for angle grinders) or shank size (for die grinders, typically 1/4" or 1/8") match your tool.

- Desired Finish: Coarse abrasives for rapid removal, finer abrasives for smoother finishes.

- Safety Standards: Look for accessories that meet recognized safety standards (e.g., ANSI, EN).

Other Essential Accessories:

- Collets: For die grinders, have spare collets (1/4", 6mm, 1/8", 3mm) to match your burr shanks. Ensure they are clean and in good condition for proper grip.

- Backing Pads: For sanding discs or conditioning discs.

- Wrenches: For changing discs on angle grinders or collets on die grinders.

- Air Tool Oil & Lubricator: Essential for daily maintenance to prevent corrosion and ensure smooth motor operation. An in-line lubricator can automate this.

- Filter-Regulator-Lubricator (FRL) Unit: Highly recommended for your air line to provide clean, regulated, and lubricated air to your tools.

Brand Insights and Customer Considerations

Choosing a reputable brand can significantly impact your satisfaction and the tool's longevity.

- Market Leaders & Strengths:

- Ingersoll Rand: Known for robust, industrial-quality tools with a long heritage. Strong warranty and parts availability.

- Shinano: One of the Best Air tools brand locally know for Japanese craftsmanship durability and precision, all their tools are 100% made in Japan.

- Snap-on: Premium tools focused on professionals, particularly in automotive. Exceptional quality, precision, and often higher price.

- Chicago Pneumatic (CP): Good reputation for reliable and durable tools, widely used in automotive and MRO (Maintenance, Repair, Operations).

- AIRCAT: Known for innovation in noise reduction and powerful, comfortable composite tools.

- DEWALT, Makita, Bosch (Air Tool Lines): These power tool giants also offer air tools, leveraging their brand reputation for quality and user-focused design.

- Information Gain: Customer surveys often highlight that beyond the tool itself, factors like warranty length, ease of warranty claims, availability of spare parts, and responsive customer/technical support are crucial in brand loyalty.

- Emerging Trends in Brand Preference:

- Focus on Ergonomics & Vibration Reduction: Users are increasingly prioritizing tools that reduce fatigue and risk of injury.

- After-Sales Support: Digital support platforms, video tutorials, and accessible local service centers are becoming more important.

- Transparency: Brands that are open about manufacturing processes, material sourcing, and provide clear, comprehensive documentation are gaining trust.

The Future of Air Grinder Technology: What's Next?

The air tool industry continues to evolve, driven by demands for greater efficiency, safety, and user comfort.

- Smart Integration & Monitoring: While less common in purely pneumatic tools compared to electric/battery, there's potential for sensors to monitor usage hours (for maintenance scheduling) or airflow efficiency. Some higher-end industrial systems might integrate performance monitoring.

- Advanced Materials: Lighter, stronger composite materials for housings, improved alloys for motor components, and more durable bearing technologies.

- Enhanced Ergonomics & Vibration Dampening: Continued research into handle designs, tool balance, and internal mechanisms to further reduce vibration transmitted to the operator. This is critical for meeting stricter occupational health and safety standards.

- Quieter Operation: Ongoing development of muffler technology and motor designs to reduce noise levels without compromising power – an area where brands like AIRCAT have already made significant strides.

- Modular Designs: Some tools may feature more modular components for easier and more cost-effective repair and maintenance.

- Sustainability in Manufacturing: Greener manufacturing processes, use of recyclable materials, and designs that are easier to service rather than replace.

While air grinders are mature tools, innovation continues, focusing on refining the user experience, enhancing durability, and improving safety and environmental aspects.

Choosing the right air grinder and using it correctly can dramatically improve your efficiency and the quality of your work. By understanding the types, features, safety requirements, and accessories, you're now well-equipped to make an informed decision.

Frequently Asked Questions (FAQs) for Tend Industrial Supplies Customers:

- Q: How often should I oil my air grinder, and what type of oil should I use?

- A: Most air grinders benefit from daily oiling, especially if used frequently. Add 3-5 drops of specialized air tool oil directly into the air inlet before each day's use. If using the tool continuously for long periods, a few drops every couple of hours can be beneficial. Using an in-line lubricator in your air system can automate this. Always use oil specifically formulated for pneumatic tools, as other oils can damage seals or leave gummy deposits.

- Q: My air grinder seems to lack power or bogs down easily. What's the most common cause?

- Check Air Pressure: Ensure you have a consistent 90 PSI at the tool inlet while the tool is running.

- Check CFM: Your air compressor must be able to supply the CFM required by the grinder. If the compressor is too small or other tools are drawing air, performance will suffer.

- Hose Diameter/Length: A hose that is too narrow or too long can restrict airflow. Use a 3/8" diameter hose for most grinders, and keep the length practical.

- Kinks or Leaks: Check for kinks in the air hose or leaks in connections.

- Tool Maintenance: A dirty air filter in the tool or lack of lubrication can also reduce power.

- A: The most common causes are insufficient air supply or incorrect air pressure.

- Q: What is the difference between a "die grinder" and an "angle grinder"?

- Die Grinder: The accessory (like a carbide burr or mounted stone) extends straight out from the end of the tool, much like a drill bit. They are typically used for precision grinding, deburring, polishing, and working in tight spaces. They often have higher RPMs and use smaller accessories held in a collet.

- Angle Grinder: The accessory (like a grinding disc or cutting wheel) is mounted at a 90-degree angle to the tool body. They are generally more powerful and used for heavier material removal, cutting, and surface preparation on larger areas. They have lower RPMs and use larger diameter discs attached to a spindle.

- A: The main difference is the orientation of the grinding accessory relative to the tool body and their typical applications.

- Q: Can I use woodworking accessories on my air grinder for metal, or vice-versa?

- Woodworking burrs or sanding accessories are often designed for softer materials and may wear out extremely quickly, overheat, or even break if used on metal at high speeds.

- Metalworking abrasives are usually too aggressive for wood and can cause burning, tearing, or a poor finish.

- Crucially, always ensure the accessory's maximum RPM rating is suitable for your grinder's speed, regardless of the material.

- A: Generally, no. Accessories are designed for specific materials and tool speeds.

- Q: What are the signs that my air grinder needs professional servicing?

- Significant loss of power or speed despite adequate air supply.

- Excessive vibration or unusual noises (grinding, whining, rattling).

- Overheating of the tool body even with proper lubrication and airflow.

- Air leaking from unusual places on the tool housing.

- Collet or spindle issues: Difficulty securing or releasing accessories, or noticeable wobble.

- If basic maintenance like oiling and cleaning doesn't resolve an issue, it's best to consult a professional or Tend Industrial Supplies for service options to prevent further damage.

- A: Look out for these signs:

Related Articles:

Die Grinders vs. Angle Grinders: A Complete Guide to Choosing the Right Power Tool

Mastering Precision: A Deep Dive into Die Grinders for Intricate Metalwork and Finishing

The Essential Guide to Air Grinders: Types, Features, and Power Fundamentals

15 Essential Pneumatic Tools Every Workshop Must Have

Conclusion

Mastering air grinders isn't just about owning one; it's about making informed choices to elevate your craftsmanship and efficiency. By understanding the diverse types available, matching them to specific applications, and ensuring you meet their power fundamentals (like CFM and PSI requirements), you unlock the full potential of these versatile tools.

Crucially, safety should always be your top priority, while selecting the right accessories ensures precision and durability. When you meticulously choose, correctly power, and diligently maintain your air grinder, you're not just performing a task—you're executing it with precision, speed, and confidence. Embrace these principles, and your air grinder will consistently deliver exceptional results, transforming challenging jobs into seamless successes.

Ready to elevate your workshop's capabilities with the perfect air grinder? At Tend Industrial Supplies, we offer a wide range of high-quality air grinders, accessories, and pneumatic system components to meet the demands of both professionals and dedicated DIYers.

- Browse Our Extensive Online Catalog: Explore detailed specifications and find the air grinder that matches your exact needs at tendsupplies.com.

- Expert Advice: Not sure which air grinder is right for you? Our knowledgeable team is here to help! Contact us at sales@tendsupplies.com or call us for personalized recommendations.

- Complete Your Setup: Don’t forget to check out our selection of air hoses, FRL units, couplers, and a comprehensive range of grinding discs and accessories.

Invest in power, precision, and durability with Tend Industrial Supplies. Your projects deserve the best!